-

Yinzhuang Industrial zone,Mengcun county,Cangzhou city,Hebei province,China

Stainless Reducer vs. Carbon Steel: Which is Better?

Stainless Reducer vs. Carbon Steel: Which is Better?

Ever found yourself staring at two seemingly similar metal components, wondering which one would serve your project better? You’re not alone. The debate between stainless steel and carbon steel continues to challenge engineers, manufacturers, and DIY enthusiasts alike. With critical factors like corrosion resistance, strength, and cost all hanging in the balance, making the wrong choice could mean the difference between a project that lasts decades and one that fails prematurely. 💡

In harsh environments where moisture is prevalent, stainless steel’s chromium-rich composition creates a protective oxide layer that shields against rust and corrosion. Meanwhile, carbon steel boasts superior hardness and tensile strength when properly heat-treated, often at a more budget-friendly price point. But which truly delivers better value? The answer isn’t as straightforward as you might think. The perfect choice depends on your specific application requirements, maintenance commitment, and operating conditions.

In this comprehensive guide, we’ll dissect the fundamental differences between these two materials, analyzing everything from corrosion resistance and durability to edge retention and maintenance requirements. By the time you finish reading, you’ll have the knowledge to confidently select the right material for your specific needs – whether you’re working on industrial piping, manufacturing tools, or constructing durable infrastructure. Let’s settle this metal matchup once and for all! 🔍

Understanding the Fundamental Differences

Understanding the Fundamental Differences

A. Composition: Carbon Steel vs. Stainless Steel

The fundamental distinction between carbon steel and stainless steel lies in their chemical composition. Carbon steel primarily consists of iron and carbon, with carbon content ranging from 0.05% to 2.5%. This carbon content significantly influences the material’s strength and hardness properties. Higher carbon percentages generally result in increased hardness but decreased ductility.

In contrast, stainless steel is an iron alloy containing a minimum of 10.5% chromium. This critical chromium content creates a protective oxide layer on the material’s surface, giving stainless steel its signature corrosion resistance. Many stainless steel variants also contain nickel, which further enhances their durability and corrosion-resistant properties.

B. Manufacturing Processes and Classifications

Both carbon steel and stainless steel are classified based on their composition and manufacturing methods.

Carbon steel is categorized into three main types based on carbon content:

- Low carbon steel: Contains up to 0.3% carbon, offering high ductility but low hardness

- Medium carbon steel: Contains 0.3% to 0.6% carbon, providing a balance of strength and toughness

- High carbon steel: Contains 0.6% to 2% carbon, delivering high hardness but reduced ductility

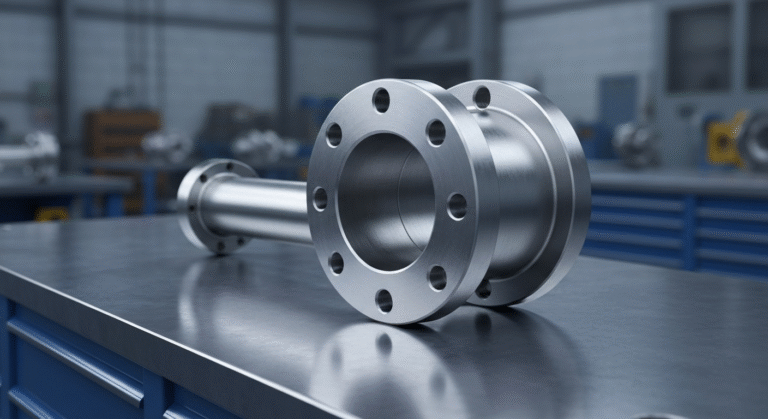

Stainless steel reducers, like other stainless steel components, are typically manufactured using various welding techniques. The production of forged parts employs both cold and hot forming processes, with the ‘Outer Die Method’ being particularly popular. In this method, pipe sections are cut and then pressed within an outer die, with one end compressed to achieve the desired reduced diameter—a technique especially effective for small and medium-sized reducers.

C. Key Physical Properties That Impact Performance

The physical properties of carbon and stainless steel significantly affect their performance in various applications:

| Property | Carbon Steel | Stainless Steel |

|---|---|---|

| Strength | High tensile strength, especially in high-carbon variants | Good strength with superior ductility and toughness |

| Hardness | Increases with carbon content | Varies by type, with martensitic (high-carbon) stainless steels offering highest hardness |

| Ductility | Decreases as carbon content increases | Generally higher than carbon steel |

| Weight | Similar density to stainless steel | Similar density to carbon steel |

| Thermal properties | Different thermal expansion rate than stainless steel | Different thermal expansion rate than carbon steel |

The differing thermal expansion rates between carbon and stainless steel create challenges when welding these materials together. Their differences in electrical conductivity also contribute to potential structural failures in welded joints if proper techniques and materials aren’t employed.

Now that we have covered the fundamental differences between carbon steel and stainless steel reducers, we’ll examine perhaps the most critical factor in choosing between these materials: corrosion resistance. This characteristic often becomes the deciding factor in many industrial applications where environmental conditions play a significant role.

Corrosion Resistance: The Critical Factor

Corrosion Resistance: The Critical Factor

Now that we’ve explored the fundamental differences between stainless reducers and carbon steel, let’s examine one of the most crucial distinctions between these materials: their resistance to corrosion.

Why Carbon Steel Rusts and How to Prevent It

Carbon steel, composed primarily of iron with 0.05% to 2.1% carbon, is inherently susceptible to rust when exposed to moisture. Unlike its stainless counterpart, carbon steel lacks the natural protection against oxidation. When carbon steel comes into contact with oxygen and moisture, it oxidizes and deteriorates into iron oxide, commonly known as rust.

To prevent corrosion in carbon steel:

- Regular application of protective coatings

- Proper storage in dry environments

- Application of specialized anti-rust treatments

- Routine maintenance checks

Despite these preventative measures, carbon steel will always require more attention to maintain its integrity compared to stainless steel, especially in humid or wet environments. This maintenance necessity significantly impacts its long-term cost and practical applications.

Stainless Steel’s Chromium Oxide Layer Protection

The defining characteristic of stainless steel is its minimum chromium content of 10.5%. This chromium forms a remarkable passive layer of chromium oxide on the surface of the metal. This invisible protective barrier is what gives stainless steel its signature corrosion resistance.

The chromium oxide layer:

- Self-repairs when damaged

- Prevents oxygen from reaching the underlying metal

- Forms spontaneously in the presence of oxygen

- Provides continuous protection without additional treatments

This natural protection mechanism is why stainless steel can maintain its appearance and structural integrity even in challenging environments where carbon steel would quickly deteriorate.

Performance in Different Environmental Conditions

Environmental factors significantly influence how these materials perform over time:

Moisture and Humidity:

- Carbon steel rapidly corrodes in high-moisture environments

- Stainless steel maintains integrity even in humid conditions

Temperature Variations:

- Carbon steel can experience accelerated corrosion at elevated temperatures

- Stainless steel remains stable across a wider temperature range

Chemical Exposure:

- Carbon steel is highly reactive to many chemicals

- Stainless steel offers superior resistance to chemical corrosion

Marine Environments:

- Carbon steel requires extensive protection in saltwater environments

- Stainless steel (particularly higher grades) can withstand salt exposure

Industrial Settings:

- Carbon steel may deteriorate quickly when exposed to industrial pollutants

- Stainless steel provides reliable performance in harsh industrial conditions

In environments requiring hygiene and cleanliness, such as food processing or medical applications, stainless steel is overwhelmingly preferred due to its corrosion resistance, which prevents contamination and makes cleaning easier.

With this comprehensive understanding of corrosion resistance between these materials, we’ll next examine their strength and durability characteristics to help determine which material might be better suited for specific applications.

Strength and Durability Comparison

Strength and Durability Comparison

Now that we’ve explored the critical factor of corrosion resistance, let’s delve into how stainless reducers and carbon steel compare in terms of strength and durability—attributes that significantly impact their performance in various applications.

Tensile Strength and Hardness Variations

Carbon steel generally exhibits superior tensile strength and hardness compared to stainless steel, making it particularly suitable for heavy-duty applications. The strength characteristics of carbon steel are primarily determined by its carbon content, which ranges from 0.05% to 2.0%. Higher carbon content typically results in greater hardness and strength. Carbon steel is classified into three categories based on carbon content:

- Low carbon steel (0.05%-0.25%): More malleable but less strong

- Medium carbon steel (0.26%-0.60%): Balanced strength and workability

- High carbon steel (0.61%-2.1%): Maximum strength and hardness

Carbon steel’s impressive strength properties are further enhanced through processes like quenching and work hardening, contributing to its high fatigue strength and making it ideal for structural applications where load-bearing capacity is paramount.

Stainless steel, while generally not as strong as carbon steel, still offers considerable strength depending on its specific type. Among the five types of stainless steel—austenitic, ferritic, martensitic, duplex, and precipitation-hardened—certain varieties like martensitic and precipitation-hardened stainless steels can achieve significant hardness levels.

Heat Resistance and High-Temperature Stability

Stainless steel significantly outperforms carbon steel in terms of heat resistance and stability at elevated temperatures. The chromium content in stainless steel (minimum 10.5%) contributes to its exceptional temperature resilience, allowing it to maintain structural integrity and corrosion resistance even under extreme thermal conditions. This makes stainless steel reducers preferable for high-temperature applications in industries like chemical processing, power generation, and food processing.

Carbon steel, while strong, has limitations when exposed to high temperatures for extended periods. Without additional protective treatments, carbon steel can experience accelerated oxidation and structural degradation when subjected to elevated temperatures, potentially compromising its durability and performance in high-heat environments.

Impact of Heat Treatment on Material Performance

Heat treatment processes significantly influence the performance characteristics of both materials:

For carbon steel, heat treatment is a critical factor in determining its final properties. Processes such as quenching can substantially increase the hardness of carbon steel, though sometimes at the expense of ductility. These treatments allow manufacturers to customize carbon steel’s properties for specific applications, balancing strength with workability.

Stainless steel’s response to heat treatment varies by type. Martensitic stainless steels, for instance, can be hardened through heat treatment similar to carbon steels. Precipitation-hardening stainless steels develop their optimal strength and hardness through specialized aging treatments. Austenitic stainless steels, the most common type, cannot be hardened by heat treatment but maintain their corrosion resistance and ductility across a wide temperature range.

With this comprehensive understanding of strength and durability factors, we’ll next explore edge retention and sharpness—properties that are particularly relevant for applications requiring precision cutting or prolonged performance without maintenance.

Edge Retention and Sharpness

Edge Retention and Sharpness

Now that we’ve examined the strength and durability characteristics of both materials, let’s focus on a critical factor for cutting applications: edge retention and sharpness, which often determines the practical utility of steel in various applications.

Carbon Steel’s Superior Edge Capability

Carbon steel demonstrates exceptional edge retention capabilities due to its fine grain structure and superior hardening properties. With hardness ratings typically ranging from 55-70 HRC, carbon steel blades maintain their sharpness significantly longer under similar conditions compared to their stainless counterparts. The high carbon content (0.8 to 2.1%) contributes to a razor-sharp edge that excels in cutting performance.

Additionally, carbon steel is notably easier to sharpen when maintenance is required. This allows users to quickly restore the blade’s edge to optimal condition without extensive effort. The material’s inherent toughness also provides resilience against edge deformation, making it particularly suitable for high-impact applications where maintaining cutting performance is essential.

Stainless Steel’s Maintenance of Sharpness

While stainless steel generally doesn’t match carbon steel’s edge retention, it offers respectable performance with hardness ratings typically between 55-60 HRC. The chromium content (minimum 10.5%) that provides corrosion resistance does affect the steel’s edge-holding capabilities. Stainless steel can be more challenging to sharpen due to its wear-resistant properties.

However, the actual performance of stainless steel varies significantly based on specific alloys and heat treatment. Higher-quality stainless steel blades with proper heat treatment can perform admirably, sometimes rivaling lower-quality carbon steel options. The key advantage of stainless steel lies in its ability to maintain consistent performance in humid or corrosive environments where carbon steel would deteriorate.

Real-World Performance in Cutting Applications

In practical applications, the difference between these materials becomes evident through user experiences. Knife enthusiasts often note that carbon steel provides superior cutting performance in situations where edge retention is paramount. For professional chefs or woodworkers who require precision cutting, carbon steel often represents the preferred choice.

Community discussions reveal that while many users prioritize edge retention, others in tactical or field environments value toughness and ease of sharpening more highly. The sharpening angle also significantly impacts edge retention, with users seeking a balance between toughness and maintaining a sharp edge.

It’s worth noting that both steel types come in various grades that affect their performance. A high-quality stainless steel blade may outperform a low-quality carbon steel one, emphasizing that material grade and manufacturing quality are as important as the fundamental steel type. Some users report satisfaction with properly heat-treated budget stainless steels like 8Cr13MoV, while others remain skeptical about inconsistent manufacturing quality.

With these edge retention and sharpness factors in mind, next we’ll examine the cost considerations and value assessment to determine which material offers better long-term investment for specific applications.

Cost Considerations and Value Assessment

Cost Considerations and Value Assessment

Now that we’ve examined the edge retention and sharpness differences between stainless and carbon steel reducers, let’s analyze their economic implications, which often become deciding factors in material selection.

Initial Investment Differences

The upfront cost discrepancy between stainless steel and carbon steel is significant. Stainless steel typically commands a premium price ranging from $2 to $5 per pound, primarily due to its alloying elements such as chromium and nickel that enhance its corrosion resistance. In contrast, carbon steel is considerably more affordable, with prices ranging between $0.50 to $2 per pound, depending on the carbon content and whether it’s a basic structural grade or a higher-quality alloy.

This price differential means stainless steel can be two to five times more expensive than carbon steel at the point of purchase. For context, stainless steel containers like drums average around $850, while comparable carbon steel drums cost approximately $120—a substantial difference that impacts project budgeting, especially for large-scale applications.

Long-Term Maintenance Requirements and Costs

While the initial investment favors carbon steel, the maintenance equation shifts the economic balance:

Carbon Steel Maintenance: Requires regular upkeep to prevent rust and degradation. This includes costs for protective coatings, periodic inspections, and potential repairs or treatments. These ongoing expenses can accumulate significantly over time, especially in corrosive environments.

Stainless Steel Maintenance: Benefits from minimal maintenance requirements due to its inherent corrosion resistance. The chromium content (minimum 10.5%) forms a protective oxide layer that prevents rust and deterioration, resulting in lower long-term servicing costs.

The maintenance disparity is particularly pronounced in harsh environments where carbon steel’s susceptibility to chemical reactions necessitates more frequent attention and protective measures.

Lifespan and Replacement Frequency

The durability difference between these materials directly impacts their economic value over time:

Carbon Steel Lifespan: While strong and initially cost-effective, carbon steel typically has a shorter operational life in many applications, especially those exposed to moisture, chemicals, or variable temperatures. This necessitates more frequent replacements, increasing the total cost of ownership.

Stainless Steel Longevity: The superior corrosion resistance and durability of stainless steel translate to a longer service life. Despite the higher initial investment, its extended lifespan often results in fewer replacements, providing better long-term value in demanding applications.

When calculating true cost efficiency, the replacement frequency becomes a critical factor. In applications where corrosion is a concern, the extended lifespan of stainless steel can offset its higher upfront cost through fewer replacement cycles and reduced downtime.

With these cost considerations in mind, next, we’ll explore application-specific selection criteria to help determine which material best suits particular usage scenarios, balancing technical requirements with economic factors.

Application-Specific Selection Criteria

Application-Specific Selection Criteria

Now that we have covered the cost considerations and value assessment of stainless reducers versus carbon steel, let’s examine how to select the appropriate material based on specific applications. The choice between stainless and carbon steel reducers should be guided by the particular demands of your project.

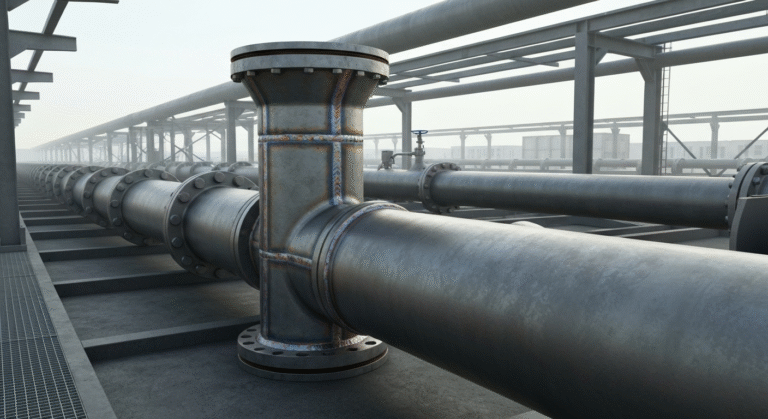

Industrial and Construction Applications

In industrial settings, the selection of reducer material is critical for system performance and longevity. Stainless steel reducers, particularly those made from 316L stainless steel, offer superior corrosion resistance, making them ideal for environments with high moisture or chemical exposure. According to our reference materials, these reducers are manufactured to rigorous standards (ASTM A403 and ANSI B16.9) and are available in multiple sizes and schedules (S/5 to S/80).

For piping systems where fluid characteristics are a concern, the choice between concentric and eccentric reducers becomes important. Concentric reducers align the center lines of both ends and are most suitable for vertical systems, particularly at pump inlets where preventing air accumulation is crucial. Meanwhile, eccentric reducers align the larger pipe’s center line with the bottom of the smaller end, making them the preferred choice for horizontal systems to prevent gas buildup.

Tools and Cutting Implements

When it comes to tools and cutting implements, both stainless and carbon steel have their place. The manufacturing process of steel pipe reducers involves various techniques, primarily utilizing welded pipes along with necessary filling materials. For tools requiring precision and minimal maintenance, stainless steel offers advantages, though at a higher cost point.

The ‘Outer Die Method’ is particularly effective for producing small and medium-sized reducers, where the pipe is cut and then pressed within an outer die to compress one end to a smaller diameter. This technique delivers high-quality reducers that maintain structural integrity even under stress.

Firearms and High-Stress Applications

For high-stress applications such as firearms components or industrial equipment under extreme pressure, the selection criteria must prioritize strength and reliability. Stainless steel butt weld reducers, available in both concentric and eccentric designs, facilitate changes in pipe size to meet specific hydraulic flow requirements while ensuring high strength and corrosion resistance.

The theoretical bursting pressures and dimensional specifications provided by manufacturers like Shaw Stainless & Alloy become crucial factors in selecting the appropriate reducer for high-stress environments. These products are designed to withstand significant pressure and provide reliable performance even under demanding conditions.

With this understanding of application-specific selection criteria, we’ll next explore the maintenance requirements for both stainless and carbon steel reducers, which will further inform your decision-making process based on long-term care considerations.

Maintenance Requirements

Maintenance Requirements

Now that we’ve examined the application-specific selection criteria for both materials, it’s important to consider the ongoing maintenance requirements that each type of steel demands. The long-term care needs can significantly impact your overall satisfaction and the total cost of ownership over time.

Carbon Steel’s Care Regimen

Carbon steel requires a more intensive maintenance schedule due to its inherent vulnerability to corrosion. Without proper care, carbon steel components can quickly deteriorate, especially when exposed to moisture, chemicals, or varying environmental conditions. The maintenance regimen for carbon steel typically includes:

- Regular inspection for signs of rust or corrosion

- Application of protective coatings or treatments

- Cleaning and drying after exposure to moisture

- Reapplication of protective oils or waxes periodically

- Potential repainting or refinishing as protective layers wear down

This higher maintenance requirement stems from carbon steel’s chemical composition, which lacks the corrosion-resistant properties found in stainless steel. Even with protective measures in place, carbon steel parts generally require vigilant monitoring and care to prevent degradation over time.

Stainless Steel’s Low-Maintenance Benefits

In contrast, stainless steel offers significant advantages in terms of maintenance requirements. The minimum 10.5% chromium content creates a self-healing protective oxide layer that provides inherent resistance to corrosion and rust. This translates to several maintenance benefits:

- Minimal cleaning requirements beyond basic surface cleaning

- No need for protective coatings or treatments in most applications

- Excellent resistance to environmental factors like humidity and temperature fluctuations

- Reduced inspection frequency due to higher durability

- Lower long-term maintenance costs despite higher initial investment

These low-maintenance characteristics make stainless steel particularly valuable in applications where ongoing access for maintenance is difficult or where maintenance downtime would be costly.

Balancing Maintenance Effort with Performance Needs

When determining which material best suits your application, carefully consider the balance between maintenance requirements and performance needs:

- For structural applications in controlled environments, carbon steel’s lower initial cost may outweigh its higher maintenance requirements

- In harsh environments with exposure to chemicals, moisture, or corrosive elements, stainless steel’s minimal maintenance needs often justify its higher upfront cost

- Calculate the total cost of ownership including both initial investment and projected maintenance expenses over the expected service life

- Consider the availability of maintenance resources and accessibility of components

- Evaluate the consequences of potential maintenance failures for safety-critical applications

The decision ultimately depends on your specific project parameters. While carbon steel requires more frequent attention and protective measures to maintain its integrity, proper maintenance can extend its service life considerably. Stainless steel, though more expensive initially, often proves more economical in the long run due to its reduced maintenance needs and longer service life in challenging environments.

Conclusion

Choosing between stainless steel and carbon steel reducers ultimately depends on your specific application requirements. While stainless steel offers superior corrosion resistance and requires minimal maintenance, carbon steel provides greater strength, better edge retention when properly treated, and is typically more cost-effective. The environmental conditions, frequency of use, and your willingness to perform regular maintenance should all factor into your decision-making process.

Remember that both materials have proven their worth across various industries for good reason. Carbon steel excels in applications where strength and cost efficiency are paramount, while stainless steel is the preferred choice in corrosive environments where longevity without intensive maintenance is essential. By carefully evaluating the factors discussed throughout this guide—from corrosion resistance to application-specific criteria—you can confidently select the reducer material that will deliver optimal performance for your particular needs.