-

Yinzhuang Industrial zone,Mengcun county,Cangzhou city,Hebei province,China

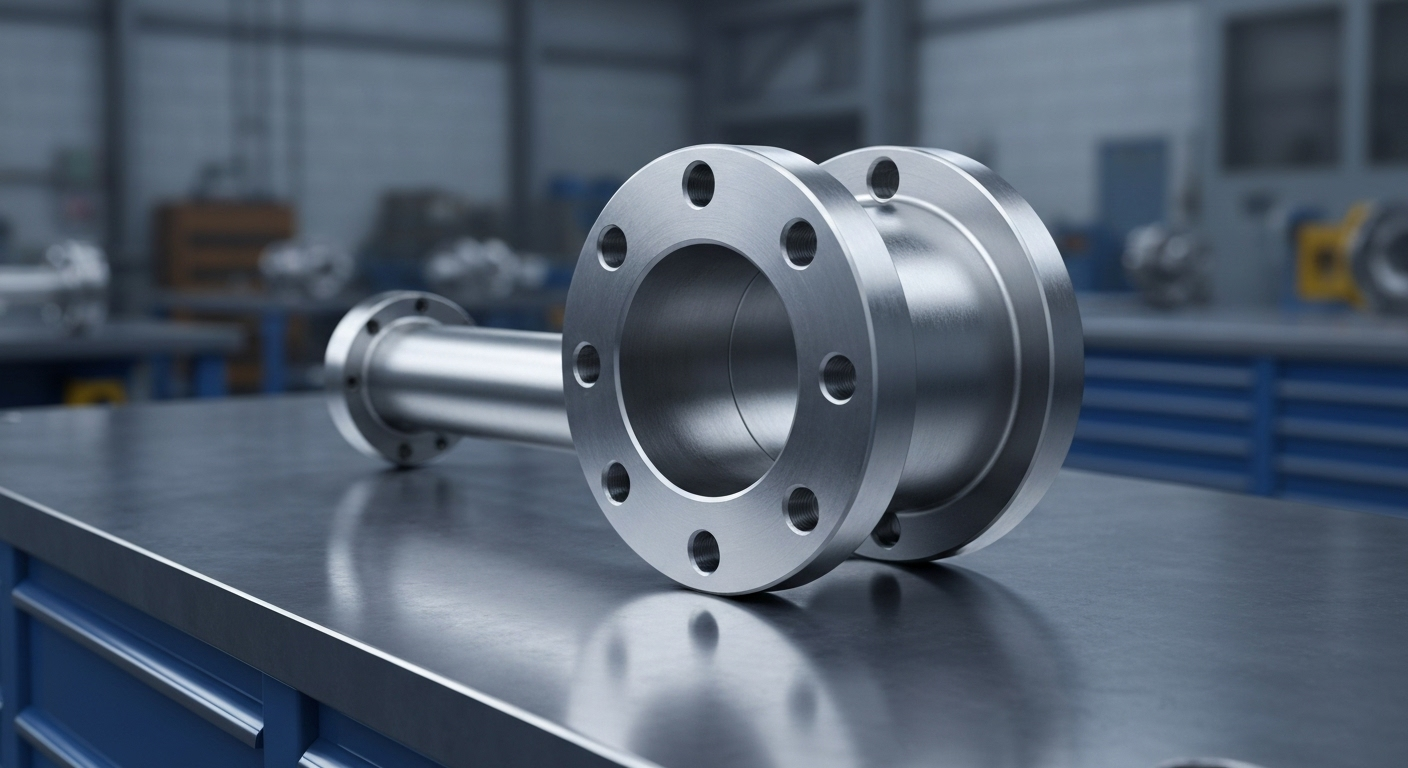

Stainless Steel WN Flange: Key Features and Advantages

Key Highlights

- Stainless steel weld neck flanges are designed with a long tapered hub for superior reinforcement in high-pressure systems. The weld neck design ensures a smooth transition from the pipe to the flange, reducing stress and increasing durability.

A typical pressure rating for a 304 weld neck flange ranges from 150 to 2500 pounds (Class 150 to Class 2500), depending on the specific requirements of the piping system and manufacturer specifications.

- The weld neck design ensures a smooth transition from the pipe to the flange, reducing stress and increasing durability.

- Commonly made from 304 or 316 stainless steel, these flanges offer excellent corrosion resistance and malleability.

- A raised face on a weld neck flange helps create a stronger, more reliable seal within the piping connection.

- These stainless steel flanges are ideal for demanding applications due to their strength and performance under pressure and temperature changes.

Introduction

When building or maintaining an industrial piping system, every component matters. Choosing the right pipe flange is crucial for ensuring a secure, leak-proof connection that can withstand demanding conditions. The stainless steel weld neck (WN) flange stands out as a top choice for reliability and strength. This type of flange is specifically engineered for high-stress applications, providing a robust solution that you can count on. Are you looking for a flange that offers both performance and longevity? Let’s explore what makes the stainless steel weld neck flange a go-to option.

Understanding Stainless Steel Weld Neck (WN) Flanges

A stainless steel weld neck flange is a specific kind of flange designed to transfer stress to the pipe, which helps to reduce high stress concentration at the base of the flange. Unlike various types of other flanges, its distinct neck-like extension makes it easily recognizable and highly effective. This design is what sets the WN flange apart as a premier steel pipe flange for critical applications.

You’ll find that this neck flange is bored to match the inside diameter of the pipe it’s being connected to. This precise fit allows for a seamless flow and minimizes turbulence and erosion. We will look closer at the unique design of this flange and the popular stainless steel grades used to manufacture it.

Design and Structure of WN Flanges

The most defining feature of a weld neck flange is its long tapered hub. This hub provides crucial reinforcement to the connection point, making it suitable for applications involving high pressure or extreme temperatures. The design transfers stress from the flange to the pipe itself, significantly reducing stress concentration at the base of the hub. The neck of the flange is butt-welded directly to the end of a pipe.

This structure ensures that the inside diameter of the neck flange matches the pipe’s bore, creating a smooth, unobstructed path for fluid or gas. A 304 weld neck flange is simply this type of flange made from grade 304 stainless steel. It is commonly used in industrial piping systems for oil, gas, chemical processing, and water treatment, where its strength and corrosion resistance are highly valued.

The flange face includes precisely drilled bolt holes for secure connection to another flange or piece of equipment. The overall dimensions, including the outside diameter and wall thickness, are standardized to ensure compatibility across different systems.

Popular Grades Used: 304 vs. 316 Stainless Steel

When selecting a stainless steel type of flange, the material grade is a critical decision. The two most popular choices are 304 and 316 stainless steel, each offering distinct advantages. Grade 304 is the most common standard for stainless steel, known for its excellent malleability, weld-ability, and strong corrosion resistance in most environments.

Grade 316, on the other hand, contains molybdenum, an addition that enhances its properties significantly. According to the American Iron and Steel Institute, “The addition of molybdenum… enhances the corrosion resistance, particularly against chlorides and other industrial solvents.” [Source: https://www.aksteel.com/sites/default/files/2018-11/316-316l-stainless-databulletin.pdf] This makes 316 stainless steel superior for applications in harsh chemical or marine environments and at elevated temperatures, where it provides excellent tensile strength and stress-rupture resistance.

Here’s a quick comparison to help you decide:

Feature | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

Primary Advantage | General-purpose corrosion resistance and malleability. | Enhanced corrosion resistance, especially to chlorides. |

Key Component | Chromium-Nickel alloy. | Chromium-Nickel-Molybdenum alloy. |

Common Uses | Food processing, chemical tanks, general industrial piping. | Marine applications, chemical processing, medical implants. |

Cost | More economical. | Higher initial cost. |

Essential Features of Raised Face WN Flanges

Beyond the hub design, another important feature you’ll encounter with a weld neck flange is the “raised face” (RF). A raised face flange has a small portion of its gasket surface raised above the bolting circle face. This design concentrates more pressure on a smaller gasket area, creating a much stronger and more reliable seal.

This feature is especially important in a high-integrity piping system where preventing leaks is a top priority. The combination of a weld neck design and a raised face makes this flange one of the most secure options for connecting pipes, valves, and other equipment. Let’s examine the pressure ratings and sizes associated with these robust flanges.

Pressure Ratings and Common Classes

Stainless steel weld neck flanges come in various pressure ratings and classes, making them versatile for many applications. Common classes, such as Class 150, 300, 600, and higher, determine their suitability for different industrial piping systems. High-pressure environments typically require flanges designed with thicker walls and robust materials to withstand stress concentration. Understanding these ratings ensures that the correct type of flange is chosen for your project, contributing to the overall integrity and safety of the piping system.

Available Sizes and Typical Applications

Stainless steel weld neck flanges are available in many different sizes to fit a wide range of pipes. The size is typically referred to by its nominal pipe size (NPS), which corresponds to the pipe it will be welded to. This ensures compatibility with other stainless steel fittings and components within your system.

What sizes are typically available for 304 weld neck flanges? You can find them in a broad spectrum of dimensions to suit various project needs. Common nominal sizes include:

- 0.5 inch

- 1 inch to 4 inches

- 6 inches to 8 inches

- 10 inches to 12 inches

Thanks to their robust design, these flanges are used across various industries. You will find them in critical industrial piping systems for chemical processing, oil and gas refinement, power generation, and water treatment plants. Their reliability makes them a preferred choice wherever high pressure and temperature are factors.

Key Advantages of Stainless Steel WN Flanges

The choice of a stainless steel weld neck flange brings numerous benefits to any piping project. This type of flange is renowned for its exceptional strength and reliability, especially under severe service conditions. The superior performance comes from a combination of its unique design and the inherent qualities of stainless steel.

When you need a connection that will last, resist harsh environments, and maintain the integrity of your system, the WN flange is an excellent investment. We’ll now look more closely at the specific advantages of its durability and why 304 stainless steel is such a popular material choice.

Durability, Corrosion Resistance, and Performance

One of the primary advantages of using a 304 stainless steel flange is its exceptional durability and corrosion resistance. Stainless steel naturally forms a passive layer of chromium oxide that protects it from rust and corrosion, making it far superior to standard carbon steel in many applications. This resistance ensures a longer service life and reduces maintenance costs over time.

The long weld neck design itself is a major contributor to the flange’s robust performance. As noted by the American Society of Mechanical Engineers (ASME), the tapered hub of a weld neck flange provides a gradual transition of stress from the flange to the pipe wall, which is “beneficial under conditions of high bending stress due to line expansion or other forces.” [Source: https://www.asme.org/codes-standards/find-codes-standards/b16-5-pipe-flanges-flanged-fittings] This significantly reduces the risk of failure at the connection point compared to other flange types.

Combining the inherent strength of stainless steel with the superior engineering of the weld neck design results in a flange that offers unmatched performance. It can handle high pressures, temperature fluctuations, and corrosive substances without compromising the integrity of your piping system.

Why Choose 304 Stainless Steel for Your Flange Needs

So, why use a 304 stainless steel flange for your project? The answer lies in its perfect balance of performance, versatility, and cost-effectiveness. Grade 304 stainless steel is often called the “workhorse” of stainless steels for good reason. It provides excellent corrosion resistance for a wide range of industrial environments.

Its inherent malleability and weld-ability make it easy to fabricate and install, which can help streamline your project timeline. A 304 stainless steel weld neck flange provides the strength and reliability needed for a critical piping system without the higher cost associated with more specialized alloys like 316.

For most standard industrial applications, including water treatment, food and beverage, and general chemical transport, 304 stainless steel offers more than enough protection and strength. It’s a reliable, durable, and economical choice that delivers outstanding value and performance for your flange needs.

Selecting and Installing the Right WN Flange

Once you’ve decided that a weld neck flange is right for your project, the next steps are selection and installation. When placing an order, be sure to include any special requirements, like a request for Material Test Reports (MTRs), in the order notes. Good suppliers pride themselves on speed of order fulfillment, often shipping items within a few business days.

It’s also wise to check the return policy; many companies offer refunds for unused items within a specific timeframe, giving you peace of mind. Proper selection is only half the battle; correct installation is key to ensuring the flange performs as expected.

Steps for Proper Flange Installation

Proper installation is essential for the performance and safety of a 304 weld neck flange. Because it requires welding, the process should be handled by a qualified technician. An improper weld can create a weak point in your piping system.

Here are the general steps for how to properly install a weld neck flange:

- Preparation: Ensure the end of the pipe and the bore of the flange are clean and properly beveled for welding.

- Alignment: Carefully align the flange with the pipe, making sure the bore of the flange matches the inside diameter of the pipe.

- Welding: Perform a butt weld to securely join the neck of the flange to the end of the pipe.

- Connection: Align the flange with the mating flange or valve.

- Gasketing and Bolting: Insert the correct gasket and tighten the bolts or studs, such as a Teflon stud, in a star pattern to ensure even pressure.

Whether you use in-house technicians or a third party for installation, following these steps is crucial. Using the right stainless steel fittings and ensuring a high-quality weld will create a strong, leak-free connection that lasts.

Comparing Weld Neck Flanges to Other Types

Understanding what sets a weld neck flange apart from other types helps clarify its value. Each kind of flange serves a different purpose. For instance, blind flanges are used to seal the end of a pipe, while a lap joint flange is used with a stub end for applications requiring frequent disassembly.

The primary difference between a weld neck flange and other common types like slip-on or threaded flanges lies in the connection method and strength. A slip-on flange slides over the pipe and is welded in two places, while a threaded flange is screwed on. Neither provides the same level of structural reinforcement as a weld neck flange.

Here’s what sets a weld neck flange apart:

- Strength: The long, tapered hub provides superior reinforcement.

- Stress Distribution: It transfers stress to the pipe, reducing fatigue.

- Connection: A single, high-integrity butt weld joins it to the pipe.

- Flow: The matched bore ensures a smooth, unobstructed flow path.

- Applications: It is the preferred choice for high-pressure, high-temperature, and critical services, unlike a socket weld or lap joint flange which are often used in less demanding situations.

Conclusion

In conclusion, stainless steel weld neck flanges offer a unique combination of durability and performance that is hard to match. Their design and structure provide reliable sealing capabilities, making them ideal for various applications, especially in high-pressure environments. Whether you choose 304 or 316 stainless steel, these flanges ensure long-lasting performance against corrosion and wear. Investing in the right WN flange can significantly enhance the efficiency of your systems. If you have any questions about selecting or installing stainless steel WN flanges, feel free to reach out for assistance. Remember, the right choice today can save you time and resources in the long run!

Frequently Asked Questions

Are stainless steel WN flanges suitable for high-temperature environments?

Yes, absolutely. The design of a stainless steel weld neck flange is ideal for high-temperature and high-pressure service. The robust butt weld and tapered hub provide structural stability, while materials like 316 stainless steel offer excellent strength and creep resistance at elevated temperatures, ensuring reliability in a demanding piping system.

How do I determine the correct class and size for my application?

To determine the correct size, match the pipe flange’s nominal size and inside diameter to your pipe. To select the right class, such as Class 150, you must know your piping system’s maximum operating pressure. Choose a class with a pressure resistance rating that safely exceeds your system’s requirements.

What sets a weld neck flange apart from slip-on or threaded flanges?

A weld neck flange is distinguished by its long, tapered hub that is butt-welded to the end of the pipe. This design transfers stress to the pipe, reducing stress concentration at the flange base. This makes it structurally superior to a slip-on flange or threaded flange for high-pressure applications.