-

Khu công nghiệp Yinzhuang, huyện Mengcun, thành phố Cangzhou, tỉnh Hà Bắc, Trung Quốc

Mua ống nối góc hàn 5 inch ở đâu trực tuyến?

Điểm nhấn chính

Here are the key takeaways from this guide on 5-inch butt weld elbows:

Understand the core differences between a long radius elbow and a short radius elbow to select the right fit for your flow requirements.

To properly install a 5 inch butt weld elbow, whether it is a short radius elbow or a long radius elbow, first ensure the pipe ends are clean and properly aligned. Then, tack weld the elbow in position, check for accurate orientation, and complete the weld around the circumference, ensuring the weld is uniform to maintain the correct radius and optimal strength.

- Understand the core differences between a long radius elbow and a short radius elbow to select the right fit for your flow requirements. Whether you are selecting a short radius elbow or a long radius elbow for your piping system, proper installation is crucial. To install a 5 inch butt weld elbow, ensure the pipe ends are properly prepared with clean bevels and aligned carefully. Tack weld the elbow in place, verify the correct orientation and radius for the flow, then proceed with a full weld following industry standards, using the proper techniques for carbon steel or stainless steel as required.

Learn how to choose the best material, like durable carbon steel or corrosion-resistant stainless steel, for your piping system.

- Learn how to choose the best material, like durable carbon steel or corrosion-resistant stainless steel, for your piping system.

- Get familiar with key specifications, including standard thickness ratings like SCH 40 and angle configurations.

- Discover why 90-degree elbows are for sharp turns and 45-degree elbows ensure a smoother flow.

- Find tips on how to identify and verify quality suppliers online.

Giới thiệu

When you are building or maintaining a piping system, getting the details right is essential. Pipe fittings are the crucial components that connect everything, and elbows play the vital role of changing the direction of flow. A 5-inch butt weld fitting is specifically designed to be welded directly onto your pipe, creating a strong and leak-proof connection. Are you looking for the right elbow for your project? This guide will walk you through the different types, materials, and specifications to help you make an informed choice online.

Understanding 5 Inch Butt Weld Elbow Fittings

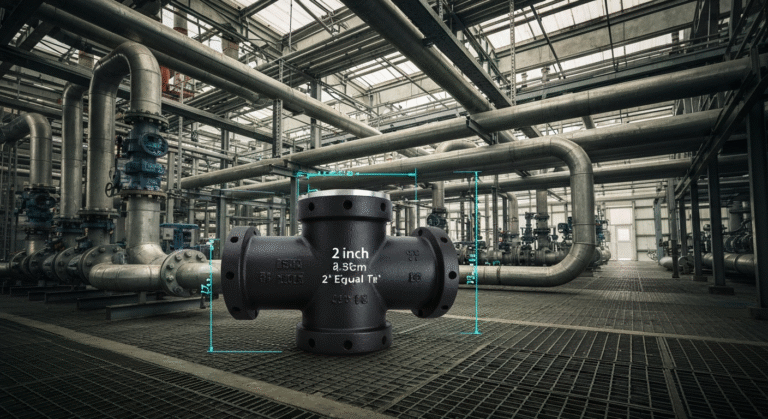

A 5-inch butt weld elbow is a specific type of pipe fitting used to create a turn in a pipeline. The “5-inch” measurement refers to the nominal pipe diameter it is designed to connect with, ensuring a seamless fit. These fittings are fundamental in various industries, from construction to chemical processing.

The term “butt weld” describes the connection method. The ends of the elbow are beveled to match the pipe, allowing them to be welded edge-to-edge. This creates a robust and permanent joint that becomes part of the piping itself. Understanding the different designs and materials available is the next step in choosing the right elbow.

Long Radius vs Short Radius Designs for 5 Inch Elbows

One of the most important distinctions in elbow design is the choice between a long radius and a short radius. A long radius (LR) elbow has a curvature radius that is 1.5 times the pipe’s diameter. This design creates a gentler, wider turn for the fluid passing through it. The primary benefit is a smoother flow with less resistance and a minimal pressure drop.

In contrast, a short radius (SR) elbow has a curvature radius equal to the pipe’s diameter. This results in a much sharper, more compact turn. While this design is perfect for projects with tight space constraints, it creates more turbulence and higher flow resistance. The abrupt change in direction can lead to a greater pressure drop in the system.

Ultimately, the choice depends on your system’s needs. If your priority is maintaining high flow rates and low pressure, a long radius elbow is the superior option. However, if you are working in a confined space where a compact design is necessary, a short radius elbow provides a practical solution, especially in low-pressure pipelines.

Choosing Between Carbon Steel and Stainless Steel Materials

When selecting a 5-inch butt weld elbow, the material is just as important as the design. Carbon steel is a very common and reliable choice. It offers excellent strength and durability at a cost-effective price point, making it suitable for a wide range of general-purpose applications where corrosion is not a primary concern.

On the other hand, stainless steel is the go-to material for systems that require superior corrosion resistance. Grades like 304 and 304L are widely available and are ideal for industries handling chemicals, food, or other corrosive substances. Stainless steel ensures the purity of the product and the longevity of the piping system, even under harsh conditions.

For specialized applications involving very high pressure or extreme temperatures, you might also consider alloy steel fittings. Your final decision should be based on the specific fluid your pipes will carry, the operating pressure, and the environmental conditions the piping system will face.

Key Specifications and Dimensions of 5 Inch Butt Weld Elbows

Before you purchase a 5-inch butt weld elbow, it’s crucial to understand its key specifications. The “5-inch” size refers to the nominal diameter of the pipe that the elbow will be joined with. This ensures compatibility and a consistent pathway for fluid to travel through your system.

Beyond the diameter, other dimensions like wall thickness and the angle of the bend are critical for a proper fit and optimal performance. These specifications ensure that the fitting can handle the pressure of your system and route the pipeline correctly. Let’s look closer at the standard thickness ratings and angle configurations you will encounter.

Standard Thickness Ratings (Including SCH 40)

The wall thickness of a butt weld elbow is defined by its schedule (SCH) rating. What is the purpose of these ratings? A schedule rating indicates the fitting’s ability to withstand internal pressure. A higher schedule number, such as SCH 80, means a thicker wall, while a lower number like SCH 40 has a thinner wall.

Choosing the correct schedule is essential for the safety and integrity of your pipeline. The elbow’s schedule must match the schedule of the pipe you are connecting it to. This ensures a uniform inside diameter, preventing flow disruption and potential weak points. For example, SCH 40 is a very common thickness used in many applications. You can typically find SCH 40 5-inch butt weld elbows from most online suppliers.

Many suppliers provide detailed dimension charts to help you verify all measurements before purchasing. These charts list the exact dimensions based on the nominal pipe size and schedule.

Specification | Mô tả |

|---|---|

Nominal Pipe Size (NPS) | The standard size of the pipe the elbow fits (e.g., 5 inches). |

Schedule (SCH) | Determines the wall thickness (e.g., SCH 40). |

Center-to-Face | The distance from the center of the elbow to the face of the opening. |

Loại vật liệu | The type of steel used (e.g., Carbon Steel, Stainless 304). |

45 Degree vs 90 Degree Elbow Configurations

Another critical specification for your 5-inch butt weld elbow is the angle of the bend. The most common configurations you will find are 45-degree and 90-degree elbows, each serving a distinct purpose in directing fluid flow.

A 90-degree elbow creates a sharp, right-angle turn in the pipeline. This is the standard choice for most directional changes in a piping layout. However, this sharp turn causes more significant friction and turbulence, resulting in a higher pressure loss compared to a more gradual bend. It is ideal when a precise 90-degree change is needed.

In contrast, a 45-degree elbow offers a gentler change in direction. This smoother path helps maintain better flow characteristics and minimizes pressure loss, making it a great choice for optimizing flow efficiency.

Here is a quick comparison:

- Directional Change: A 90-degree elbow makes a quarter turn, while a 45-degree elbow makes a one-eighth turn.

- Flow Characteristics: Fluid flow is smoother through a 45-degree elbow.

- Pressure Loss: A 90-degree elbow introduces a greater pressure drop.

- Application: Use 90-degree elbows for standard routing and 45-degree elbows to improve system efficiency or for slight directional adjustments.

Buying 5 Inch Butt Weld Elbow Fittings Online in Singapore

With a clear understanding of what you need, the next step is procurement. Buying 5-inch butt weld fittings online has become an efficient way to source parts for projects of any size. The digital marketplace allows you to connect with a global network of suppliers, including many based in hubs like Singapore. These suppliers often cater to international clients, providing access to a wide range of products that might not be available locally. This convenience simplifies the purchasing process, from comparing specifications to placing an order.

When buying online, your focus should be on finding a supplier that promises excellence and reliability. The goal is not just to find the cheapest butt weld fitting but to secure a high-quality component that guarantees the safety and longevity of your piping system. Vetting your supplier is a critical step in ensuring your online procurement is successful and your project standards are met.

Leading Suppliers, Product Range, and How to Verify Quality

You can absolutely get 5-inch butt weld elbows from suppliers in Singapore and other major industrial centers through online platforms. Leading suppliers distinguish themselves by offering an extensive product range that covers various materials, sizes, and specifications. This demonstrates their expertise and ability to meet diverse project needs.

A quality supplier will have a comprehensive inventory, including different grades of materials. For instance, if you require stainless steel, you should be able to find 5-inch butt weld elbows in both 304 and 304L grades to suit your specific corrosion resistance and welding needs. A broad product range is a good sign of a well-established and capable supplier.

To ensure you are buying a quality product, take a few steps to verify the supplier’s commitment to excellence.

- Look for internationally recognized certifications, such as ISO credentials, which indicate adherence to quality management standards.

- Inquire about their quality control measures, such as inspection processes for wall thickness and material integrity.

- Review their company profile and any available factory information to gauge their manufacturing capabilities.

- Confirm they can provide material test reports for the fittings you order.

Kết luận

In conclusion, finding the right 5-inch butt weld elbow fittings online doesn’t have to be a daunting task. By understanding the different designs, materials, and specifications, you can make an informed decision that suits your project needs. Whether you’re opting for carbon steel or stainless steel, knowing the key features will help you select high-quality fittings that perform effectively. Don’t hesitate to explore leading suppliers in Singapore, as they can offer a range of products and ensure quality verification. If you need assistance or have questions about your options, feel free to reach out for personalized guidance tailored to your requirements!

Any schedule 5 6G tig pipe tips? : r/Welding

For schedule 5 6G TIG pipe welding, ensure proper fit-up and cleanliness of the 5 inch butt weld elbow fittings. Use a consistent travel speed and maintain a steady arc length to avoid defects. Practicing on scrap pieces can help fine-tune your technique before tackling the actual project.

Any schedule 5 6G tig pipe tips? : r/Welding

When welding 5-inch butt weld elbow fittings using Schedule 5 6G technique, ensure proper fit-up and alignment. Use appropriate filler material and maintain a consistent travel speed to avoid defects. Preheat the pipe if necessary, and always follow safety protocols for optimal results in your welding project.