-

Zona industrial de Yinzhuang, concelho de Mengcun, cidade de Cangzhou, província de Hebei, China

Flange WN vs. Flange Slip-On: Qual é o melhor?

Flange WN vs. Flange Slip-On: Qual é o melhor?

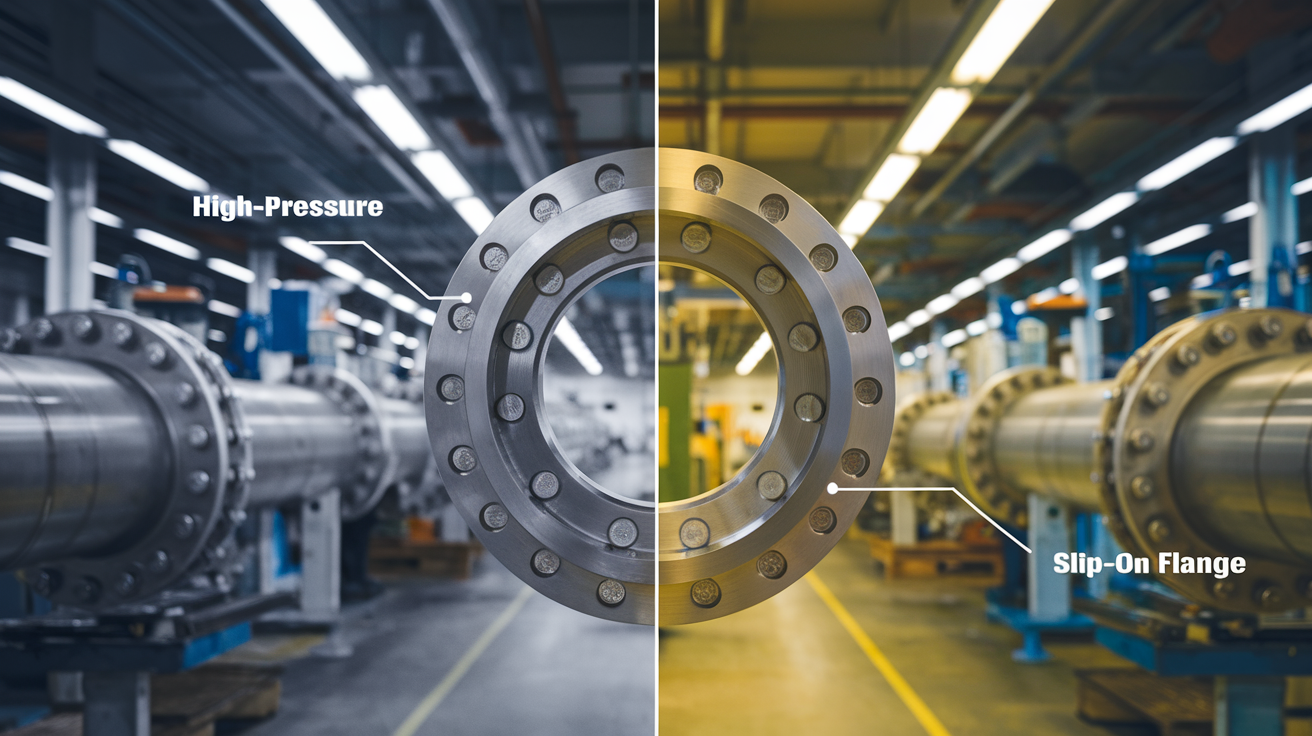

Ao projetar sistemas de tubulação, a escolha entre Flanges com colar soldado (WN) e Flanges deslizantes pode afetar significativamente o sucesso, a segurança e o orçamento do seu projeto. Embora ambos tenham a função essencial de conectar tubos e componentes, as suas diferenças fundamentais em termos de design, requisitos de instalação e características de desempenho criam um ponto de decisão crítico para engenheiros e empreiteiros. Com um oferecendo resistência superior, mas a um custo mais elevado, e o outro proporcionando simplicidade de instalação, mas potenciais compromissos a longo prazo, escolher errado pode levar a falhas prematuras do sistema ou despesas desnecessárias.

Nos ambientes de alto risco do processamento petroquímico, transporte de petróleo e gás ou geração de energia, é importante compreender quando a resistência superior de um flange WN — aproximadamente vida útil um terço mais longa do que a sua contraparte slip-on — justifica o seu investimento inicial mais elevado torna-se crucial. Por outro lado, em aplicações menos exigentes, como tratamento de água ou sistemas HVAC, a relação custo-benefício e a instalação mais simples do flange slip-on podem ser a escolha mais inteligente. Este guia abrangente examinará as diferenças críticas entre esses dois tipos de flange em processos de instalação, capacidades de resistência, considerações de custo e aplicações ideais, capacitando-o a fazer a seleção ideal para os requisitos específicos do seu projeto.

Compreender os tipos de flanges e os seus designs

Compreender os tipos de flanges e os seus designs

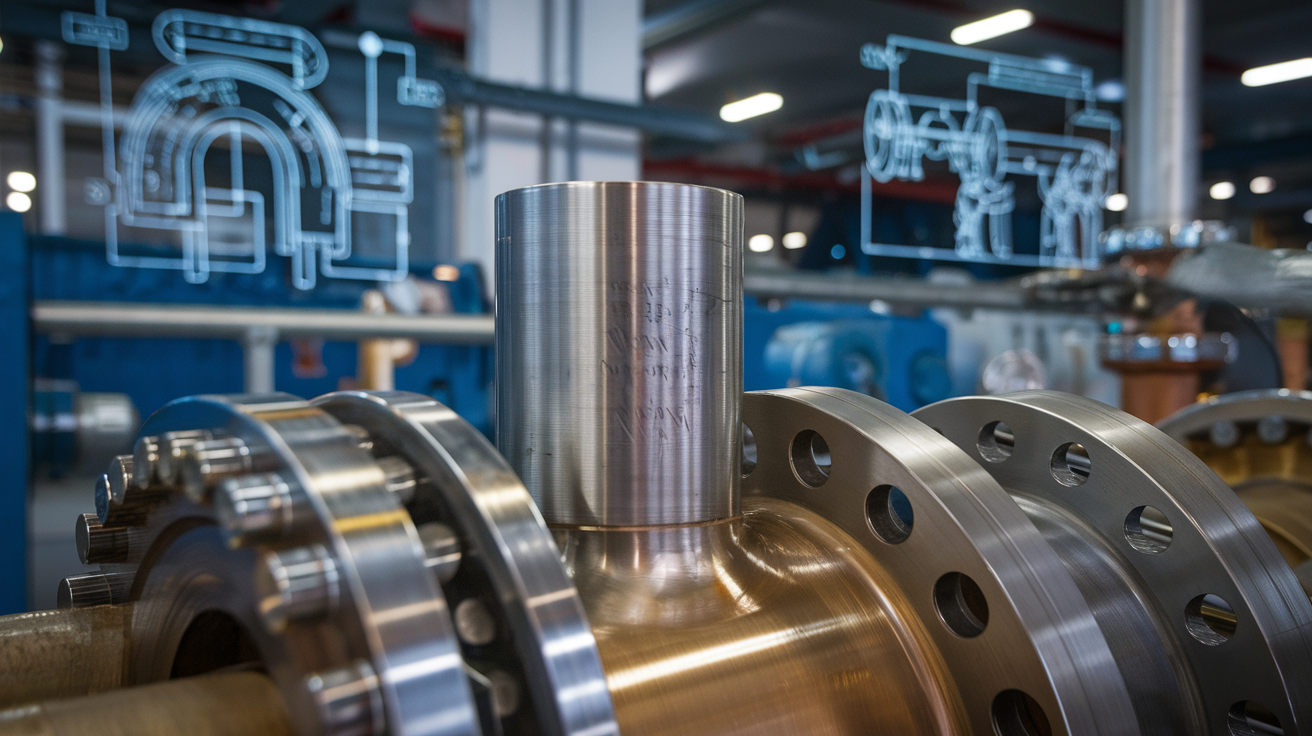

O que é um flange com pescoço soldado (WN)

Um flange Weld Neck, comumente referido como flange WN, é caracterizado pelo seu design distinto de cubo longo e cónico. Esta estrutura especializada melhora o reforço e distribui a tensão de forma mais eficaz por todo o ponto de ligação. O design permite a soldadura de topo com penetração total tanto no interior como no exterior, criando uma junta robusta e sem costuras com o tubo.

Os flanges WN são especificamente projetados para aplicações de alta pressão e alta temperatura, onde a confiabilidade é crucial. O seu design reduz a turbulência e minimiza a erosão dentro do sistema de tubulação, tornando-os ideais para indústrias críticas, como petróleo e gás, petroquímica e geração de energia.

As principais características dos flanges Weld Neck incluem:

- Resistência e durabilidade superiores

- Excelente resistência à expansão térmica

- Alta tolerância ao esforço mecânico

- Risco reduzido de falha em condições extremas

- Distribuição de tensão melhorada através do cubo cónico

O que é um flange deslizante?

Um flange Slip-On apresenta um diâmetro interno ligeiramente maior do que o diâmetro externo do tubo, permitindo que ele deslize ou “deslize” sobre o tubo durante a instalação. Este tipo de flange é fixado através de soldagem em ângulo nas bordas internas e externas, onde o flange se encontra com o tubo.

Os flanges Slip-On são soluções mais económicas, concebidas principalmente para sistemas de baixa a média pressão e aplicações com temperaturas moderadas. O seu design mais simples torna-os particularmente adequados para aplicações não críticas em indústrias como tratamento de água e sistemas de climatização.

As principais características dos flanges Slip-On incluem:

- Processo de instalação mais fácil e rápido

- Requisitos de precisão reduzidos para o corte de tubos

- Custo inicial mais baixo em comparação com flanges WN

- Alinhamento simplificado durante a instalação

- Versatilidade em várias aplicações industriais gerais

Principais diferenças de design

As diferenças fundamentais de design entre flanges Weld Neck e Slip-On afetam significativamente o seu desempenho, adequação à aplicação e requisitos de instalação:

| Caraterística | Flange com colar soldado | Flange deslizante |

|---|---|---|

| Estrutura | Cubo longo e cónico | Design simples e plano |

| Método de soldagem | Soldagem de topo | Soldadura de filete (interior e exterior) |

| Força | Elevado | Moderado |

| Distribuição de tensões | Excelente | Limitado |

| Resistência a fugas | Superior | Moderado, mais propenso a vazamentos |

| Manuseamento de pressão | Aplicações de alta pressão | Aplicações de baixa a média pressão |

| Custo | Mais alto | Inferior |

| Complexidade da instalação | Requer mais habilidade e tempo | Mais simples e rápido |

Os flanges com pescoço soldado proporcionam resistência superior através da sua ligação perfeita com o tubo, distribuindo a tensão uniformemente e minimizando os pontos fracos. Isto torna-os a escolha preferida para aplicações críticas que envolvem condições extremas, materiais perigosos ou onde uma falha do sistema teria consequências graves.

Em contrapartida, os flanges Slip-On oferecem uma solução mais económica com requisitos de instalação mais simples, tornando-os ideais para aplicações industriais gerais onde as restrições orçamentais são uma consideração e as condições operacionais são menos exigentes.

Agora que compreendemos os projetos fundamentais e as diferenças entre esses dois tipos de flanges, vamos examinar como essas características de projeto afetam os seus processos de instalação na próxima secção, “Comparação dos processos de instalação”.”

Comparação do processo de instalação

Comparação do processo de instalação

Agora que explorámos os diferentes tipos de flanges e seus designs, vamos examinar como as flanges WN e as flanges slip-on diferem nos seus processos de instalação, o que é um fator crítico ao selecionar a flange adequada para o seu sistema de tubulação.

Requisitos de instalação do colar soldado

Os flanges com pescoço soldado requerem um processo de instalação mais complexo devido ao seu design com um cubo longo e cónico. A instalação envolve:

- Soldagem de topo com penetração total tanto no interior como no exterior do flange

- Alinhamento preciso entre o tubo e o flange antes da soldagem

- Soldadores mais qualificados, com formação especializada para uma instalação adequada

- Tempo adicional para preparação e soldagem em comparação com outros tipos de flanges

- Atenção cuidadosa para garantir a distribuição adequada da tensão em toda a conexão

A técnica de soldagem de topo utilizada com flanges WN cria uma conexão perfeita entre o tubo e o flange, resultando em resistência e durabilidade superiores. No entanto, isso acarreta requisitos de instalação mais trabalhosos e custos de mão de obra mais qualificada.

Simplicidade de instalação deslizante

Os flanges deslizantes oferecem vantagens significativas no que diz respeito à facilidade de instalação:

- A flange simplesmente desliza sobre o tubo, com o seu diâmetro interno ligeiramente maior do que o diâmetro externo do tubo.

- O alinhamento é mais fácil e tolerante durante o processo de instalação

- A soldagem ocorre principalmente na borda externa, com soldas de filete tanto na parte interna quanto na externa.

- É necessária menos precisão ao cortar tubos para instalação de flanges deslizantes.

- A instalação pode ser concluída mais rapidamente com menos mão de obra especializada.

Este processo de instalação simplificado é a razão pela qual os flanges deslizantes são frequentemente preferidos para aplicações menos críticas e onde as restrições orçamentais são um fator importante. A redução das necessidades de mão de obra traduz-se diretamente em poupanças de custos durante a instalação.

Métodos de soldagem e necessidades de inspeção

Os métodos de soldagem para esses dois tipos de flange diferem significativamente:

Flanges com colar soldado:

- Exigem técnicas de soldagem de topo que criam soldas de penetração total

- São necessários procedimentos de inspeção mais rigorosos para garantir a integridade das soldaduras.

- Frequentemente requerem testes radiográficos ou ultrassónicos para aplicações críticas

- Pode ser necessário tratamento térmico pós-soldagem em aplicações de alta tensão

- Crie menos turbulência no percurso do fluxo devido à transição perfeita

Flanges deslizantes:

- Utilize soldadura de filete nas superfícies interna e externa

- Tenha requisitos de inspeção mais simples para aplicações não críticas

- Pode apresentar pontos fracos potenciais devido à exigência de soldagem dupla

- Geralmente requerem procedimentos de teste menos extensos

- Criar potenciais restrições de fluxo ou turbulência no ponto de conexão

Com essa compreensão de como cada tipo de flange é instalado, podemos agora passar a examinar suas características de desempenho e resistência, que estão diretamente relacionadas à forma como essas diferenças de instalação afetam a confiabilidade a longo prazo do sistema de tubulação.

Análise de desempenho e resistência

Análise de desempenho e resistência

Agora que explorámos as diferenças de instalação entre flanges WN e flanges slip-on, vamos examinar como esses dois tipos de flanges se comparam em termos de desempenho e resistência — fatores críticos que, em última análise, determinam a sua adequação para várias aplicações.

Resistência à pressão e à temperatura

As flanges WN demonstram capacidades superiores de manuseamento de pressão e temperatura em comparação com as alternativas slip-on. O design cónico do cubo das flanges com pescoço soldado permite uma melhor distribuição da tensão ao longo da ligação, tornando-as ideais para ambientes de alta pressão e alta temperatura. Esta característica de design permite que as flanges WN suportem variações extremas de temperatura sem comprometer a integridade estrutural.

Em contrapartida, os flanges deslizantes oferecem capacidades limitadas de manuseamento de pressão. A sua resistência calculada sob pressão interna é aproximadamente dois terços da resistência dos flanges com pescoço soldado. Esta resistência reduzida torna os flanges deslizantes mais adequados para sistemas de baixa a média pressão, onde condições extremas não são uma preocupação.

Integridade estrutural e vida útil sob fadiga

A integridade estrutural das flanges WN supera significativamente as opções slip-on devido ao seu design de solda de topo com penetração total. Essa técnica de soldagem cria uma transição perfeita entre o tubo e a flange, distribuindo a tensão de maneira mais uniforme e reduzindo os pontos de falha potenciais.

Uma diferença crucial está na vida útil à fadiga — os flanges slip-on têm aproximadamente um terço da vida útil à fadiga dos flanges weld neck. Essa diferença substancial torna os flanges WN a escolha preferida para aplicações com cargas cíclicas ou flutuações de pressão. A menor integridade estrutural dos flanges slip-on deve-se principalmente aos pontos fracos potenciais criados pelo processo de soldagem dupla (interna e externa), o que pode levar a um risco maior de falha ao longo do tempo.

Características do fluxo e turbulência

Os flanges com pescoço soldado minimizam a turbulência, a erosão e a restrição de fluxo nos sistemas de tubulação. O design suave e cónico cria uma transição mais suave para o fluxo de fluidos em comparação com os flanges deslizantes. Essa redução na turbulência é particularmente importante em aplicações de alta velocidade ou sistemas onde a queda de pressão deve ser minimizada.

As flanges deslizantes, com a sua solda interna recuada, podem criar pequenas interrupções no fluxo que podem contribuir para o aumento da turbulência. Embora isso possa não ser significativo em aplicações de baixo fluxo, torna-se uma consideração importante em sistemas críticos onde a eficiência do fluxo é fundamental.

Com esses fatores de desempenho e resistência em mente, a seguir examinaremos as considerações de custo entre esses dois tipos de flanges, já que os benefícios de desempenho das flanges WN devem ser ponderados em relação ao seu investimento inicial mais elevado.

Considerações sobre custos

Considerações sobre custos

Agora que examinámos as diferenças de desempenho e resistência entre flanges WN e flanges slip-on, é importante avaliar o seu impacto económico. As considerações de custo vão além do preço inicial de compra e incluem a instalação e despesas a longo prazo.

Despesas iniciais de compra

A diferença inicial de custo entre estes tipos de flanges é significativa:

Flanges deslizantes: Geralmente mais baratos inicialmente, tornando-os uma opção atraente para projetos com orçamento limitado. O seu design mais simples requer menos material e tempo de fabricação, resultando em custos de aquisição mais baixos.

Flanges com pescoço de soldadura: Têm um preço inicial mais elevado devido ao seu design mais complexo, com um cubo cónico. O material adicional e a precisão de fabrico contribuem para o seu preço premium.

De acordo com os materiais de referência, os flanges deslizantes oferecem um investimento inicial mais económico, o que os torna particularmente atraentes para aplicações não críticas e sistemas que operam em condições de pressão mais baixa.

Custos de mão de obra e tempo de instalação

O processo de instalação tem um impacto significativo nas despesas gerais do projeto:

Flanges deslizantes:

- Mais fácil e rápido de instalar devido ao seu design simples de encaixe

- Requer duas soldaduras (uma no interior e outra no exterior)

- Menos precisão necessária para o alinhamento, reduzindo as necessidades de mão de obra

- Menor nível de habilidade necessário para a instalação, reduzindo potencialmente os custos de mão de obra

Flanges com pescoço de soldadura:

- Exigir soldadores mais qualificados para uma instalação adequada

- É necessário um alinhamento preciso para a soldadura de topo com penetração total

- Dedique mais tempo para instalar corretamente

- Custos de mão de obra mais elevados devido ao aumento da complexidade e dos requisitos de qualificação

Embora os flanges deslizantes pareçam mais económicos durante a instalação, vale a pena notar que eles requerem duas soldaduras e inspeções, o que pode compensar parcialmente a economia de mão de obra.

Economia da manutenção a longo prazo

Ao considerar o custo total de propriedade:

Flanges deslizantes:

- Mais propenso a vazamentos ao longo do tempo

- Pode exigir manutenção e substituição mais frequentes

- Maior potencial de tempo de inatividade em aplicações industriais

- Menos durável em ambientes exigentes, podendo levar a uma substituição mais precoce

Flanges com pescoço de soldadura:

- A durabilidade superior reduz a frequência de substituição

- Melhor resistência a condições extremas minimiza as necessidades de manutenção

- Menor probabilidade de vazamentos reduz os custos de reparo

- A vida útil mais longa oferece melhor valor a longo prazo, apesar do investimento inicial mais elevado.

Para aplicações críticas ou sistemas que operam em condições extremas, os benefícios económicos a longo prazo dos flanges com pescoço soldado muitas vezes superam os seus custos iniciais mais elevados.

Com esses fatores de custo em mente, a seguir exploraremos as aplicações adequadas para cada tipo de flange, a fim de ajudar a determinar qual opção é melhor para requisitos operacionais específicos.

Aplicações adequadas para cada tipo de flange

Aplicações adequadas para cada tipo de flange

Agora que abordámos as considerações de custo dos diferentes tipos de flanges, vamos explorar as aplicações específicas em que cada tipo se destaca. Compreender qual flange é mais adequada para a sua situação específica pode levar a um melhor desempenho, maior vida útil e operações mais rentáveis a longo prazo.

Usos ideais para flanges com pescoço soldado

Os flanges com colar soldado são a escolha preferida para aplicações críticas onde a segurança e a fiabilidade são fundamentais:

- Sistemas de alta pressãoDevido à sua resistência e suporte substanciais, os flanges com pescoço soldado são ideais para aplicações com classificações de pressão elevadas.

- Ambientes com altas temperaturas: O seu design proporciona um desempenho superior em condições de temperatura extrema.

- Infraestrutura crítica de oleodutos: Utilizado em grandes linhas de transmissão e infraestruturas onde a falha não é uma opção

- Tubos de maiores dimensões: Recomendado especificamente para sistemas de tubagem de maior diâmetro

- Aplicações com preocupações relacionadas ao stress: O pescoço cónico distribui a tensão de forma mais uniforme, reduzindo o risco de falha na junção entre o flange e o tubo.

Em indústrias como petróleo e gás, processamento químico e geração de energia, flanges com colar de solda são frequentemente a escolha padrão devido à sua construção robusta e desempenho confiável em condições exigentes.

Melhores aplicações para flanges deslizantes

Os flanges deslizantes oferecem vantagens práticas em cenários menos exigentes:

- Aplicações de baixa pressão: Ideal para sistemas que operam com pressões moderadas a baixas

- Serviços não críticos: Adequado para sistemas auxiliares onde a manutenção ocasional é aceitável

- Aplicações que exigem desmontagem frequente: O seu design facilita a instalação e remoção.

- Projetos sensíveis aos custos: Quando as restrições orçamentárias são uma preocupação primordial

- Sistemas com o mínimo de tensão ou vibração: Ideal para utilização em ambientes estáveis, sem tensões mecânicas significativas.

Essas flanges são comumente encontradas em instalações de tratamento de água, sistemas de climatização e tubulações industriais em geral, onde as exigências de pressão e temperatura são moderadas.

Recomendações específicas para o setor

Diferentes indústrias desenvolveram práticas padrão para a seleção de flanges com base nos seus requisitos específicos:

- Indústria do petróleo e do gás: Normalmente segue as normas API 6A, com flanges de pescoço soldado preferidos para cabeças de poço, tubagens e equipamentos de processamento de alta pressão.

- Processamento químico: Requer considerações cuidadosas sobre a compatibilidade dos materiais, frequentemente utilizando flanges com colar soldado para materiais perigosos.

- Produção de energia: Utiliza flanges com pescoço soldado para linhas de vapor e aplicações de alta temperatura.

- Tratamento da água: Frequentemente emprega flanges deslizantes devido à sua relação custo-benefício em aplicações de baixa pressão.

- Alimentação e bebidas: Pode utilizar tipos específicos de flanges que cumpram os requisitos sanitários, equilibrando simultaneamente as considerações de custo.

Ao selecionar flanges, os engenheiros devem considerar a temperatura, a pressão, o tipo de fluido e a compatibilidade dos materiais, além das normas e regulamentações do setor.

Tendo em mente os requisitos da aplicação, a seguir, examinaremos as considerações materiais para flanges, que influenciam ainda mais a sua adequação a ambientes e condições específicos.

Considerações materiais

Considerações materiais

Agora que abordámos as aplicações adequadas para cada tipo de flange, é essencial compreender como a seleção do material afeta o desempenho e a longevidade da flange em vários ambientes.

Tipos e classes de aço disponíveis

Os materiais das flanges desempenham um papel fundamental para garantir a durabilidade e a funcionalidade dos sistemas de tubagem. Eles devem resistir ao calor, à pressão, às vibrações e à corrosão, mantendo uma vedação à prova de fugas. Alguns materiais comuns incluem:

Aço carbono: O material mais prevalente devido à sua resistência e relação custo-benefício. Adequado para sistemas de pressão moderada a alta e aplicações em temperatura ambiente a alta em ambientes não corrosivos ou levemente corrosivos. A ASTM A36 é uma especificação comum para flanges de aço de baixo carbono.

Aço inoxidável: Oferece maior resistência à corrosão e durabilidade, tornando-o ideal para indústrias de processamento químico e de alimentos e bebidas. A norma ASTM A182 abrange flanges de aço inoxidável e liga.

Aço de liga leve: Particularmente os tipos de cromo-molibdénio, recomendados para ambientes de alta temperatura e alta pressão. Essenciais na indústria de petróleo e gás e em fábricas de processamento químico.

Aço inoxidável duplex e super duplex: Oferecem resistência superior e excepcional resistência à corrosão, tornando-os ideais para ambientes agressivos e aplicações de alta resistência.

Liga de níquel: Apresenta propriedades excepcionais em condições extremas, incluindo altas temperaturas e ambientes corrosivos. Adequado para centrais nucleares e aplicações marítimas.

Alumínio: Preferido para aplicações leves, como sistemas de irrigação.

Ferro dúctil: Económico, com maior resistência ao escoamento, adequado para aplicações sem contacto.

Seleção de materiais com base na aplicação

Ao selecionar o material adequado para o flange, considere estes fatores:

- Tipo médio: A substância que flui através dos tubos afeta a compatibilidade dos materiais.

- Temperatura e pressão: Diferentes materiais têm níveis de tolerância variados.

- Condições ambientais: Exposição a elementos corrosivos ou condições meteorológicas extremas

- Requisitos de manutenção: Alguns materiais requerem inspeções mais frequentes.

- Restrições orçamentárias: Materiais premium, como flanges forjadas, oferecem maior resistência, mas a um custo mais elevado.

Os métodos de fabrico também afetam o desempenho do material:

- Flanges de placa: Económico, mas com falta de resistência e variedade de materiais

- Flanges fundidas: Produzido a partir de metal fundido, proporcionando flexibilidade a um custo mais baixo, mas com menor resistência.

- Flanges forjadas: Fabricado através do aquecimento e moldagem do material, oferecendo a mais alta resistência a um preço premium.

Conformidade com as normas da indústria

Várias organizações estabelecem normas que determinam a composição química e as especificações dos materiais utilizados nas flanges:

- ASTM: Fornece especificações como ASTM A36 para aço de baixo carbono e ASTM A240 para aço inoxidável e flanges de liga.

- AWWA: Define normas para aplicações em obras hidráulicas

- ANSI/ASME: Estabelece classificações de pressão-temperatura através de normas como a ASME B16.5, com dimensões constantes em todas as classes de pressão.

As normas dimensionais para flanges metálicas e padrões de furos para parafusos incluem:

- ASME B16.1 para ferro fundido

- ASME B16.5 para várias classes de aço

- ASME B16.47 para flanges maiores

- MSS SP-44 para flanges de tubagem de aço mais pequenas

As limitações materiais especificam que as flanges devem ser fundidas, forjadas ou em placas, com materiais de aparafusamento em conformidade com a norma ASME B16.5. Tanto para flanges WN como slip-on, garantir a conformidade com estas normas é essencial para a segurança, desempenho e intercambiabilidade entre sistemas.

Ao escolher entre flanges WN e flanges slip-on, a decisão depende, em última instância, dos requisitos específicos da sua aplicação. Os flanges com pescoço soldado oferecem resistência superior — cerca de um terço a mais de vida útil e 50% mais resistência sob pressão em comparação com os flanges slip-on — tornando-os ideais para sistemas de alta pressão e alta temperatura em indústrias críticas, como petroquímica e geração de energia. O seu design cónico e soldaduras de topo de penetração total garantem excelente distribuição de tensão e restrição mínima de fluxo, embora exijam instalação mais qualificada e maior investimento inicial.

As flanges deslizantes, embora menos robustas, oferecem soluções económicas para sistemas de baixa a média pressão em aplicações não críticas, como tratamento de água e AVAC. O seu processo de instalação mais simples e os custos iniciais mais baixos tornam-nas atraentes para projetos em que as restrições orçamentais são significativas. Antes de fazer a sua escolha, avalie cuidadosamente os requisitos de pressão e temperatura do seu sistema, as considerações relativas aos materiais, as capacidades de instalação e as necessidades de manutenção a longo prazo. A escolha certa equilibrará os requisitos de desempenho com as restrições orçamentais, garantindo que o seu sistema de tubagem funcione de forma segura e eficiente durante muitos anos.