-

Zona industriale di Yinzhuang, contea di Mengcun, città di Cangzhou, provincia di Hebei, Cina

Tubo in acciaio inox: Una soluzione duratura per le esigenze di tubazioni

Punti salienti

- Stainless steel pipe offers exceptional durability and resistance to corrosion, making it a long-lasting solution for various applications.

- Common grades like 304 and 316 are available in seamless or welded stainless steel tubes to meet specific project demands.

- Pipe specifications are defined by standards like ASTM and schedules, such as schedule 40, which indicates wall thickness. The welding of stainless steel tubes is streamlined by using beveled ends, which simplifies preparation and saves time. To properly maintain and clean stainless steel pipes, regularly wipe them down with a mild detergent or specialized stainless cleaner to remove dirt, debris, and fingerprints. Avoid harsh chemicals or abrasive materials that can harm the surface or reduce corrosion resistance. Proper cleaning helps preserve the durability and appearance of stainless steel tubes.

- The welding of stainless steel tubes is streamlined by using beveled ends, which simplifies preparation and saves time.

- Quality is verified through methods like positive material identification testing and ultrasonic testing, which uses high frequencies.

- You can customize the features of the finished product, like its internal diameter, through secondary processes like honing.

Introduzione

If you need a piping solution that you can rely on and that will last a long time, stainless steel is a very good option. One reason is that it does not rust or get damaged by most kinds of corrosion, so you can use it in many places and for many uses. It is important to know the right diameter and nominal wall thickness you need before you start your project. The way the stainless steel pipe works depends on what goes into the chemistry of the metal and things like heat treating. If you want your pipes to have a smooth and even finish inside, the main purpose of honing is to make the inner surface just right, so the pipe fits what you need.

Types of Stainless Steel Pipes Used in the United States

In the United States, there are many kinds of stainless steel tubes used in businesses. The 300 series stainless steel, including grades 304 and 316, is very common. For places that need more strength and better protection from corrosion, duplex grades such as 2205 and 2507 work well. Some of these stainless steel pipes use nickel for special jobs.

You need to pick between a seamless tube and a welded pipe. Both have a cylindrical geometric design, but they are made differently. Many businesses, like Penn Stainless, sell a lot of these stainless steel tubes online. You should think about your project’s need for pressure and your budget when picking between seamless and welded. Knowing the features of these options will help you make a good choice.

304 vs. 316 Stainless Steel Pipe: Material Properties and Differences

Choosing between 304 and 316 stainless steel is a common decision. Both are austenitic stainless steels known for their strength and corrosion resistance, but their properties differ slightly. The main differences between 304 and 316 stainless steel pipes stem from their chemical composition.

The key distinction lies in the chemistry of the metal. Grade 316 contains molybdenum and a higher nickel content, which gives it superior resistance to chlorides and other corrosive elements compared to grade 304. This makes it a better choice for marine or chemical processing environments. Positive material identification testing is often used to verify the grade of the pipe before installation.

Caratteristica | 304/304L Stainless Steel | 316/316L Stainless Steel |

|---|---|---|

Primary Advantage | Excellent general-purpose corrosion resistance | Enhanced corrosion resistance, especially against chlorides |

Key Alloy Difference | Standard chromium-nickel content | Contains added molybdenum and higher nickel content |

Applicazioni comuni | Food processing, structural, general plumbing | Marine environments, chemical processing, medical implants |

Verification | Confirmed with positive material identification testing | Confirmed with positive material identification testing |

Ultimately, the selection depends on the environment where the pipe will be used. While 304 is suitable for most applications, 316 provides an extra layer of protection in more aggressive conditions. Both grades can undergo heat treating to modify their mechanical properties.

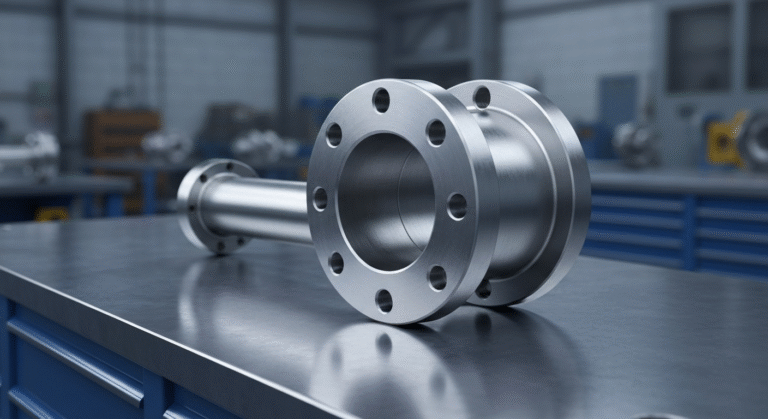

Seamless vs. Welded Stainless Steel Pipe: Choosing the Right Option

When you need to pick between seamless and welded stainless steel pipes for your project, it comes down to how they are made and what you want for your job. A seamless tube is pushed out from a solid piece of steel. You get a smooth shape without any seams. A welded pipe is rolled from a sheet, and the seam is joined together. This seam is treated so that it is not easy to see.

Both types of stainless steel pipes give you something different. You have to think about what you need when it comes to pressure, price, and size. Look at these points:

- Seamless Tube: If you want good strength and use in high-pressure spots, this is the way to go. Its turning process makes sure you get a cylindrical geometric design for the tube.

- Welded Pipe: If you care about price and want bigger sizes, welded pipes are more likely to be what you pick. You can make the ends beveled for a complementary tube end, making the welding of stainless steel tubes faster because weld prep time is shorter.

The result of hardening by heat treat treatment can help both kinds of pipe by making them stronger and tougher. For most jobs, a welded pipe does what you want. If your work has a lot of stress or risk, go for a seamless tube, as it is stronger and provides the benefits of normalizing and gives you peace of mind with stainless steel tubes.

Applications and Standards for Stainless Steel Pipes

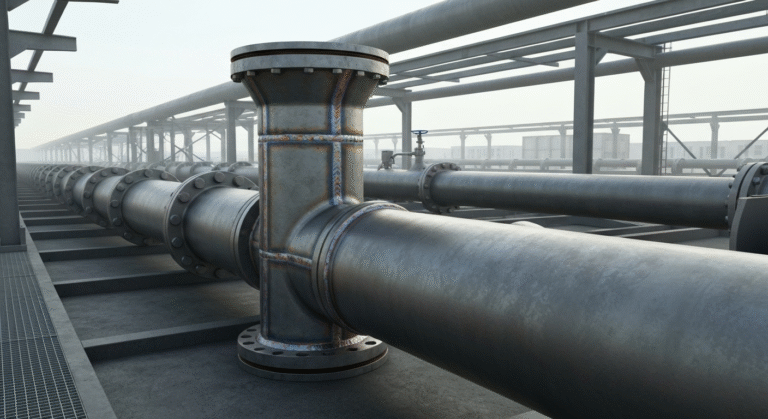

Stainless steel pipes are used in many places. You can find them in homes and big factories. There are rules for how these pipes are made to keep everyone safe and make the pipes work well. Groups like ASTM decide what the pipes should be made of, how thick they need to be, and how they are checked for problems. One rule you see a lot is schedule 40. This tells you about the pipe’s nominal wall thickness.

To make sure the pipes are good, they are tested in different ways. A test called ultrasonic testing, also known as UT, uses sound energy at high frequencies. This test looks for problems inside the pipe but does not harm it. The main purpose of honing, a secondary machining operation involving an abrasive rotating tool, is to make the interior surface of a cylinder smooth and achieve the right dimensions to reach a particular diameter. All these steps help make sure the pipe’s thickness and the whole pipe from places like Penn Stainless are good for your needs.

Common Uses in Plumbing, Construction, and Industry

Stainless steel is used a lot in plumbing, building, and factories because it has great strength and fights off corrosion. The material lasts for a long time, so it helps lower costs over the years for repairs and replacements. What are the typical uses of stainless steel pipes in plumbing and building work?

You see stainless steel pipes in many places. People pick the right grade and type, like duplex stainless steel, based on what the job needs. Here is how they get used:

- Plumbing: There are pipes that move clean water and wastewater in homes and big buildings.

- Costruzione: These pipes be used for support work, in handrails, and also to move fluids through buildings.

- Industry: You find these pipes moving chemicals, gases, or hot liquids in plants where things get made, refineries, and places that handle food.

- Specialized Systems: Workers use fittings with pipes. These fittings are mostly stainless steel or brass, letting them build piping setups that meet special needs.

You be able to pick from more than one sch (schedule), different thicknesses, and many diameters, which make stainless steel able to fit many jobs. Whether you want a small pipe for house water lines or a big, thick pipe for a factory furnace, there be a stainless steel choice. That way you get strong protection from corrosion.

Standards and Specifications: Understanding Schedule 40 and ASTM A312

To keep things safe and the same every time, stainless steel pipes must match set rules and standards. Standards like ASTM A312 are important for stainless steel pipes. ASTM A312 is used for pipes that are seamless, straight-seam welded, and heavy cold-worked welded. These stainless pipes are made for high heat and places where things could rust.

Have you heard of schedule 40 stainless steel pipe? The “schedule” says what the pipe’s nominal wall thickness is. Sch 40 gives you a normal thickness. This way, you get a good mix of strength, weight, and how much stuff it can hold. There is a lot of use for this in work places and businesses. People use it to move water, gas, and other fluids where there is moderate pressure.

To check that these pipes match the standards, people do different tests. One way is ultrasonic testing. This test uses high frequencies to find any problems inside the stainless pipe. There is also positive material identification testing and sometimes even additional positive material identification testing. These tests show what metal is in the pipe. The testing might be done by the company that makes the pipe or by an independent laboratory. This helps make sure the pipe meets every rule and expectation about things like thickness and stainless material.

Conclusione

To sum it up, stainless steel pipes are a good choice because they are strong and work well in many places. They last a long time and do not rust easily. That is why you see them in things like plumbing, building sites, and big work jobs. When you know the difference between types like 304 and 316 stainless steel — and learn about seamless or welded pipes — you will be able to pick the right one for your needs. When you follow the rules for this kind of piping, your pipes will last longer and work better. If you want to switch to stainless steel pipes or need help, you can contact us for a free consultation.

Domande frequenti

What are the corrosion resistance properties of 304 vs. 316 stainless steel pipe?

Both 304 and 316 stainless steel are good for stopping rust. But 316 stainless steel works better. The chemistry of the metal in 316 has molybdenum, which helps protect from harsh chemicals and chlorides. You can check each grade using positive material identification testing.

How do I calculate the correct size and dimensions for a stainless steel pipe installation?

To get the right size for your stainless steel, check the details in your project’s engineering papers. You must find out the outside diameter and the nominal wall thickness. Make sure you take correct measurements of the stainless steel product so the fittings work with it. This will help keep the cylindrical geometric design and make sure all parts fit as they should.

What is the difference in cost between 304 and 316 stainless steel pipes?

Usually, 316 stainless steel costs more than 304 stainless steel. This happens because of the chemistry of the metal. 316 stainless steel has extra parts like more nickel and molybdenum, and this makes the material more costly. For the right price, you should talk to suppliers. Penn Stainless Products is one place you can ask for stainless steel prices.