-

Yinzhuang Industrial zone,Mengcun county,Cangzhou city,Hebei province,China

T de acero al carbono: Tipos y aplicaciones en tuberías

Key Highlights

- Carbon steel tees are reliable pipe accessories, offering excellent durability, resistance, and performance in demanding applications.

- They are widely used in industries like petrochemical plants, power stations, and construction projects to effectively manage fluid or gas flow.

- Various types of tees, including equal tees and reducing tees, cater to different piping system requirements.

- Strict manufacturing standards like ASME and ANSI ensure quality and compatibility with global systems.

- The production process involves robust techniques such as forging and butt welding for optimum strength.

- Carbon steel tees can be customised in sizes, finishes, and grades to suit specific needs and operational demands.

Introduction

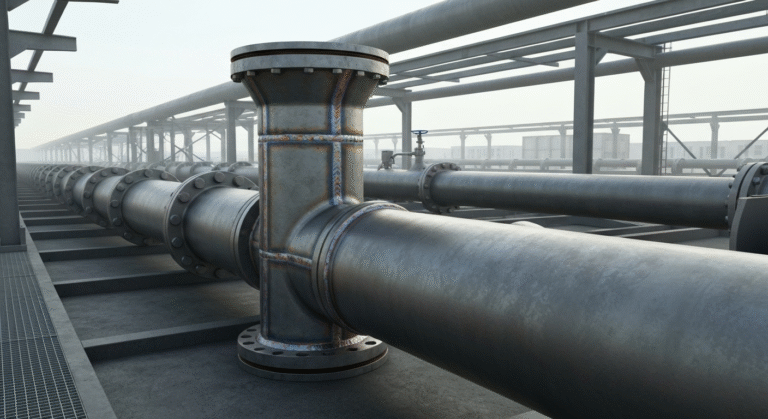

Carbon steel tees, also called “tee acero carbono,” are very important in many industrial piping systems. Made from high-quality acero carbono, these fittings help with smooth and strong connections. They let people move fluids, gases, or even thick liquids without trouble. You can find a tee like this in petrochemical plants and also in places that treat wastewater with a specific cantidad. The strong and flexible design of tee acero carbono makes it great for many types of work. This flexibility and strength let the tee acero carbono fit the needs of different industries, while still giving long-lasting and good results.

Características del acero al carbono para tuberías

Carbon steel, also known as “acero carbono,” is known for being very strong and lasting a long time when used in pipes. This type of steel can handle a lot of stress from the environment and can take on a lot of hard use without breaking. That is why many industries pick “acero carbono” when they need strong and reliable parts. It does a good job with high pressure and changing temperatures, so work goes ahead smoothly and does not stop, even when things get tough.

Also, “acero carbono” is a good choice because it saves money while still being very strong. The tough build of this steel, and how well it fits in with many pipe systems, means you get good quality and dependability. This makes things safer for people and helps the system last for many years.

Composición química y propiedades mecánicas

The chemical makeup of carbon steel, or “acero carbono,” has carbon, manganese, phosphorus, and sulphur but in set ranges. The amount of carbon in the steel makes a big difference in how strong and hard it will be. Manganese makes the steel more sturdy when it is under heavy use. These levels are checked and set by rules so that each industry can get what they need when working with fluids or gases.

Mechanical properties like tensile and yield strength show if the steel can deal with a lot of force or pressure. One example is ASTM A234 WPB, which can be used for both medium and high heat. It is very strong and does not wear out easily. Because of these things, “acero carbono” is chosen for important jobs where you need to trust the steel.

There are a lot of grades for this steel, such as WPL6, which can be used at low temperatures. When you pick the right grade, it helps people get the job done right, no matter if it is in the cold or in pressured plants. The way “acero carbono” comes in these many types shows how flexible and useful this steel is for different pipe fittings.

Ventajas del uso de acero al carbono en sistemas de tuberías

Carbon steel has many benefits, so it is a great choice for piping systems. It is strong and holds up well, even when there is high pressure or heat. Many industries use “acero carbono” because it is a good value for the money and it lasts for a long time.

- The material is strong, so it helps keep chemical and oil refineries safe.

- It handles changes in heat, which is why power and energy companies use it.

- You can get it in different sizes and types, so it works for systems here and around the world.

- Its smooth inside and tight joins help the fluid move easily.

Also, “acero carbono” works well with many welding methods. This makes it easy to use in different systems. Because it works so well and can fit in with other materials, it is often used in today’s piping systems for many industries.

Tipos de T de acero al carbono

Carbon steel tees, known as “tee acero carbono,” are made in different types for different pipe setups. Equal tees have the same diameter on all sides, so the fluid or gas moves evenly. Reducing tees help change the flow size, which is good for systems that need that kind of choice.

These piping parts help things run smoothly in places like waste sites and chemical plants. There are also many grades and finishes for “tee acero carbono” fittings, so they can fill many industrial needs and still work really well.

T igual (Tee recta)

La tee recta o t igual se usa mucho en sistemas de tuberías. Este accesorio, como el codo de acero, facilita la unión de tuberías en ángulos de 90 grados. La tee suele estar fabricada en acero al carbono, lo que le da buena resistencia y durabilidad. El diseño de la tee hace que el proceso de soldadura sea más fácil, ayudando a unir diferentes piezas de tubería. Es ideal para aplicaciones donde es importante mantener un mismo diámetro en todo el sistema. Gracias a esto, la tee recta se ve como una opción confiable y versátil para la construcción de tuberías que llevan fluidos.

T reducida (Reducing tee)

La t reducida, también conocida como tee reductora, es un accesorio clave en los sistemas de tuberías. Se usa para unir tuberías que tienen diferentes diámetros. Esta pieza tiene una forma especial que ayuda a que los fluidos pasen sin problemas de un tubo a otro. Así, el flujo es mejor y hay menos resistencia.

Normalmente, está hecha de acero carbono. Este material da mucha durabilidad y buena resistencia, por lo que funciona bien bajo varias condiciones. En el proceso de soldadura, el cuello de soldadura hace que la unión sea fuerte y estable. Esto es muy importante para mantener seguro todo el sistema. Por estas razones, la tee reducida es muy usada en aplicaciones industriales.

Proceso de fabricación de las T de acero al carbono

The way carbon steel tees are made starts with choosing the right raw materials. People use either seamless or welded steel for this work. After that, they use steps like forging and heating. This helps make the tee strong.

Each tee goes through testing. It gets certifications so that it is safe and works well in any place in the world. The proceso includes things such as welding and coating, based on what you need it for. These steps help make sure you get good quality accesorios that are ready for use in big industries.

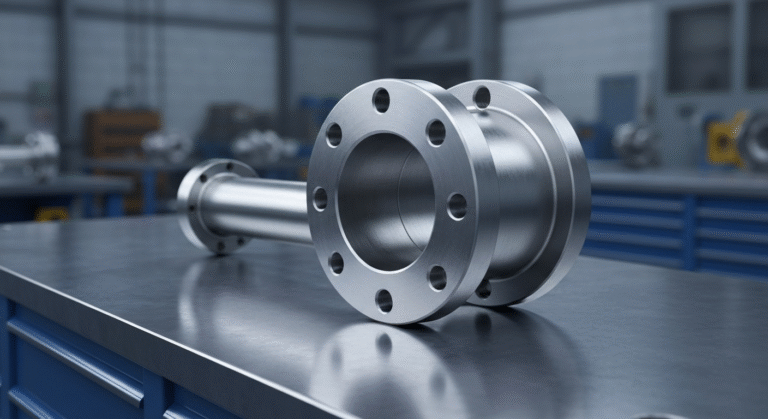

Forjado y soldadura a tope

Forging is key in the “proceso de soldadura” because it helps shape raw steel into tough tee fittings by using heat and pressure. This step makes sure that every fitting has the same quality. The pipe flow stays smooth and steady because of this process.

Butt welding, also called “soldadura a tope,” is used to join tee fittings to pipes without gaps. The “cuello de soldadura” shape helps the fittings line up right, which cuts down on turbulence and gives better safety when in use. Welding makes each seal tight and each joint strong. This matters a lot when systems need to handle high pressure.

Good “soldar” methods meet top global standards, like ANSI B16.9 and ASME B16.28. These ways of doing the work give more trust that every product will last, even when it goes through different tough environments. This makes each structure built in this proceso strong and reliable.

Normas y certificaciones aplicables en Chile

In Chile, carbon steel tees in manufacturing are made using world-recognized standards called “normas” like ASME and ANSI. These rules make sure the parts fit together in different industries.

Certifications show that these fittings meet high demands for “calidad.” This means they last long and work well. Some well-known normas are ANSI B16.9 and B16.11, made for jobs that need accuracy and strong systems.

Sticking to the right “materiales” and standards like ansi lets local industries use top-quality piping. This also helps the products stay good and reliable for a long time.

Conclusion

En resumen, las T de acero al carbono son muy importantes en sistemas de tuberías. Esto se debe a que tienen mucha resistencia y duran bastante tiempo. Su composición química, y los diferentes tipos que hay, hacen que cada parte de estas piezas sea clave en el uso de las mismas. Así sea que uses T igual o T reducida, es bueno saber para qué sirven y cómo se hacen para escoger la mejor para tu trabajo. También, es importante que conozcas las normas y certificaciones que existen en Chile para asegurarte de usar productos de calidad. Si quieres saber más sobre este tema o necesitas ayuda personalizada, puedes contactarnos para recibir una consulta gratis.

Frequently Asked Questions

¿Cuáles son los principales usos de la T de acero al carbono en tuberías?

A “tee acero carbono” is mostly used to move fluids in places like oil refineries, gas plants, and chemical plants. This tee helps direct the flow the right way at many work sites. It is an important piece to make sure things go well and keep the work steady. People trust the tee acero carbono when they need to change the path of fluids in these areas. The use of acero and carbono makes the product strong for many jobs.

¿Qué diferencias existen entre una T igual y una T reducida?

An equal tee has pipe openings that are all the same size. A reducing tee has one branch that is a different size. This helps with changing how much liquid or gas moves through it. For “ejemplo,” you use an equal tee when you want the flow to stay the same in all directions. Reducing tees are good in systems where there are different “cantidades” in each line.

¿Cómo se determina la calidad de una T de acero al carbono?

The quality of a producto such as a carbon steel tee depends on how well it meets normas like ANSI B16.9. Certifications check the steel grade and make sure the producto will work well for different uses. This helps you know that the tee is good and will be strong enough for the job. For inquiries, you can also consult for prices by WhatsApp.

¿Son compatibles las T de acero al carbono con otros materiales de tubería?

“Tee acero carbono” works well with other materials, like “acero inoxidable” and “aluminio.” The good “compatibilidad” of these materials helps the system. It lets you use parts made from different things and makes sure they fit together without any problems.

¿Qué mantenimiento requieren las T de acero al carbono en instalaciones industriales?

Carbon steel tees do not need a lot of “mantenimiento.” You only have to check for things like rust or any wear in the joints. The “durabilidad” of these tees is very good. They last a long time even in tough “instalaciones.” This means you can keep the costs under “cuenta” over time.