-

Khu công nghiệp Yinzhuang, huyện Mengcun, thành phố Cangzhou, tỉnh Hà Bắc, Trung Quốc

Bạn muốn một cấu hình tùy chỉnh?

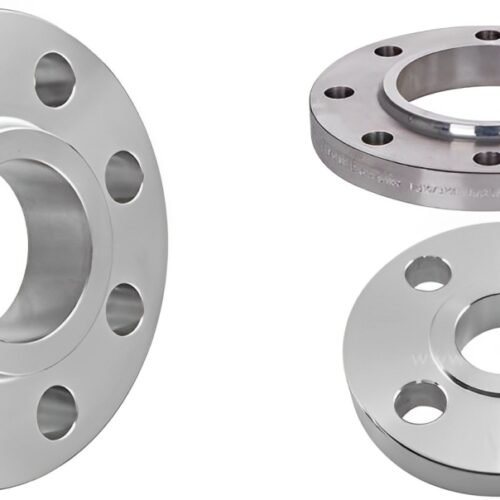

SO Flange

Giá gốc là: $7.70.$7.00Giá hiện tại là: $7.00.

- Chất lượng cao cấp

- Thanh toán an toàn

- Bảo đảm hài lòng

- Giao hàng toàn cầu

- Bảo đảm hoàn tiền

Slip-On Flange: A Comprehensive Guide on Design, Benefits, and Applications

Slip-on flange—often referred to as an SO flange—is engineered to slide over a pipe, thanks to its inner diameter being slightly larger than the pipe’s outer diameter. This design feature allows the pipe to be easily inserted into the flange before being secured with fillet welds on both the top and bottom. The result is a reliable and efficient connection between piping and equipment.

Key Design Features

Innovative Construction

Slip-on flanges feature a flat, uncomplicated face. Their design permits the flange to be slipped onto the pipe effortlessly, after which it is welded into place. This construction method ensures straightforward alignment and simplifies the overall installation process.

Easy Installation Process

One of the major advantages of slip-on flanges is their user-friendly installation. Since these flanges do not require perfect end-to-end alignment, installers can position them quickly and then secure them with fillet welding. This not only saves time but also reduces the chance of misalignment errors.

Versatile Applications

Commonly employed in low-pressure systems, slip-on flanges are ideal for a variety of industries such as oil and gas, water treatment, and chemical processing. Their design is tailored to meet the demands of fluid systems where extreme pressures are not a primary concern.

Cost-Effective Solution

Compared to more complex alternatives like weld-neck flanges, slip-on flanges offer a more economical solution. Their simpler design and less labor-intensive installation contribute to lower overall project costs.

Material Variety

Slip-on flanges can be manufactured from different materials, including carbon steel, stainless steel, and various alloys. This flexibility allows them to be used in diverse environments based on specific application requirements.

Limitations for High-Pressure Use

Despite their advantages, slip-on flanges are typically not recommended for high-pressure applications. The design—especially the reliance on weld joints—may not provide the same level of integrity as other flange types under extreme conditions.

Product Range and Standards

Specifications

Standards: ASTM A105 for carbon steel and ASTM A182 for alloy and stainless steel.

Material Options: Carbon steel, alloy steel, and stainless steel.

Size Range: Standard sizes from 1/2″ to 24″, with custom options available up to 60″.

Pressure Ratings: Available in Class 150 up to Class 2500.

Face Types: Options include Raised Face (RF) and Ring Type Joint (RTJ).

International Standards

Slip-on flanges are also manufactured in accordance with international standards such as ASME B16.5 for pipe flanges, BS 3293, and DIN 86029, ensuring quality and consistency across different markets.

Welding Methods and Face Types

Welding Variants

There are two primary classifications of slip-on flanges:

Plate Welded Slip-On Flanges: Ideal for applications where ease of installation and cost are major factors.

Hubbed Pipe Welded Slip-On Flanges: These offer mechanical properties that are intermediate between integral and loose flanges, providing a balance of strength and ease of use.

Face Designs

Raised Face (RF) Flanges: Featuring a slight protrusion on the inner surface, these flanges are designed to improve gasket seating and enhance sealing performance. The height of the raised face typically increases with higher pressure ratings.

RTJ Flanges: With a precisely machined groove on the raised face, RTJ flanges are engineered for high-pressure applications. The groove allows for the secure placement of a gasket ring, ensuring superior sealing compared to the standard RF design.

Dimensions, Pressure Ratings, and Manufacturing Methods

Common Dimensions and Pressure Classes

Slip-on flanges are available in common outer diameters ranging from 1/2″ to 24″, with special orders up to 60″. They cover a wide spectrum of pressure classes, including Class 150, 300, 400, 600, 900, 1500, and 2500 (expressed in either # or LB). These ratings correspond to pressure numbers (PN) from 2.5 to 250.

Manufacturing Techniques

Slip-on flanges are produced using several methods:

Forging: Offers the highest quality, making these flanges the most widely used despite their higher cost.

Steel Cutting and Casting: These methods provide additional options for specific applications, allowing for flexibility in production based on project needs.

Advantages and Comparisons

Benefits of Slip-On Flanges

Lower Installation Costs: Simplified alignment and welding reduce both time and expense.

Enhanced Seal Reliability: Dual welding (inside and outside) offers robust leak prevention.

Reduced Fabrication Time: The ability to slide the pipe into the flange minimizes the need for precision cutting.

Comparison with Weld-Neck Flanges

Pressure Strength: The internal pressure capacity of a slip-on flange is roughly two-thirds that of a weld-neck flange.

Durability: Slip-on flanges generally have a shorter service life—approximately one-third that of weld-neck flanges.

Welding Requirements: They require two fillet welds (one on each side), and care must be taken to leave a gap between the pipe end and flange to avoid damaging the face.

Installation Constraints: Since the flange must first slide over the pipe, combinations such as flange-plus-elbow or flange-plus-tee are not feasible due to misalignment issues.

Kết luận

Slip-on flanges present an excellent balance of simplicity, cost-efficiency, and performance in low-pressure piping systems. While they may not be ideal for high-pressure environments, their ease of installation and material versatility make them a popular choice for many industrial applications. Engineers and project managers should weigh the benefits against potential limitations when deciding between slip-on and other flange types, ensuring that the selected product meets both performance and budgetary requirements.

Giao hàng nhanh chóng

Nhà máy của chúng tôi được trang bị các dây chuyền sản xuất tự động hoàn toàn cho phụ kiện ống, cho phép chúng tôi đáp ứng hiệu quả các yêu cầu của khách hàng.

Cách Cảng Thiên Tân khoảng 100 km, chúng tôi có thể vận chuyển hàng hóa đến cảng một cách nhanh chóng để xuất khẩu. Vị trí gần gũi này giúp tối ưu hóa hoạt động logistics, giảm thời gian vận chuyển và đảm bảo giao hàng đúng hẹn cho khách hàng.

Đóng gói đáng tin cậy và an toàn

Chúng tôi ưu tiên việc đóng gói an toàn cho sản phẩm để đảm bảo chúng đến tay khách hàng một cách an toàn và trong tình trạng tốt nhất. Đối với các phụ kiện ống có kích thước nhỏ, chúng tôi sử dụng hộp gỗ chắc chắn, cung cấp sự bảo vệ vững chắc trong quá trình vận chuyển. Đối với các phụ kiện ống có kích thước lớn, chúng tôi sử dụng pallet được bọc chặt bằng màng PE co giãn, giúp bảo vệ hiệu quả các sản phẩm và ngăn ngừa sự xâm nhập của độ ẩm, có thể dẫn đến quá trình oxy hóa. Phương pháp này đảm bảo tính tin cậy và an toàn của việc đóng gói, duy trì chất lượng sản phẩm trong suốt quá trình vận chuyển.

Đánh giá

Chưa có đánh giá nào.