-

Zona industriale di Yinzhuang, contea di Mengcun, città di Cangzhou, provincia di Hebei, Cina

Long Radius Elbow vs. Short Radius: What’s the Difference?

Punti salienti

- A long radius elbow has a bend radius that is 1.5 times the pipe diameter, promoting smoother fluid flow. If you need to purchase a long radius elbow online for different pipe sizes, there are many suppliers and industrial marketplaces, such as Grainger, Ferguson, and Alibaba, where you can easily find various long radius elbows by specifying the required pipe diameter.

A short radius elbow has a bend radius equal to the pipe diameter, making it ideal for tight spaces.

- A short radius elbow has a bend radius equal to the pipe diameter, making it ideal for tight spaces.

The choice between a long radius and short radius pipe fitting directly impacts pressure loss and flow turbulence.

If you need to purchase long radius elbows online for different pipe sizes, many major industrial suppliers and specialized plumbing retailers offer a range of options. Browse platforms such as Grainger, McMaster-Carr, or Ferguson, where you can filter by pipe diameter, bend radius, and material to find the right products for your project.

- The choice between a long radius and short radius pipe fitting directly impacts pressure loss and flow turbulence.

- Long radius elbows are preferred for high-pressure, high-flow-rate systems to reduce energy loss.

- Short radius elbows are used where space is limited and a sharper turn is necessary.

Introduzione

Welcome to the world of piping systems! When you need to change the flow direction in a pipeline, you’ll use a special pipe fitting called an elbow. But did you know there are different types? The two most common are long radius and short radius elbows. While they both do the same basic job, their design differences have a big impact on your system’s performance. Choosing the right one is key to ensuring efficiency, managing pressure, and fitting everything into your available space.

Understanding Pipe Elbows in Piping Systems

In any piping system, an elbow is a crucial component used to change the direction of fluid. Think of it as a joint that allows pipes to turn a corner. These fittings are essential for navigating obstacles and creating the desired layout for your pipelines.

However, every time you add a bend, you introduce some flow resistance. The design of the elbow determines how much resistance is created, which can affect the overall efficiency of your system. Next, we’ll explore the specific role of elbows and the common materials used to make them.

The Role of Elbows in Fluid Flow and Direction

The primary job of an elbow is to redirect fluid flow. You can find them in various angles, with 45 and 90 degrees being the most common, allowing you to customize the path of your pipeline. This change of direction is fundamental in complex systems found in industrial plants and residential plumbing.

How an elbow affects fluid flow depends heavily on its bend radius. A long radius elbow, which has a gentler curve, allows for a smoother transition. This design minimizes turbulence and flow resistance. It’s used in applications where maintaining a steady flow and low pressure drop is critical, such as in high-pressure oil and gas pipelines.

Conversely, a sharper bend creates more turbulence and increases resistance. The pipe size also plays a part in the overall dynamics. Properly selecting an elbow based on its radius and angle ensures your system operates efficiently and prevents unnecessary energy loss.

Standard Materials Used for Elbow Manufacturing

The material of an elbow is just as important as its shape, determining its durability, strength, and suitability for different environments. Manufacturers select materials based on the fluid being transported, the operating pressure, and temperature.

For many industrial applications, steel is the material of choice. You will commonly find elbows made from:

- Carbon steel: A strong and cost-effective option for general-purpose applications.

- Stainless steel: Known for its excellent corrosion resistance, making it perfect for chemical processing and water treatment.

- Alloy steel: Used for high-temperature and high-pressure services, offering enhanced strength and durability.

These materials are often used to create elbows from seamless steel pipe, which provides a uniform and robust structure without any weak points from welding seams. This ensures the elbow can withstand demanding conditions and offer a long service life.

Long Radius Elbows Explained

A long radius (LR) elbow is defined by its larger curve. Specifically, the bend radius of a long radius elbow is 1.5 times the nominal pipe diameter (R=1.5D). This gradual bend is the key to its performance, as it is designed for smoother flow.

This design makes the LR elbow appear flatter and longer than its short radius counterpart. When fluid passes through it, the gentle turn minimizes turbulence and pressure drop, making it a favorite for efficiency-focused systems. Let’s look closer at its features, applications, and available sizes.

Key Features of Long Radius Elbows

The defining characteristic of a long radius elbow is its larger bend radius. This design feature offers several distinct advantages in a piping system, primarily related to flow efficiency. The distance from the center of the pipe to the centerline radius of the bend is longer, creating a more gradual turn.

This gentle curve results in a much smoother fluid transition compared to a sharper elbow. The main benefits include:

- Reduced pressure drop as fluid moves through the bend.

- Minimized turbulence and potential for erosion on the pipe wall.

- A more consistent and smooth flow, which is crucial for sensitive processes.

In short, a long radius elbow is less disruptive to the fluid’s path. While a short radius elbow has a radius equal to the pipe diameter, the long radius elbow’s 1.5D measurement provides a stark contrast, prioritizing flow performance over a compact footprint.

Common Applications in Industrial and Residential Piping

You should choose a long radius elbow when your piping system requires smooth, efficient flow with minimal pressure loss. This makes them the go-to choice for high-pressure and high-flow-rate applications where performance is a top priority.

In the industrial sector, you’ll find them in power plants, oil and gas pipelines, and chemical processing facilities. In these settings, reducing energy loss and preventing flow-related issues are critical for operational safety and efficiency. For example, a long radius elbow helps maintain fluid velocity without creating excessive back pressure.

Their benefits also extend to commercial and residential systems. Long radius elbows are commonly used in water treatment facilities and larger HVAC systems. In these applications, they help ensure the entire piping system runs smoothly and effectively, reducing strain on pumps and other equipment.

Available Angles, Sizes, and Material Types

Long radius elbows are available in a variety of standard angles to meet different piping layout needs. The most common angles you’ll find are 90 degrees and 45 degrees, which handle the majority of directional changes. However, custom angles like 60 or 180 degrees can also be sourced for special projects.

The sizing of these elbows is based on the nominal pipe diameter they connect to. It’s crucial to match the elbow’s size to your pipe to ensure a perfect fit. Long radius elbow dimensions are standardized, so an engineer can easily specify the correct part for the job.

They also come in various material types, including carbon steel, stainless steel, and alloy steel, to suit different applications. Here is a sample of common long radius elbow dimensions based on the ASME B16.9 standard:

Nominal Pipe Size (NPS) | Center-to-Face (90° Elbow) |

|---|---|

2″ | 76.2 mm |

4″ | 152.4 mm |

6″ | 228.6 mm |

8″ | 304.8 mm |

Short Radius Elbows Overview

A short radius (SR) elbow offers a much sharper turn than its long radius counterpart. The key identifier for this type of elbow is its small bend radius, which is equal to the nominal pipe diameter (R=1D). This compact design is its biggest advantage.

Because of its tight C-shape, the SR elbow is perfect for installations where space is a major concern. It allows you to make a 90-degree turn in the smallest footprint possible. Now, let’s examine the specific characteristics and common uses of this compact pipe fitting.

Characteristics and Typical Uses of Short Radius Elbows

The most notable feature of a short radius elbow is its sharper bend. This design results from a relatively small bend radius, making the elbow look more compact and abrupt. This is a significant difference from a long radius elbow, which has a gentler, more sweeping curve.

Because of their compact shape, short radius elbows are the ideal solution for piping systems with space constraints. They are often used in tight areas where a long radius elbow simply wouldn’t fit, such as in dense industrial plants or within machinery. Their ability to make a sharp turn is invaluable for compact designs.

However, this tight turn comes with a trade-off. The fluid passing through a short radius elbow experiences greater flow resistance and turbulence. This can lead to a higher pressure drop and some energy loss, making them less suitable for high-velocity or high-pressure systems where smooth flow is a priority.

Material Options and Installation Considerations

Just like long radius elbows, short radius elbows are manufactured from a range of durable materials to meet the demands of various industries. The choice of material depends on factors like the fluid’s corrosive properties, system temperature, and pressure.

Common material options include:

- Carbon steel: An economical and strong choice for general use.

- Stainless steel: Selected for its superior corrosion resistance, ideal for chemical or food-grade applications.

- Alloy steel: Used in high-stress environments requiring extra strength and temperature resistance.

The primary installation consideration for short radius elbows is the limited space they are designed for. Their compact form is their main benefit, allowing engineers to route pipe in tight corridors. When planning an installation, the reduced installation space required for an SR elbow can be a decisive factor in the design of the entire piping system.

Comparing Long Radius vs. Short Radius Elbows

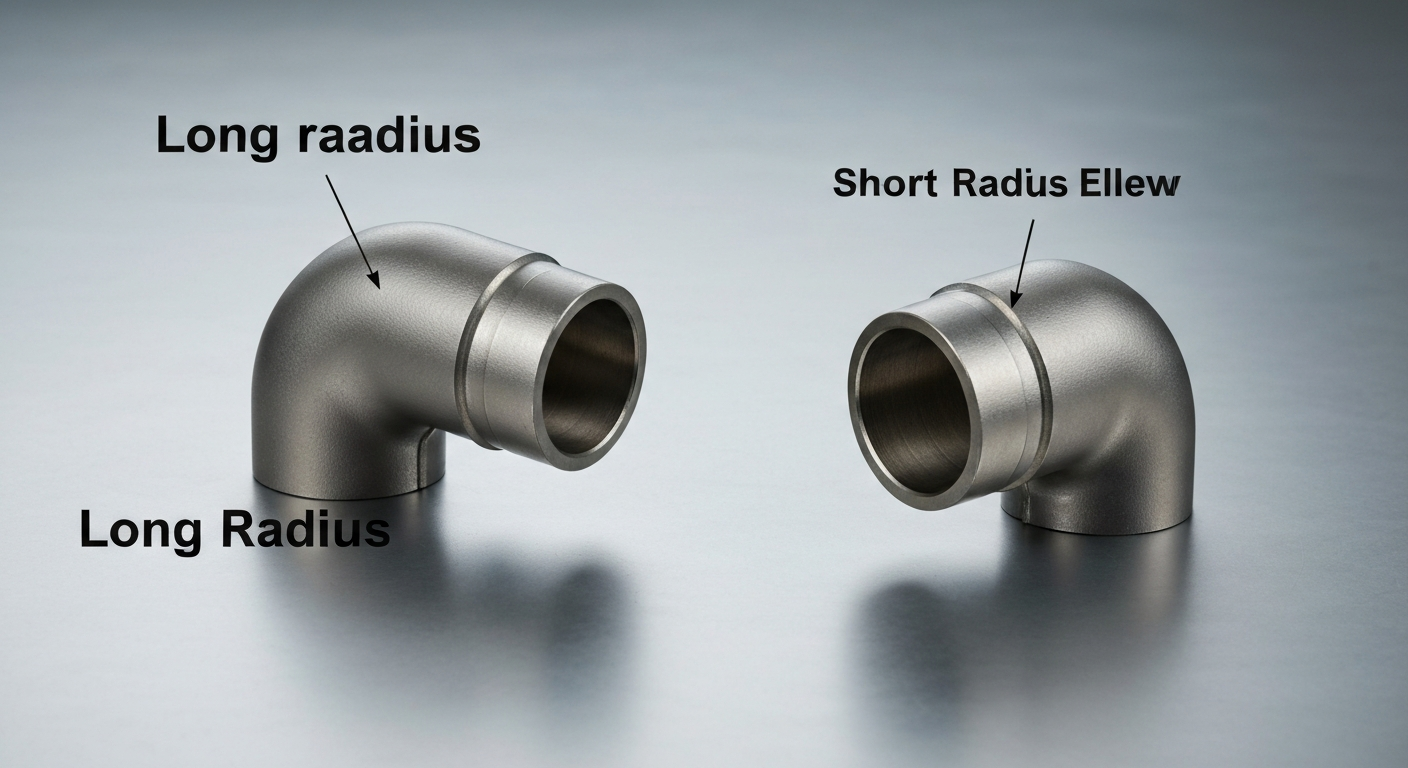

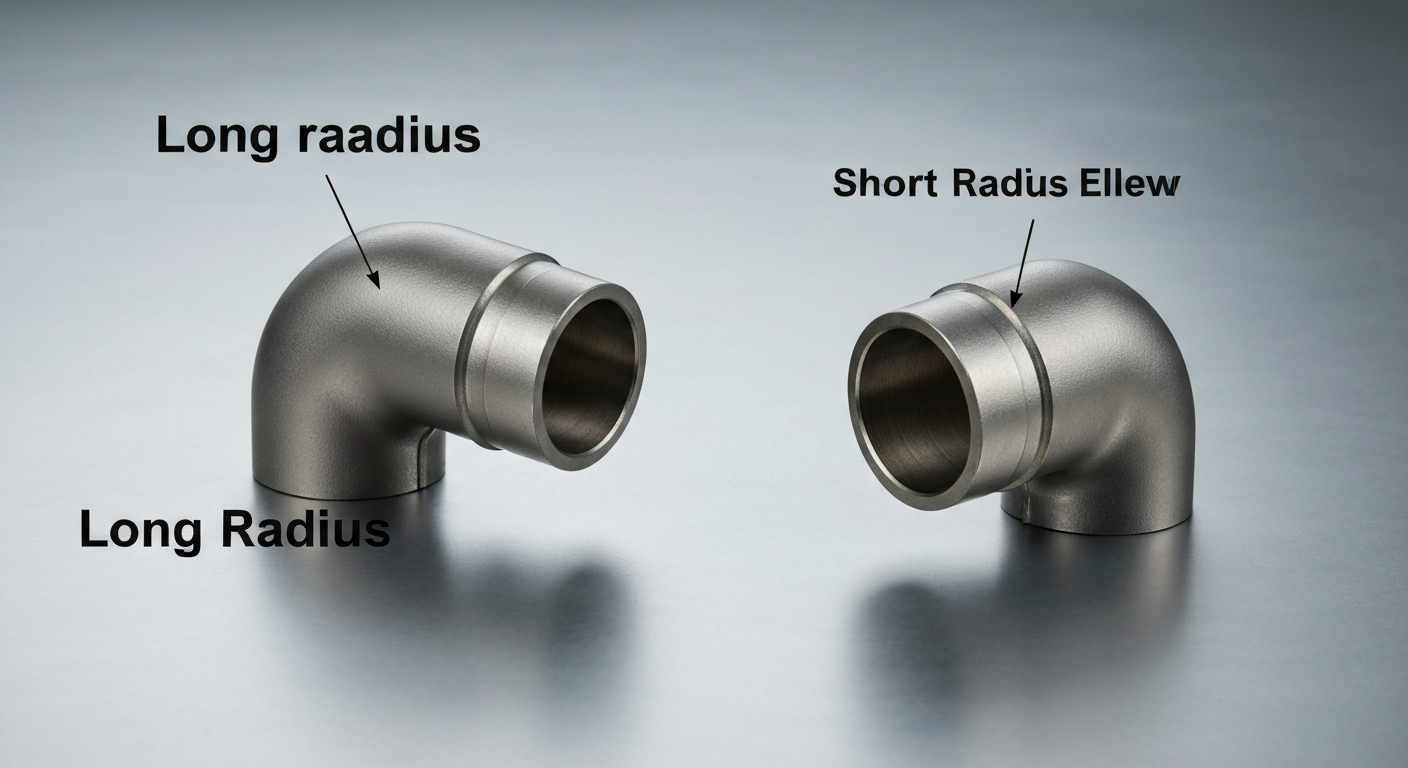

When you place a long radius and short radius elbow side-by-side, the difference in their curvature is immediately obvious. This single design variation is the source of all their performance differences, impacting everything from flow efficiency to installation requirements.

Choosing between them is a balancing act. Do you need to prioritize smooth flow and low pressure loss, or is your primary concern fitting the pipe into a tight space? Understanding their head-to-head differences will help you make the right decision for your project.

Differences in Design, Performance, and Selection Criteria

The core difference between these two elbows lies in their bending radius, which directly influences their performance. A long radius elbow has a radius of 1.5 times the pipe diameter, while a short radius elbow’s radius is equal to the pipe diameter.

This design choice leads to significant differences in how they handle fluid flow. Here’s a quick comparison:

- Pressure Loss: Long radius elbows cause less pressure loss, making them better for maintaining flow efficiency. Short radius elbows create a higher pressure drop.

- Flow Characteristics: The gentle curve of an LR elbow ensures smoother flow, while the sharp turn of an SR elbow can cause turbulence and higher energy loss.

- Application: LR elbows are ideal for high flow rate and high pressure systems. SR elbows are best for low-pressure lines or where space is limited.

Your selection criteria should be based on these factors. If your system cannot tolerate a significant pressure drop or you need to protect it from erosion, a long radius elbow is the better choice. If space is your main constraint, a short radius elbow is the practical solution.

ASME B16.9 Specifications for Piping Elbows

To ensure that pipe fittings are consistent and reliable, industries rely on the standard specification known as ASME B16.9. This standard covers factory-made wrought buttwelding fittings, including elbows. It dictates the dimensions, tolerances, materials, and markings for these components.

The ASME B16.9 standard is critical because it guarantees that an elbow from one manufacturer will be dimensionally identical to one from another, allowing for interchangeability and predictable performance. For elbows, the standard clearly defines the radius of curvature for both long and short radius types based on the nominal size of the pipe.

This specification ensures that when you order a 4-inch long radius 90-degree elbow, you get a part with the correct dimensions for your system. The key difference specified by ASME B16.9 is the center-to-face dimension, which is determined by the radius.

Tipo di gomito | Radius of Curvature (as per ASME B16.9) |

|---|---|

Raggio lungo (LR) | 1.5 x Nominal Pipe Size (NPS) |

Raggio corto (SR) | 1.0 x Nominal Pipe Size (NPS) |

Choosing Between Long Radius and Short Radius Elbows

Deciding on the right type of elbow comes down to the specific applications of your piping system. There is no universally “better” option; the choice depends entirely on your project’s unique requirements, balancing flow performance against physical constraints.

You’ll need to consider factors like the fluid’s velocity, the acceptable pressure drop, and the available installation space. Making an informed decision ensures your system operates reliably and efficiently. Let’s break down the factors that will guide your selection.

Factors Influencing Selection in the United States

When designing a piping system, several key factors will influence your choice between a long and short radius elbow. The first is the nature of the fluid flow. If you are dealing with a high flow rate or transporting abrasive materials, a long radius elbow is the better choice to minimize erosion and pressure loss.

Another critical factor is the available space. If you are working in a tight or congested area with limited space, a short radius elbow is often the only practical option. Its compact design allows for sharp turns where a long radius elbow would not fit.

Finally, consider the overall system pressure and pipe size. For high-pressure systems, the smoother flow of a long radius elbow reduces stress on the piping and equipment. Conversely, for low-pressure lines where a small pressure drop is negligible, a short radius elbow may be a perfectly acceptable and cost-effective choice.

Sizing Elbows for Different Pipeline Requirements

Selecting the correct size of elbow is crucial for a leak-free and efficient pipeline. The first step is to match the nominal pipe size of the elbow to the pipe you are connecting it to. For example, if you have a 4-inch pipe, you must use a 4-inch elbow.

The next consideration is the bend radius, which is your choice between a long radius or short radius elbow. As we’ve discussed, this decision depends on your flow and space requirements. The diameter of the elbow must precisely match the pipe diameter to ensure a proper weld or connection.

When ordering, you will need to specify the nominal pipe size, the angle (e.g., 90 or 45 degrees), the elbow type (long or short radius), and the material. Using standardized long radius elbow dimensions ensures that you get a fitting that aligns perfectly with your pipeline, guaranteeing structural integrity.

Installation Methods for Butt Welded Elbows

Butt weld elbows are a common choice for creating strong, leak-proof connections in industrial piping, especially when using seamless steel pipe. This installation method involves welding the beveled ends of the elbow directly to the ends of the pipes.

The process requires precision to ensure the pipes and the center of the elbow are perfectly aligned. A proper butt weld creates a continuous, robust connection that becomes an integral part of the pipeline, capable of withstanding high pressures and temperatures. Let’s explore how to prepare for this process.

Preparing for Welding and Assembly

Proper preparation is the key to a successful butt weld installation. A butt weld long radius elbow is essentially a standard LR elbow with beveled ends designed to be welded directly onto a steel pipe. The installation process starts long before the welding torch is lit.

First, you must ensure that the ends of both the pipe fitting and the steel pipe are clean and free of any contaminants like rust, oil, or dirt. The beveled edges should be inspected to ensure they are uniform and ready for welding.

Proper alignment is also critical. To prepare for assembly, you should:

- Align the elbow and pipe, ensuring there is no misalignment.

- Set the correct gap between the two pieces, as specified by the welding procedure.

- Tack weld the components in place to hold them steady during the final welding process.

Technical Tips for Successful Installation

A successful installation of a butt weld elbow goes beyond just preparation. Following best practices during the welding process ensures a strong, reliable joint that minimizes flow issues. This is especially important in demanding environments like the chemical industry.

The quality of the weld directly affects the performance of the elbow. A poor weld can create internal obstructions that increase flow resistance and pressure loss, defeating the purpose of using a long radius elbow. To ensure a good installation, it’s important to use a qualified welder who follows a certified welding procedure.

Here are a few technical tips for a successful installation:

- Ensure full penetration of the weld to create a strong, seamless joint.

- Avoid creating excessive weld material on the inside of the pipe, as this can disrupt flow.

- Perform post-weld inspections to check for any defects.

Conclusione

In summary, understanding the differences between long radius and short radius elbows is crucial for effective piping design and installation. Each type has its own unique features and applications, influencing fluid flow and system efficiency. By carefully considering factors such as design specifications, material options, and installation methods, you can ensure that your piping system operates optimally. Whether you’re working on an industrial project or a residential plumbing task, selecting the right elbow can make a significant difference in performance and durability. If you have any further questions or need assistance with your piping needs, feel free to reach out for expert advice!

Domande frequenti

When should I use a long radius elbow versus a short radius in my piping design?

You should use a long radius elbow in your piping system when you need to minimize flow resistance and pressure drop, especially in high-velocity lines. Choose a short radius elbow when you have limited space and need to make a sharp turn, provided a higher pressure drop is acceptable.

Are long radius elbows available in stainless steel, ductile iron, and copper?

Yes, long radius elbows are manufactured in a wide variety of materials. While stainless steel is very common for its corrosion resistance, you can also find them made from ductile iron, copper, carbon steel, and various alloys to suit different temperature, pressure, and fluid compatibility requirements.

How do I select the correct size of long radius elbow for my pipeline?

To select the correct size, match the elbow’s nominal pipe size to your pipe’s diameter. The long radius elbow dimensions are standardized, so the bend radius is fixed at 1.5 times the diameter of the pipe. The most important step is ensuring the pipe diameter and elbow size are identical for a proper fit.