-

중국 허베이성 창저우시 멍췬현 인좡 공업구

탄소강 맞대기 용접 감압기: 종합 가이드

주요 특징

- Carbon steel butt weld reducers are essential pipe fittings used to connect pipes of different diameters.

- The butt weld connection method ensures high strength and a leak-proof seal for system reliability.

- These fittings offer excellent corrosion resistance and durability, especially in high-pressure environments.

- They come in two main types: concentric and eccentric, each designed for specific pipeline layouts.

- Carbon steel is a popular material choice for its strength and cost-effectiveness.

- Proper selection ensures a smooth flow transition, minimizing pressure drop and turbulence.

소개

If you work in an industry that relies on piping systems, you understand how crucial each component is for safe and efficient operation. A carbon steel butt weld reducer plays a vital role by seamlessly joining pipes of different diameters. These simple yet effective fittings are fundamental for managing fluid or gas flow and maintaining system integrity. This guide will cover everything you need to know about these essential components, from their design and applications to the standards they must meet.

What Is a Carbon Steel Butt Weld Reducer?

A carbon steel butt weld reducer is a specific type of steel pipe fitting designed to connect two pipes of different sizes. Its main purpose is to reduce the pipe diameter along a straight run, which helps adjust the flow rate of the fluid or gas inside. These components are commonly used in various industrial pipelines, including oil and gas, chemical processing, and power generation, where changing pipe dimensions is a regular requirement.

The “butt weld” aspect of its name refers to the installation method. The ends of the reducer are beveled to perfectly match the ends of the pipes. When welded together, this creates a strong, permanent, and leak-proof joint. This connection method makes butt weld reducers ideal for high-pressure and high-temperature systems where reliability and durability are paramount. They are different from socket weld or threaded fittings, as the butt weld creates a continuous metal structure.

Key Features and Design Principles

One of the primary design features of a carbon steel butt weld reducer is its ability to create a smooth flow transition between pipes. The gradual taper of the fitting minimizes turbulence and pressure loss, which contributes to the efficient operation of the pipeline system.

The use of carbon steel provides superior strength, making these butt weld fittings suitable for demanding industrial applications. While materials like stainless steel offer better corrosion resistance for specific chemical applications, carbon steel provides a fantastic balance of strength, durability, and cost-effectiveness for moderate and high-temperature services.

Compared to other materials, carbon steel is a workhorse known for its robustness. It can handle significant pressure and temperature variations without compromising structural integrity. This combination of affordability and performance makes carbon steel the go-to choice for countless piping networks that don’t require the specialized properties of alloy or stainless steel.

Common Applications in Singapore Industry

In Singapore’s diverse industrial landscape, carbon steel butt weld reducers are indispensable components in complex piping networks. They are essential for ensuring system integrity where pipelines need to connect to equipment with different inlet or outlet sizes.

Their strength and reliability make them a top choice in sectors that demand high performance and safety. You will frequently find these fittings in environments where managing flow between different pipe sizes is a daily operational need.

Some of the most common industries include:

- 석유 및 가스: For connecting main pipelines to smaller distribution lines.

- 발전: Used in power stations for steam and water lines.

- 화학 처리: Critical for managing the flow of various chemicals through processing units.

- Water Treatment Plants: For adjusting pipe sizes throughout the treatment process.

Types of Carbon Steel Butt Weld Reducers

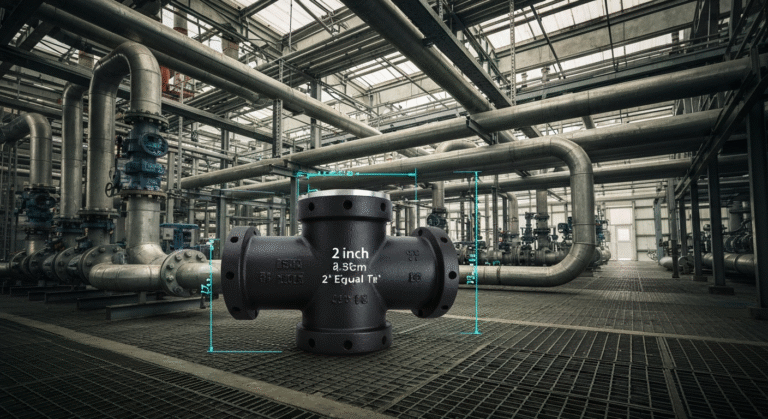

When selecting a carbon steel steel pipe reducer, you’ll encounter two main types: the concentric reducer and the eccentric reducer. Both serve the same primary function of reducing pipe size, but their shapes and applications differ significantly.

The choice between them depends entirely on the layout of your piping system. A concentric reducer is symmetrical, while an eccentric reducer is offset. Understanding the distinction is key to ensuring proper fluid flow and preventing potential issues within your pipeline. The following sections will explain their differences and typical uses in more detail.

Concentric vs Eccentric Reducers: Differences and Uses

The primary difference between these two fittings lies in their shape. Concentric butt weld reducers are cone-shaped, with both the inlet and outlet sharing a common centerline. This design is ideal for vertical pipe runs, as it maintains the center axis of the pipe.

Eccentric butt weld reducers, on the other hand, have an offset centerline. One side of the reducer is flat, which is a critical factor in horizontal pipelines. This flat side prevents air or gas from getting trapped at the top of the pipe or sediment from accumulating at the bottom, ensuring a smooth, uninterrupted flow.

Choosing the right type is essential for pipeline efficiency. Here’s a quick comparison:

기능 | 동심 감속기 | 편심 감속기 |

|---|---|---|

Shape | Symmetrical, cone-shaped | Asymmetrical, offset |

Centerline | Shared between inlet and outlet | Inlet and outlet centerlines are different |

Primary Use | Vertical pipe runs | Horizontal pipe runs |

Advantage | Simple design, easy installation | Prevents air/sediment trapping |

Typical Sizes and Dimensions Found in the Market

Carbon steel butt weld reducers are available in a vast range of sizes to accommodate nearly any piping configuration. Dimensions are typically specified by the nominal pipe size (NPS) of the larger and smaller ends. They can connect large mains to much smaller diameter pipe systems with ease.

The wall thickness of the fitting, known as its “schedule,” is another crucial dimension. It must match the schedule of the connecting pipes to ensure the integrity of the weld and the pressure-handling capacity of the system.

Common sizes for these fittings connect ports of different diameters ranging from small-scale to large industrial applications. Typical sizes you might find include:

- 1/2″ x 1/4″

- 4″ x 3″

- 8″ x 6″

- 24″ x 20″

- 48″ x 24″

Material Grades, Schedules, and Standards

The performance of carbon steel fittings depends heavily on their material grades and adherence to industry standards. While this guide focuses on carbon steel, similar fittings are also made from alloy steel or stainless steel, which are chosen for their unique properties when dealing with specific corrosion media or extreme temperatures.

Understanding these specifications, including common designations like ‘Schedule 40,’ ensures you select a fitting that is safe, reliable, and compatible with your system. We will now look at what these grades and standards mean for your project.

Understanding Grades and ‘Schedule 40’ Specification

When you see material grades like ASTM A234 WPB, it tells you a lot about the fitting. ASTM A234 is the standard for wrought carbon and alloy steel fittings for moderate and high-temperature service. The ‘WPB’ signifies that it’s a weldable, pressure-rated grade with a specific minimum yield strength, making it a very common and reliable choice.

The term ‘Schedule 40’ refers to the wall thickness of the pipe fitting. The schedule number is a way to classify the thickness, and a higher number indicates a thicker wall. A thicker wall allows the fitting to withstand higher pressure.

Therefore, a Schedule 40 reducer is a fitting with a standard wall thickness suitable for a wide range of applications. For systems that operate under exceptionally high pressure, you would select a fitting with a higher schedule number, such as Schedule 80 or 160, to ensure safety and durability.

ASME B16.9 and Other Relevant International Standards

To ensure safety and interchangeability, all steel pipe fittings must comply with strict international standards. The American Society of Mechanical Engineers (ASME) and the American Society for Testing and Materials (ASTM) set the primary regulations in the United States.

For butt weld reducers, ASME B16.9 is the key standard. It governs the dimensions, tolerances, and markings for factory-made wrought buttwelding fittings. This ensures that a reducer from one manufacturer will perfectly match a pipe or fitting from another, which is critical for maintaining system integrity.

Other important standards include ASTM A234, which specifies the material properties, and MSS SP-75, which covers fittings used in high-pressure oil and gas pipelines. Adherence to these standards guarantees that the fitting can safely handle the pressures and temperatures it was designed for, providing peace of mind during construction and operation.

결론

In conclusion, understanding carbon steel butt weld reducers is essential for anyone involved in industrial applications. Their design principles, types, and material specifications play a crucial role in ensuring the efficiency and safety of piping systems. By choosing the right type—be it concentric or eccentric—and adhering to relevant standards like ASME B16.9, you can optimize your projects effectively. Moreover, regular maintenance and proper installation will enhance the longevity and performance of these critical components. If you have any questions or need further assistance, feel free to reach out. Your insights into this topic could significantly impact your projects!

자주 묻는 질문

How do you select the right size of carbon steel butt weld reducer?

To select the right steel pipe reducer, you must know the diameters of the two pipes you are connecting. The reducer size is specified by these two measurements, such as 4″ x 3″. Another critical factor is the wall thickness, or schedule, which must match the connecting pipes for a secure weld.

What are the main installation steps for carbon steel butt weld reducers?

Installation involves cleaning the pipe ends and the fitting, then aligning them for a snug fit. The pieces are tack-welded to hold them in place, followed by a full butt weld around the joints. This creates a strong, leak-proof seal and a smooth transition for efficient operation.

How can carbon steel butt weld reducers be inspected or maintained?

Regular visual inspection is key for maintenance. Check for signs of external or internal corrosion, wear and damage, or leaks around the welds. In industrial settings like power stations or chemical processing plants, more advanced inspection methods may be used to ensure the fitting’s integrity over time.