-

Промышленная зона Иньчжуан, уезд Мэнцюнь, город Цанчжоу, провинция Хэбэй, Китай

Seamless Pipe Standards: ASTM and ASME Overview

Основные моменты

- Seamless pipes are forged from a single steel billet, giving them superior strength and no weld seam, unlike welded pipe.

- ASTM and ASME are the primary organizations that provide specifications for pipe manufacturing and performance.

- ASTM A106 is a key standard for seamless carbon steel pipe used in high-temperature, high-pressure services. Pipe schedules, like schedule 40 and schedule 80, define the wall thickness, which correlates to pressure-handling capabilities.

If you’re looking to buy custom-cut seamless carbon steel pipes, you can source them from industrial suppliers, specialized steel distributors, or manufacturers that offer custom fabrication services. Many steel pipe suppliers provide cutting options to meet specific wall thickness and length requirements while adhering to ASTM and seam requirements.

- Pipe schedules, like schedule 40 and schedule 80, define the wall thickness, which correlates to pressure-handling capabilities.

- Seamless pipe is often required for critical applications due to its higher minimum yield strength and reliability under stress.

- Common specifications include grades like Grade B, which outlines specific chemical and mechanical properties.

Введение

When you need to pick materials for industrial piping systems, choosing between welded pipe and seamless pipe is very important. Each type of pipe gets its main features from how the pipe is made. You should know this in order to pick the best one. The standards from groups like ASTM and ASME help you make sure that the piping is safe, works well, and saves money for you. This guide talks about what a seamless pipe is. It also tells you how it stacks up against welded pipe. You will get to see the main specifications so you have the facts needed to choose the right type of pipe for your project.

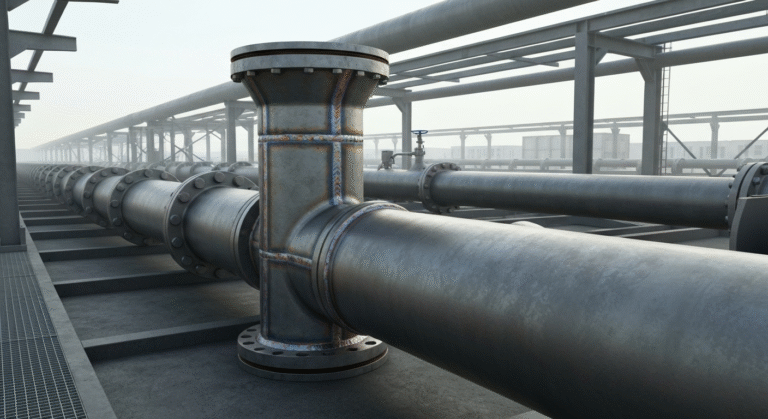

Seamless Pipe Basics and Industry Applications

A seamless steel pipe does not have a welded seam. This gives it strong support and makes it better for use in tough jobs. Many industries like refineries, power plants, and petrochemical sites pick seamless steel pipe. They choose it because it can handle high pressure and temperature without problems.

Seamless steel pipe is not like pipe made with electric resistance welding (ERW). It has the same structure and strength all the way through its diameter. Groups like the American Petroleum Institute (API) often say that people must use seamless pipe for moving important fluids or gases. You will see this kind of piping in boilers, ships, and other places that face a lot of stress.

What Defines a Seamless Pipe: Key Characteristics

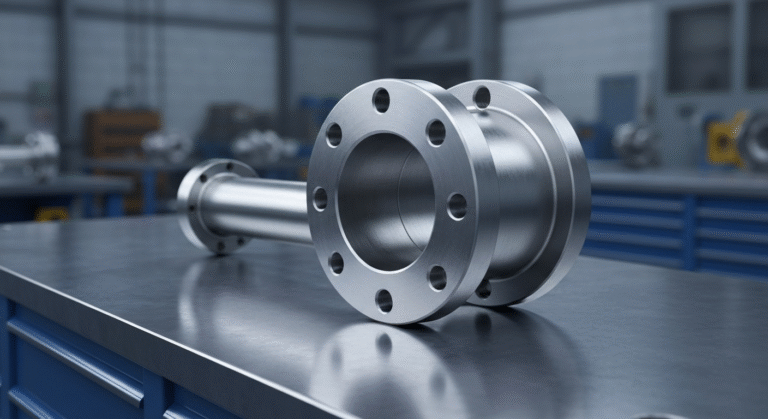

The main thing that makes a seamless steel pipe different is how it is made. The process starts with a solid round piece of steel called a billet. People heat the billet until it gets very hot. Then a tool called a mandrel pushes through the center to make it hollow like a cylinder.

After this, the hollow billet is rolled and stretched. This helps get the right diameter and wall thickness for the pipe. Because the pipe is made from one piece of metal, there is no weld seam along it. Not having a seam gives the pipe more strength than other pipes.

This way of making seamless steel pipe means it is one solid piece. You can bend it, do similar forming operations, or use flanging with no weak points where a seam would be. Each steel pipe has to meet strict rules for specifications, size, and strength, so you know it will be reliable.

Common Industrial Uses for Seamless Carbon Steel Pipes

Seamless carbon steel pipes are a key part of many industries that work in tough conditions. These pipes have a strong build, making them a good choice to move fluids and gases at high pressure and high heat. Their smooth and even shape helps them stand up to corrosion, which is important around chemicals that can eat away at other metals.

Because seamless carbon steel pipes have high minimum yield strength, they hold up well under a lot of stress. These pipes stand strong and do not bend or break easily. That is why people use them for critical piping in refineries, power plants, and places where medicine is made. Do you know if your industry uses pipes like these?

Common uses for seamless carbon steel pipes include:

- Oil and gas drilling and searching for new spots

- Moving steam and hot liquids in power plants

- Use in hydraulic systems and boiler parts

- Carrying high-pressure fluids in petrochemical plants

Comparing Seamless and Welded Pipes

The main difference between welded pipe and seamless pipe is about how they are made. Welded pipe is made from a steel ribbon, also called skelp. This skelp is rolled so it forms a tube shape. After that, the edges of the steel are joined together using a welding process. Most of the time, this welding is done with electric resistance. This is sometimes called ERW, and it uses an electrical current to melt and fuse the edges together.

When you make a welded pipe this way, you get a seam that runs down the length of the pipe. People use to see the seam as a weak spot, especially when you compare it to seamless pipe. Today, the welding process and electric resistance have improved a lot. But groups like API and ANSI still see a difference between welded pipe and seamless pipe. This is very important when you use the pipe for things where there is high pressure.

Major Differences in Structure and Performance

The structural difference between a welded and a seamless steel pipe directly impacts its performance. A welded pipe contains a weld seam, which can be a point of vulnerability under extreme stress or corrosive conditions. In contrast, a seamless pipe’s uniform structure eliminates this concern, offering more predictable and reliable performance.

This difference is reflected in industry specifications. While a welded pipe may have a more consistent nominal wall thickness because it starts as a flat sheet, the rolling and stretching process for seamless pipe can lead to minor inconsistencies. However, the overall strength of seamless pipe is generally considered superior.

Below is a table summarizing the key differences:

Характеристика | Seamless Pipe | Welded Pipe |

|---|---|---|

Производство | Extruded from a single solid billet | Rolled from a flat steel sheet (skelp) and welded |

Структура | No seams or joints | Contains a longitudinal weld seam |

Pressure Rating | Superior for high-pressure and high-temperature use | Suitable for low to medium-pressure applications |

Стоимость | Generally more expensive due to a complex process | More cost-effective, especially in larger diameters |

Толщина стенок | Can have minor inconsistencies | Typically more uniform wall thickness |

Availability | More common in smaller to medium diameters | Available in very large diameters |

Why Seamless Pipe Is Preferred in High-Pressure Environments

The main reason people pick seamless pipe for use in places with high pressure and higher temperatures is safety. There is no welded seam in this pipe. That is important because the seam is often where things go wrong in a pipe. A seam can have things like corrosion, stress, or defects. These problems can cause the pipe to fail under tough working conditions.

Seamless pipes give people more confidence about how the pipe will act because the whole pipe has the same structure. The pipes also have a greater minimum yield strength. This means they can take on more force before they start to bend or change shape. That makes seamless pipes important for piping where fluids or gases must stay inside even at higher temperatures.

Many times, the rules for what pipe to use will say that stronger grades, like grade c, should be in seamless form. These stronger pipes are needed for really tough jobs. The pipe is sturdy all way around and does not have weak spots. This helps it work as it should and keeps people safe, even when the pipe is pushed to its highest performance. With welding or the welding process, even though there have been new improvements, it still cannot always promise this same level of safety and strength as seamless pipes can.

ASTM and ASME Standards for Seamless Pipes

Standards organizations like ASTM International and the American Society of Mechanical Engineers (ASME) set rules for piping used in industries. The specification from these groups tell you about the pipe’s chemical make-up, its strength, size, and how it gets tested. This helps you know what is needed to make and use piping.

You must follow these requirements if you work in industry or construction. It is not a choice; it is the way to be safe and sure. The specification will give you every detail, like how a pipe is made and what else is needed for a job, including any supplementary requirements for what you plan to do. When you know these standards, you can get the right piping for what you need.

Overview of ASTM A106 Specifications and Pipe Schedules

ASTM A106 is a common specification for seamless carbon steel pipe. The pipes made to this standard are used mostly in high-temperature jobs. They are good for bending and flanging too. This specification offers several grades. The most used ones are grade b and grade c. Each grade has its own limits for things like carbon and manganese inside the steel pipe. This changes how strong or bendable the pipe will be.

ASTM A106 also works with pipe schedules. These numbers, like SCH 40 and SCH 80, tell you the nominal wall thickness of the carbon steel pipe. A larger number, such as SCH 80, means the wall is much thicker compared to SCH 40 of the same diameter. Thicker walls let the pipe handle more pressure inside.

When you pick a carbon steel pipe based on this specification, you should say what grade you want, such as grade b, and also list the schedule, like SCH 80. This is how you make sure you get the right wall thickness and material for the pressure and temperature of your job. SCH 80 pipes are often used for heavy tasks in big factories where higher pressure is common.

Understanding ASME Requirements and Marking Practices

The ASME standard for seamless pressure pipe is called ASME SA106. It often matches up with the ASTM A106 specification. ASME uses these materials for boilers, pressure vessels, and other related systems. You must follow the ASME specification if the equipment needs to meet the ASME Boiler and Pressure Vessel Code.

It is important for each pipe to have the right marking. Each piece of pipe must be stenciled or stamped with the key information. These marks help you check that the pipe meets the needed specification. The marks should show the manufacturer’s name, what material grade it is (A106 B or C), as well as the schedule number or wall thickness, and the length.

The mark will also tell you if the pipe has gone through heat treatment and if it passed hydrostatic testing. Hydrostatic testing shows the pipe can handle pressure. This helps trace the pipe back to its source and lets you confirm that the pipe has the right minimum yield strength, its diameter, and its wall thickness.

Заключение

To sum up, knowing about seamless pipe standards, especially those from ASTM and ASME, is very important. These rules help people pick strong materials that work well in high-pressure areas. They also help keep things safe and meeting all needed rules at work. If you work in construction, making things, or any different area that needs seamless pipes, it helps a lot to stay aware of these standards. This way, your work turns out better. If you want to know more about seamless pipes or need help with choosing the right specs for your job, you can ask for expert help.

Часто задаваемые вопросы

Are beveled end seamless pipes superior to plain end types?

A beveled end is not always better than others. It just has another use. Beveled end seamless carbon steel pipes help make welding to another pipe or fitting simple. Plain end pipes are there for socket-weld connections or when you have to use mechanical couplings with them.

How do I select between schedule 40 and schedule 80 seamless pipes?

The choice comes down to the needed pressure rating. For pipes with the same diameter and material, a schedule 80 pipe will have more wall thickness than a schedule 40 pipe. You should choose schedule 80 if the pressure will be higher.

What sizes are available for seamless carbon steel pipes in the US?

Seamless carbon steel pipes come in many sizes. The sizes are usually given as Nominal Pipe Size (NPS) in inches. You can get these pipes in carbon steel under ASTM standards with diameters from 1/4 inch up to 36 inches. There are also different wall thickness options for each diameter.