-

Промышленная зона Иньчжуан, уезд Мэнцюнь, город Цанчжоу, провинция Хэбэй, Китай

Discover the Best 1 Inch Steel Pipe Elbow for Your Project

Основные моменты

Here is a quick look at what you need to know about 1 inch steel pipe elbows:

- A pipe elbow is a crucial pipe fitting used to change the direction of flow in a piping system.

- The most common angles are 90 degrees and 45 degrees, each serving different functions.

- You can choose between long radius (LR) and short radius (SR) elbows depending on your pressure and space needs.

- Connection types include butt weld, socket weld, and threaded, offering various installation methods.

- Materials like stainless steel offer excellent corrosion resistance for demanding environments.

- Key dimensions to consider include diameter, radius, and wall thickness.

Введение

Welcome to the world of plumbing and piping! If your project involves routing a pipe around a corner or an obstacle, you’ll need an elbow. A 1 inch steel pipe elbow is one of the most fundamental pipe fittings, designed to change the direction of flow between two pipes. Whether you are working with stainless steel for its durability or other materials, understanding how to choose the right elbow is key to a successful and leak-free system. Let’s explore what makes these small parts so important.

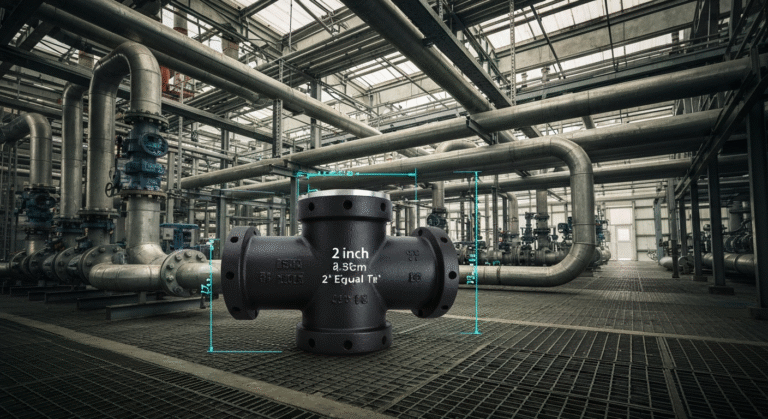

Types and Dimensions of 1 Inch Steel Pipe Elbows

When you’re looking for a 1 inch steel pipe elbow, you’ll quickly find they come in various types and sizes. The primary differences are the angle of the bend and the radius of the curve. The most common is the 90 degree elbow, but 45-degree options are also widely available for more gradual turns in your piping.

Beyond the angle, dimensions like the outside diameter, wall thickness, and radius are critical. These measurements must match your existing steel pipe to ensure a proper fit. Industry specifications, such as those from ASME, provide a standard for these dimensions, ensuring compatibility across different parts. Next, we will cover the specific measurements and the main differences between elbow angles.

Standard Measurements for 1 Inch Steel Pipe Elbow

Understanding the standard measurements of a 1 inch steel pipe elbow is essential for any project. The nominal pipe diameter of “1 inch” is a starting point, but the actual dimensions, including the outside diameter and wall thickness, are defined by specifications like ASME B16.9. The thickness of the elbow wall is often designated by a schedule (SCH) number, such as SCH 40 or SCH 80. A higher schedule number indicates a thicker wall, which can handle higher pressure.

These standardized dimensions ensure that a 1 inch degree elbow from one manufacturer will fit with a steel pipe from another, as long as they adhere to the same specifications. The radius, which determines how sharp the turn is, is another key measurement. A long radius (LR) elbow has a radius 1.5 times the pipe diameter, while a short radius (SR) is equal to the pipe diameter.

Here is an example of what standard dimensions might look like for a 1 inch elbow:

Dimension | Long Radius (LR) | Short Radius (SR) |

|---|---|---|

Nominal Pipe Size | 1″ | 1″ |

Center to Face | 1.50″ | 1.00″ |

Wall Thickness (SCH 40) | 0.133″ | 0.133″ |

Differences Between 45 Degree and 90 Degree Elbows

The most obvious difference between a 45 degree and a 90 degree elbow is the angle of the turn they create. A 90 degree elbow, also called a “quarter bend,” creates a sharp, right-angle turn in your pipeline. In contrast, a 45 degree elbow provides a more gradual change in direction. This seemingly small difference has a significant impact on fluid flow within the steel pipe.

The sharper turn of a 90 degree elbow creates more friction and pressure drop compared to a 45 degree elbow. For this reason, 90 degree elbows are used when a direct, sharp turn is structurally necessary. On the other hand, 45 degree elbows are preferred in applications where maintaining flow rate and minimizing pressure loss are important. They are often used in pairs to create a 90-degree offset that is smoother than a single 90 degree elbow.

Here’s a quick summary of the differences:

- Directional Change: A 90 degree elbow creates a sharp, perpendicular turn, while a 45 degree elbow creates a gentler, diagonal turn.

- Friction and Pressure: A 45 degree elbow produces less friction and a lower pressure drop in the pipeline.

- Common Applications: 90 degree elbows are common for connecting pipes to pumps and deck drains, while 45 degree fittings are popular in water supply facilities and food industrial networks.

Choosing the Right 1 Inch Elbow for Your Application

Selecting the correct 1 inch elbow for your project goes beyond just the angle. Your specific application will determine whether you need a long radius or short radius elbow. These pipe fittings might look similar, but their internal curve has a big impact on how fluids move through your steel pipe system. The choice affects both pressure and the physical space required for installation.

For example, a system that needs to maintain high pressure and a high flow rate will benefit from a different type of elbow than a system in a tight, confined space. Whether you are using stainless steel for its durability or another material, matching the fitting to the job is key. We’ll now look at the differences between long radius and short radius options to help you decide.

Long Radius vs Short Radius Options

The main distinction between long radius (LR) and short radius (SR) elbows is the radius of the curve relative to the pipe’s diameter. A long radius elbow has a curve radius that is 1.5 times the nominal diameter of the pipe. In contrast, a short radius elbow has a radius equal to the pipe’s nominal diameter, resulting in a much tighter turn.

This difference in radius directly affects the flow characteristics within the steel pipe. Long radius elbows offer a smoother path for fluids, which minimizes turbulence and pressure drop. This makes them the standard choice for most applications, especially those involving high flow rates or the transport of solids. Short radius elbows are typically used only in tight spaces where a long radius elbow would not fit.

Here’s how to choose between them:

- Длинный радиус (LR): Choose this for high-pressure and high-flow-rate pipelines where minimizing friction is important. The smoother turn reduces pressure loss.

- Короткий радиус (SR): Use this type for low-pressure applications or when space is limited. It allows for a much more compact turn.

- Default Choice: Long radius elbows are the more common and generally preferred of the two pipe fittings.

Connection Methods and Material Choices for 1 Inch Pipe Elbows

Once you’ve decided on the angle and radius, the next step is to consider how the elbow will connect to your steel pipe. The three main connection methods for these fittings are butt weld, socket weld, and threaded. Each method has its own benefits and is suited for different pressure levels and installation requirements.

In addition to connection types, the material of the elbow is just as important. While this guide focuses on steel, elbows are made from various materials, including carbon steel, stainless steel, and even copper or plastic. The choice of materials depends on factors like corrosion resistance, strength, and the type of fluid being transported. Let’s look closer at these connection styles and material options.

Butt Weld, Socket Weld, and Threaded Elbows Explained

Understanding the different connection types helps you select the right pipe fittings for your job. Butt weld elbows are designed to be welded directly, end-to-end, to the pipe. This method creates a strong, leak-proof connection, making it the preferred choice for high-pressure and high-temperature applications. The butt welding process requires beveled ends on both the elbow and the pipe for a solid joint.

Socket weld elbows feature a recessed area, or socket, where the pipe end is inserted before being welded. This design is easier to align than a butt weld joint but is generally used for smaller pipe diameters and lower-pressure systems. Threaded elbows have internal threads that screw onto the matching external threads of a pipe, much like common nuts and bolts. This method allows for easy assembly and disassembly, making it ideal for systems that may need maintenance or modification.

Here is a breakdown of the connection types:

- Butt Weld: Ends are welded directly to the pipe ends. Best for high-pressure and high-temperature pipelines.

- Socket Weld: The pipe is inserted into a socket on the elbow and then welded. Good for smaller diameter pipes.

- Threaded: The elbow is screwed onto the pipe. Excellent for easy installation and maintenance.

Common Materials Used in 1 Inch Steel Pipe Elbows

The material of your 1 inch elbow plays a huge role in its performance and longevity. Carbon steel is a common and cost-effective choice, known for its high strength and hardness. It’s a reliable option for general-purpose applications where extreme corrosion isn’t a concern.

For projects that demand superior corrosion resistance, stainless steel is the go-to material. Stainless steel pipe fittings, particularly grades like SS304 and SS316, can withstand harsh environments, including chemical plants and marine settings. While often grouped with steel, other materials like copper are also used for pipe fittings, especially in plumbing systems, due to their excellent resistance to water corrosion. The right material choice depends entirely on your project’s specific needs for strength, durability, and resistance to corrosion.

Key materials and their uses include:

- Углеродистая сталь: Offers great strength and hardness, making it suitable for many industrial applications.

- Нержавеющая сталь: Provides superior corrosion resistance, ideal for chemical, food-grade, and marine environments.

- Легированная сталь: Contains other elements to enhance properties like strength and temperature resistance.

- Other Materials: Fittings are also available in copper, plastic, and rubber for specific uses like plumbing and low-pressure hosing.

Installation Tips and Compatibility Considerations

Proper installation is crucial for a leak-free and durable pipeline. Ensuring compatibility between your 1 inch elbow and the connecting pipes is the first step. This involves matching the diameter, wall thickness, and material. For threaded fittings, it’s also vital to match the thread standards to prevent leaks or connection failure.

Using the right tools and techniques, such as applying sealants for threaded connections or using proper welding procedures, will ensure a secure fit. Compatibility also extends to the application environment, such as choosing the right material for marine applications. We will now discuss thread standards, necessary tools, and how to assess an elbow for specific uses.

Thread Standards (BSP, NPT) and Fitting Tools

When working with threaded fittings, you’ll encounter two main thread standards: NPT and BSP. NPT (National Pipe Thread) is the American standard, featuring tapered threads that create a seal when tightened. BSP (British Standard Pipe) is common in many other parts of the world and comes in two forms: tapered (BSPT) and parallel (BSPP). It is critical to use the same thread standard for both the elbow and the pipe, as NPT and BSP are not compatible.

The tools you need for installation depend on the connection type. For threaded elbows, a pipe wrench is essential for tightening the fittings, and thread sealant tape or compound is needed to ensure a leak-proof seal. For socket weld and butt weld elbows, you will need welding equipment and the expertise to use it safely.

Here are some tools you might need:

- Threaded Fittings: Pipe wrench, thread sealant tape or paste.

- Weld Fittings: Welding machine (for butt weld or socket weld).

- General: Pipe cutters or saws for preparing the pipe ends, and measuring tape.

- Clamps: Stainless steel clamps can be used to attach elbows to rubber hoses.

Measuring Radius and Assessing Use for Marine Applications

Measuring the radius of an elbow is simpler than it sounds. The radius is the distance from the centerline of the pipe opening at one end to the face of the opposite opening. For a 90-degree elbow, you can measure from the center of one opening to the plane of the other opening’s face. This measurement confirms whether you have a long radius (1.5 x diameter) or short radius (1.0 x diameter) elbow.

When it comes to marine applications, the choice of material is critical due to the highly corrosive saltwater environment. A standard steel pipe elbow would rust quickly. For this reason, stainless steel elbows are an excellent choice for marine projects. Their inherent resistance to corrosion makes them perfect for systems like deck drains, engine cooling, and water supply facilities on boats and offshore platforms.

Considerations for marine use include:

- Материал: Stainless steel (like grade SS316) is highly recommended for its excellent corrosion resistance.

- Приложения: Ideal for deck drains, water pressure pumps, and other onboard plumbing.

- Connections: Welded connections are often preferred for their durability in a vibrating marine environment.

Заключение

In conclusion, choosing the right 1-inch steel pipe elbow is essential for ensuring the efficiency and durability of your project. Whether you’re opting for a 45-degree or 90-degree elbow, understanding the differences, connection methods, and materials is key to making an informed decision. Take the time to assess your specific needs, consider installation tips, and ensure compatibility with your existing systems. By doing so, you not only enhance the performance of your piping system but also extend its longevity. If you’re ready to start your project with high-quality elbows, don’t hesitate to explore our recommendations or contact us for personalized guidance!

Часто задаваемые вопросы

Where to Buy 1 Inch Stainless Steel Pipe Elbows Online in Singapore?

You can purchase 1 inch stainless steel pipe elbows from various online hardware and industrial suppliers in Singapore. Look for reputable retailers that offer a wide range of pipe fittings and specify the grade of stainless steel (e.g., SS304 or SS316) to ensure you get the right product for your project’s needs.

Can You Use a 1 Inch Steel Pipe Elbow for Marine Projects?

Yes, you absolutely can, but it is crucial to use a stainless steel pipe elbow. The high corrosion resistance of stainless steel makes it the ideal material for marine environments, protecting against rust and degradation from saltwater. It’s commonly used for applications like deck drains and onboard water systems.

What Should I Consider When Selecting an Elbow for My Project?

When selecting a 1 inch elbow, consider the required angle (e.g., 45° or 90°), the radius (long or short), the connection type (threaded, socket weld, or butt weld), and the material (carbon steel vs. stainless steel). Your choice should be based on your specific application, pressure requirements, and space constraints.