-

Khu công nghiệp Yinzhuang, huyện Mengcun, thành phố Cangzhou, tỉnh Hà Bắc, Trung Quốc

Bạn muốn một cấu hình tùy chỉnh?

Cút thép carbon

Khoảng giá: từ $0.19 đến $330.00

ASTM A234 WPB 90 Degree Seamless Elbow

Contact us for prices on more sizes

Size: 1/2”~80”,DN15~DN2000

Lịch trình: Sch 20, 40, STD, 80, 160, XXS

Tên gọi: ASTM / ASME A234, A860, A420

Cấp độ: WPB/C, WPHY 42, 46, 52, 60, 65, 70, WPL 3, 6, 9

Type: Seamless Elbow and Weld Elbow

Contact us for more price discounts!

- Chất lượng cao cấp

- Thanh toán an toàn

- Bảo đảm hài lòng

- Giao hàng toàn cầu

- Bảo đảm hoàn tiền

Thép carbon Elbow ASTM A234 WPB 90 degree seamless & welded

Elbows are essential pipe fittings used to change the direction of pipes in various piping systems. These fittings are made from thép carbon, a strong and durable material known for its ability to resist wear and corrosion. Whether you need to change the direction of your pipes by 90 degrees, 45 degrees, or reduce the size of the pipe, elbows offer reliable, long-lasting solutions. They are widely used in industries such as oil and gas, construction, power plants, water treatment, and more.

What is a Pipe Elbow?

Pipe elbow is connects two sections of pipe and allows the pipe to change direction. These elbows are designed to handle high pressure and high temperature, making them ideal for a variety of applications. Pipe elbows are available in several types, including 90-degree elbows, 45-degree elbows, and reducing elbows, allowing for flexibility in different piping systems.

Elbows are made to meet high industry standards such as Tiêu chuẩn ASTM A234 WPB for pressure piping systems, ensuring strength, reliability, and durability.

Types of Elbows

1. Seamless Elbow

Seamless elbow is made from a single piece of steel without any welds. This design makes the elbow stronger and more durable, with better resistance to pressure. Seamless elbows are used in applications that require high mechanical strength.

2. Weld Elbow

Weld elbow is connected to the pipe by welding. This creates a leak-proof seal. Weld elbows are available in different angles and radii, including 90-degree elbows, 45-degree elbows, and long radius hoặc short radius elbows. Welded elbows are often used when a permanent, secure connection is needed.

3. Long Radius Elbow

Long radius elbow (LR elbow) has a bend radius that is 1.5 times the diameter of the pipe. These elbows are designed for smooth fluid flow and are ideal when you want to minimize pressure loss and maintain efficient flow in the system.

4. Short Radius Elbow

The short radius elbow (SR elbow) has a smaller bend radius, equal to the pipe’s diameter. It is used in tight spaces where a sharp turn is necessary. While more compact, short radius elbows may create higher resistance to flow compared to long radius elbows.

5. 90-Degree Elbow

The 90-degree elbow is one of the most common types of elbows. It changes the direction of the pipe by 90 degrees, which is useful for sharp turns in the pipe layout. You can choose between a long radius hoặc short radius elbow depending on your space and flow needs.

6. 45-Degree Elbow

45-degree elbow is used when the pipe needs to change direction by 45 degrees. This type of elbow provides a smoother flow compared to a 90-degree elbow and is typically used in systems that require moderate directional changes.

7. Reducing Elbow

Reducing elbow is designed to connect pipes of different sizes. It allows for a change in both direction and pipe diameter, maintaining a consistent flow while reducing the pipe size.

Coating Options for Carbon Steel Elbows

Elbows can be coated to improve their resistance to corrosion and increase their lifespan. Some common coating options include:

1. Black Painting Elbow

Black painting is a cost-effective coating option that helps protect elbows from rust and corrosion. It is commonly used in general industrial applications where the elbows are exposed to moisture or dirt.

2. PE Coating Elbow

PE (Polyethylene) coating is often applied to elbows for outdoor applications. It creates a protective barrier against moisture and chemicals, ensuring the elbow lasts longer in harsh conditions.

3. Galvanized Elbow

A galvanized elbow is coated with zinc to prevent rust and corrosion. This coating is particularly useful in environments where the elbows are exposed to moisture or chemicals, helping extend their durability.

Benefits of Elbows

- Độ bền: Elbows are built to last, handling high pressure, temperature, and wear.

- Hiệu quả về chi phí: Compared to other materials like thép không gỉ hoặc alloy steel, carbon steel elbows are more affordable, offering reliable performance at a lower cost.

- Đa năng: Available in a wide range of sizes, angles, and coatings, elbows can be customized for any piping system.

- Khả năng chống ăn mòn: Protective coatings like galvanization và PE coating help protect the elbows from rust and corrosion, extending their lifespan.

Standards and Certifications

Elbows are manufactured according to international standards to ensure high quality and performance. Some of the key standards include:

- Tiêu chuẩn ASTM A234 WPB: This specification covers the production of elbows and fittings used in pressure piping systems. It ensures that the elbows meet strict mechanical and dimensional requirements.

- ASME B16.9: This standard outlines the specifications for factory-made butt-welding fittings, including elbows. It provides details on dimensions, tolerances, and pressure-temperature ratings for these fittings.

Applications of Elbows

Elbows are used in a variety of industries, including:

- Oil & Gas: For transporting oil, gas, and other fluids through pipelines.

- Sản xuất điện: In power plants to connect different sections of piping.

- Water Treatment: In systems for water and sewage processing.

- Xây dựng: For HVAC systems, plumbing, and other mechanical installations.

Kết luận

Elbows are crucial pipe fittings that provide strength, durability, and flexibility in piping systems. Whether you need 90-degree elbows, 45-degree elbows, hoặc reducing elbows, these fittings are designed to handle high-pressure and high-temperature environments. With coatings like Bức tranh đen, PE coating, and galvanization, elbows offer long-lasting protection against corrosion.

If you’re looking for high-quality elbows that meet industry standards such as Tiêu chuẩn ASTM A234 WPB và ASME B16.9, be sure to choose a trusted supplier who offers a range of sizes, coatings, and configurations to suit your project’s needs.Carbon steel elbows continue to be a top choice for reliable, cost-effective, and high-performance pipe systems across industries.

| Cân nặng | Không áp dụng |

|---|---|

| OD | 1/2'', 3/4'', 1'', 1 1/4'', 1 1/2'', 2'', 2 1/2'', 3'', 4'', 5'', 6'', 8'', 10'', 12'', 14'', 16'', 18'', 20'', 24'' |

| Độ dày | SCH10S, SCH20, SCH40 |

Giao hàng nhanh chóng

Nhà máy của chúng tôi được trang bị các dây chuyền sản xuất tự động hoàn toàn cho phụ kiện ống, cho phép chúng tôi đáp ứng hiệu quả các yêu cầu của khách hàng.

Cách Cảng Thiên Tân khoảng 100 km, chúng tôi có thể vận chuyển hàng hóa đến cảng một cách nhanh chóng để xuất khẩu. Vị trí gần gũi này giúp tối ưu hóa hoạt động logistics, giảm thời gian vận chuyển và đảm bảo giao hàng đúng hẹn cho khách hàng.

Đóng gói đáng tin cậy và an toàn

Chúng tôi ưu tiên việc đóng gói an toàn cho sản phẩm để đảm bảo chúng đến tay khách hàng một cách an toàn và trong tình trạng tốt nhất. Đối với các phụ kiện ống có kích thước nhỏ, chúng tôi sử dụng hộp gỗ chắc chắn, cung cấp sự bảo vệ vững chắc trong quá trình vận chuyển. Đối với các phụ kiện ống có kích thước lớn, chúng tôi sử dụng pallet được bọc chặt bằng màng PE co giãn, giúp bảo vệ hiệu quả các sản phẩm và ngăn ngừa sự xâm nhập của độ ẩm, có thể dẫn đến quá trình oxy hóa. Phương pháp này đảm bảo tính tin cậy và an toàn của việc đóng gói, duy trì chất lượng sản phẩm trong suốt quá trình vận chuyển.

Carbon Steel Grades & Properties

| Grade | C | Mn | Si | S | P |

|---|---|---|---|---|---|

| A234 WPB | ≤0.3 | 0.29-1.06 | ≤0.1 | ≤0.058 | ≤0.05 |

| A105 | ≤0.35 | 0.6-1.0 | 0.1-0.35 | ≤0.04 | ≤0.035 |

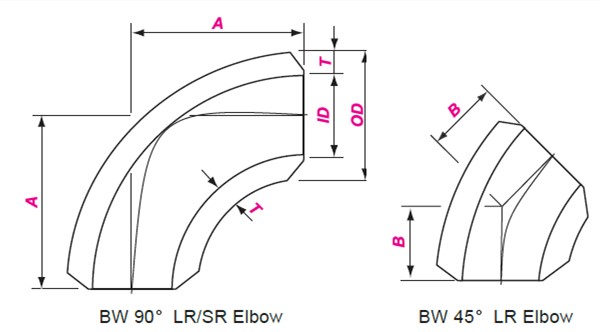

Drawing & Specification for BW Elbow

Butt Weld Elbow Drawing

| Nominal Diameter | Outside Diameter at Bevel | A | B | ||

|---|---|---|---|---|---|

| DN | Chỉ số hài lòng của khách hàng (NPS) | OD | Long Radius | Short Radius | Long Radius |

| 15 | 1/2 | 21.3 | 38 | – | 16 |

| 20 | 3/4 | 26.9 | 38 | – | 19 |

| 25 | 1 | 33.7 | 38 | 25 | 22 |

| 32 | 1 1/4 | 42.4 | 48 | 32 | 25 |

| 40 | 1 1/2 | 48.3 | 57 | 38 | 29 |

| 50 | 2 | 60.3 | 76 | 51 | 35 |

| 65 | 2 1/2 | 73 | 95 | 64 | 44 |

| 80 | 3 | 88.9 | 114 | 76 | 51 |

| 90 | 3 1/2 | 101.6 | 133 | 89 | 57 |

| 100 | 4 | 114.3 | 152 | 102 | 64 |

| 125 | 5 | 139.7 | 190 | 127 | 79 |

| 150 | 6 | 168.3 | 229 | 152 | 95 |

| 200 | 8 | 219.1 | 305 | 203 | 127 |

| 250 | 10 | 273 | 381 | 254 | 159 |

| 300 | 12 | 323.9 | 457 | 305 | 190 |

| 350 | 14 | 355.6 | 533 | 356 | 222 |

| 400 | 16 | 406.4 | 610 | 406 | 254 |

| 450 | 18 | 457.2 | 686 | 457 | 286 |

| 500 | 20 | 508 | 762 | 508 | 318 |

| 550 | 22 | 559 | 838 | 559 | 343 |

| 600 | 24 | 610 | 914 | 610 | 381 |

| 650 | 26 | 660 | 991 | 660 | 406 |

| 700 | 28 | 711 | 1067 | 711 | 438 |

| 750 | 30 | 762 | 1143 | 762 | 470 |

| 800 | 32 | 813 | 1219 | 813 | 502 |

| 850 | 34 | 864 | 1295 | 864 | 533 |

| 900 | 36 | 914 | 1372 | 914 | 565 |

| 950 | 38 | 965 | 1448 | 965 | 600 |

| 1000 | 40 | 1016 | 1524 | 1016 | 632 |

| 1050 | 42 | 1067 | 1600 | 1067 | 660 |

| 1100 | 44 | 1118 | 1676 | 1118 | 695 |

| 1150 | 46 | 1168 | 1753 | 1168 | 727 |

| 1200 | 48 | 1220 | 1829 | 1220 | 759 |

| 1300 | 52 | 1321 | 1981 | 1321 | 821 |

| 1400 | 56 | 1422 | 2134 | 1422 | 883 |

| 1500 | 60 | 1524 | 2286 | 1524 | 947 |

| 1600 | 64 | 1626 | 2438 | 1626 | 1010 |

| 1700 | 68 | 1727 | 2591 | 1727 | 1073 |

| 1800 | 72 | 1829 | 2743 | 1829 | 1137 |

| 1900 | 76 | 1930 | 2896 | 1930 | 1199 |

| 2000 | 80 | 2032 | 3048 | 2032 | 1263 |

Đánh giá

Chưa có đánh giá nào.