-

Zona industrial de Yinzhuang, concelho de Mengcun, cidade de Cangzhou, província de Hebei, China

Stainless Steel Pipe Elbow: 90° vs. 45° Explained

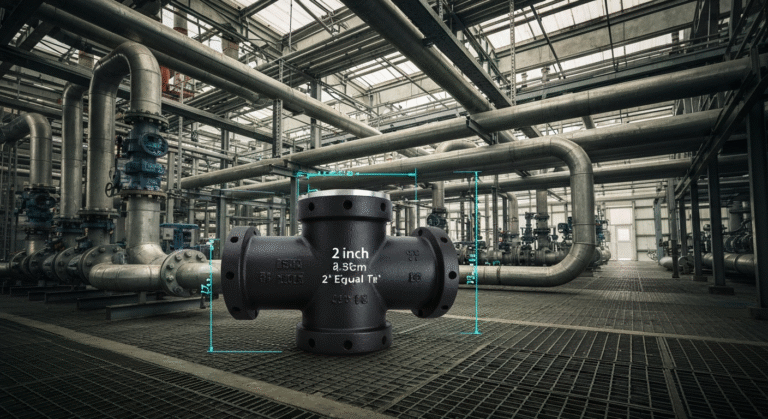

butt weld 90 degree stainless steel pipe long radius elbow

Principais destaques

Here are the key takeaways about stainless steel pipe elbows:

- Stainless steel pipe elbows are essential fittings for changing the flow direction in a piping system.

- The main difference between a 90 degree and a 45 degree elbow is the angle of the turn they create.

- These fittings are valued for their excellent corrosion resistance and durability, making them suitable for many industries.

- Choosing the right elbow involves considering the pipe diameter, flow requirements, and available space.

- Types include butt weld, threaded, and socket weld, each offering different installation benefits.

Introdução

When building or maintaining a piping system, you often need to change the direction of the flow. That’s where stainless steel pipe elbows come in. These crucial pipe fittings are designed to connect two pipes and redirect liquids or gases at a specific angle. Made from a durable alloy steel, stainless steel is the material of choice for its impressive strength and corrosion resistance. Understanding these components is the first step toward ensuring your project is efficient, reliable, and built to last.

What Is a Stainless Steel Pipe Elbow?

A stainless steel pipe elbow is a fitting used in plumbing and industrial piping to connect two pipes of the same diameter, creating a turn. Its primary purpose is to change the direction of the fluid path without causing significant pressure drops or turbulence. This makes them a fundamental part of any complex pipe network.

Thanks to their stainless steel construction, these elbows offer exceptional durability and resistance to corrosion and rust. This makes them ideal for demanding environments, including those with extreme temperatures or exposure to harsh chemicals. Their strength ensures a long service life for your piping system. Now, let’s explore their specific uses and the different types available.

Main Purposes and Applications of Pipe Elbows

The main job of any pipe elbow is to alter the flow direction within a system. This simple function is critical in navigating obstacles, optimizing layouts, and directing fluids to their intended destinations. The excellent mechanical properties of stainless steel make these elbows a reliable choice for maintaining system integrity under pressure.

Their resistance to corrosion makes them indispensable in a variety of sectors. You will find them frequently used in applications where hygiene and purity are paramount. These industries include:

- Chemical industry

- Pharmaceutical industry

- Food and beverage industry

- HVAC systems

In these fields, the material’s inability to contaminate the product it carries is just as important as its ability to change the flow direction. This combination of features makes stainless steel elbows a versatile and essential component for countless projects.

Types of Stainless Steel Pipe Elbows (Including Butt Weld Elbow, Threaded, and Socket Weld)

Several types of stainless steel pipe elbows play a crucial role in piping systems. The butt weld elbow is ideal for creating strong, permanent connections, while the threaded elbow allows for easier assembly and disassembly, perfect for maintenance. A socket weld elbow, on the other hand, offers excellent welding quality, ensuring durability under high pressure. Each type is designed to handle various pressure ratings and flow directions, making them suitable for diverse applications in industries such as pharmaceuticals, chemicals, and water supply.

90 Degree vs. 45 Degree Stainless Steel Pipe Elbow: Core Differences

The most obvious difference between a 90 degree and a 45 degree stainless steel pipe elbow is the angle of the turn. A 90 degree elbow creates a sharp, right-angle bend, while a 45 degree elbow provides a gentler, more gradual change in direction. This fundamental distinction impacts flow dynamics and how the fitting is used in a piping layout.

The choice between them depends entirely on your system’s needs. The degree elbow you select will influence factors like pressure drop, frictional resistance, and the physical space required for installation. Both types are available with different radius of curvature options to further refine the flow characteristics. Let’s look closer at their design and how it affects their use.

Design, Flow Patterns, and Typical Uses

The design of a 90 degree elbow forces a sharp change in flow direction. This abrupt turn can create more pressure drop and turbulence compared to a 45 degree elbow. For this reason, 90 degree elbows are perfect for tight spaces and applications where a right-angle turn is necessary to navigate the piping layout.

A 45 degree elbow, with its gentler bend, creates a smoother transition. This results in less frictional resistance and a lower pressure drop, making it a better choice for systems where maintaining flow rate is critical. Its durability and corrosion resistance are just as high as its 90 degree counterpart.

Typical uses vary based on these characteristics:

- 90 Degree Elbows: Used in plumbing, structural applications, and compact piping systems.

- 45 Degree Elbows: Preferred in high-pressure lines, long-distance piping, and systems where flow efficiency is a priority.

- Both: Suitable for various wall thickness requirements to handle different pressures.

Comparing Installation Methods and Space Requirements

When planning your piping project, installation and space are major considerations. A 90 degree elbow is the ideal solution for tight corners, as it requires the minimum amount of space to make a sharp turn. This makes it invaluable when you need to run a pipe along a wall or around a piece of equipment.

In contrast, a 45 degree elbow requires more physical space to complete its turn because the bend is more gradual. While it takes up more room, the installation can be more forgiving in systems where a slight adjustment to the piping route is needed. The outer diameter of the elbow must always match the pipe for a proper fit, regardless of the angle.

The production method of the elbow (butt weld, socket, or threaded) will also influence the installation process. Butt welding, for example, demands precise alignment and high welding quality to handle the specified pressure level, whereas threaded fittings are simpler to install but are typically used for lower-pressure applications.

Choosing the Right Stainless Steel Pipe Elbow for Your Project

Selecting the correct stainless steel pipe elbow is critical for the success and safety of your project. The right choice depends on several factors, not just the angle of the turn. You must consider the pipe’s diameter, the pressure of the system, and the fluid being transported. The most commonly used type might not always be the best for your specific needs.

To ensure compatibility and safety, it’s important to select fittings that adhere to recognized standards, such as the American standard (ASME/ASTM) or other national standard guidelines. Understanding these factors will help you make an informed decision. Let’s look at the key elements influencing your choice of size, radius, and material.

Factors Affecting Size, Radius Choice, and Material Grade Selection

Choosing the right elbow goes beyond just the angle. The first factor is the nominal pipe diameter and wall thickness, which must match your pipeline to ensure a perfect fit and handle the internal pressure. Next is the radius choice. Long radius (LR) elbows offer smoother flow and less pressure drop, while short radius (SR) elbows are used for tight spaces.

The material grade is another critical decision. The most common grades are 304/304L and 316/316L stainless steel. Grade 316/316L offers superior corrosion resistance due to its molybdenum content, making it ideal for marine and chemical applications.

Here are the key factors to consider:

- Operating Pressure and Temperature: Determines the required wall thickness and material grade.

- Fluid or Gas Type: Influences the choice of material grade for corrosion resistance.

- Space Constraints: Dictates whether a long radius or short radius elbow is more suitable.

- Mechanical Properties: Ensures the fitting can withstand the system’s physical stresses.

Price Considerations and Where to Buy Quality Stainless Steel Pipe Elbows in the United States

The price of a stainless steel pipe elbow is influenced by several factors. The material grade is a primary driver, with highly specialized alloys like Duplex or 904L costing more than standard 304 or 316 grades. The size, wall thickness, and type of elbow (e.g., butt weld vs. threaded) also play a significant role in the final cost.

When looking to buy quality fittings, it’s essential to find a reputable supplier. Many businesses now offer an online purchase option, making it convenient to source the parts you need. Look for suppliers who provide detailed specifications and can confirm that their products meet US standards like ASME and ASTM. This guarantees you are receiving a high-quality, reliable product.

Key factors affecting the price include:

- Material Grade (304, 316L, Duplex)

- Size and Diameter

- Espessura da parede (Schedule)

- Type (LR, SR, Butt Weld, Threaded)

- Manufacturer and Supplier

Conclusão

In summary, understanding the differences between 90° and 45° stainless steel pipe elbows is essential for any piping project. Each type serves unique purposes and applications, influencing factors such as flow patterns, installation methods, and space requirements. By carefully considering your project’s specific needs, including size, radius choice, and material grade, you can make an informed decision that enhances both functionality and efficiency. Whether you’re tackling a residential plumbing task or a complex industrial application, choosing the right elbow is vital to ensuring a smooth installation process. If you need guidance in selecting the best stainless steel pipe elbows for your project, don’t hesitate to reach out for expert advice!

Perguntas mais frequentes

When should I use a long radius or short radius stainless steel elbow in piping systems?

Use a long radius (LR) elbow when you need to minimize pressure drop, reduce friction, and maintain a smoother flow direction, which is ideal for high-pressure or high-velocity systems. A short radius (SR) elbow is best for tight spaces where a sharp turn is necessary and a higher pressure drop is acceptable.

What is the difference between butt weld and threaded stainless steel elbows?

The main difference is the connection method. A butt weld pipe fitting is welded directly to the pipe, creating a permanent, leak-proof seal with excellent welding quality. A threaded elbow has threads and is screwed onto the pipe, allowing for easier installation and disassembly, but it is generally used for lower-pressure systems.

How do I correctly install a stainless steel pipe elbow?

Proper installation depends on the type of pipe fitting. For a butt weld elbow, you must precisely align the ends with the pipe of the same diameter and perform a full penetration weld. This ensures a strong, sealed joint that maintains the system’s corrosion resistance and structural integrity.