-

Yinzhuang Industrial zone,Mengcun county,Cangzhou city,Hebei province,China

The Ultimate Guide to Black Paint Carbon Steel Elbows

The Ultimate Guide to Black Paint Carbon Steel Elbows

In the world of industrial piping systems, black paint carbon steel elbows stand as unsung heroes – critical components that ensure the smooth flow of fluids while maintaining structural integrity under demanding conditions. Whether you’re an engineer working on a complex pipeline project or a contractor seeking the right fittings for your installation, understanding these essential connectors can mean the difference between a system that thrives for decades and one that fails prematurely. With standards like ASME B16.9 governing their production and sizes ranging from NPS 1/2″ to a massive 48″, these versatile components deserve closer examination.

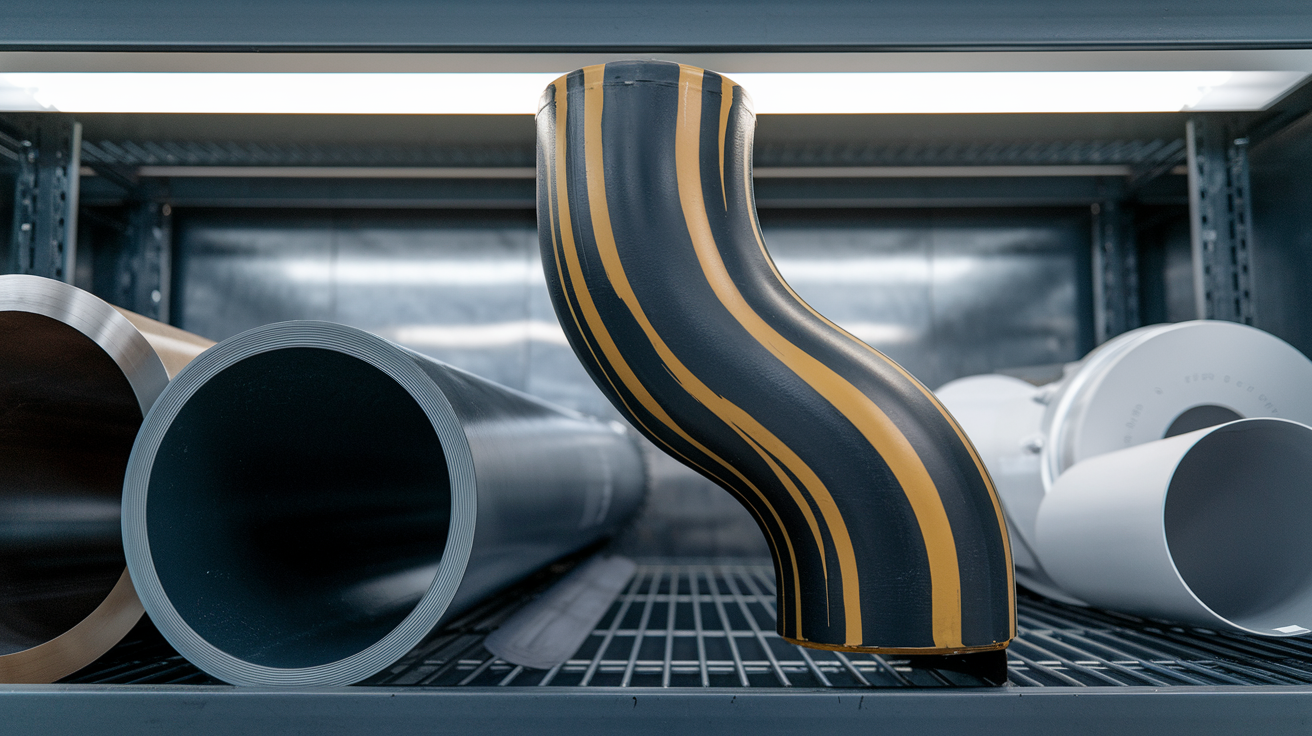

Why should you care about the finer points of black paint carbon steel elbows? Because choosing the wrong specification, material grade, or surface treatment can lead to costly failures, unexpected maintenance, and even safety hazards. The black paint coating isn’t just for aesthetics—it provides crucial protection against corrosion, extending service life and maintaining system efficiency. From ASTM A234 WPB for moderate temperature applications to specialized coatings for underground systems, the choices may seem overwhelming but are essential to get right.

In this comprehensive guide, we’ll walk you through everything you need to know about black paint carbon steel elbows, from basic understanding of carbon steel properties to installation best practices. We’ll explore the various types, specifications, protective coatings, and selection criteria that will empower you to make informed decisions for your specific applications. Let’s dive into the world of these critical piping components and discover how to maximize their performance in your systems.

Understanding Carbon Steel Elbows

Understanding Carbon Steel Elbows

What are carbon steel elbows and their primary standards

Carbon steel elbows are essential pipe fittings designed to change the direction of fluid flow in piping systems. These components are governed by specific industry standards that ensure consistent quality and performance. The primary standards for carbon steel elbows include ASME B16.9 and SH3408, which define specifications for dimensions, tolerances, and testing requirements. These fittings are available in various sizes ranging from NPS 1/2″ to 48″ and come in different schedules including Sch 20, 40, and XXS to accommodate different pressure requirements.

Key material grades: ASTM A234 WPB and A420 WPL6

Two primary material grades dominate the carbon steel elbow market:

ASTM A234 WPB: This is the most commonly used grade for general-purpose applications. It offers excellent weldability and strength properties suitable for moderate temperature services.

ASTM A420 WPL6: Specifically designed for low-temperature applications, this grade provides enhanced toughness and impact resistance in cryogenic conditions.

These grades are manufactured to precise specifications to ensure reliability in various industrial applications, from oil and gas to manufacturing and chemical processing facilities.

Chemical composition and temperature service capabilities

The performance of carbon steel elbows is directly related to their chemical composition:

ASTM A234 WPB has a chemical composition that typically includes:

- Carbon: 0.30% max

- Manganese: 0.29-1.06%

- Phosphorus: 0.050% max

- Sulfur: 0.058% max

- Silicon: 0.10% min

This composition provides ASTM A234 WPB elbows with temperature service capabilities ranging from moderate to high temperatures.

ASTM A420 WPL6 contains controlled amounts of alloying elements that enhance its low-temperature performance. It’s specifically engineered for services that operate below ambient temperatures, maintaining structural integrity and preventing brittleness in cryogenic environments.

Carbon steel, characterized by its high carbon content, offers increased strength and hardness compared to other alloy steels, though with somewhat reduced plasticity. This makes carbon steel elbows particularly suitable for high-pressure applications where structural integrity is paramount.

Now that we have covered the fundamentals of carbon steel elbows, including their standards, key material grades, and temperature service capabilities, we’ll explore the various types and specifications of black paint carbon steel elbows in the next section.

Types and Specifications of Black Paint Carbon Steel Elbows

Types and Specifications of Black Paint Carbon Steel Elbows

Now that we understand the fundamentals of carbon steel elbows, let’s explore the various types and specifications available in the market for black paint carbon steel elbows.

A. Long radius vs. short radius elbows

Carbon steel elbows are primarily categorized into two types based on their bend radius:

Long radius elbows: These have a center line radius that is 1.5 times the nominal pipe size (NPS). Long radius elbows are available in both 90-degree and 45-degree configurations, making them versatile for various piping layouts. They provide smoother fluid flow with less turbulence and pressure drop, making them ideal for high-flow applications.

Short radius elbows: These feature a center line radius equal to the nominal pipe size (NPS). Short radius elbows are typically only available in 90-degree configurations. They are more compact and require less space for installation, making them suitable for areas with space constraints.

B. Size ranges and schedules available

Black paint carbon steel elbows adhere to industry standards such as ASME B16.9 and SH3408, and are available in a wide range of sizes and wall thicknesses:

- Size range: Typically available from NPS 1/2″ (DN 15) to NPS 48″ (DN 1200)

- Schedule options: Common schedules include:

- Schedule 20

- Schedule 40

- Schedule 80

- Schedule 160

- Schedule XXS (Extra Extra Strong)

The schedule number refers to the wall thickness of the elbow, with higher numbers indicating thicker walls suitable for higher pressure applications.

C. Dimensional specifications and configurations

Carbon steel elbows conform to specific dimensional standards to ensure compatibility across piping systems:

- Standard angles: 90-degree and 45-degree are the most common configurations

- Connection types:

- Butt weld (most common for carbon steel elbows)

- Socket weld

- Threaded connections

Butt weld carbon steel elbows have specific dimensional requirements based on their nominal diameter. For example:

| Nominal Diameter (DN) | NPS | Outside Diameter at Bevel (mm) |

|---|---|---|

| 15 | 1/2″ | 21.3 |

| 50 | 2″ | 60.3 |

| 100 | 4″ | 114.3 |

| 200 | 8″ | 219.1 |

| 400 | 16″ | 406.4 |

Carbon steel elbows are manufactured through two primary methods: welding polygonal shells that transform into tubular shapes under pressure, or by heating and molding seamless or welded pipes into the desired elbow configuration.

With the types and specifications of black paint carbon steel elbows covered, we’ll next explore the various surface treatments and protective coatings that enhance their durability and performance in different environments.

Surface Treatments and Protective Coatings

Surface Treatments and Protective Coatings

Now that we’ve explored the types and specifications of black paint carbon steel elbows, let’s examine the critical protective coatings that extend their service life and enhance performance in various environments.

Black paint application process and benefits

Black paint coating for carbon steel elbows represents one of the most common protective treatments in the industry. The application process involves carefully cleaning the steel surface before applying specialized anti-corrosion paint formulations. This coating creates a protective barrier that significantly enhances the elbow’s resistance to environmental factors and chemical exposure.

The benefits of black paint coatings are substantial, especially considering that a 2016 NACE International study estimated global corrosion costs at approximately $2.5 trillion. By implementing proper black paint treatments, industries can substantially reduce these costs while extending the operational life of their pipe systems.

Alternative coatings: polyethylene and galvanizing

While black paint remains popular for carbon steel pipe fittings, alternative protective coatings offer specific advantages for particular applications:

Zinc metal plating (galvanizing): This highly effective method creates a protective zinc patina that significantly enhances the steel elbow’s resistance to corrosion and wear. Galvanized carbon steel elbows perform exceptionally well in outdoor and high-moisture environments.

Nickel electroplating: This treatment improves both hardness and corrosion resistance of carbon steel elbows, making it particularly valuable for industrial pipe fittings used in injection molding and other demanding applications.

Electroless nickel plating: Using a chemical process rather than electricity, this method creates a uniform anti-corrosive coating ideal for precision components in high-stress environments.

Corrosion resistance properties compared to other steel types

Carbon steel elbows with protective coatings offer varying degrees of corrosion resistance compared to other steel types:

Unlike stainless steel, which naturally forms a passive oxide layer, carbon steel fittings rely entirely on their protective coatings for corrosion resistance. The effectiveness of these coatings varies by application:

- Black paint carbon steel elbows provide good general protection but may require more frequent maintenance than specialized coatings.

- Hard chrome plating enhances natural corrosion resistance while providing superior wear protection, particularly valuable in automotive applications.

- Proprietary hard chrome impregnation processes can further increase wear resistance and lubricity, ensuring components are protected from various types of corrosion.

Selecting the appropriate protective coating for carbon steel elbows depends on the specific environmental conditions, chemical exposure, and operational stresses they will encounter. The right combination of steel specifications and protective treatments ensures optimal performance across diverse sectors, including medical, automotive, and chemical industries.

With this understanding of surface treatments and protective coatings, we can now explore the various applications and uses of black paint carbon steel elbows across different industries.

Applications and Uses

Applications and Uses

Now that we have explored the various surface treatments and protective coatings for carbon steel elbows, it’s important to understand where these specialized fittings are actually deployed in real-world scenarios.

A. Industrial piping systems and environmental remediation

Black paint carbon steel elbows play a crucial role in industrial piping systems across numerous sectors. With a global carbon steel market valued at over $880 billion in 2019 and projected growth through 2027, these components have become indispensable in modern industrial infrastructure.

Carbon steel elbows are extensively utilized in oil and gas pipelines, where their strength and durability allow them to withstand high pressures and extreme temperatures. Their corrosion resistance properties, enhanced by protective coatings, make them ideal for environmental remediation projects where exposure to harsh chemicals and elements is common.

HVAC systems also rely heavily on carbon steel pipe fittings, with both 90-degree and 45-degree elbows facilitating the necessary directional changes in complex industrial ventilation networks. The rigorous quality checks during manufacturing ensure these components maintain efficient and reliable performance in critical industrial applications.

B. Gas and water distribution networks

Carbon steel elbows are fundamental components in gas and water distribution infrastructure. Both long radius and short radius elbows serve specific purposes in these networks:

- Long radius elbows (with center-to-end distance 1.5 times the nominal pipe size) are preferred for gas and water systems where flow efficiency is paramount, such as connections to pumps and valves.

- Short radius elbows prove valuable in confined spaces within distribution networks, providing the same directional change capability in a more compact design.

These fittings come in various connection styles including socket weld, butt weld, and threaded options, allowing engineers to select the most appropriate joining method for specific distribution system requirements.

C. Construction and structural applications

The construction industry represents one of the largest markets for carbon steel elbows. These components are integral to building steel frames, fixture installations, and comprehensive piping systems throughout modern structures.

Low carbon steel elbows are particularly favored in construction applications due to their excellent ductility while still meeting structural requirements. Custom sizes and angles, such as 60° and 120° elbows, can be manufactured to address particular construction challenges where standard 90-degree or 45-degree bends are insufficient.

The sustainable nature of carbon steel also makes these elbows increasingly popular in eco-conscious construction projects, as the material is highly recyclable, aligning with green building initiatives.

With these diverse applications in mind, next we’ll examine the critical selection criteria for carbon steel elbows, helping you determine which specifications and features are most important for your specific project requirements.

Selection Criteria for Carbon Steel Elbows

Selection Criteria for Carbon Steel Elbows

Now that we’ve explored the various applications and uses of black paint carbon steel elbows across industries, it’s crucial to understand how to select the right elbow for your specific requirements. Making an informed choice ensures optimal performance, longevity, and cost-effectiveness of your piping system.

A. Size and schedule considerations

When selecting carbon steel elbows, pipe diameter is a primary consideration that directly impacts flow rates and system efficiency. The proper sizing of elbows must align with the connected pipes to maintain consistent fluid transfer throughout the system. Schedule refers to the wall thickness of the elbow, which varies according to industry standards.

For carbon steel elbows, common schedules include:

- Schedule 40 for standard applications

- Schedule 80 for higher pressure requirements

- Schedule 160 for extreme pressure scenarios

The choice between long radius elbows (with a radius 1.5 times the pipe diameter) and short radius elbows (with a radius equal to the pipe diameter) depends on space constraints and flow requirements in your piping system.

B. Thickness and pressure ratings

Thickness selection directly correlates with the pressure rating needed for your application. Higher pressure systems require thicker-walled carbon steel elbows to withstand operational stresses. When evaluating pressure ratings:

- High-carbon variants provide superior tensile strength, making them suitable for high-pressure scenarios common in oil and gas applications

- Low-carbon options offer greater malleability for low-pressure uses

- Environmental conditions and operational temperatures must be factored into pressure rating calculations

Proper thickness selection ensures that the elbow can withstand both internal pressure from fluid flow and external stresses from installation and environmental factors.

C. Cost-effectiveness compared to alternatives

When evaluating the economic aspects of carbon steel elbows with black paint coating, consider:

- Initial investment versus long-term durability

- Maintenance requirements and associated costs

- Installation complexity and labor requirements

- Performance under specific operational conditions

Carbon steel elbows often represent a balance between cost and performance, particularly when compared to more expensive alternatives like stainless steel or alloy fittings. The black paint coating adds corrosion resistance, potentially extending service life and reducing replacement frequency in various industrial environments.

With these selection criteria in mind, the next section will explore installation and maintenance best practices to ensure your carbon steel elbows perform optimally throughout their service life.

Installation and Maintenance Best Practices

Installation and Maintenance Best Practices

Now that we’ve explored the selection criteria for carbon steel elbows, it’s essential to understand how to properly install and maintain these critical piping components. Proper installation and maintenance not only extend the service life of black paint carbon steel elbows but also ensure the integrity and safety of your entire piping system.

Proper Welding Techniques for Carbon Steel

When installing carbon steel pipe fittings, adhering to proper welding protocols is crucial:

- Surface Preparation: Ensure all surfaces are clean and free from contaminants before welding

- Preheat Requirements: Carbon steel elbows often require preheating to prevent thermal stress

- Weld Sequencing: Follow appropriate sequencing to minimize distortion

- Post-Weld Treatment: Implement proper cooling procedures to maintain structural integrity

Industrial pipe fitting installation requires qualified welders who understand the specific requirements of carbon steel materials. This helps prevent issues like thermal expansion that can compromise the integrity of your piping system.

Preventing Rust and Oxidation

Black paint carbon steel elbows come with a protective coating, but additional measures may be necessary:

- Maintain Protective Coatings: Regularly inspect and touch up the black paint coating when needed

- Environmental Protection: Install in environments that minimize exposure to corrosive elements

- Cathodic Protection: Consider implementing cathodic protection systems for underground installations

- Proper Drainage: Ensure systems are designed to prevent water accumulation

Protective coatings for steel elbows provide the first line of defense against corrosion, but routine inspection remains essential for early detection of coating failures.

Long-term Maintenance Requirements

To ensure the longevity of your carbon steel pipe connections:

- Regular Inspection Schedule: Establish routine inspection protocols to check for signs of wear, corrosion, or coating breakdown

- Documentation: Maintain detailed records of installation dates, maintenance activities, and observations

- Cleaning Procedures: Develop appropriate cleaning procedures that won’t damage protective coatings

- Replacement Planning: Monitor component condition to plan for timely replacements before failures occur

With proper installation techniques and consistent maintenance practices, black paint carbon steel elbows can provide reliable service throughout their expected lifespan, maximizing your investment and ensuring system safety and efficiency.

Conclusion

Black paint carbon steel elbows represent a crucial component in various piping systems, offering exceptional durability and performance across multiple industries. As we’ve explored throughout this guide, these fittings adhere to strict standards like ASME B16.9, come in various configurations including long radius (90° and 45°) and short radius (90°) options, and feature protective coatings that significantly extend their service life. The black paint surface treatment specifically provides cost-effective rust protection that maintains structural integrity even in challenging environments.

When selecting carbon steel elbows for your applications, remember to consider the specific requirements of your project, including temperature ratings, pressure classifications, and environmental conditions. Proper installation and regular maintenance are essential to maximize the lifespan and performance of these components. With the right knowledge about specifications, surface treatments, and best practices covered in this guide, you can make informed decisions that ensure reliability and efficiency in your piping systems for years to come.