-

Yinzhuang Industrial zone,Mengcun county,Cangzhou city,Hebei province,China

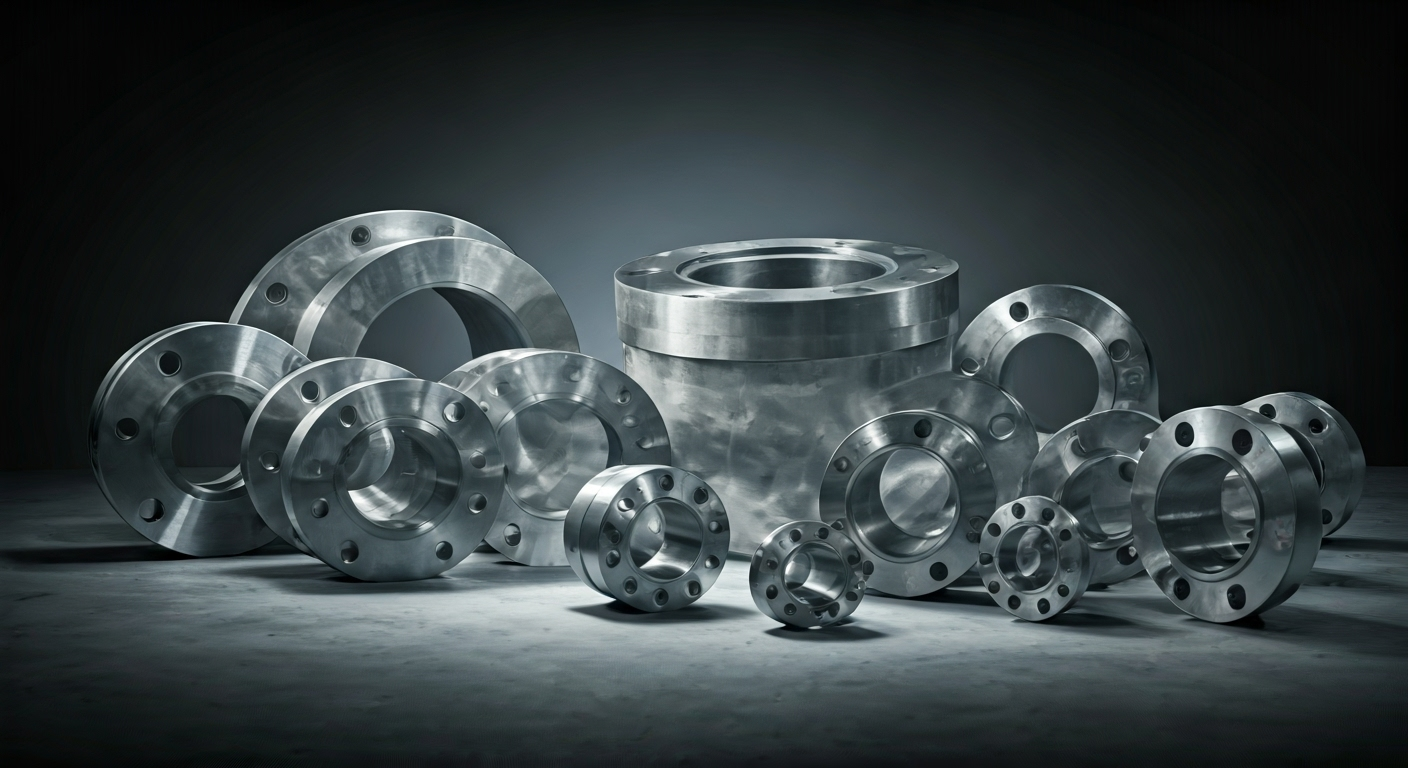

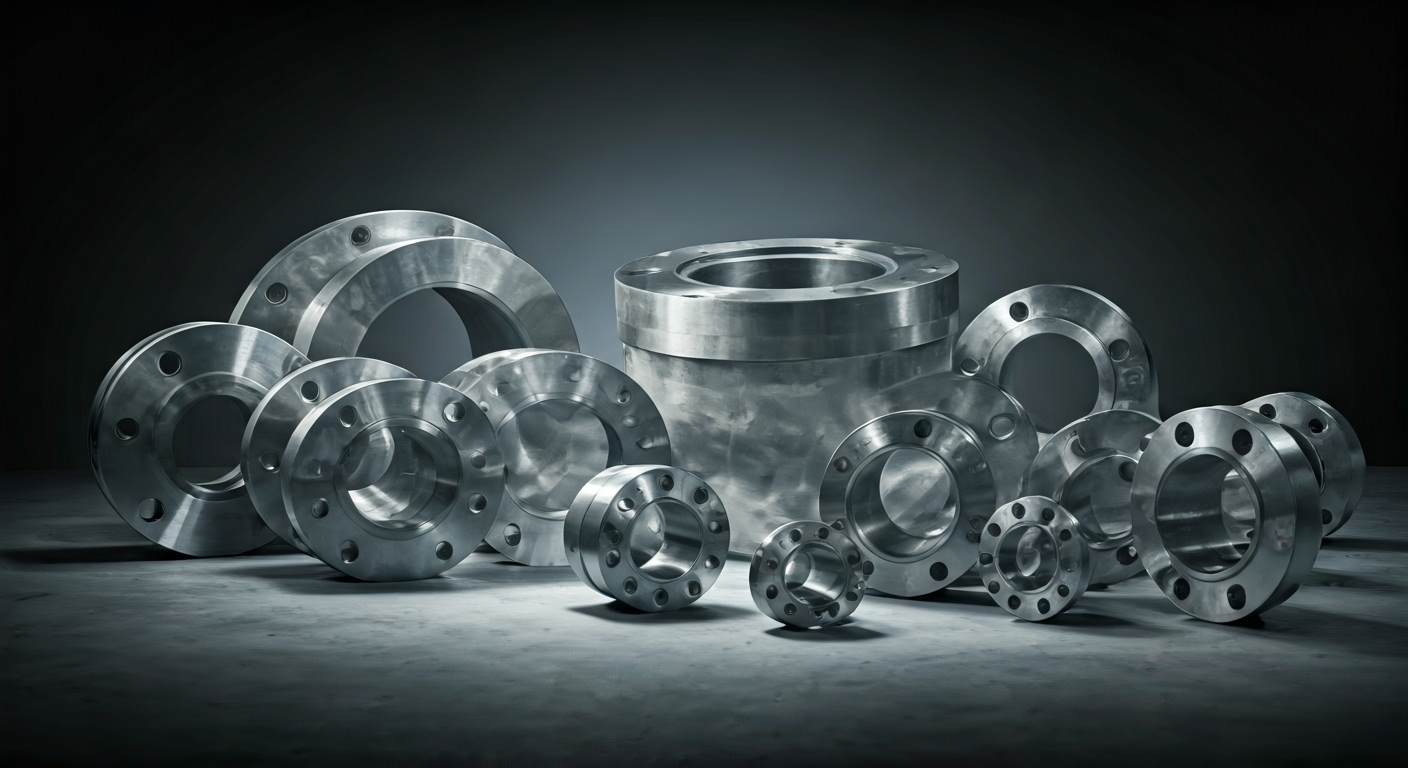

Complete Guide to WN FLANGE Specifications

Key Highlights

- A weld neck flange, also known as a welding neck flange, features a long tapered neck, making it ideal for smooth stress distribution in piping systems.

- It is available in carbon steel and stainless steel, providing options for diverse applications, including process plants and pipelines.

- Designed to handle high pressures, these flanges ensure structural integrity and reduce stress concentration at the pipe connection.

- The tapered hub promotes a smooth transition, minimizing turbulence and erosion within the system.

- Common face types include raised face (RF) and ring type joint (RTJ) for different sealing requirements.

- Precision engineering and quality forging make them suitable for demanding environments in the oil, gas, and other industries.

Introduction

Weld neck flanges are very important in many piping systems. You will see them used a lot in different industries. They have a design that gives strong and steady connections. This makes them very useful in places where the pressure is high, such as process plants.

A weld neck flange gets butt-welded to the pipe. This gives you one joint with no gap. It helps everything work better. The weld neck helps to spread stress out so it does not put too much on one spot. This problem happens a lot at pipe junctions.

These flanges are made in many materials and sizes. This makes the weld neck a good fit for many kinds of industries. They work well in high-pressure piping operations, where strong connections are needed the most.

Overview of Weld Neck Flanges

A weld neck flange is a part made with a tapered hub shape. This special hub makes it easy to join to the pipe. The design helps lower stress in the pipe and gives it better strength. The weld neck flange can have a raised face (RF) or a ring type joint (RTJ) surface, based on what you need for your job.

Weld neck flanges fit well with pipes and help the flow. They stop turbulence and also keep erosion down. These flanges are strong and work well when there is high pressure and heat. That is why many people like to use them in tough conditions.

Key Features and Design Benefits

The design of a weld neck flange focuses on its smooth transition and strong support. This type of flange has a tapered hub that spreads out the force from the pipe. It helps the weld last longer even in tough jobs. The smooth curve of the hub cuts down on turbulence. This keeps the system working well and protects both the pipe and the flange.

One more good thing about this weld neck is the extra reinforcement it gives at the joint. This strong support makes the flange right for pipelines that face high-speed flow or big changes in pressure. The face of the weld neck flange is shaped to fit with the pipe, so it stops flow problems.

By making a tight and strong join, this flange helps stop problems like erosion or fatigue building up in the system over the years. These great features help the welding neck flange be a top pick for jobs in oil, gas, and chemical plants and other big sites.

Types of Weld Neck Flanges (Standard vs. Long Weld Neck)

Standard weld neck flanges have a tapered neck. This gives a smooth transition from the weld neck flange to the pipe. This smooth transition helps keep the weld strong and brings better flow inside the pipe. People mostly use these when the wall thickness and pressure are not too high.

On the other hand, long weld neck flanges come with a much longer neck. These work well for places with high pressure. The design uses a longer tapered hub. This gives added reinforcement and keeps down turbulence in the flow. Because of this, they are good for process plants and tough pipeline systems where the wall thickness, a smooth transition, and extra weld support all matter.

Material Specifications for Carbon & Stainless Steel Weld Neck Flanges

The material of a weld neck flange plays a big role in how it works. Carbon steel flanges made from ASTM A105 are strong and can stand up to high temperatures. Because of this, they are good for big jobs that need a lot of strength. On the other hand, stainless steel flanges like ASTM A182 can fight off corrosion. This is very important when you are using them in places with chemicals or near the sea.

These weld neck flanges are made by forging. This process makes the grain in the metal better and improves how strong the flange will be. Flanges must follow ASTM and ASME rules so that their quality is always high and you get good, long-term use from them.

Common Grades Used in Singapore Industries

In Singapore, weld neck flanges follow worldwide standards, so they fit many needs and uses. The grades cover materials such as carbon steel, stainless steel, and other alloys.

Material Grade | Applications |

|---|---|

ASTM A105 (Carbon Steel) | Good for high-pressure pipelines and fittings |

ASTM A182 F304/F316 (Stainless Steel) | Used for places with a lot of corrosion like chemical plants |

UNS S31803 (Duplex Steel) | Works well in marine and very corrosive areas |

Inconel 625 (Nickel Alloy) | Fits jobs in high-temperature spots, such as refineries |

All these materials meet the ASME and ANSI WN standards. This makes it easy for people to use them with most projects. The different properties in each one mean they can take on big and important jobs. You will see these flanges in all places from weld pipelines, new oil work, as well as plants that ask for safe and tough pipeline fittings to handle both corrosion and heat.

Factors Affecting Material Selection

Choosing the right material for a welding neck flange means you have to think about a few things. Some of the most important are:

- Corrosion and erosion resistance: This is important for any job that uses a lot of chemicals or water.

- Wall thickness: The flange needs to have the same thickness as the pipe you are using it with. This helps make everything safer and work better.

- Operating environments: The material has to be strong enough to handle high pressures, very hot or cold temperatures, or rough conditions.

In fields like oil and gas, or when working with petrochemicals, the materials are usually tested. They need to hold up against signs of wear, like fatigue and piping erosion, to make sure the neck flange lasts. Picking the wrong material for your welding neck or when thinking about wall thickness can lead to problems with how well the system works or how long it lasts. It may also be unsafe.

Long weld neck Flange

The long weld neck flange (LWN) comes with a long hub that stands out from other kinds. It is made to fit special needs, such as being used as a nozzle in pipelines and process plants. The longer shape helps give extra reinforcement. So, your system gets more support and stays solid, even when the work gets tough.

This type of flange has a strong build. It can handle lots of stress without a problem, and this makes it important when you have to join big equipment or columns. There is also the choice of LWN Heavy Barrel. That one has a thicker wall, and it is meant for jobs that need even more strength.

The way the LWN flange is built helps you do careful, exact jobs. You can count on it to last a long time if you need your pipeline to stay steady and firm.

Reducing Weld Neck Flange

A reducing weld neck flange is special because it can join pipes with different diameters. The tapered bore design of this weld neck flange helps lower flow resistance. This design helps keep the system working well.

The smaller neck in the flange makes it easy to connect to small valves or fittings. This is helpful when there is not much space in the pipelines. You will often see these flanges in industries where pipes have to fit close together.

A reducing weld neck flange can also help connect pipes that do not match in size. This changes the direction in a safe way and helps keep the system strong. This type of weld flange is good for those who want both flexibility and safety in their piping system.

NW Long Weld Neck Flanges

NW Long Weld Neck Flanges stand out in high-pressure work. These flanges can have a ring type joint (RTJ) or a raised face on the sealing surface. They make sure the stress spreads along the pipe instead of collecting in one spot.

This setup cuts down on stress where the flange meets the pipe. So, it be great for things that have heavy loads, move a lot, or get hot and cold often. Plus, the long weld neck gives strong and steady weld connections, which is important for process systems that really need it.

You will find that the oil and gas industry and petrochemicals use NW weld neck flanges a lot. These raise performance in tough, high-pressure places thanks to the raised face and RTJ.

Materials of WN Flanges

Weld Neck Flanges (WN) are made from different materials. You can get them in carbon steel, stainless steel, and nickel alloys. Many people pick carbon steel like ASTM A105. This is because the flange has good strength for tough places, and it saves money.

If you need better protection against corrosion, go for stainless steel such as ASTM A182 F304 or F316. If you want more from your flange, alloys such as Inconel 625 can work well for use in high heat or high pressure. These have great reliability.

These flanges are made with forging. They follow ASTM and ASME standards. Because of this, you get dimensional stability and your material will last longer.

Weld Neck Flange Dimensions

Dimensions for Weld Neck Flanges change depending on what you need them to do. You can see some usual sizes made to fit ASME B16.5 standards in the chart here:

Nominal Pipe Size (NPS) | Bore Diameter (in) | Outside Diameter (in) |

|---|---|---|

1/2” | 0.62 | 3.50 |

2” | 2.07 | 6.00 |

10” | 10.02 | 16.00 |

24” | 23.25 | 32.00 |

The thickness and pressure classes of these weld neck flanges come in a range of options. This means you get the flexibility to fit different piping jobs with different system pressures. Always check that the part you choose matches your piping specifications like bore size, flange thickness, and diameter.

Conclusion

In short, knowing about weld neck flange details is key when you want the right fit and function in different jobs. You need to look at the main features, what materials are used, and the size when it comes to carbon and stainless steel weld neck flanges. This helps you make smart choices for better use and longer life. No matter if the work is for high-pressure jobs or just picking the right type, it’s good to know these neck flange details so you do not make mistakes that cost more later. It also keeps your whole system safe. If you want help picking the best weld neck flange for your needs, reach out now and get a free talk with our experts!

Frequently Asked Questions

What are the main differences between carbon steel and stainless steel weld neck flanges?

Carbon steel weld neck flanges are good when you need strength for high-pressure jobs. But, they do not fight off corrosion. Stainless steel weld neck flanges, such as those made to ASTM standards, work better against corrosion and chemicals. These stainless steel options are a great pick for piping in tough places, like marine and process plants, where corrosion can be a big problem.

How do I select the right weld neck flange for high-pressure applications?

To pick the right weld neck flange for high pressures, you should check if the wall thickness matches your needs. Make sure the pressure rating and material meet the needed standards, like ASTM or ASME. A strong flange design gives reinforcement and spreads out stress. This helps the system stay safe and solid when in use.

What are the typical standards and certifications for weld neck flanges in Singapore?

In Singapore, weld neck flanges usually follow ASTM, ASME, and ANSI standards. This helps make sure the material used is strong and the work is done with care. These standards be important so the weld neck flanges can stand up to hard work and high use in big areas like oil, gas, and chemical jobs.

Can weld neck flanges be used with other flange types?

Yes, you can use weld neck flanges along with other flange types like slip-on or threaded flanges in the piping system. Make sure that the design, material, and use match well. This helps you get safe and strong links to fittings and valves.

What maintenance is required to ensure long service life of weld neck flanges?

Regular checks are important to stop corrosion and wear in weld neck flanges. You should look at the piping to see if there is erosion or any kind of damage. Clean it when it is needed. The right care helps the weld neck flange be more reliable, work better, and last longer.