-

Yinzhuang Industrial zone,Mengcun county,Cangzhou city,Hebei province,China

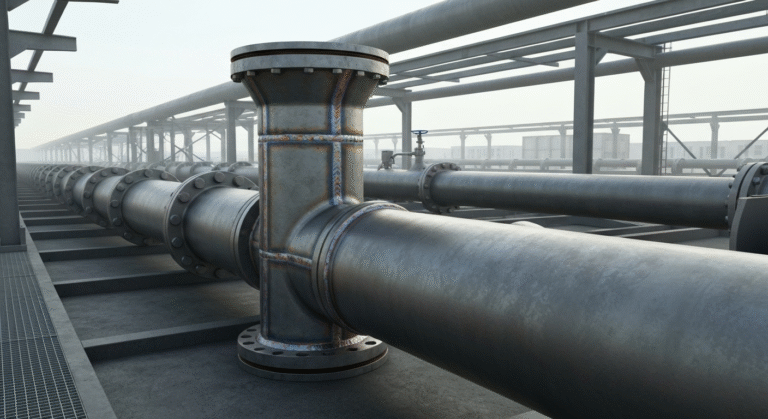

Top Quality Hot-Dip Galvanized Elbow for Every Application

Key Highlights

- Hot-dip galvanized elbows offer unmatched corrosion resistance, ensuring durability in harsh environments.

- Designed with various degree elbows, they provide flexibility to accommodate diverse piping configurations.

- Available in robust materials like stainless steel and PVC, they suit industrial, residential, and commercial applications.

- Feature customizable fittings and connectors for seamless installation in plumbing and conduit systems.

- Precision manufacturing ensures optimal bend radius and standard radius, contributing to efficient fluid and gas flow.

- Sustainability-focused production aligns with modern environmental standards.

Introduction

Hot-dip galvanized elbows are important fittings used in many piping and conduit systems. You can find these in different angles, like 45° or 90°, to help change the way a fluid or gas moves. These elbows keep the flow tight so no leaks come out. They are made by using a hot-dip method, which gives them strong protection against corrosion. This makes them great for all types of weather and hard uses. People use them in both big industrial setups and small home jobs. These elbows offer good reliability, can be used in lots of ways, and support sustainability, so you get solid, long-lasting results.

Key Features of Hot-Dip Galvanized Elbows

The main thing that makes hot-dip galvanized elbows special is their strong corrosion resistance. The zinc used in the hot-dip process puts a layer on the fittings. This layer helps them fight off rust, even when used in places with a lot of water or chemicals. It makes the elbows last a long time.

Also, the way their bend radius and standard radius are made helps fluids go through smoothly. This keeps the system working well. These fittings come in many types. So, they fit the needs of homes, big factories, and other businesses, making sure they are useful and can be trusted.

Superior Corrosion Resistance for Chilean Climates

Chile has the kind of weather that changes a lot, from thick sea air to dry deserts. This can make it tough for piping and the way it works. Hot-dip galvanized elbows are a good answer for this. They have a zinc coat that helps keep out corrosion. This coat protects the elbows from wet air, chemicals, and quick changes in heat.

The hot-dip way makes sure the elbows meet ANSI standards. Because of this, people know they can count on these elbows, even when conditions are hard. You can also get elbows made of stainless steel. These work even better if there is high heat and a lot of pressure.

But these elbows do not just work well. They also help with sustainability. You will not have to replace them as often, so you will use up fewer resources. These elbows last longer, which is good for the earth. This makes them a smart pick for places with harsh weather, and for projects that want to take care of the planet.

Durability Across Industrial and Residential Applications

Hot-dip galvanized elbows are made to be used in many different places. They work well in both industrial settings and at home. They are very strong and last a long time. In places like factories, where you find pvc fittings, these elbows do a great job. They handle high pressure and can stand up to chemicals. This makes sure the system keeps working for a long time.

When these elbows are used in homes, they fit right into plumbing systems and connectors. This helps make your home’s pipes safer and run better. The elbows are made from stainless steel and malleable iron. These good materials help them last for many years.

Making these elbows also focuses on sustainability. They do not wear out quickly, so you do not have to change them often. When used with fasteners and fittings, these elbows work even better. All these things together make them a must-have in many different places and for many types of work.

Types and Specifications of Galvanized Elbows Available in Chile

Hot-dip galvanized elbows come in different types and sizes. You can get them in standard designs or have them made for your own needs. There are different degree elbows like 45° and 90°. This helps you use them in many kinds of piping work and with many kinds of flow directions.

You can also make changes to these fittings. For example, you can pick a standard radius or ask for the size you need. This gives a lot of flexibility to use these elbows for almost any system. They work well for industry, home, and business projects in Chile. This way, you get the right fittings for your job.

Common Angles and Sizes (45°, 90°, Reducers, and More)

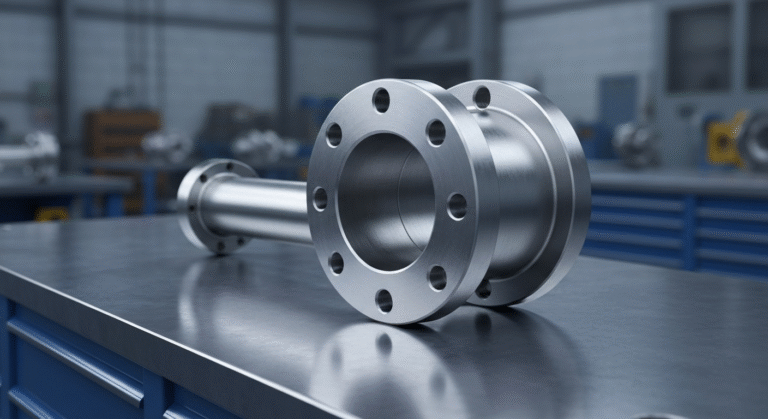

Different angles and sizes of fittings are needed to get the right flow and function in piping systems. The 45° and 90° elbows are two of the most common types. These elbows let the pipe change direction in a good way. Reducers help by joining pipes of different sizes, and they meet standard radius needs. You can make each fitting work for special uses. This helps with sustainability, as these strong designs fight off corrosion. When you use the right elbows and connectors, you improve the strength of the whole system and help it last longer.

Material Standards and Certifications Relevant to Chile

Regulations and certifications help keep hot-dip galvanized elbows safe and reliable in Chile. Meeting ANSI standards is very important. It shows that the elbows follow strict worldwide rules for their materials.

Materials like stainless steel and PVC do well because they last a long time and stand up to chemicals. The key certifications for these products be:

- ISO 9001 for steady and good quality control.

- ANSI B16.3 to show they keep their shape under pressure and heat.

- Environmental Sustainability Standards for green and earth-friendly making.

- FM/UL Certifications to make sure they are safe to use in firefighting.

These rules and certifications show that the elbows will work in tough places. They also show that the makers are thinking about sustainability. This helps people feel good and safe when they choose these products.

Choosing the Right Hot-Dip Galvanized Elbow for Your Project

Finding the right elbow means you need to look at what your piping system needs. Think about customization options, such as what size pipe you have and if it matches the right material for your fluid or gas.

To get the best results, pick from many fittings and connectors made for both home and industrial use. When you get tailored choices, the setup will go more smoothly and can last longer for all kinds of systems.

Factors to Consider: Pressure, Compatibility, and Installation

Choosing the right elbow for the job means you have to look at a few important things so it fits your project’s needs:

- Pressure Requirements: The elbow you pick needs to handle the pressure in the pipeline, no matter if it is low or high.

- Material Compatibility: Stainless steel is a good choice if you are dealing with something that will corrode. PVC works well for water systems.

- Connection Type: Threaded fittings are simple to put in. A welded fitting gives you a seal that will last.

- Size and Radius: The size of the pipe and the bend radius both matter. To keep things running smoothly, these have to match.

- Installation Guidelines: Make sure to use the right mounting steps for these fittings. Doing this is good for performance and can cut down on wear.

When you focus on these points, your piping system will work well and need less fixing or stops. This makes things easier over time.

Tips for Ensuring Long-Term Performance and Safety

Keeping pipeline operations steady depends on good care methods. One key part is dealing with corrosion, most of all in places that get a lot of moisture. Be sure to use stainless steel fasteners to hold elbows in place. This will help your setup last longer.

Doing maintenance checks on a regular basis helps you see any wear and tear before it turns into big repairs. Using materials that last, like stainless steel, can make your pipes stay in good shape for more years and lower harm to the planet.

Safety gets better when you follow the right steps during setup, like making sure connectors are strong. When you pay attention to these things, your pipe system is more likely to work well for a long time.

Conclusion

To sum up, picking the right hot-dip galvanized elbow matters a lot for strong and steady use in many jobs. These parts are made to handle different needs, from better corrosion resistance that suits Chile’s weather to many kinds and specs you can choose from. When you know the main features, the types, and what to look for during setup, you can make good choices. This helps your project work better and keeps it safe. If you use good elbows, you’ll also be sure that you follow rules and your work will last a long time and be strong. If you want to raise your project’s level with the best hot-dip galvanized elbows, contact us and we will help you.

Frequently Asked Questions

What makes hot-dip galvanized elbows suitable for Chile’s environment?

The hot-dip coating gives good corrosion resistance, and this is important in Chile’s many different types of weather. Stainless steel and ANSI standards help these last for a long time, even when there is a lot of moisture or the air is dry. These elbows work well and give strong fittings when you use them in tough places.

Are these elbows compatible with both water and gas pipelines?

Yes, hot-dip galvanized elbows work well with water and gas pipelines. The connectors and PVC fittings help make sure there are no leaks. Using materials like stainless steel makes them fit well with different pressures and types of fluids.

How do I select the correct size and type for my application?

To pick the right elbow, you need to look at the degree elbow angle, the pipe radius, and which way you want the flow to go. Make sure the inch size fits your system. You should also think about customization if you have special needs or the area has different conditions. This will help make sure everything works well.

What certifications should I look for in Chile?

Make sure you follow the rules set by ANSI, ISO 9001, and sustainability certifications. You need to use good materials like stainless steel and PVC because they meet set rules. The right certification shows there is steady quality and that these products can be trusted in many uses.

How long does a hot-dip galvanized elbow typically last?

These elbows last for many years because of the hot dip process and how they resist corrosion. If you do regular maintenance and use good fittings, you can help them last even longer. This is a good way to meet your sustainability goals.