-

Yinzhuang Industrial zone,Mengcun county,Cangzhou city,Hebei province,China

The Ultimate Guide to Carbon Steel Butt Weld Elbows

The Ultimate Guide to Carbon Steel Butt Weld Elbows

Have you ever wondered what keeps industrial piping systems flowing smoothly around corners and bends? Behind every efficient pipeline network lies a critical component that often goes unnoticed: the carbon steel butt weld elbow. These essential fittings might seem simple at first glance, but they represent the culmination of precise engineering, careful manufacturing, and strategic selection that can make or break a piping system’s performance and longevity.

From the standard 3D, 5D, and 7D bend radius specifications to the various manufacturing processes that ensure structural integrity, carbon steel butt weld elbows are far more complex than meets the eye. Whether you’re an engineer designing a new system, a procurement specialist sourcing components, or a maintenance professional troubleshooting issues, understanding these critical connectors is essential for success. The difference between an optimal and suboptimal elbow choice can impact everything from flow efficiency to system lifespan — a distinction that translates directly to your bottom line.

In this comprehensive guide, we’ll explore everything you need to know about carbon steel butt weld elbows, from fundamental types and specifications to selection criteria and best practices for installation and maintenance. By the end, you’ll have the knowledge to make informed decisions that enhance system performance while minimizing costly downtime and replacements. 💪

Understanding Carbon Steel Butt Weld Elbows

A. Definition and basic characteristics

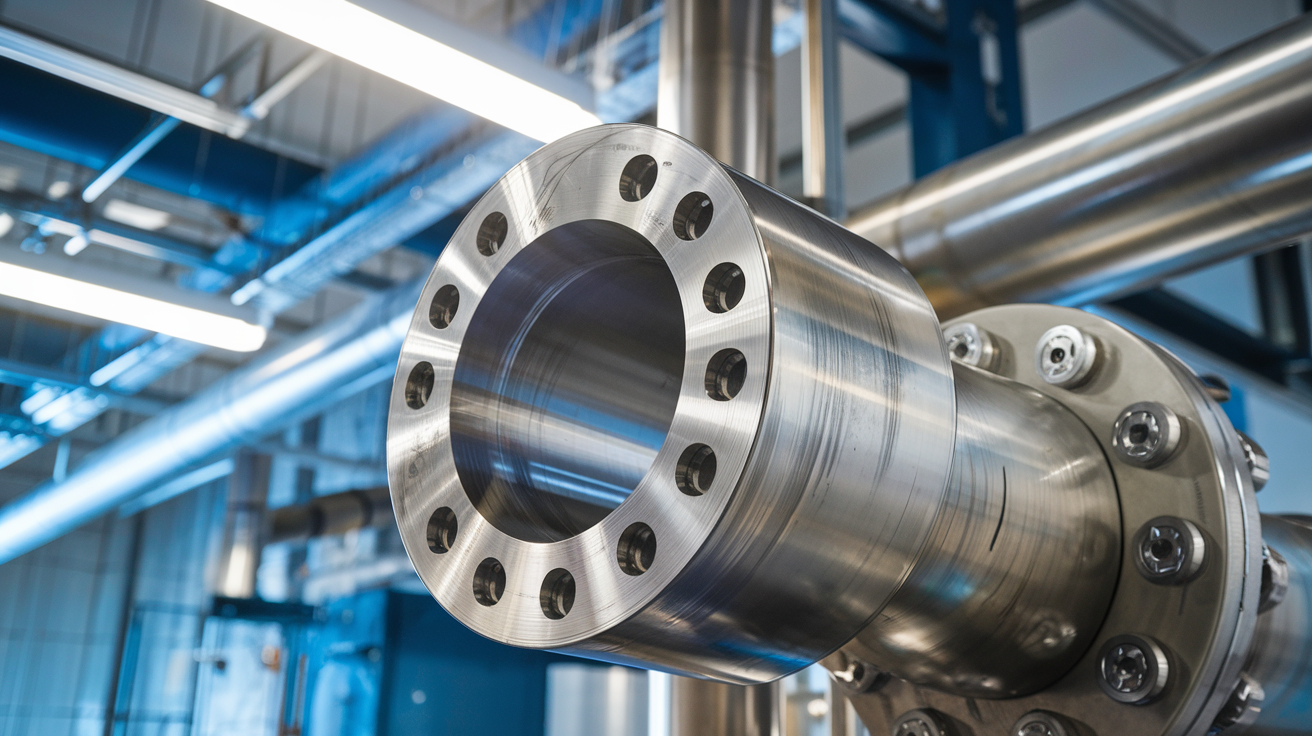

Carbon steel butt weld elbows are pipe fittings designed to change the direction of flow in piping systems. They’re manufactured by forming carbon steel into curved sections with ends prepared for butt welding directly to pipes. Unlike threaded or socket weld fittings, these elbows have no internal threads or sockets – just beveled ends ready for full-penetration welds.

The most common configurations include 45° and 90° bends, with 180° return bends used in specific applications. They come in two standard radius types:

- Long radius (LR): 1.5 times the pipe diameter

- Short radius (SR): 1.0 times the pipe diameter

Carbon steel grades typically used include ASTM A234 WPB, which provides excellent strength and temperature resistance up to 750°F.

B. Common industry applications

These fittings are workhorses in numerous industries:

- Oil and gas: Throughout refineries and pipelines where reliability is non-negotiable

- Power generation: In steam lines and cooling systems where high pressure and temperature handling is crucial

- Chemical processing: Where corrosion resistance matters alongside mechanical strength

- Construction: In HVAC systems and building utilities

- Manufacturing: In process piping systems moving materials through production facilities

They shine in high-pressure, high-temperature applications where welded connections offer superior safety and reliability.

C. Key advantages over other fitting types

Carbon steel butt weld elbows bring serious benefits to the table:

- Superior joint strength: The full-penetration weld creates a joint as strong as the pipe itself

- Leak resistance: No threads or mechanical connections means fewer potential leak points

- Smooth flow path: The seamless interior reduces turbulence and pressure drops

- Space efficiency: Their compact design requires minimal space for installation

- Cost-effectiveness: Despite higher initial costs than threaded options, lifetime value is outstanding

- Longevity: Properly installed butt weld joints routinely outlast other connection types

- Pressure ratings: Can handle significantly higher pressures than comparable flanged or threaded fittings

When system integrity and longevity matter most, nothing beats a properly installed carbon steel butt weld elbow.

Types and Specifications of Butt Weld Elbows

Standard Bend Angles and Configurations

Ever wondered why some elbows turn at 45° while others make a full 90° turn? Carbon steel butt weld elbows come in several standard bend angles to accommodate various piping layouts:

- 90° elbows: The most common configuration, creating a right-angle turn

- 45° elbows: Used for gradual directional changes

- 180° elbows: Also called return bends, creating a U-turn in piping systems

Beyond angles, these fittings are categorized by their radius:

- Long radius (LR) elbows have a center-to-end distance equal to 1.5 times the nominal pipe diameter

- Short radius (SR) elbows measure just 1.0 times the nominal diameter

The choice between LR and SR impacts flow characteristics and pressure drop. Long radius elbows create less turbulence—perfect when smooth flow matters.

Custom and Compound Bend Options

Standard bends not cutting it for your complex piping system? That’s where custom options come in.

Custom carbon steel butt weld elbows can be manufactured with:

- Non-standard angles (22.5°, 60°, or anything in-between)

- Compound bends (multiple angles in a single fitting)

- Specific radius requirements for tight spaces

These custom solutions often solve installation headaches in retrofit projects or cramped industrial settings. While they cost more and have longer lead times, they eliminate the need for multiple standard fittings and reduce potential leak points.

Material Grades and Compatibility

Carbon steel butt weld elbows come in various material grades, each with specific chemical compositions and mechanical properties:

| Grade | ASTM Standard | Common Applications |

|---|---|---|

| A234 WPB | ASTM A234 | General purpose, moderate temperatures |

| A420 WPL6 | ASTM A420 | Low-temperature service |

| A860 WPHY | ASTM A860 | High-yield applications |

Material selection must consider:

- Operating temperature range

- Pressure requirements

- Chemical compatibility with transported fluids

- Cost constraints

Matching your elbow material grade with your piping system ensures long-term reliability and prevents premature failures. Most carbon steel elbows can handle temperatures up to 427°C (800°F), but specific grades push that limit even higher.

Bend Radius Fundamentals

How bend radius is determined

Ever wondered how manufacturers determine the perfect bend for your carbon steel elbow? It’s actually pretty straightforward.

Bend radius refers to the distance from the center of the curve to the centerline of the pipe. This crucial measurement determines how gradually or sharply your piping system changes direction.

The calculation typically follows this formula:

- Bend Radius = Pipe Diameter × D value

For example, if you’re working with a 4-inch pipe and need a 3D bend radius, your calculation would be:

4 inches × 3 = 12 inches bend radius

Pipe wall thickness also plays a major role. Thinner walls allow for tighter bends without compromising structural integrity, while thicker walls might require more gradual bends to avoid material stress and potential failure.

Common specifications (3D, 5D, and 7D)

The industry standard for carbon steel butt weld elbows typically falls into three categories:

| Type | Description | Best For |

|---|---|---|

| 3D | Radius = 3 × pipe diameter | Space-constrained installations, lower flow requirements |

| 5D | Radius = 5 × pipe diameter | Standard industrial applications, balanced flow/space needs |

| 7D | Radius = 7 × pipe diameter | High-flow systems, minimal pressure drop requirements |

3D elbows create a tighter turn, saving space but increasing turbulence. 5D elbows strike a balance between space and flow efficiency. 7D elbows create the most gradual turn, significantly reducing pressure drop and turbulence.

Selecting the appropriate radius for specific applications

Choosing the right bend radius isn’t just about what fits—it’s about what works best for your system.

For high-velocity fluid systems, go with 5D or 7D elbows. The gradual turn minimizes turbulence, reducing wear on pipe walls and extending system life.

Working with thick, abrasive slurries? A 7D elbow dramatically reduces particle impact on the outer radius, preventing premature erosion.

Tight mechanical rooms or congested pipe racks? 3D elbows might be your only option when space is at a premium.

For systems requiring regular pigging or cleaning, larger radius elbows (5D or 7D) allow maintenance equipment to pass through more easily.

Remember that pressure drop increases with tighter bends. In critical applications where system efficiency is paramount, the energy savings from reduced pumping requirements can quickly justify the additional cost of larger radius elbows.

Manufacturing Processes and Quality Standards

Production Methods and Technologies

Ever wondered how those sturdy carbon steel butt weld elbows are made? The manufacturing process isn’t just about bending metal—it’s an art form backed by serious engineering.

Most carbon steel elbows are produced through one of three methods:

Hot forming – Steel is heated to around 2000°F until it’s malleable, then pressed into dies. This creates stronger elbows with uniform wall thickness.

Cold forming – Metal is bent at room temperature using mandrels and pressure. These elbows are precise but may need stress relief after forming.

Forging – Material is hammered or pressed into shape, creating incredibly durable fittings for high-pressure applications.

For those specialized 3D and 5D long radius elbows? They’re typically made with specialized induction bending machines that gradually form the pipe while maintaining wall integrity.

Industry Standards and Compliance Requirements

Think you can just make an elbow any way you want? Think again. These critical components must meet strict standards:

- ASME B16.9 – The bible for butt weld fitting dimensions

- ASTM A234 – Defines material requirements for carbon steel fittings

- API 5L – Essential for pipeline applications

- MSS SP-75 – Covers high-strength carbon steel fittings

Non-compliance isn’t just a paperwork problem—it can lead to catastrophic failures. That’s why reputable manufacturers ensure every batch meets these requirements through rigorous testing.

Quality Assurance Protocols

The difference between a reliable elbow and a future headache comes down to quality control:

Material testing – Chemical composition and mechanical properties are verified before manufacturing begins

NDT (Non-Destructive Testing) – X-ray, ultrasonic, and magnetic particle inspections detect invisible flaws without damaging the product

Hydrostatic testing – Elbows are pressurized beyond their rated capacity to ensure safety margins

Dimensional inspection – Every measurement is checked against specifications, including wall thickness, ovality, and bend radius

Smart buyers always ask for documentation of these tests. MTRs (Material Test Reports) provide full traceability from raw material to finished product—your insurance policy against premature failures.

Selection Criteria for Butt Weld Elbows

System pressure and temperature considerations

Choosing the right carbon steel butt weld elbow starts with understanding your system’s operating conditions. High-pressure systems demand elbows with thicker walls and higher pressure ratings. If your system runs at 1500 PSI, don’t cut corners with components rated for just 1000 PSI.

Temperature is equally critical. Carbon steel behaves differently at various temperatures:

- At extremely high temps (above 800°F), carbon steel can experience creep

- In sub-zero conditions, it becomes more brittle

- Thermal cycling can accelerate wear

The wall thickness calculation isn’t just a suggestion—it’s what keeps your system from failing catastrophically. Schedule 40 might be fine for moderate conditions, but heavy-duty industrial applications often require Schedule 80 or beyond.

Corrosion resistance requirements

Carbon steel butt weld elbows aren’t naturally corrosion-resistant. Without proper consideration, you’ll be replacing them way sooner than planned.

For enhanced corrosion protection, consider:

- Specialized coatings for chemical exposure

- Galvanized options for moisture-prone environments

- Material grade selection based on specific corrosive agents

The reality? Many engineers underestimate environmental factors. That elbow might handle pressure perfectly but fail prematurely if your system carries corrosive materials or operates in humid conditions.

Cost-efficiency and longevity factors

The cheapest elbow rarely saves money long-term. When evaluating cost-efficiency:

| Factor | Impact on Longevity |

|---|---|

| Material grade | Higher carbon content = better wear resistance |

| Wall thickness | Thicker walls extend service life in abrasive applications |

| Manufacturing quality | Poorly made elbows develop weak points quickly |

Installation quality dramatically affects lifespan too. A perfectly specified elbow installed with improper welding techniques might fail within months instead of years.

Smart buyers focus on total ownership cost—including downtime, replacement labor, and potential system damage from failures. Sometimes paying 30% more upfront extends service life by 300%.

Installation and Maintenance Best Practices

Proper Welding Techniques

Getting the weld right on carbon steel butt weld elbows isn’t just about strength—it’s about creating a joint that’ll stand the test of time. First things first: prep work matters. Clean those surfaces until they shine and bevel the edges at the correct angle (typically 37.5°).

When it comes to the actual welding, most pros swear by the GTAW (TIG) method for the root pass. Why? It gives you that clean, precise start that sets up everything else. For the fill and cap passes, SMAW or FCAW work great, especially on thicker walls.

Heat control is critical. Too hot and you’ll warp the elbow; too cool and you’re looking at poor penetration. Maintain your preheat temperatures between 200-300°F for carbon steel, and don’t rush the cooling process.

Remember that tack welds aren’t just temporary—they’re part of your final weld. Make them count.

Testing and Inspection Procedures

You’ve welded your elbow. Now what? Verification is non-negotiable.

Visual inspection comes first—always. Look for undercutting, porosity, or cracks. If something looks off, it probably is.

For critical applications, these tests are worth every penny:

- Radiographic testing (RT): Gives you the full picture of what’s happening inside the weld

- Ultrasonic testing (UT): Perfect for finding those hidden internal defects

- Magnetic particle inspection (MPI): Great for surface and near-surface flaws in your carbon steel joints

- Hydrostatic testing: The ultimate pressure test—typically at 1.5 times the design pressure

Document everything. That inspection report might seem like paperwork now, but it’s gold when system issues pop up later.

Preventative Maintenance Strategies

The best maintenance plan for carbon steel butt weld elbows starts before problems appear. Regular inspection schedules are your first line of defense—check those high-flow and direction-change points at least quarterly.

Wall thickness monitoring is crucial. Use ultrasonic thickness gauges to track erosion patterns, especially at the extrados where wear happens fastest.

Corrosion inhibitors and proper water chemistry management can double your elbows’ lifespan in wet systems. For external surfaces, don’t skimp on protective coatings.

Temperature cycling causes stress. If your system undergoes frequent heating/cooling cycles, increase your inspection frequency accordingly.

Keep a maintenance log for each critical elbow. Pattern recognition in maintenance data can help you predict failures before they happen and optimize replacement schedules.

When you finally need to replace an elbow, always analyze the wear pattern. It tells you whether the issue was installation, material selection, or simply the expected end of service life.

Carbon steel butt weld elbows play a crucial role in modern piping systems, offering reliability and versatility across various industrial applications. As we’ve explored throughout this guide, understanding the types, specifications, bend radius fundamentals, and manufacturing standards is essential for making informed decisions. The selection process must carefully consider factors such as operating conditions, pressure requirements, and system compatibility to ensure optimal performance and longevity.

Proper installation and adherence to maintenance best practices are equally important for maximizing the service life of these components. Whether you’re working with standard 3D, 5D, or 7D bend radiuses or require custom compound bends for complex piping layouts, choosing quality products from reputable manufacturers is paramount. By following the guidelines outlined in this comprehensive resource, you’ll be well-equipped to navigate the technical considerations and make sound choices for your specific piping system requirements.