-

Zone industrielle de Yinzhuang, comté de Mengcun, ville de Cangzhou, province de Hebei, Chine

Blind Flange: Key Component in Pipe Fittings

Faits marquants

- A blind flange is a solid disc used to close off the end of a piping system, effectively stopping flow.

- These crucial pipe fittings create a secure seal, making them ideal for pressure testing and maintenance.

- By providing a bolted access point, a blind flange allows for easier system upkeep and future expansion.

- They are available in various materials, including carbon steel and stainless steel, to suit different environments.

- The pressure rating and dimensions are specified by standards like ANSI/ASME and AWWA.

Introduction

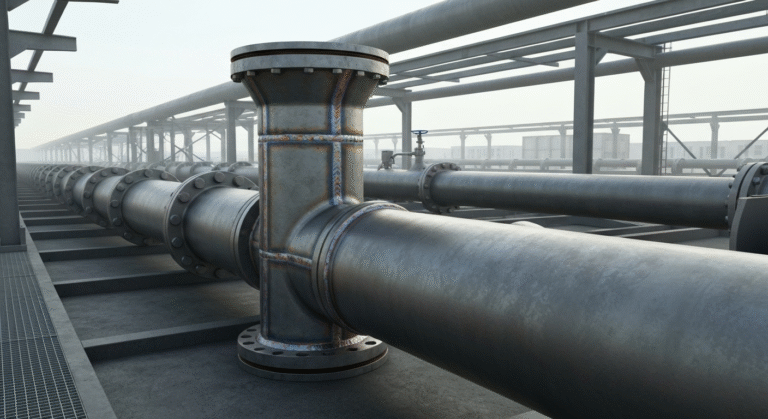

When you think about a complex piping system, you might picture long stretches of pipe and intricate valves. However, one of the most essential pipe fittings is often overlooked: the blind flange. This simple component plays a critical role in the safety and functionality of pipelines across numerous industries. A blind flange is used to seal the end of a pipe, making it indispensable for maintenance, testing, and modifications. This post will explore everything you need to know about this key component.

Understanding Blind Flanges in Pipe Fittings

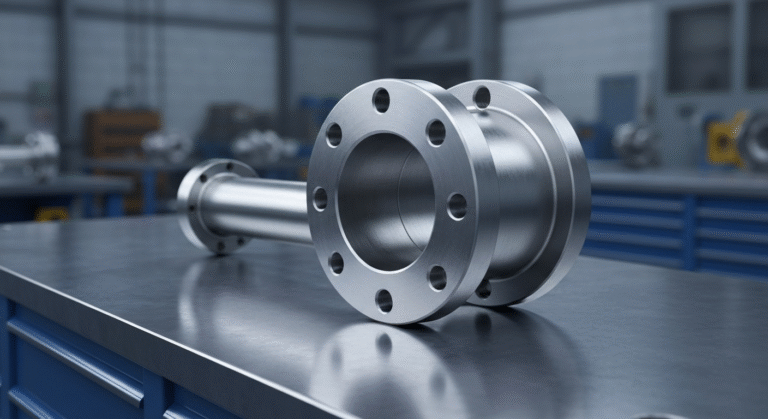

A blind flange is a solid, circular plate without a center bore, which sets it apart from other flange types. Its primary purpose is to seal the end of a piping system or a vessel opening, preventing the flow of liquids or gases. This simple design is what makes it so effective for isolating sections of a pipeline.

Unlike components that are welded into place, a blind flange is bolted, allowing for easier access when needed. When paired with a gasket, it creates a secure seal capable of holding pressure. This makes it perfect for temporarily closing a line for repairs or for pressure rating tests within the piping system.

Definition and Primary Functions

At its core, a blind flange is a solid disc designed to completely block an opening in a piping system. While most pipe fittings are created to connect pipes and continue the flow of fluids, a blind flange does the exact opposite. It acts as a cap, providing a definitive stop at the end of a pipeline or a vessel port. This solid barrier is fundamental for managing and maintaining the integrity of the system.

The most important function of a blind flange is to create a secure seal. This is vital when a portion of the pipeline needs to be shut down for maintenance or is no longer in use. By bolting it to an existing flange, you can confidently stop the flow without worrying about leaks, provided it’s installed correctly with a proper gasket.

Another key function is its role as an access point. Because blind flanges are bolted on, they can be removed with relative ease. This feature is incredibly useful for system inspections, cleaning, or if you plan for future expansion of the pipeline. It offers a practical way to prepare a system for later modifications without requiring cutting or welding.

How Blind Flanges Are Used in Piping Systems

In a typical piping system, blind flanges are used to terminate a line. They are bolted onto the end of a pipeline or to a flanged valve, effectively capping it off. The installation involves aligning the bolt holes with the connecting flange and tightening the bolts evenly to ensure a consistent, leak-proof seal with the help of a gasket. This straightforward process makes them a practical choice for many applications.

The versatility of blind flanges allows them to be used in several key scenarios within industrial and commercial pipe fittings. Their common uses include:

- Pressure Testing: Sealing a system to check its ability to withstand its designated pipe pressure.

- System Isolation: Temporarily closing a line to perform repairs, modifications, or cleaning on a section of a pipeline without affecting the entire system.

- Permanent Termination: Closing off the end of a pipeline that is no longer needed but needs to remain sealed.

This ability to provide easier access for upkeep or future connections makes blind flanges a valuable component. Their simple yet effective design ensures that the flow of fluids can be stopped reliably, whether for a short-term task or a long-term closure.

Types and Materials of Blind Flanges

Blind flanges are not a one-size-fits-all solution; they come in a variety of materials to meet the demands of different environments. Common options include carbon steel, stainless steel, and alloy steel. The material is chosen based on factors like the fluid in the pipe, operating temperature, and pressure. For instance, stainless steel is preferred for its corrosion resistance in chemical processing applications.

In addition to materials, these standard flanges are manufactured to meet specific blind flange dimension requirements under codes like ANSI/ASME and AWWA. This ensures they fit correctly and can handle the system’s pressure. Forged blind flanges, for example, are known for their exceptional strength and durability, making them suitable for high-pressure service. These materials specifications and design standards are crucial for ensuring safety and reliability.

Carbon Steel, Stainless Steel, and Other Options

When you need a strong and reliable solution for general industrial applications, carbon steel blind flanges are often the top choice. Their durability and cost-effectiveness make them a go-to for mechanical and piping systems where extreme corrosion isn’t a primary concern. Forged blind flanges made from carbon steel are particularly tough and can withstand significant pressure.

On the other hand, if your project involves corrosive materials or requires a clean environment, stainless steel is the ideal material. It resists rust and is widely used in chemical processing, water treatment, and food-grade applications. Beyond these, other materials like alloy steel and nickel alloys are available for high-temperature or highly specialized systems that demand superior performance across different pressure classes.

Choosing the right material is essential for the longevity and safety of your system. Here’s a quick comparison of common options:

Matériau | Caractéristiques principales | Common Use Cases |

|---|---|---|

Acier au carbone | Strong, durable, and cost-effective | General industrial and mechanical applications |

Acier inoxydable | Resists corrosion and rust, hygienic | Chemical processing, water treatment, food industry |

Acier allié | High strength and temperature resistance | High-pressure and high-temperature services |

Comparing Blind Flanges with Slip-On, Threaded, and Other Flange Types

The most significant difference between a blind flange and other flange types is its solid design. Unlike slip-on, threaded, or weld neck flanges, a blind flange has no opening, or bore, for fluid to pass through. Its sole purpose is to seal the end of a pipe, whereas other flanges are designed to connect two pipes or join a pipe to a valve or other fitting.

This fundamental difference in design dictates their use. Consider these distinctions between flange types:

- Function: Blind flanges block flow completely, while other flanges facilitate a connection to continue flow.

- Structure: A blind flange is a solid plate, but a slip-on flange slides over the pipe and a threaded flange screws onto it.

- Application: Use a blind flange for termination or isolation. Use other types for building and extending pipelines.

The main advantage of using a blind flange is its ability to create a reliable, tight seal that prevents leaks and allows for easy future access. However, its obvious drawback is that it cannot be used in a part of the system where continuous flow is required. In those cases, other flange types are the necessary choice for creating a connection.

Conclusion

In conclusion, blind flanges play a vital role in ensuring the integrity of piping systems, offering a reliable and efficient solution for various applications. By understanding their functions, types, and materials, you can make informed decisions that enhance the safety and performance of your projects. Whether you’re dealing with carbon steel, stainless steel, or considering comparisons with other flange types, careful selection and installation are crucial. Don’t underestimate the importance of these components in maintaining system reliability. If you’re looking for more personalized guidance on choosing the right blind flange for your needs, feel free to reach out for a free consultation.

If you are searching for high-quality carbon steel blind flanges, reputable suppliers and manufacturers often provide a range of certified options to meet your project specifications. You can find these products through specialized industrial supply stores, piping distributors, or by contacting us directly for recommendations and sourcing support.

Questions fréquemment posées

What are the key specifications for ASTM A105 blind flanges?

The ASTM A105 specification covers forged carbon steel blind flanges for ambient and high-temperature service. Key specifications include material composition, manufacturing method, and mechanical properties. The blind flange dimension requirements, such as diameter and thickness, are defined by standards like ASME B16.5, which outlines general dimensions based on different pressure classes and specific measurements.

What safety measures should be followed when installing or removing a blind flange?

For safe installation or removal, first ensure the pipeline is completely depressurized and drained. Proper cleaning of the flange faces is essential for a good seal. Always use a new gasket and tighten the bolts in a star pattern to apply even pressure. This helps prevent gas leaks and ensures a secure connection.

What are the pros and cons of choosing a blind flange over other types of pipe flanges?

The primary advantage of a blind flange is its ability to create a tight seal, which is perfect for isolating a line or planning for future expansion without leaks. The main disadvantage is that, unlike other flange types, it completely blocks flow and cannot be used to connect two sections of pipe.

What’s the difference between blind flange vs blank flange?

A blind flange is a solid disc used to seal the end of a piping system, preventing flow, while a blank flange serves as a temporary cover for an opening. Essentially, blind flanges are permanent fixtures, while blank flanges are often used for maintenance or inspection purposes.

What’s the difference between blind flange vs blank flange?

A blind flange is a solid disk that covers the end of a pipe, effectively sealing it off. In contrast, a blank flange is used to close off a piping system but may have holes for bolting. Both serve sealing purposes but differ in design and application.