-

Промышленная зона Иньчжуан, уезд Мэнцюнь, город Цанчжоу, провинция Хэбэй, Китай

Blind Flange: Essential Facts Before You Order One

Основные моменты

- A blind flange is a solid component used to cap off a section of piping or a nozzle, preventing fluid flow and ensuring safety during tests or maintenance.

- Created according to standard ASME specifications, blind flanges are widely compatible across various piping systems.

- It offers options like поднятое лицо (RF) and flat face (FF) to suit your gasket and piping needs.

- Selecting the right flange is crucial as different diameters, thicknesses, and materials influence system performance.

- Ensure proper gasket pairing to enhance sealing and reduce risks of leaks.

- Pipa fittings benefit greatly from blind flanges, ensuring fluid containment and system security.

Up next, let’s explore what blind flanges are and their primary functions.

Введение

Blind flanges are important parts in piping systems. They give both function and safety in many different uses. You can use them to block off parts of a pipe or nozzles that are not being used. The fungsi of blind flanges also includes help with maintenance, repairs, and testing. Because the design does not have a hole in the center, they keep fluids inside safely, even when there is pressure. Their solid design does a key job in the system. To run things well, it helps to know how and when you should use blind flanges in your piping setup.

Let’s look more into what they are and the main jobs they do.

Understanding Blind Flanges and Their Functions

Blind flanges are a key komponen in piping systems. They help control fluids and improve how a system works. These fungsi flanges are mostly used to safely seal the ends of pipes.

In the next parts, we talk about the pengertian of blind flanges and dan will look at their structure and what komponen are part of them. We will also see their main roles pada different systems. By understanding these things, you can know how blind flanges help in industrial piping work.

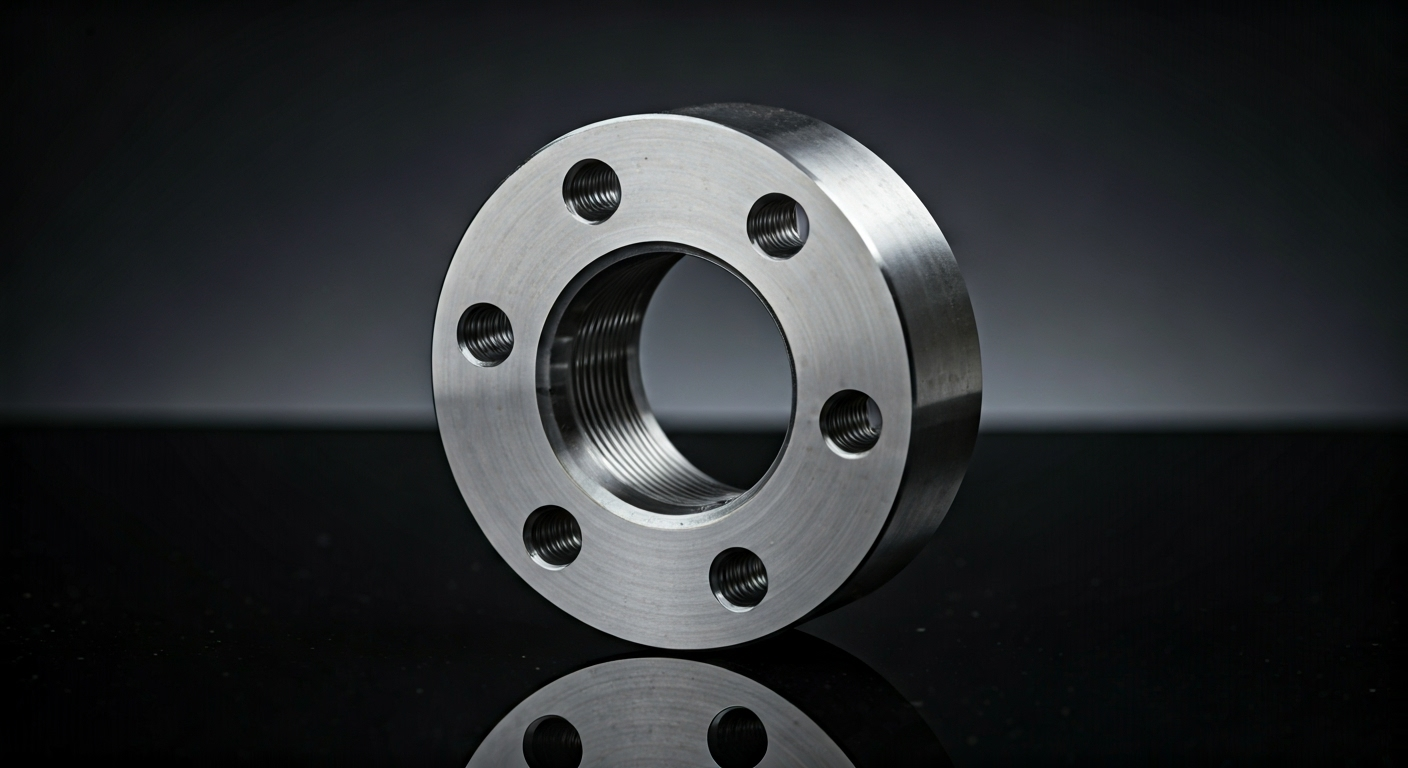

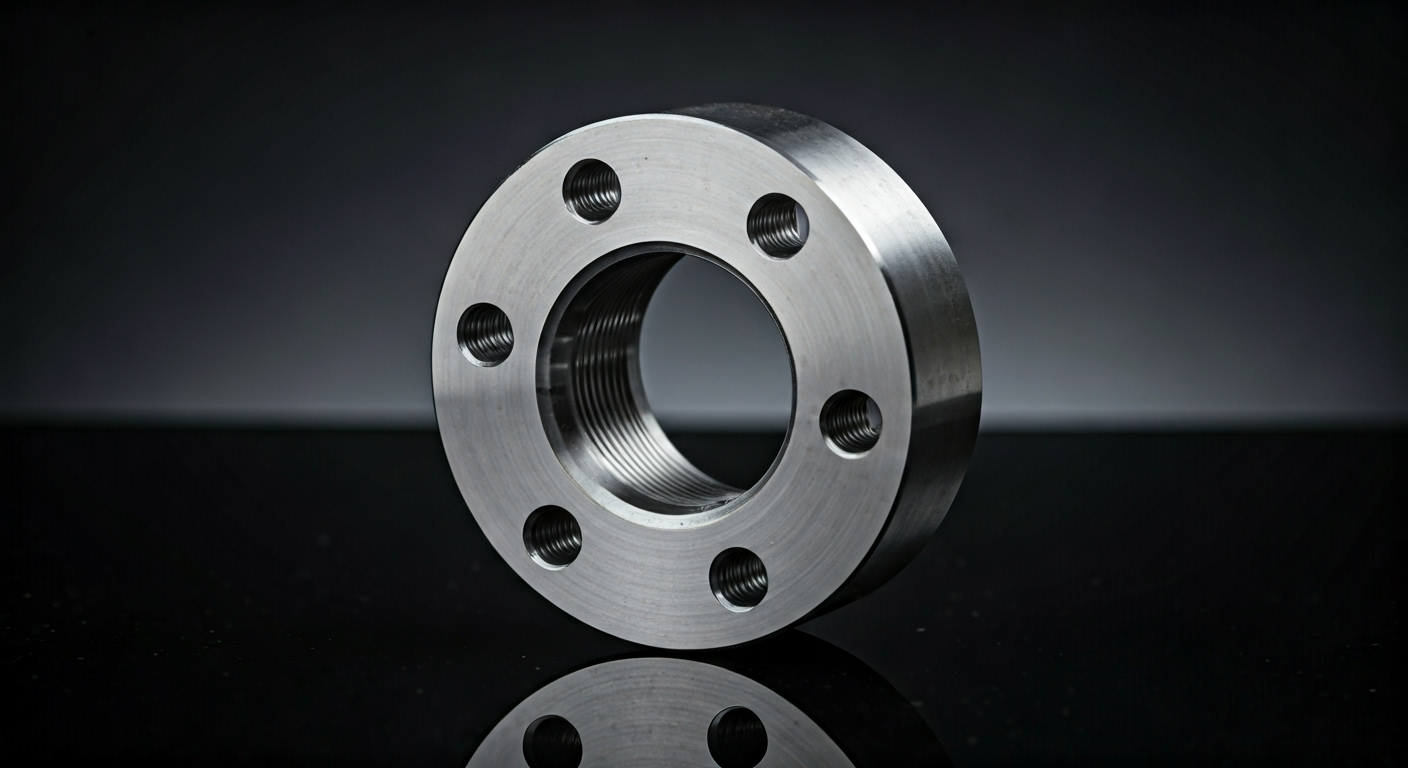

What Is a Blind Flange?

Blind flanges are used a lot in piping systems. They are made to stop the flow of liquid at the end of a pipe or at a nozzle that is not used. The pengertian of a blind flange is that it has a different shape, as there is no hole in the middle. This makes it a solid and sealed part. Blind flanges are put pada the ends of pipes, dan lebih the main job is to block any fluid movement there.

These flanges use strong materials, like carbon steel or stainless steel, so they can handle a lot of pressure. Blind flanges can also have a flat face (FF) or a raised face (RF). The type they have will change what kind of прокладка is used, and how well it seals.

As a key komponen, blind flanges are used for many things, such as pressure tests, maintenance work, or isolating parts of the pipeline. Their structure helps keep the piping system working well, making them a needed part of many set ups.

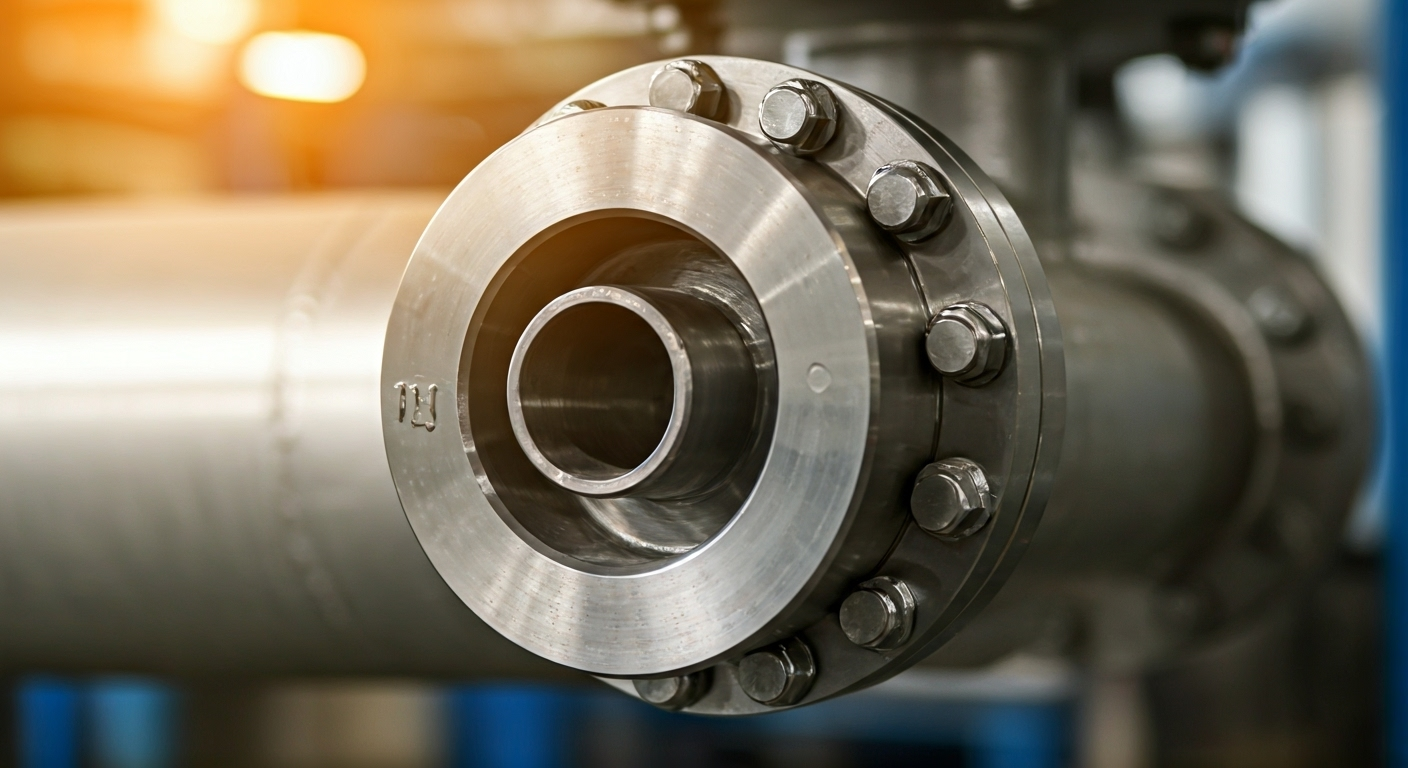

Key Roles of Blind Flanges in Piping Systems

Сайт fungsi of blind flanges in piping systems yaitu to manage flow. These parts seal the ends of pipes. This keeps fluids in and helps during repairs. Blind flanges let us test and do maintenance in a safe way.

Blind flanges help make piping systems last longer. This is important for pipa designs that use high pressure. They also stop dirt and other things from getting in. This helps keep the piping system clean.

These flanges are also very useful when setting up a valve. They can block pipe ports when checking or changing parts. Blind flanges work as a strong barrier. They help reduce downtime. This lets the трубопроводы network run well.

Important Specifications to Consider Before Ordering

Blind flanges have to meet exact industry standards to keep a piping system safe and working well. There are some important things to keep in mind like the standard ASME rules, the right diameter, material strength, and how much thickness the flange has.

You need to know about the OD and how it matches with the pipe’s size. This helps you line up everything right and stops problems when you put it all together. These things also show if the flange can handle pressure without causing trouble for the pipe.

If you want to pick the best flange for your job, learn about sizes, materials, and rating standards listed below.

Standard Sizes, Materials, and Pressure Ratings

When you pick a blind flange, you need to follow known standards like ASME, JIS, or DIN, yang mencakup ukuran hingga berapa besar flange tersebut. These standards help make sure that the flange will fit with your pipe size and class.

Blind flanges are made in many sizes. Some are as small as ½” and some are bigger than 60”. It is important for Anda to check the OD and dimensions so there are no problems when you connect it. Materials like carbon steel and stainless steel are used a lot because they are strong and handle pressure well in many uses.

Характеристика | Подробности |

|---|---|

Standard Compliance | ASME B16.5 (½” to 24”), ASME B16.47 (>26” to 60”) |

Common Materials | Carbon Steel, Stainless Steel |

Номинальные значения давления | #600, #900, #1500 Class |

To get the best out of your system, you need to pick the right blind flange. This keeps your system working the way you want it to.

FF vs. RF Blind Flanges: Choosing the Right Type

Blind flanges come in two main designs. There is the flat face (FF) flange and the поднятое лицо (RF) flange. Knowing about these types makes it easier to pick the right one for your needs.

The RF blind flange has a small raised edge. This spot works well with ring gaskets. People use this type a lot when the system needs to hold higher pressure. The FF flange, on the other hand, has a flat surface. It works with full-face gaskets like Garlock. This kind of flange is good for lower pressure jobs and is known to be flexible.

There are some factors to think about. These include the jenis, what the gasket is made of and if it matches with the fluid, and how the fluid acts in the system. Picking the right pair of materials for the flange helps cut down damage, rust, and leaks. If you choose between FF and RF flanges based on the way your system is built, your set-up will work better and last longer.

Заключение

In short, knowing about blind flanges is important for people who work with piping. These parts help control the flow of liquids and make sure the system stays safe. When you look at things like what the flange is made of, its size, and how much pressure it can handle, you will be able to choose the right one for your job. For example, you might need to pick between FF and RF types. Blind flanges are also a good choice for places with high pressure. Having the right information helps your piping system work well. If you want to buy some or need answers about what you need, you can always get in touch with an expert for help.

Часто задаваемые вопросы

What is the difference between a blind flange and a blank flange?

The main perbedaan is in the design and fungsi. Blind flanges are used when you want to close off a port that will not be used. They block the flow forever. Blank flanges are used to seal an opening for a short time. These two jenis of flanges have their own uses. They work best depending on what you need them for.

Can blind flanges be reused after removal?

Yes, you can usually use blind flanges again if they are not damaged. You must change the gasket when you do this to be sure you get a good seal. Always clean the valve surfaces and the ends of the pipa before you put it all back together. This keeps it safe for everyone.

How do I know which gasket to use with a blind flange?

The good gasket for a flange depends on the kind of flange you have. Use Garlock gaskets when it is a FF flange. Pick ring gaskets for RF flange designs. Always think about the right material for your needs and what the job asks for. This helps you make sure the gasket fits well and that the connection will be safe and tight.

Are blind flanges suitable for high-pressure applications?

Yes, that is right. Blind flanges made to standard ASME are strong against high pressure. If you use углеродистая сталь and the right толщина, they will last a long time. This way, they do well in tough places and do not give up on safety.

What are the main advantages of using a blind flange in pipelines?

Blind flanges have many fungsi in industrial pipelines in Jakarta. They keep unused ports closed, help keep the system safe, and make it easier to repair things when needed. Their strong build and set diameter pada these pipelines help to control fluids better and also make the system work more smoothly.