-

중국 허베이성 창저우시 멍췬현 인좡 공업구

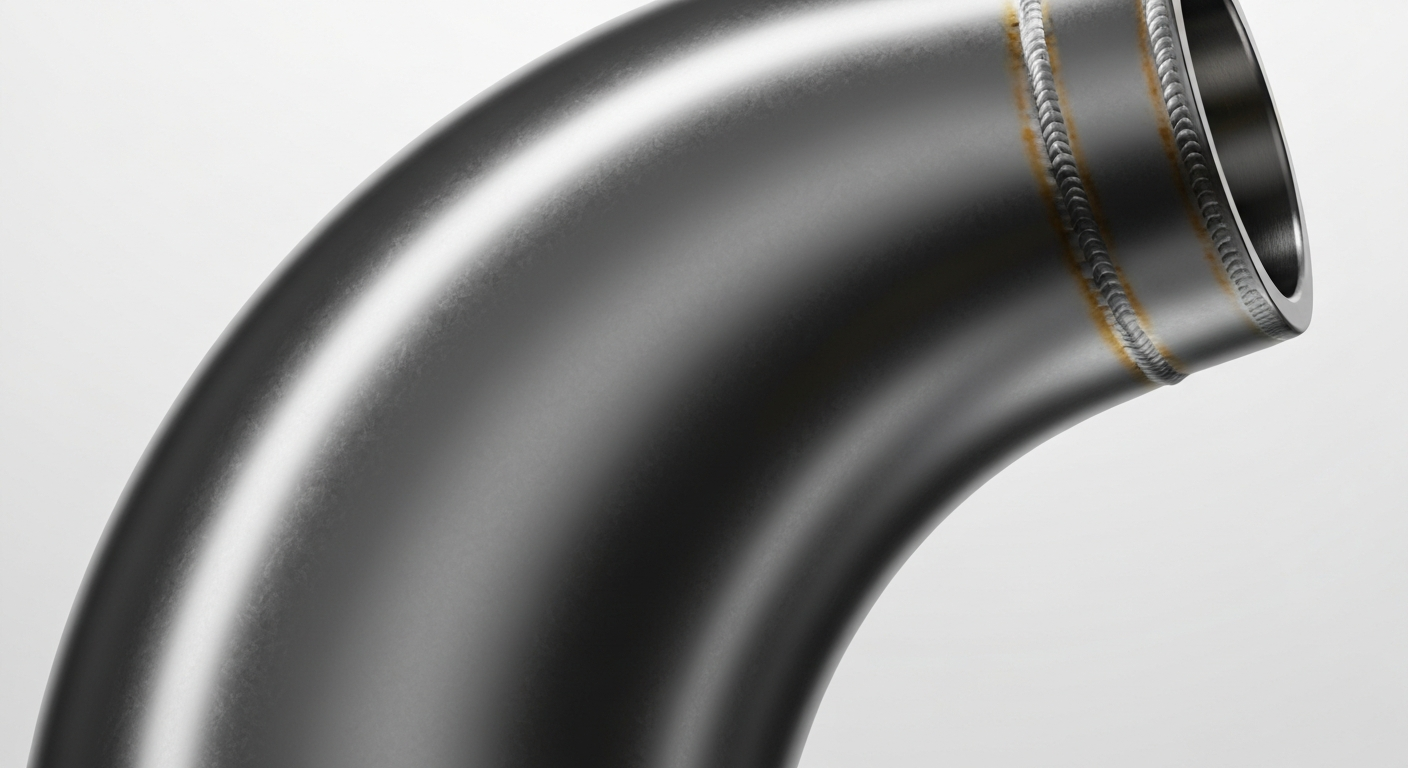

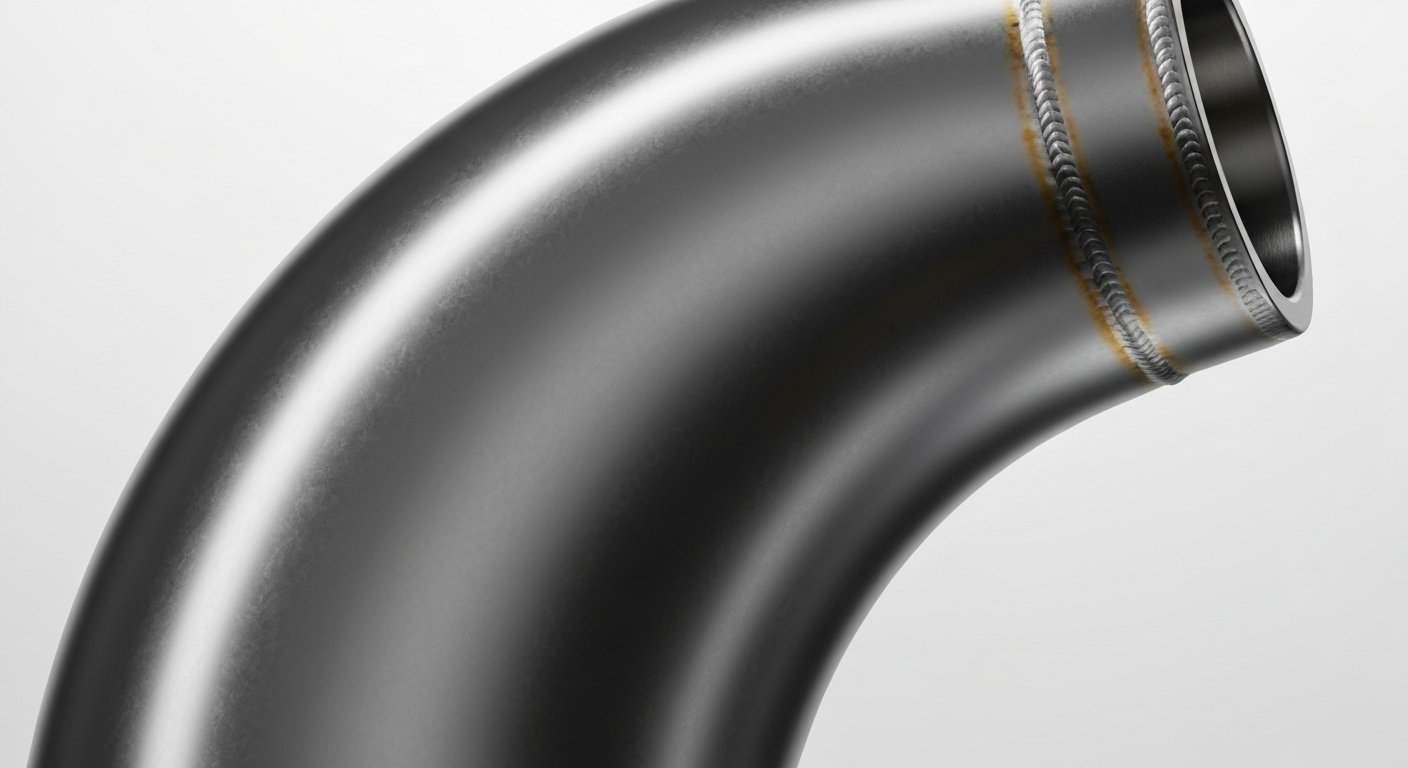

Stainless Steel 304 Butt Weld Elbow: A Complete Guide

주요 특징

Here are the key takeaways from our guide on stainless steel 304 butt weld elbows:

- Stainless steel 304 butt weld elbows are essential pipe fittings used to change the direction of flow in piping systems.

- A major advantage of this stainless steel is its excellent corrosion resistance, making it suitable for harsh environments.

- These fittings offer exceptional durability and a long service life, ensuring reliability in critical applications.

- They are used across a variety of industries, including chemical processing, plumbing, and power plants.

- Selection depends on factors like radius, size, and schedule to match specific pressure and flow requirements.

소개

Welcome to our complete guide on the stainless steel 304 butt weld elbow. When you’re working with piping systems, choosing the right components is crucial for success. These essential pipe fittings are celebrated for their strength and durability, providing a secure, welded connection that lasts. Whether you’re in the gas industry or food processing, understanding how these fittings work can make a significant difference in the efficiency and safety of your operations. Let’s explore what makes this type of fitting a top choice for professionals.

Understanding Stainless Steel 304 Butt Weld Elbow

A stainless steel 304 butt weld elbow is a specific type of fitting designed to be welded directly onto a pipe, creating a strong and leak-proof joint. This method is preferred for piping systems that require high performance and reliability. These buttweld fittings are fundamental components for changing the direction of a pipeline.

You can find these elbows in many different sizes and angles, such as 45° and 90°, allowing for flexibility in system design. Understanding their features and uses is the first step in selecting the right component for your project. We’ll look closer at the definition of this material and its common applications.

Definition and Features of 304 Stainless Steel

So, what exactly is a stainless steel 304 butt weld elbow? It’s a fitting made from one of the most common types of SS, Grade 304, which contains chromium and nickel. This composition gives it excellent resistance to corrosion and oxidation. The “butt weld” part means it is beveled at each end so it can be welded directly to the end of a pipe, forming a continuous and robust connection.

The mechanical properties of 304 stainless steel are impressive. It features a tensile strength of around 75,000 psi, which means it can handle significant pressure without failing. This high strength contributes to its exceptional durability and makes it compliant with demanding industry standards.

Thanks to these features, this fitting is a reliable choice for creating turns in a pipeline. It ensures that the system maintains its integrity and can withstand the pressures of daily operation in various industrial settings. You’ll find it used everywhere from chemical plants to water supply systems.

배관 시스템에서의 일반적인 용도

The primary function of a butt weld elbow is to change the flow direction within a piping system. This simple but critical task is necessary for navigating obstacles and designing efficient layouts. Available in angles like 90° and 45°, these elbows allow you to route pipes exactly where they need to go.

Their versatility makes them indispensable in a wide range of applications. The durability and corrosion resistance of stainless steel 304 make it a perfect material for many demanding environments. You’ll see these fittings used in everything from simple plumbing to complex industrial setups.

Here are some of the most common applications:

- Chemical Plants: For safely transporting corrosive chemicals.

- 발전: In high-pressure steam and water lines in power plants.

- 식음료 산업: Where hygiene and resistance to contamination are essential.

- 석유 및 가스 산업: For pipelines that are exposed to harsh environmental conditions.

Advantages of Stainless Steel 304 Butt Weld Elbows

Choosing the right material for your buttweld fittings can significantly impact your system’s performance and lifespan. A wide range of stainless steel grades is available, but 304 stands out for several reasons. Its inherent properties make it one of the most popular choices for elbows and other fittings.

The main benefits include exceptional corrosion resistance and a long service life, which translates to lower maintenance costs and greater peace of mind. Let’s look at why these advantages make SS 304 butt weld elbows a smart investment for your projects.

Corrosion Resistance and Durability

One of the key benefits of choosing a 304 stainless steel butt weld elbow is its superior corrosion resistance. The chromium content in the alloy forms a passive layer on the surface that protects it from rust and corrosion, even in harsh environments. This makes it ideal for applications involving moisture or corrosive substances.

This resistance directly contributes to the fitting’s durability. Unlike other materials that might degrade over time, stainless steel 304 maintains its structural integrity. This ensures a long service life and reduces the need for frequent replacements, saving you time and money.

Here’s why its durability is a major plus over other materials:

- It withstands exposure to various chemicals in chemical processing.

- It performs reliably in both high- and low-temperature settings.

- It resists atmospheric corrosion, making it suitable for outdoor use.

- The material does not contaminate the fluids it transports, which is vital for the food and beverage industry.

Performance in High and Low Pressure Applications

Yes, a 304 stainless steel butt weld elbow can absolutely be used for both high and low-pressure systems. Its high strength and robust construction make it incredibly versatile. For high-pressure applications, the seamless design created by butt welding ensures a joint that is as strong as the pipe itself, preventing leaks under extreme pressure.

The key to its performance lies in factors like wall thickness, often referred to as the “schedule.” By selecting an elbow with the appropriate schedule, you can ensure it meets the pressure demands of your system. Thicker walls provide greater strength for high-pressure environments, while thinner walls are sufficient for low-pressure applications.

This flexibility allows you to use the same reliable material across different parts of a project. Whether you are managing gentle fluid flow in a water supply system or high-pressure steam in a power plant, the 304 stainless steel butt weld elbow provides consistent and dependable performance.

Standards and Specifications for Stainless Steel 304 Butt Weld Elbows

To ensure safety and reliability, stainless steel 304 butt weld elbows must be manufactured according to strict specifications. Several international organizations set these industry standards, including ASME, ASTM, ANSI, and ISO. These standards govern everything from material composition to dimensional tolerances.

When you purchase fittings that meet these specifications, you can be confident in their quality and performance. Adhering to these guidelines ensures interchangeability and proper function within any compliant piping system. Let’s examine some of the key standards you should be aware of.

ASTM A403 WP304 Overview

The designation ASTM A403 WP304 is a specific standard that you’ll frequently encounter. ASTM A403 refers to the standard specification for wrought austenitic stainless steel piping fittings. The “WP” stands for wrought product, and “304” identifies the specific grade of stainless steel. This standard ensures that the buttweld pipe fittings have the correct chemical composition and mechanical properties for their intended use.

When an elbow is marked with this code, it means it has been manufactured and tested according to these rigorous industry standards. This guarantees its weldability, strength, and corrosion resistance. The standard covers various types of fittings, including elbows, tees, and reducers.

Here is the typical chemical composition for Grade 304 stainless steel under this standard:

요소 | 콘텐츠 (%) |

|---|---|

탄소(C) | 0.08 max |

망간(Mn) | 2.00 max |

실리콘(Si) | 0.75 max |

인(P) | 0.045 max |

유황(S) | 0.030 max |

크롬(Cr) | 18.0 – 20.0 |

Nickel (Ni) | 8.0 – 11.0 |

Singapore Standards and Global Certifications

In addition to ASTM standards, global certifications play a crucial role in verifying the quality of pipe fittings, especially in international markets like Singapore. Certifications from organizations like ISO (International Organization for Standardization) and ASME (American Society of Mechanical Engineers) provide an extra layer of assurance that the products meet global quality and safety benchmarks.

For projects in Singapore, sourcing fittings that comply with these internationally recognized standards is essential. It ensures compatibility with existing infrastructure and adherence to local regulatory requirements. These certifications confirm that the manufacturer follows consistent, high-quality production processes.

When purchasing stainless steel 304 butt weld elbows, look for suppliers who can provide documentation for these certifications. Key global standards to look for include:

- ISO 9001:2000: This indicates the manufacturer has a certified quality management system.

- ASME B16.9: This standard covers the dimensions and tolerances for factory-made wrought buttwelding fittings.

- ASTM A403: This confirms the material specifications for wrought austenitic stainless steel fittings.

Selection Guide for Size, Schedule, and Radius

Choosing the correct stainless steel 304 butt weld elbow is more than just picking a material. You need to consider the size of the fitting, its wall thickness (known as the schedule), and its radius. These factors are critical for ensuring proper fit, flow, and pressure handling in your piping system.

With so many different sizes and configurations available, making the right choice can seem daunting. However, understanding these three key parameters will help you select the perfect elbow for your specific application. Let’s break down how to choose the right radius, size, and schedule.

Choosing Between Long Radius and Short Radius

The radius of an elbow determines how sharp the turn in the pipeline will be. There are two primary types: long radius (LR) and short radius (SR). The main difference between them is the curvature. A long radius elbow has a curve radius that is 1.5 times the pipe’s nominal diameter, creating a gentler turn. A short radius elbow has a radius equal to the pipe’s nominal diameter, resulting in a much sharper turn.

Your choice between these different shapes affects the flow of fluids. A long radius elbow creates less flow resistance and pressure drop, making it ideal for applications where maintaining flow rate is important. A short radius elbow is used in tight spaces where a compact fitting is necessary, but it creates more turbulence and pressure loss.

Consider these points when choosing:

- 긴 반경(LR): Lower pressure drop, less friction, and smoother flow.

- 짧은 반경(SR): Fits in compact areas, but increases pressure loss.

- Flow Rate: For high-velocity systems, LR elbows are generally preferred.

- Space: If space is limited, an SR elbow might be your only option.

How to Select Size and Schedule for Your Application

Selecting the right size and schedule for a stainless steel 304 butt weld elbow is crucial for a successful pipeline. The size of the elbow must match the nominal pipe size (NPS) of your pipeline to ensure a proper fit. Sizes can range from 1/8″ to 48″ NB (Nominal Bore) or even larger for custom applications.

The schedule refers to the wall thickness of the elbow. Common schedules include Schedule 40 and Schedule 80. A higher schedule number means a thicker wall. Schedule 80 has a thicker wall than Schedule 40, making it suitable for higher pressure applications. You should choose a schedule that matches the wall thickness of the connecting pipes.

To make the right choice, first identify the nominal size of your pipe. Then, determine the operating pressure of your system. For high-pressure systems, you will likely need a higher schedule, like Schedule 80 or even Schedule 160. For standard or low-pressure applications, Schedule 40 is often sufficient.

Installation Guidelines for Stainless Steel 304 Butt Weld Elbows

While the term “easy installation” is relative, butt weld pipe fittings offer a straightforward and highly effective connection method when performed correctly. The process involves welding the beveled ends of the elbow directly to the pipe. This critical task is typically handled by certified welders, not just general plumbers, to ensure a high-integrity seal.

Proper installation is key to leveraging the full strength and leak-proof benefits of these fittings. This involves careful preparation of the pipe and fitting, using the right welding techniques, and following strict safety protocols. Let’s review the essential steps for a successful installation.

Preparation and Welding Techniques

Installing a 304 stainless steel butt weld elbow begins with proper preparation. The ends of both the pipe and the fitting must be clean and free of any oil, grease, or contaminants. The beveled edges should be inspected to ensure they are smooth and correctly angled for a strong buttweld joint.

Once prepared, the elbow and pipe are aligned and tacked into place. The choice of welding technique is important; Tungsten Inert Gas (TIG) welding is often preferred for stainless steel as it produces a clean, high-quality weld. The welder must ensure full penetration to create a seamless joint that is as strong as the pipe itself.

Key steps in the process include:

- Cleaning: Thoroughly clean the surfaces to be welded to prevent contamination.

- 정렬: Precisely align the elbow and pipe to ensure a straight and secure connection.

- 용접: Use an appropriate welding technique, like TIG, to create a full-penetration weld around the entire circumference of the joint.

Safety Practices and Quality Assurance

Safety practices are paramount during the installation of any pipe fittings, especially when welding is involved. Welders must use appropriate personal protective equipment (PPE), including gloves, helmets, and protective clothing, to prevent injury from sparks, heat, and UV radiation. Proper ventilation is also crucial to avoid inhaling harmful fumes.

Quality assurance is equally important to guarantee the integrity of the weld. After welding, the joint should undergo inspection. Visual inspection is the first step, but for critical applications, non-destructive testing (NDT) methods like radiography (X-ray) or dye penetrant testing are used to check for internal defects.

Following established ASME standards for both the welding procedure and the subsequent testing ensures that the connection is safe, reliable, and leak-free. This rigorous quality control process confirms that the joint can withstand the system’s operating pressures and conditions for its entire service life.

Maintenance Tips for Industrial Applications

Even though stainless steel 304 is known for its durability, routine care and maintenance are still important, especially in demanding industrial applications. Regular inspection of your pipeline can help you identify potential issues before they become major problems, ensuring the longevity and safety of your system.

A proactive approach to maintenance helps preserve the integrity of the butt weld elbows and the entire pipeline. Simple checks and troubleshooting can prevent costly downtime and repairs. Let’s cover some essential tips for inspection and addressing common issues.

Inspection and Routine Care

Yes, there are specific maintenance tips that can extend the life of your stainless steel 304 butt weld elbows. The most important practice is regular inspection. Visually check the elbows and surrounding pipeline for any signs of damage, discoloration, or surface corrosion. While 304 is resistant, specific aggressive chemicals or environmental factors can still cause issues over time.

Focus your inspection on the welded joints, as these are critical points in the system. Look for any cracks, pitting, or signs of leakage. In systems carrying corrosive fluids, more frequent and thorough inspections may be necessary.

Here are a few routine care tips for industrial applications:

- Regular Visual Checks: Schedule periodic visual inspections to catch early signs of wear or corrosion.

- Cleaning: Keep the exterior surfaces clean to prevent the buildup of corrosive deposits.

- System Monitoring: Monitor system pressure and flow rates, as sudden changes can indicate a problem like a blockage or leak.

Troubleshooting Common Issues

When troubleshooting issues with stainless steel fittings, the most common concern is unexpected corrosion. If you spot rust or pitting, the first step is to identify the cause. It could be due to exposure to a chemical that is particularly aggressive towards 304 steel or contamination from carbon steel particles during installation.

To address this, you may need to clean and passivate the affected area to restore the protective layer. In severe cases, the fitting might need to be replaced. Ensuring that only stainless steel tools are used during installation can help prevent this type of cross-contamination.

Another potential issue is leakage at the weld. This is often due to an improper weld during installation. If a leak is detected, the system should be shut down, and the joint will need to be repaired by a certified welder. This highlights the importance of quality assurance during the initial installation to ensure the durability of the fittings across various industries.

Comparing 304 and 304L Stainless Steel Butt Weld Elbows

When selecting stainless steel fittings, you will often see two very similar grades: 304 and 304L. While their mechanical properties are nearly identical, there is a small but important difference in their chemical composition that affects their performance, particularly after welding.

Understanding the 304 vs 304L distinction is crucial, especially for applications in chemical processing or those requiring extensive welding. This choice can impact the long-term corrosion resistance of your fittings. Let’s compare their properties and identify the best uses for each grade.

Key Chemical and Mechanical Differences

The primary way to differentiate between 304 and 304L stainless steel is by their carbon content. The “L” in 304L stands for “low carbon.” Standard 304 stainless steel has a maximum carbon content of 0.08%, while 304L has a maximum of just 0.03%. This small change has a significant impact on the material’s properties after welding.

During welding, the heat can cause chromium and carbon to combine, forming chromium carbide at the grain boundaries. This process, known as sensitization, reduces the amount of chromium available to fight corrosion, making the weld area susceptible to decay. The lower carbon content in 304L minimizes this effect, making it more resistant to intergranular corrosion after welding.

Other mechanical properties, like tensile strength and yield strength, are very similar between the two types of SS, though Grade 304 is slightly stronger.

속성 | Stainless Steel 304 | Stainless Steel 304L |

|---|---|---|

탄소(C) | 0.08% max | 0.03% max |

Tensile Strength | ~515 MPa | ~485 MPa |

Yield Strength | ~205 MPa | ~170 MPa |

Weldability | Good | 우수 |

Best Uses for Each Grade

Choosing between these different grades depends entirely on your application. Standard 304 stainless steel is an excellent, all-purpose choice for a huge range of projects. It’s strong, corrosion-resistant, and cost-effective for general applications where heavy welding is not required.

On the other hand, 304L is the superior choice for projects that involve extensive welding. Its low carbon content prevents sensitization, ensuring that the corrosion resistance of the weld zones is not compromised. This makes it ideal for heavy-gauge components and applications where post-weld heat treatment is not practical.

Here’s a quick guide on where to use each grade:

- Use 304 for: General purpose applications, plumbing, and structural components with minimal welding.

- Use 304L for: Chemical processing, the pharmaceutical industry, and power plants where welded joints are exposed to corrosive environments.

- Heavy-Duty Welding: Always prefer 304L for applications requiring thick sections to be welded.

Sourcing Certified Stainless Steel 304 Butt Weld Elbows in Singapore

Finding a reliable source for certified stainless steel 304 butt weld elbows is crucial for ensuring the quality and safety of your project. In a major hub like Singapore, you’ll find numerous suppliers, traders, and manufacturers. The key is to identify those who can provide certified products that meet international standards.

When sourcing these components, always prioritize suppliers who offer full traceability and documentation for their products. This guarantees that you are getting genuine, high-quality stainless steel fittings. Let’s go over how to find top suppliers and what you should check before you buy.

Top Online Suppliers and Manufacturers

You can buy certified stainless steel 304 butt weld elbows online from various industrial supply platforms and direct-from-manufacturer websites. When searching online, especially in a competitive market like Singapore, it’s important to look for established suppliers with a strong reputation for quality.

Start by searching for manufacturers or large-scale traders that specialize in stainless steel pipe fittings. Many reputable companies have an online presence where you can browse their product catalogs, view specifications, and request quotes. Check for customer reviews and case studies to gauge their reliability and service quality.

To find the best online suppliers, consider these tips:

- Look for suppliers who are ISO 9001 certified.

- Check if they stock products from well-known manufacturers.

- Verify that they can provide Material Test Certificates (MTCs) for their products.

- Use B2B platforms that connect buyers with certified suppliers in the Singapore region.

What to Check Before Purchasing

Before finalizing your purchase of buttweld elbows, there are several critical details to verify. Don’t just focus on the price; the quality and compliance of the fittings are far more important for the safety and longevity of your system. Always ask for proper documentation.

First, confirm that the fittings meet the required standards for your project, such as ASTM A403 and ASME B16.9. Ask the supplier to provide a Material Test Certificate (MTC) or a certificate of conformity. This document verifies the chemical composition, mechanical properties, and that the product has passed required tests.

Also, check the markings on the fitting itself. A quality buttweld elbow should be clearly stamped with the manufacturer’s name, material grade (e.g., WP304), size, schedule, and heat number for traceability. Checking these specifications ensures you receive exactly what you ordered and can trust its performance.

결론

In summary, understanding and effectively utilizing Stainless Steel 304 Butt Weld Elbows can significantly enhance your piping systems’ performance and longevity. From their corrosion resistance and durability to the proper selection and installation practices, these components are vital in various industrial applications. As we’ve discussed, maintaining these elbows through routine inspections and care is essential for ensuring optimal functionality. Whether you’re sourcing these fittings in Singapore or elsewhere, always prioritize quality and certification for the best results. If you have any further questions or need guidance on your specific needs, feel free to reach out and ask!

자주 묻는 질문

Can stainless steel 304 butt weld elbows be used for drinking water applications?

Yes, stainless steel 304 butt weld elbows are an excellent choice for drinking water applications. Their high corrosion resistance ensures that no harmful substances leach into the water, preserving its purity. These fittings are widely used in plumbing and water supply systems because they provide a safe, durable, and long-lasting connection.

How do I tell if my fitting is long radius or short radius?

To tell if your butt weld elbow is long radius (LR) or short radius (SR), you can measure the distance from the center of the fitting to its face. For a long radius elbow, this distance will be 1.5 times the nominal pipe diameter. For a short radius fitting, it will be equal to the nominal pipe diameter.

What’s the difference between schedule 40 and schedule 80 butt weld elbows?

The difference between schedule 40 and schedule 80 butt weld fittings is the wall thickness. Schedule 80 fittings have a thicker wall than schedule 40 fittings of the same size. This thicker wall makes schedule 80 elbows stronger and able to withstand higher internal pressures, making them suitable for more demanding applications.

Beginners should not start out with TIG, yes? : r/Welding

While TIG welding offers precision, beginners might find it challenging due to its complexity. Starting with MIG welding is often recommended, as it’s easier to master. Once comfortable with the basics, transitioning to TIG for stainless steel 304 butt weld elbow projects can enhance skills and results effectively.

Beginners should not start out with TIG, yes? : r/Welding

While TIG welding offers precision, beginners may find it challenging due to its complexity. Starting with MIG or stick welding is often recommended, as these methods are more forgiving and easier to master. Once comfortable, transitioning to TIG for projects involving stainless steel 304 butt weld elbows becomes more manageable.