-

Промышленная зона Иньчжуан, уезд Мэнцюнь, город Цанчжоу, провинция Хэбэй, Китай

Производитель фитингов для труб из углеродистой стали: качество и разнообразие

Основные моменты

- Фитинги для труб из углеродистой стали: Essential components in piping and plumbing systems, made to withstand high pressure, temperature fluctuations, and environmental factors.

- Manufactured to International Standards: Adhering to specifications like ASTM, JIS, and DIN to ensure reliability and safety in usage.

- Diversity in Offerings: Available in various fittings such as elbows, reducers, tees, and flanges to suit differing requirements.

- Corrosion-Resistant Material: Designed to endure both internal and external corrosion for long-lasting durability.

- Prominent Suppliers in Singapore: Trusted manufacturers serve industries ranging from oil and gas to semiconductors.

Let’s explore more about carbon steel pipe fittings and their applications.

Введение

Carbon steel pipe fittings play a big part in many industrial systems. You will find them in manufacturing plants and in sanitation works. These fittings are strong and useful for many different uses. They help with all kinds of piping and plumbing jobs, not just in Singapore, but all over the world.

There are pipe fittings made from a mix of materials. Some are stainless steel, some are carbon steel, and others are brass. This gives companies lots of choices to match different needs. Singapore is well-known for offering high-quality pipe fittings. You can get both standard and custom-made fittings there for all types of uses.

Overview of Carbon Steel Pipe Fittings in Singapore

Singapore is a key place for pipe fittings, especially carbon steel fittings. These fittings meet high global standards for quality. People often use them in many piping and plumbing jobs. They help change the flow, connect pipes, and switch to different pipe sizes.

In this busy city, there are good manufacturers like Kian Huat Metal. They offer a wide range of fittings like elbows, tees, and reducers. These fittings work well for oil, water treatment, and food processing companies. Their fittings are strong and will last, which makes them a good choice for all uses in Singapore.

Key Properties and Advantages of Carbon Steel

Carbon steel is known for its great strength and ability to adapt to different uses. It can fight off corrosion, so it will last a long time even when there is a lot of pressure or the temperature goes up and down. This makes it a good choice for boilers and other big machines used in factories. The strong nature of carbon steel means that you will find it in chemical plants and in places where things are made.

When you look at different materials, carbon steel gives you both strength and a fair price. It is hard but also can bend as needed, so it works well for tough jobs. At the same time, you can work with it during the setup, making it a top choice for companies that need things to run well and last.

You can use carbon steel in a lot of settings—that is why it is picked for energy systems and for use in ships and by the ocean. Its ability to fight off corrosion means both the inside and outside stay in good shape. This means you will only need to do a little work to keep it running for many years. When we talk more about it, you will see that standards in the way factories make it help keep its quality high.

Common Standards and Specifications for Pipe Fittings

Meeting international standards helps make sure that carbon steel pipe fittings match strong needs in many industries. You will find well-known standards such as ASTM, JIS, DIN, and ASME. Each one sets out important things like what materials to use, how big the pipes need to be, and how much pressure they can take.

The use of these standards helps make things work well in global markets. For example, ASTM A234 talks about carbon steel fittings meant to be used in hot places. DIN and JIS pay close attention to exact pipe sizes that use the metric system. Popular pressure numbers like PN let people know the fitting will last through different uses.

You can see more details about these fitting specifications in the table here:

Технические характеристики | Материал | Размер | Стандарт |

|---|---|---|---|

ASTM A234 | Углеродистая сталь | 1/2″ to 42″ | Seamless/Welded |

ASTM A420 | Low Temp Carbon Steel | Up to Sch XXS | Moderate Temp |

ASME B16.9 | Нержавеющая сталь | 1” to 36” | ANSI/DIN Standards |

Next, you will get details about the different types of pipe fittings you can choose.

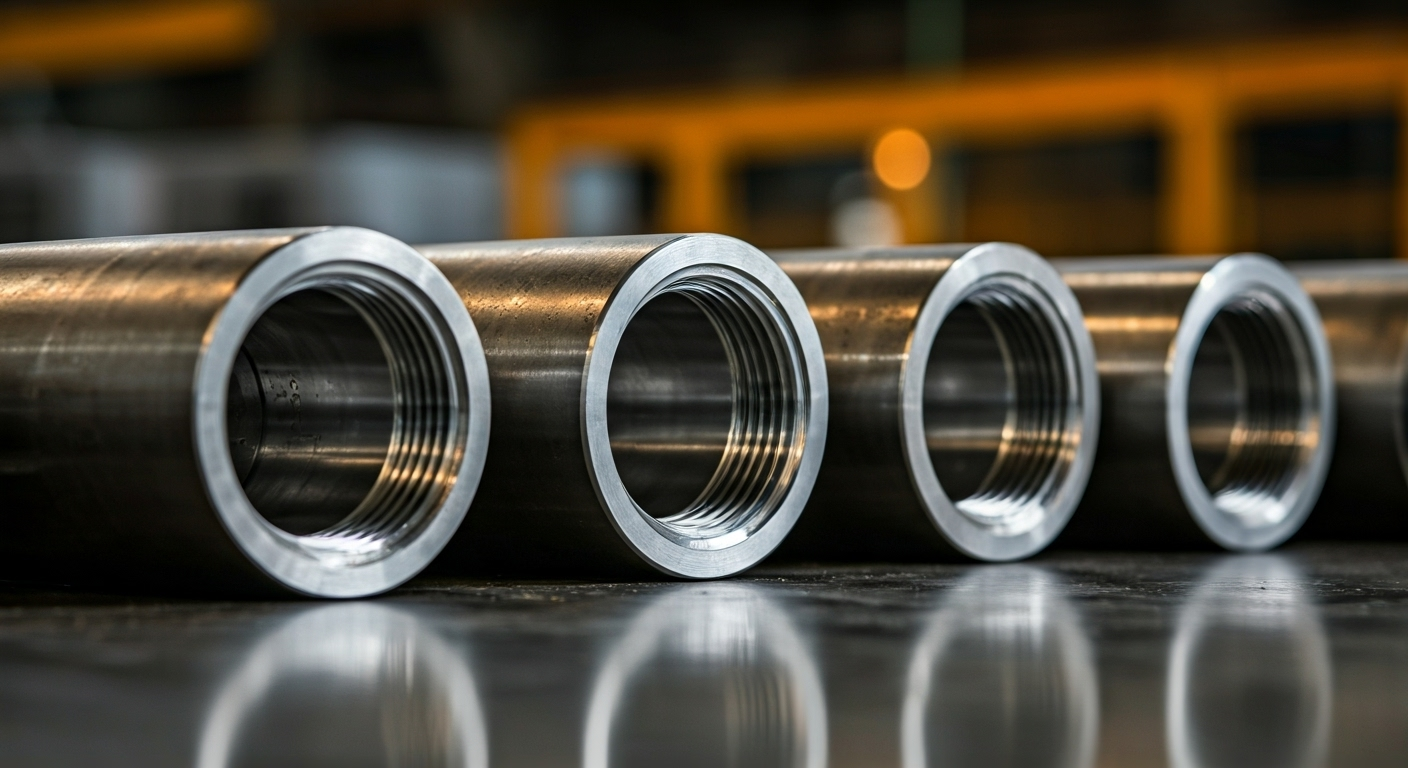

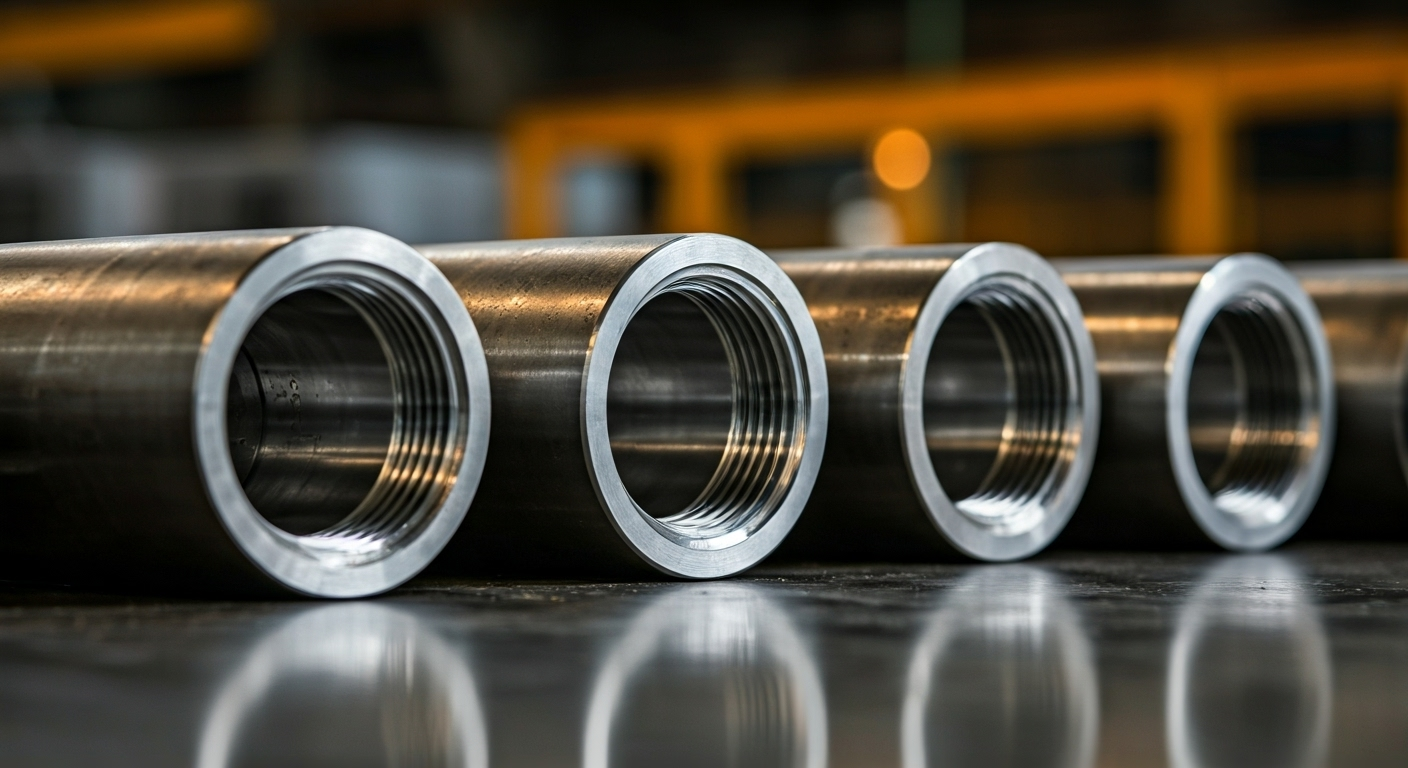

Types of Carbon Steel Pipe Fittings Offered by Manufacturers

Manufacturers give many kinds of carbon steel pipe fittings to meet different needs in the market. The most common fittings are elbows, reducers, tees, and connectors. Each of these is made for specific jobs in factories and other places. When you need to use piping for high pressure or regular plumbing at home or work, carbon steel fittings are very important.

In Singapore, top suppliers are good at making custom pipe fittings. They make sure every fitting works well with the big rules of the industry and special uses too. Their strong skills help them give reliable products. This has helped them become trusted by many who need strong and right-sized parts for their projects.

Elbows, Tees, Reducers, and Other Popular Fittings

Some fittings are used in many types of work, and each has its own job.

- Локти: These change how the flow moves, with choices at 45° and 90° angles.

- Тис: These help branch pipes off from the main line, and you see them a lot in plumbing.

- Редукторы: These help make different pipe sizes work together and help with different flow speeds.

- Connectors: These keep two pipes joined tight so there is no leak.

- Фланцы: These are key for sealing pipes and for easy repairs or checks.

Factories and makers in Singapore offer these fittings as seamless or welded types, made to fit jobs in oil rigs, water plants, and city piping. There are even advanced fittings for very high pressure or for pipes that handle strong or harsh stuff. The fittings like flanges, elbows, connectors, and others can be made to fit any piping needs or setup.

Customized Solutions and Special Applications

Custom-designed fittings are more common now in a lot of industries that need great precision. Industries like semiconductor manufacturing depend on tailored tube fittings. They do this to keep everything accurate and also to make sure the parts can handle very tough conditions.

In Singapore, there are manufacturers who are very good at making tube fittings for special needs. They can make things for places like desalination plants and food processing systems. If you need something different or unique, you will find custom solutions that get the job done well. These tube fittings are made while focusing on how to fight off corrosion and deal with high and low temperatures.

Singapore manufacturers show strong skills when it comes to making fittings for difficult jobs. They use new ideas for easy and secure installations, even when they work on complex projects. This is how they provide only high-quality tube fittings, even if the industry uses new technology and changes quickly.

Заключение

To sum up, picking a good carbon steel pipe fittings manufacturer is key for keeping your projects running well. Carbon steel has special qualities and many benefits. Knowing about the types of pipe fittings you can get helps you choose what fits your needs best. There are many kinds to pick, like elbows, tees, or even special fittings made just for you. The right manufacturer will offer a lot of options and make fittings that work for your job. If you put quality first and follow industry rules, your projects will last longer and run better. Don’t settle for less—get in touch with a trusted manufacturer today to see your options for pipe fittings and make sure your projects get the best performance.

The Importance of Choosing a Reliable Carbon Steel Pipe Fittings Manufacturer

Choosing a trusted partner when buying carbon steel pipe fittings is very important. Good suppliers in Singapore make sure that the fittings meet high quality checks. They follow international standards, such as ASTM and ASME.

When you buy from reliable manufacturers of pipe fittings, you get help from those who know your industry well. This is true for places like chemical plants, water treatment sites, or marine work. These experts also give fast delivery, which helps you avoid delays and keeps things running smoothly. This matters a lot when you work in tough conditions, like high pressure or where there could be corrosion.

Making sure your supplier is reliable helps you stay away from low-quality materials or parts that do not fit. You should always check for certifications and read what other clients say about them. This will help you find those in Singapore who care about quality and long-lasting products that meet ASTM and ASME rules. If you are new to this, the next section shows you ways to make sure you get good pipe fittings.

How to Ensure Quality When Choosing a Carbon Steel Pipe Fittings Manufacturer

Quality assurance is very important when you pick pipe fittings. You should check that the maker of the fittings follows international standards like ASTM, JIS, or ASME. These are rules that help make sure the product is good and can be trusted. Ask if the fittings get checked well, including both breaking them and checking them without breaking to make sure there are no problems before you get them.

You can contact suppliers by email to get more details about the product or to ask for certificates. Many good manufacturers will share test results and documents with you. This helps make everything clear for you. It is better to pick companies who have a strong history of giving out top-quality products again and again.

What customers say matters too. You can look at reviews and ratings in your field to see if a supplier is someone you can trust. Doing these things lowers your risk and helps keep your money safe. Now, let’s talk about the many ways that these pipe fittings are used.

Common Applications and Uses of Carbon Steel Pipe Fittings

Carbon steel fittings are used in many fields. Manufacturing, chemical plants, and energy systems all use them. You will find these fittings often in piping and plumbing. They help move fluids and gases quickly and safely.

Industries that work with boilers, valves, and connectors find these fittings helpful. Carbon steel fittings do not corrode easily. They last a long time, so people rely on them. Food processing companies and city groups also use carbon steel in their sanitation systems. These fittings are in water supply pipelines too.

The use of carbon steel fittings goes from oil rigs to farms. They show top reliability in every area. Knowing more about what is out there can help you pick the right product for your job.

Exploring the Range of Products Offered by a Trusted Carbon Steel Pipe Fittings Manufacturer

Trusted manufacturers offer a wide range of pipe fittings, which include things like valves, flanges, and coils. These fittings come in many materials such as carbon steel, brass, copper, and PVC. They can be made to fit just what each industry needs.

Flanges and valves are made for jobs where you want a strong, tight seal. Coils are often used when there is a need to move heat. In Singapore, suppliers like Kian Huat Metal give people specialty fittings in brass or copper when the job calls for something different.

With so much to choose from in their inventory, you can always find the right fittings, whether you need them for industry or city projects. These manufacturers know how to make things your way and they work to make sure you get what you need without any trouble.

Часто задаваемые вопросы

What should I look for when choosing a carbon steel pipe fittings manufacturer?

Check if the manufacturer follows international standards such as ASTM and ASME. It is good to see if they have experience and proper certification. You can also read customer reviews. Many manufacturers in Singapore will send you quality details by email. This helps you make a clear choice when you buy.

How does the quality of carbon steel pipe fittings affect their performance in industrial applications?

Fittings made from good materials last long. They do not rust or break under high pressure. This keeps boilers and piping working well. If you use weak fittings, there can be leaks, more repairs, or even stops at work. This is true for any place where these systems are used. Using proper fittings helps avoid problems with corrosion in boilers and piping.

Are there standard specifications for carbon steel pipe fittings that manufacturers must adhere to?

Yes, certifications like ASTM, JIS, DIN, and ASME set rules for what goes into the material, how big things should be, and what pressure they can take. These standards help make sure parts fit well, are safe, and last a long time in many types of work.

What are the different types and applications of carbon steel pipe fittings available in the market?

Fittings such as elbows, tees, reducers, and valves are used in piping and plumbing. People use them in things like water systems and on oil rigs. Each type helps to manage flow well. They are made to fit the right job or need.