-

Zone industrielle de Yinzhuang, comté de Mengcun, ville de Cangzhou, province de Hebei, Chine

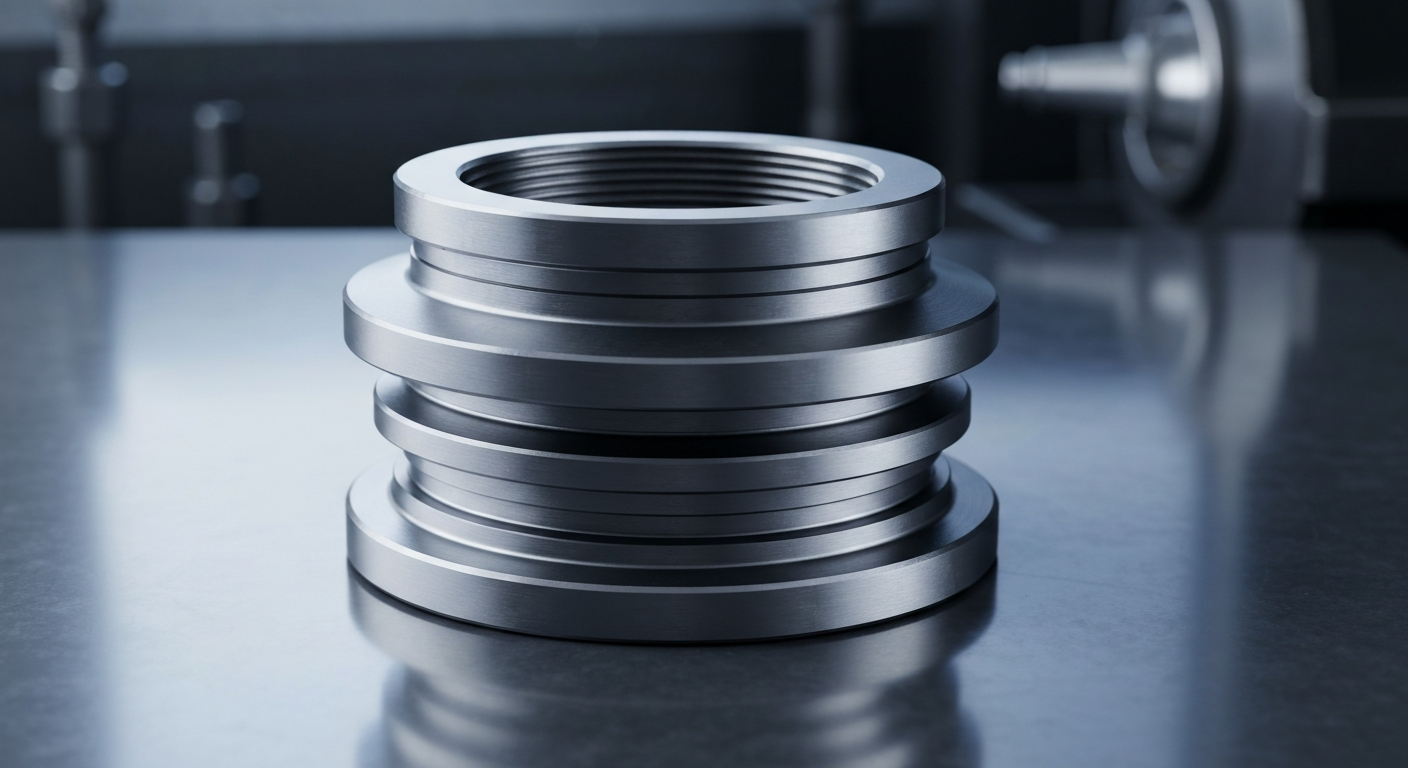

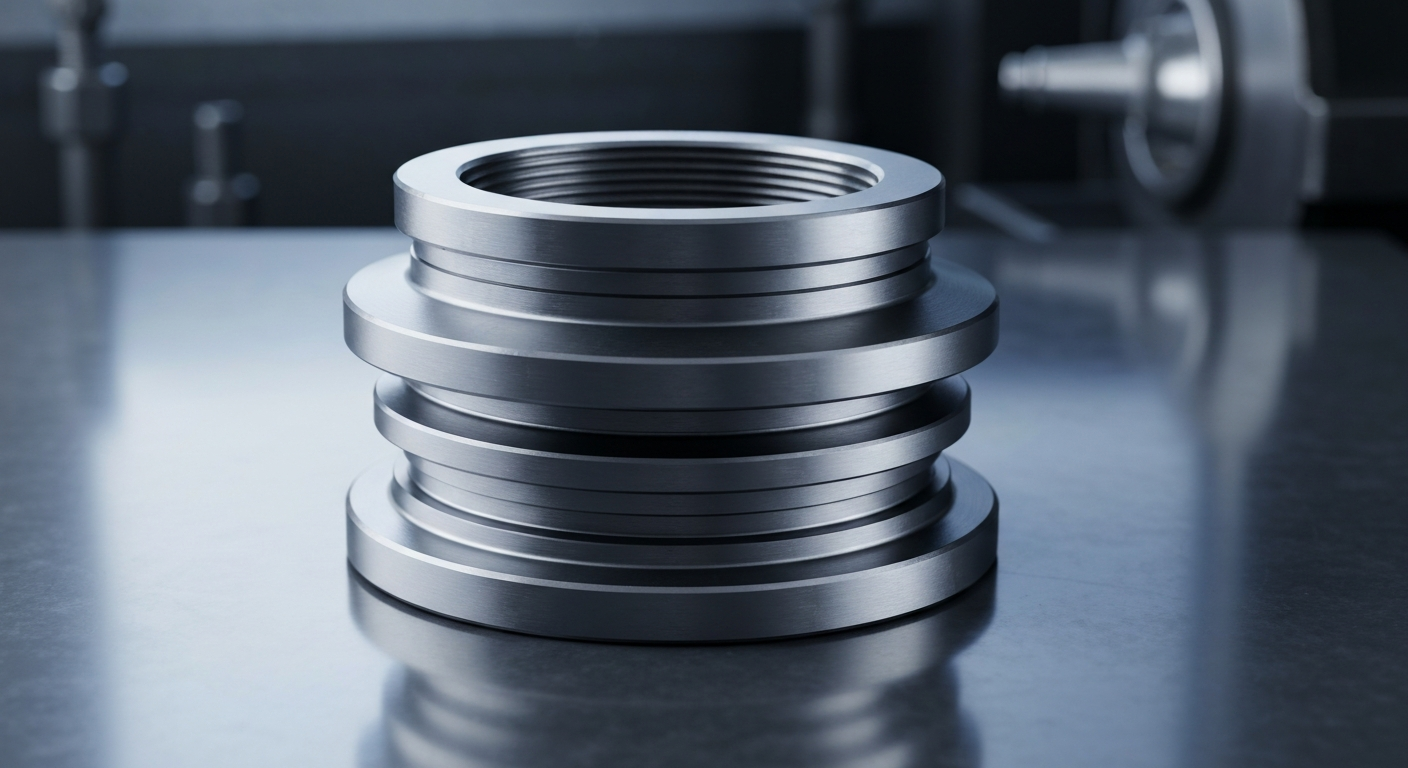

Understanding the 1 Inch Concentric Reducer in Pipe Fittings

Faits marquants

- A concentric reducer is a cone-shaped pipe fitting used to connect pipes of different sizes.

- Its symmetrical design ensures a smooth transition for fluid, minimizing turbulence in a piping system.

- This type of reducer is ideal for vertically oriented pipelines, like those connected to pump outlets.

- Common materials include durable options like stainless steel and carbon steel for industrial use.

- The primary function is to maintain a consistent centerline, promoting stable flow and pressure.

- Proper selection is key for the efficiency and safety of your piping system.

Introduction

Welcome to the world of pipe fittings! Have you ever wondered how complex piping systems connect pipes of different sizes seamlessly? The answer often lies in a small but mighty component called a reducer. Specifically, the concentric reducer is a crucial type of pipe fitting that ensures your system operates efficiently. This guide will walk you through everything you need to know about the 1-inch concentric reducer, a common yet vital part of many industrial and commercial applications.

Overview of the 1 Inch Concentric Reducer in Pipe Fittings

A 1-inch concentric reducer is a specific type of pipe fitting designed to join two pipes of different diameters. Its main purpose is to create a gradual and smooth transition, which is essential for maintaining the efficiency and stability of a piping system. By reducing the pipe size, it helps control fluid flow without causing major disruptions.

This component is easily recognizable by its symmetrical, cone-like shape. This design ensures that the centerline of both the larger and smaller pipes remains aligned. Let’s explore its definition and key applications to better understand its role.

Definition and Core Functionality

A concentric reducer is a type of pipe fitting with a distinct conical shape, where both ends are aligned along the same central axis. This symmetrical structure is its defining feature, distinguishing it from other reducer types. Its primary job is to connect a larger pipe to a smaller diameter pipe, facilitating a smooth transition for the fluid or gas flowing through.

The core functionality of a 1-inch concentric reducer revolves around its use in vertical piping. When you need to reduce the pipe size in a system where the flow is moving up or down, this fitting is the perfect choice. It helps prevent issues like backflow and ensures that the pressure remains stable as the fluid moves from the larger section to the smaller one.

This design minimizes turbulence and pressure loss, which is why it’s so valuable. By maintaining a consistent and centered flow, the concentric reducer enhances the overall performance and reliability of the entire piping network, especially in pump and compressor systems.

Key Applications in Piping Systems

The 1-inch concentric reducer is a versatile component used across various industries thanks to its effective design. Its ability to manage fluid flow makes it a staple in any piping system that requires a change in pipe diameter. You’ll find it in applications ranging from simple water lines to complex chemical processing plants.

This fitting is particularly well-suited for vertically oriented pipelines. In these setups, its symmetrical shape ensures that fluid or gas transitions smoothly without creating unwanted pockets or blockages. This is critical for maintaining system integrity and efficiency.

Parmi les applications les plus courantes, on peut citer :

- Pump and compressor systems, often at the discharge or outlet lines to ensure steady pressure.

- Vertical liquid or gas transport lines where balanced flow is necessary.

- HVAC and water distribution systems.

- Process lines in chemical and pharmaceutical plants.

Design Features of the 1 Inch Concentric Reducer

The design of a concentric reducer is straightforward yet highly effective. Its key feature is its symmetrical design, which looks like a perfect cone. This shape is fundamental to its function, allowing for a gradual and even flow transition from a larger pipe to a smaller one. This ensures a consistent flow without sudden shifts that could disrupt the system.

Because both openings share a common centerline, the fluid dynamics are predictable and stable. This simple design of a concentric reducer is what makes it so reliable for specific applications. Next, we will look at its structural characteristics and connection types.

Structural Characteristics and Flow Dynamics

The most important structural characteristic of a concentric reducer is its symmetrical design. This means the centers of the large and small ends are perfectly aligned, creating a cone shape. This alignment is what separates it from an eccentric reducer, which has an offset centerline.

This cone-shaped structure directly influences flow dynamics. As fluid passes through the reducer, the gradual tapering allows for a smooth flow transition. This design helps maintain a consistent fluid velocity and minimizes turbulence. Why does this matter? Less turbulence means less energy loss and a lower risk of pressure loss within the system.

The flow direction is managed evenly, making it ideal for vertical pipelines where gravity is a factor. By preventing abrupt changes in flow, the concentric reducer contributes to a more stable and efficient system, protecting other components like pumps and valves from potential damage caused by erratic flow.

Common End Connections and Transition Types

Concentric reducers are designed to be compatible with various installation methods, depending on the system’s needs. The type of end connections you choose will depend on factors like pressure, temperature, and the type of pipe being used. These connections ensure a secure and leak-proof transition.

One of the most common and robust connection methods is the butt weld. In a butt weld connection, the ends of the reducer are beveled and welded directly to the pipes. This creates a strong, permanent bond that is ideal for high-pressure and high-temperature applications. A 1-inch stainless steel concentric reducer is often installed this way.

Other popular end connections include:

- Flanged connections, which allow for easier removal and maintenance.

- Threaded connections, typically used in smaller, low-pressure systems.

- Socket welding, another option for smaller diameter pipes.

Common Materials Used for 1 Inch Concentric Reducers

When selecting a 1-inch concentric reducer, the material is just as important as the design. These fittings are available in a wide range of materials to suit different service conditions and media requirements across various industries. The most common choices are metals like stainless steel and carbon steel due to their strength and versatility.

However, other material variants, including plastics and alloy steels, are also available for specialized applications. The choice of material depends on factors like corrosion resistance, temperature, pressure, and the fluid being transported.

Stainless Steel and Carbon Steel Options

Stainless steel is a popular choice for concentric reducers, and for good reason. This material offers excellent corrosion resistance, making it perfect for use in food processing, pharmaceutical, and chemical systems where hygiene and purity are paramount. A stainless steel pipe fitting can handle corrosive fluids without degrading, ensuring a long service life.

Carbon steel is another widely used option. Known for its high strength and durability, carbon steel is a cost-effective choice for general industrial and utility pipelines. It’s suitable for systems that don’t involve highly corrosive materials but require a robust fitting that can withstand significant stress.

The type of pipe you are connecting will often dictate whether you choose stainless or carbon steel. Matching the reducer’s material to the pipe’s material is a best practice to prevent issues like galvanic corrosion and ensure system compatibility.

Other Material Variants and Their Uses

Beyond stainless and carbon steel, there are several other material variants available for concentric reducers. These alternatives cater to specific environmental conditions and system requirements. For example, alloy steels are used in high-pressure, high-temperature, or chemically aggressive environments where standard steels may fail.

Plastic options like PVC and CPVC are also common. These materials are lightweight, easy to install, and offer great resistance to corrosion. You’ll often find this type of pipe fitting in low-pressure applications, such as drainage, venting, and non-metallic water systems. Brass is another option, often seen in plumbing and water lines.

For industries with strict hygiene standards, special food-grade and sanitary materials are used. Stainless steel is often the base for these, but it is polished and finished to meet sanitary requirements, ensuring no contaminants are trapped. This makes it suitable for beverage and dairy processing.

Steel Pipe Reducer Schedules and Ratings

When you see a steel pipe reducer, you’ll often notice terms like “SCH 40” on it. This refers to the pipe schedule, which is a standard that dictates the wall thickness of the fitting. Along with the schedule, pressure ratings are critical for ensuring the reducer can handle the demands of your piping system.

These ratings and schedules are essential for safely connecting pipes of different diameters, especially in systems operating under pressure. Understanding what they mean will help you choose the right component for your project.

What SCH 40 Means for a 1 Inch Steel Pipe Reducer

So, what exactly does SCH 40 signify? The term “SCH” stands for schedule, and the number that follows indicates the wall thickness of a pipe or pipe fitting. For a 1-inch steel pipe reducer, SCH 40 specifies a standard thickness that is designed to handle a certain amount of internal pressure. A higher schedule number means a thicker wall.

This measurement is crucial for ensuring the structural integrity of your piping. Using a reducer with the wrong schedule could lead to system failure, especially under high pressure. SCH 40 is a common schedule used in a wide variety of commercial and industrial applications due to its balance of strength and cost.

The wall thickness of a reducer can vary between its larger and smaller ends, but both must comply with the specified schedule. Here is an example of nominal wall thickness for SCH 40 reducers:

Large End (DN) | Small End (DN) | Wall Thickness (Large/Small) in mm |

|---|---|---|

80 | 50 | 5.49 / 3.91 |

100 | 80 | 6.02 / 5.49 |

Pressure Ratings and Suitability for Different Environments

In addition to the schedule, pressure ratings are a vital piece of information for any pipe reducer. These ratings define the maximum internal pressure that a fitting can safely withstand at a given temperature. Selecting a reducer with the correct pressure rating is non-negotiable for the safety and reliability of your piping system.

The suitability of a reducer for different environments is directly tied to its pressure rating and material. For instance, a system operating at high temperatures and pressures, like a steam line, will require a reducer made from a material like alloy steel with a high-pressure rating.

When selecting a reducer, consider the following:

- The maximum operating pressure of your system.

- The operating temperature, as high temperatures can lower a material’s pressure capacity.

- The potential for pressure spikes or surges in the system. By matchingこれらのfactors to the reducer’s specifications, you ensure it is suitable for its intended environment.

Installation Methods for 1 Inch Concentric Reducers

Proper installation is key to getting the most out of your 1-inch concentric reducer. The method you choose will depend on the pipe material, system pressure, and whether the connection needs to be permanent. The most common method for steel reducers is butt weld installation, which provides a strong and durable seal.

However, there are alternative joining methods available, such as flanged or threaded connections, which might be more suitable for certain applications. Following best practices for any installation method is essential for a leak-free and efficient system.

Butt Weld Installation Steps

Butt weld installation is the preferred method for high-pressure systems because it creates a connection that is as strong as the pipe itself. This process involves welding the ends of the concentric reducer directly onto the ends of the pipes. It’s the go-to choice for permanent installations where strength and reliability are critical.

When should you choose a butt weld connection? It’s ideal for applications in the oil and gas, chemical, and power generation industries, where leaks are not an option. A butt weld concentric reducer ensures a smooth, continuous interior surface, which reduces friction and pressure drop.

The basic steps for a butt weld installation include:

- Preparing the ends of the reducer and pipes by cleaning and beveling them.

- Carefully aligning the reducer with the pipes to ensure the centerlines match.

- Welding the joint, often in multiple passes, to create a secure, full-penetration weld. Following these best practices ensures a robust and long-lasting connection.

Alternative Joining Methods and Best Practices

While butt welding is common, it’s not the only way to perform an installation. There are several alternative joining methods, each with its own set of advantages. These options are often used in systems where welding is impractical or where components may need to be disassembled for maintenance.

For example, flanged connections use bolts to join the reducer to the pipes, creating a strong but removable seal. Threaded connections are common for smaller, low-pressure pipes and allow for easy assembly and disassembly. Socket welding is another technique where the pipe is inserted into a recess in the reducer before being welded.

Regardless of the method, following best practices is crucial for ensuring a smooth fluid flow.

- Always ensure pipes and fittings are properly aligned.

- Use the correct sealant or gaskets for flanged and threaded connections.

- After installation, inspect the joints for any signs of leaks.

Comparing Concentric and Eccentric Reducers

In the world of pipe fittings, you’ll encounter two main types of reducers: concentric and eccentric reducers. While they both serve the same basic purpose of connecting different-sized pipes, their structural differences lead to very different applications. Understanding these distinctions is key to designing an effective piping system.

A concentric reducer is symmetrical, while an eccentric reducer is offset. This may seem like a minor detail, but it has a major impact on fluid dynamics. Let’s look at the structural and application differences more closely.

Structural and Application Differences

The most obvious difference between these reducers is their shape. A concentric reducer has a symmetrical design, like a cone, with a shared centerline. In contrast, eccentric reducers have an offset design, where one side is flat, causing the centerlines of the two ends to be misaligned.

This structural variation dictates their use. The symmetrical design of a concentric reducer is perfect for vertical piping. It allows for a smooth, centered flow transition, which is ideal for pump discharge lines and other vertically oriented flows.

On the other hand, eccentric reducers are the standard for horizontal pipelines.

- When installed with the flat side up in a liquid line, they prevent air pockets from forming.

- When installed with the flat side down in a gas or steam line, they allow condensate to drain.

- This offset design is critical for preventing issues like pump cavitation and liquid accumulation.

Choosing the Right Reducer for Your Project Needs

Choosing the right type of reducer comes down to one primary factor: the orientation of your piping system. Getting this choice right is fundamental to your project’s success and will help you avoid common flow problems down the line. It’s a simple decision that has a big impact.

For vertical piping systems, the choice is clear: use a concentric reducer. Its symmetrical shape ensures that flow remains aligned and stable, which is exactly what you need for upward or downward flows. This is the standard for applications like gravity-fed systems or compressor outlets.

If you are working with horizontal piping systems, an eccentric reducer is almost always the better choice. Its offset design is specifically engineered to manage the challenges of horizontal flow, such as preventing air or liquid from getting trapped. Making the correct choice between these two types is the first step in selecting the right reducer.

Standards and Certifications for 1 Inch Concentric Reducers

To ensure quality, safety, and interchangeability, 1-inch concentric reducers must comply with recognized industry standards. Organizations like ASME and ASTM publish standards that define everything from dimensions to material grades. These certifications are your guarantee that the pipe fitting will perform as expected.

These standards are especially important in critical applications, such as high-pressure systems or those requiring food-grade materials. Complying with these standards ensures that every component in your system works together seamlessly.

ASME, ASTM, and Other U.S. Pipe Fitting Standards

Key standards from the American Society of Mechanical Engineers (ASME) and the American Society for Testing and Materials (ASTM) govern the manufacturing of pipe fittings. These certifications ensure that a pipe fitting meets strict requirements for dimensional accuracy, material composition, and performance.

For butt-welded reducers, ASME B16.9 is one of the most important standards. It defines the dimensions, tolerances, and markings for factory-made wrought buttwelding fittings. Similarly, ASTM standards specify the material properties, such as the chemical composition and mechanical strength of the steel used.

Following these standards is not just a recommendation; it’s a requirement for many industrial applications to ensure safety and compatibility. Here’s a quick look at some common standards:

Standard | Description |

|---|---|

ASME B16.9 | Defines dimensions and tolerances for butt-welding fittings. |

ASME B36.10M | Specifies dimensions for welded and seamless wrought steel pipe. |

ASTM A234 | Covers wrought carbon steel and alloy steel fittings. |

ASTM A403 | Covers wrought austenitic stainless steel fittings. |

Requirements for Sanitary and Food-Grade Pipe Fittings

Yes, a 1-inch concentric reducer can absolutely be used in sanitary or food-safe applications, provided it meets specific requirements. For a pipe fitting to be considered food-grade, it must be made from materials that won’t contaminate the product and have a surface finish that prevents bacterial growth.

Stainless steel is the material of choice for these applications due to its excellent corrosion resistance and non-reactive properties. The smooth transition offered by a concentric reducer is also beneficial, as it minimizes areas where food particles or microbes could get trapped. This is a critical aspect of sanitary design.

To be certified as sanitary, a reducer must meet certain criteria:

- Made from an approved material, typically 304 or 316L stainless steel.

- Have a very smooth, polished internal surface to prevent buildup.

- Be designed for easy cleaning and sterilization. These requirements ensure the final product remains safe for consumption.

Selecting the Right 1 Inch Concentric Reducer Size

Once you’ve determined you need a concentric reducer, the next step is selecting the correct size. Reducers come in standard size options to connect common pipe diameters. For a 1-inch reducer, this means one end is designed to fit a 1-inch pipe, while the other end fits a different, smaller size.

Matching the reducer to your system is critical. An improperly sized reducer can create flow issues, increase pressure drop, and compromise the efficiency of your entire piping system. Let’s look at how to navigate the available sizes.

Understanding Standard Size Options

Concentric reducers are available in a wide range of standard size options to facilitate connections between virtually any two pipe sizes. These sizes are defined by standards like ASME B16.9, which ensures that a reducer from one manufacturer will fit a pipe from another. A “1-inch reducer” typically describes a fitting where the larger end connects to a pipe with a 1-inch nominal size.

The smaller end can be any number of standard sizes, such as 3/4-inch or 1/2-inch. When ordering, you’ll need to specify both the large and small end diameters. For example, you might order a “1 x 3/4 inch concentric reducer.” This standardization simplifies the design and construction of any piping system.

Here’s a table showing some common reducer size combinations and their lengths, per ASME B16.9:

Large End OD (mm) | Small End OD (mm) | Center Length (mm) |

|---|---|---|

88.9 | 60.3 | 102 |

114.3 | 88.9 | 127 |

168.3 | 114.3 | 152 |

Factors to Consider When Matching Reducer to System

Selecting the right reducer size involves more than just matching pipe diameters. To ensure optimal performance of your piping system, you need to consider several key factors. These factors will help you maintain a smooth fluid flow and avoid potential issues like excessive pressure drop or vibration.

First and foremost, you must know the exact outside diameters of the two pipes you are connecting. This is the most basic step in choosing the right size. Beyond that, you should consider the flow rate requirements of your system. A poorly sized reducer can act as a bottleneck, restricting flow and reducing efficiency.

Here are some critical factors to keep in mind:

- Fluid Velocity: Ensure the change in diameter does not cause the fluid velocity to exceed design limits.

- Pressure Drop: Calculate the potential pressure loss across the reducer to ensure it’s acceptable for your system.

- Material Compatibility: Always match the reducer material to the pipe material to prevent corrosion.

Typical Applications in Industry Sectors

The 1-inch concentric reducer is a workhorse in numerous industry sectors. Its simple and effective design makes it a go-to component for managing pipe size transitions in a variety of applications. You will find this fitting in everything from large-scale process piping to commercial HVAC systems.

Its role is always the same: to provide a smooth, centered transition that maintains flow stability. Whether it’s in a water line, a chemical system, or an oil and gas pipeline, the concentric reducer plays a vital part in the efficiency of the overall piping system.

Use in Process Piping and Fluid Handling

In the world of process piping, precise control over fluid handling is essential. Concentric reducers are widely used in these environments to connect different stages of a process. For example, they are commonly installed at the outlets of pumps or compressors to transition to a smaller pipe diameter, which can increase fluid velocity and pressure as needed.

This type of pipe fitting is a common sight in chemical plants, oil refineries, and pharmaceutical manufacturing facilities. In these settings, maintaining a steady and predictable flow is critical for both safety and product quality. The concentric reducer helps achieve this by minimizing turbulence and pressure fluctuations.

By ensuring a smooth transition, the reducer also helps protect sensitive equipment. An abrupt change in pipe size can cause vibrations or surges that could damage pumps, valves, and other expensive components. The gradual change provided by a concentric reducer mitigates these risks.

Role in HVAC, Water, and Chemical Systems

Beyond heavy industrial use, concentric reducers are indispensable in HVAC, water, and chemical systems. In commercial and residential HVAC systems, they are used in chilled and hot water lines to adapt to different pipe sizes as the piping system branches out through a building. This helps balance the flow distribuzione.

In municipal and industrial water systems, these fittings are used in both supply and drainage lines. They allow designers to use larger main lines and transition to smaller distribution lines, optimizing cost and performance. Their ability to ensure smooth fluid flow is key to the efficiency of these networks.

For chemical systems, the concentric reducer’s symmetrical design is perfect for vertical reactors and transport lines. It ensures that chemicals are mixed and transported evenly, without the risk of creating dead spots where material could accumulate. This is vital for maintaining process control and safety.

Conclusion

In summary, understanding the 1 inch concentric reducer is essential for anyone involved in piping systems. Its design features, material choices, and installation methods play a crucial role in ensuring efficiency and safety across various applications, from industrial processes to HVAC systems. By recognizing the importance of choosing the right reducer for your specific needs and being aware of the standards and certifications required, you can enhance system performance while reducing the risk of complications down the line. If you’re looking to dive deeper into the world of pipe fittings or need personalized guidance, get in touch with our experts for a free consultation.

Questions fréquemment posées

Can a 1 inch concentric reducer be used in sanitary or food-safe applications?

Yes, a 1-inch concentric reducer is suitable for sanitary and food-grade applications if it meets certain requirements. The pipe fitting must be made from a non-reactive material like stainless steel and have a polished, smooth interior surface to prevent microbial growth and meet all sanitary standards.

How do I select the correct steel pipe reducer size for my system?

To select the correct steel pipe reducer size, you must match it to the outside diameters of the two pipes you are connecting. Additionally, consider factors like the required flow rates, system pressure, and temperature to ensure the reducer’s schedule and pressure rating are appropriate for your piping system.

When should I choose a butt weld concentric reducer over other joining methods?

You should choose a butt weld concentric reducer for high-pressure, high-temperature, or permanent installations where strength and leak-proof integrity are top priorities. This joining method creates a connection as strong as the pipe itself, making it one of the best practices for critical applications.