-

Yinzhuang Industrial zone,Mengcun county,Cangzhou city,Hebei province,China

Blind Flanges: Essential Components in Piping Systems

Key Highlights

- Blind flanges, also known as closure plate flanges, are solid steel components without a bore that seal off the ends of pipe systems.

- They ensure safety and efficiency by providing a durable seal against leaks and supporting raised face or flat face configurations.

- Commonly made from stainless steel or carbon steel, blind flanges can handle high-pressure applications and routine maintenance needs.

- These pipe flanges are designed with bolt holes and an outer diameter suited for various pipeline specifications.

- They are ideal for isolating sections of pipelines when modifications, pressure testing, or repairs are needed.

Introduction

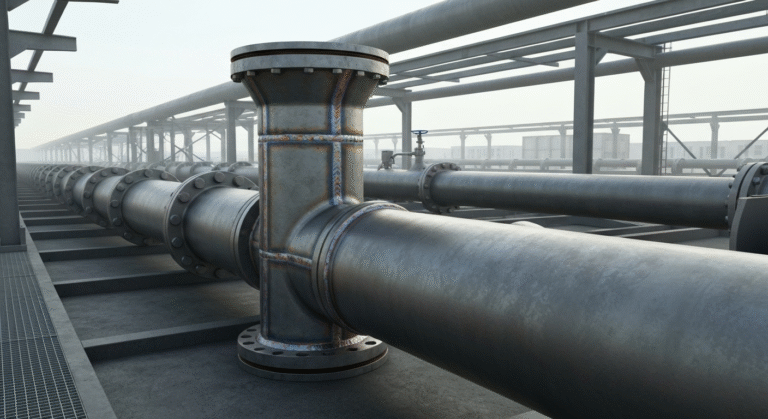

Piping systems are very important to many industries. They help move fluids, gases, and other materials in a fast and safe way. To work well, these systems need the right parts, and flanges are some of the key pieces. There are different types of flanges in use, but blind flanges are especially important. These flanges close off the end of a pipe, taking into consideration the appropriate pipe size. Blind flanges keep the pipeline safe and keep it working when people need to do repairs or make changes.

If you understand what blind flanges do and know their main features, you can choose better parts for your pipeline. This can help you make your work easier and get better results. Using the right types of flanges in your piping system is a good way to keep everything running as it should.

Understanding Blind Flanges in Piping Systems

Blind flanges work to seal off parts of a pipeline. These flanges can be used for a short time or for good. They are different from other pipe flanges because they do not have a hole in the middle called a bore. You will often see them used to separate parts of the pipeline for routine maintenance or pressure testing. Their strong build and ability to fit different pipelines make them key items in the process.

Picking the right type of flange is important for keeping your system safe and working well over time. Blind flanges stop leaks and let you make changes with care, which helps every part of the pipeline work better.

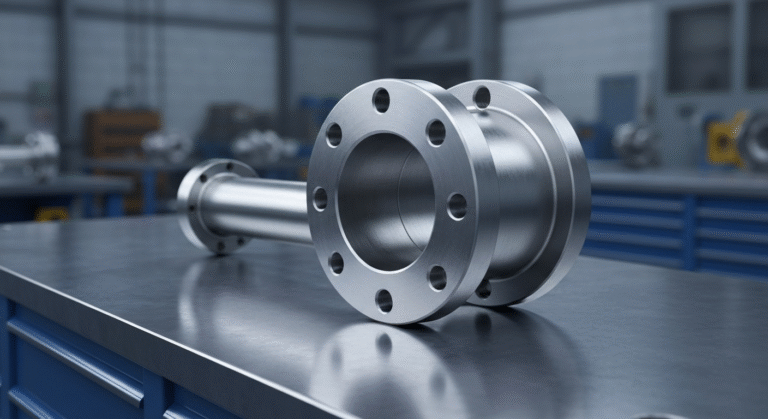

Definition and Key Features of Blind Flanges

Blind flanges are used to close off the end of a pipeline on a pressure vessel. This means there is no way for gas or liquid to pass through. These flanges do not have a bore or a hub in the middle. They do have bolt holes located around the outer diameter. This helps you attach them firmly to other parts. Blind flanges fit well with gaskets. Gaskets help seal the join tightly and stop leaks.

There are two main face types you can pick. The first is called a flat face. It is smooth and even. The other is called a raised face (RF). The raised face type has a small area that sticks out in the center, matching the diameter of the pipe, which helps improve how well it seals. Flat face types sit fully level, so they handle stress better. These two main types of blind flanges help keep the pipeline strong, even if conditions are tough.

Sometimes, you may need to match another kind of flange or fit a certain piping need. You can get custom machining for blind flanges, such as making bore holes or creating neck flanges if needed. Because blind flanges are simple and so tough, they work for many jobs. They are often chosen when you need a closure you can count on in your piping or pipeline setup.

Common Materials and Manufacturing Standards

Blind flanges are made from different strong materials. The most common ones are stainless steel and carbon steel. Stainless steel flanges are great because they resist rust and last a long time. Carbon steel flanges are also strong and are often used for places with high pressure.

Flanges that are of good quality follow rules from ANSI and ASME. These groups ensure that the variety of flanges meet strict specifications, such as thickness and tolerance requirements, including the fit for a Garlock ring gasket. Codes like ASME B16.5 and B16.47 help keep the dimensions and classes of flanges in line.

Material | Key Features |

|---|---|

Stainless Steel | Corrosion resistance, precision, extended lifespan |

Carbon Steel | High durability, cost-effective solution for heavy-duty use |

Custom Alloys | Specific uses like extreme temperatures or unique environments |

Using these materials and sticking to these standards helps grant the flanges can carry out their work well and meet the rules for different jobs in industry.

Applications and Advantages of Blind Flanges

Blind flanges are important because they help close off parts of a pipeline or piping system. This keeps things safe, especially when there is testing or service work. These flanges also help let out pressure. They work by making a tight seal, so there is less risk during jobs that use high pressure. People often use blind flanges in places like factories or plants. They are put on nozzles to close off openings and to end piping lines.

There are many good things about using these flanges. They are easy to put in, so the work can go fast. They help stop leaks, which is a big help. Blind flanges also work well, even when the job is tough. Because of this, companies in the oil, gas, and other industries look to blind flanges to keep things running smoothly and safely.

Typical Uses in Industrial and Commercial Settings

You can see blind flanges used in many places, be it at work sites or in shops. They help you seal off an area to stop the flow, and they make routine maintenance simple. Here are some main uses:

- Pressure Testing: Blind flanges keep parts of a pipeline closed, sealing off certain sections of the pipeline so you can test the pressure in the system safely and get accurate results.

- Routine Maintenance: They help you block off some parts of a pipeline, making it easier to work and stopping leaks when repairs are needed.

- Easy Access: The way these flanges are made, you can reach the ends of each section fast, which is great when you need to put in a nozzle or valve.

- Pipeline Termination: If there’s a section of a system you don’t need right now, these flanges let you shut it off, for good or just for a time.

Blind flanges are used in many fields—from machine jobs to power plants—and they always fit the needed specifications for good, safe work.

Benefits Compared to Other Pipe End Closures

Compared to other options like welded or threaded ends, blind flanges, including the threaded flange variant and socket weld flanges, stand out for a few reasons. They help with routine maintenance because you can install and remove them quickly. Their strong build helps stop leaks. This is because they work well with gaskets to keep a tight seal.

For pressure testing, blind flanges let you block off parts of the pipeline. This makes it easy to get good results without any problems for the rest of the system. They can work in many sizes and setups, such as in flat face or raised assemblies.

They last a long time and keep working, even if conditions are tough. This makes them good for times when you need to shut down or change the pipeline. Blind flanges save money, cut down on leaks, and play a key role in safe and smooth work.

Conclusion

To sum up, blind flanges are important in many industries because they help your piping work well and stay strong. Their design helps seal off parts of a pipeline and makes it easier to keep up with work and repairs. This also helps hold steady pressure in the pipeline. If you know the main features, the different materials, and how you can use these flanges, you will be better able to pick the best one for the job. Whether you work in an industry or have a business, using good blind flanges will make your piping setup work better overall. If you have questions about flanges or need help picking the right parts for your pipeline, you can always ask for expert support.