-

Zona industrial de Yinzhuang, concelho de Mengcun, cidade de Cangzhou, província de Hebei, China

Acessórios para tubos de aço carbono: Qualidade e desempenho são importantes

Principais destaques

- Os acessórios de aço-carbono, conhecidos pela sua resistência e durabilidade, são preferidos em aplicações industriais.

- Os acessórios de soldadura de encaixe proporcionam ligações sem costuras para sistemas de alta pressão.

- Os tipos mais comuns incluem flanges, tês e acoplamentos, oferecendo compatibilidade com diversos diâmetros de tubos.

- A integridade estrutural do aço-carbono garante um desgaste mínimo ao longo do tempo.

- Opções como flanges de face saliente e acoplamentos roscados respondem a necessidades específicas.

- Marcas fiáveis como a Jones Stephens garantem o cumprimento das normas de fabrico.

Introdução

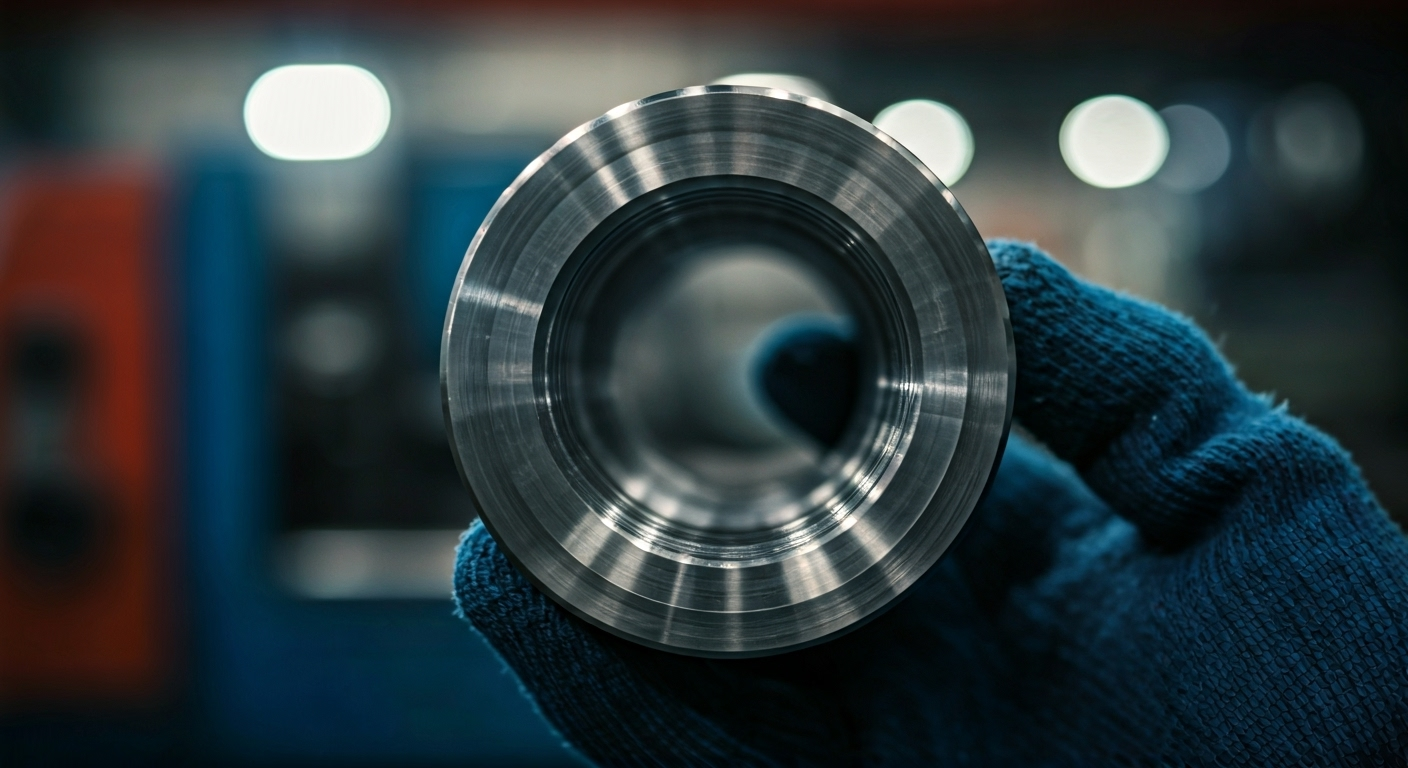

Os acessórios para tubos de aço carbono são muito importantes em muitos sistemas de tubagem. Estes acessórios são fortes e podem ser utilizados para diferentes diâmetros e tipos de tubos. Podem ser utilizados quando se pretende unir, mudar de direção ou vedar tubos. Os acessórios de aço-carbono são resistentes e funcionam bem em condições difíceis. Muitas empresas em todo o mundo utilizam acessórios de aço, especialmente em locais onde o petróleo, o gás ou a água passam pelos tubos. Nas próximas partes, iremos analisar os diferentes tipos de acessórios para tubos e acessórios em aço-carbono. Também falaremos da razão pela qual funcionam tão bem e porque é que as pessoas precisam deles para os seus sistemas.

Principais tipos de acessórios para tubos de aço carbono

Os acessórios de aço-carbono desempenham um papel importante na maioria das tubagens industriais. São utilizados muitos tipos de acessórios para tubos. As tês ajudam os tubos a ramificarem-se de diferentes formas. As uniões garantem que os tubos se juntam em segurança. As flanges proporcionam uma boa vedação para tubagens resistentes. Estes acessórios de aço são feitos para lidar com diferentes níveis de pressão e calor, para que cada sistema continue a funcionar sem problemas.

Alguns acessórios para tubos, como redutores e tampões, são feitos para utilizações especiais. Os acessórios de soldadura de encaixe ajudam a fazer ligações fortes e duradouras. Com tantas opções em acessórios de aço-carbono, pode encontrar os acessórios para tubos que se adaptam a diferentes necessidades e funcionam bem em todos os tipos de locais e condições.

Variedades comuns: Cotovelos, Tês, Acoplamentos e Flanges

Os acessórios para tubagens existem em muitas formas e tamanhos. Cada um é feito para um determinado trabalho na tubagem.

- Cotovelos: Estes acessórios ajudam a alterar a forma como um tubo se desloca. Os cotovelos são fornecidos em ângulos de 45° e 90°. Isto ajuda a fazer com que o sistema se ajuste ao que pretende.

- T-shirts: As tês são boas para dividir uma tubagem em duas. Podem adaptar-se a tubos de diferentes diâmetros e formas.

- Acoplamentos: Os acoplamentos unem dois tubos. Pode obter acoplamentos roscados ou de soldadura de encaixe para que funcionem com os seus tubos.

- Flanges: As flanges são ideais quando se pretende unir um tubo a um equipamento. As flanges de face elevada são comuns. Proporcionam uma vedação mais apertada quando a pressão é elevada.

Estes acessórios para tubos funcionam bem em diferentes configurações. Os acessórios feitos de aço-carbono são fortes e merecem a confiança de muitas indústrias. Ajudam a manter todo o sistema de tubagem a funcionar, mesmo quando as coisas se tornam difíceis.

Acessórios especializados para aplicações industriais na Austrália

Muitas instalações industriais na Austrália precisam de acessórios de aço-carbono para as suas necessidades especiais. Estes locais utilizam diferentes acessórios com base na pressão, temperatura e tipo de sistema que possuem. É importante obter o acessório correto para que tudo funcione bem.

Os acessórios de aço carbono com vedantes HNBR podem suportar temperaturas elevadas, pelo que são muito utilizados. As pessoas também utilizam conectores, tampões e válvulas de latão para determinados trabalhos em máquinas mais avançadas.

Tipo de encaixe | Aplicação |

|---|---|

Conector | Extensões de tubagem para esquemas complexos |

Tampões | Vedação de pontos finais não utilizados |

Válvulas de latão | Controlo do fluxo em condutas |

Todos estes produtos cumprem as rigorosas regras australianas, pelo que são fiáveis e seguros para o trabalho. Os engenheiros escolhem o aço-carbono e os acessórios de aço porque duram muito tempo e funcionam bem quando as coisas se tornam difíceis.

Factores que afectam a qualidade e o desempenho

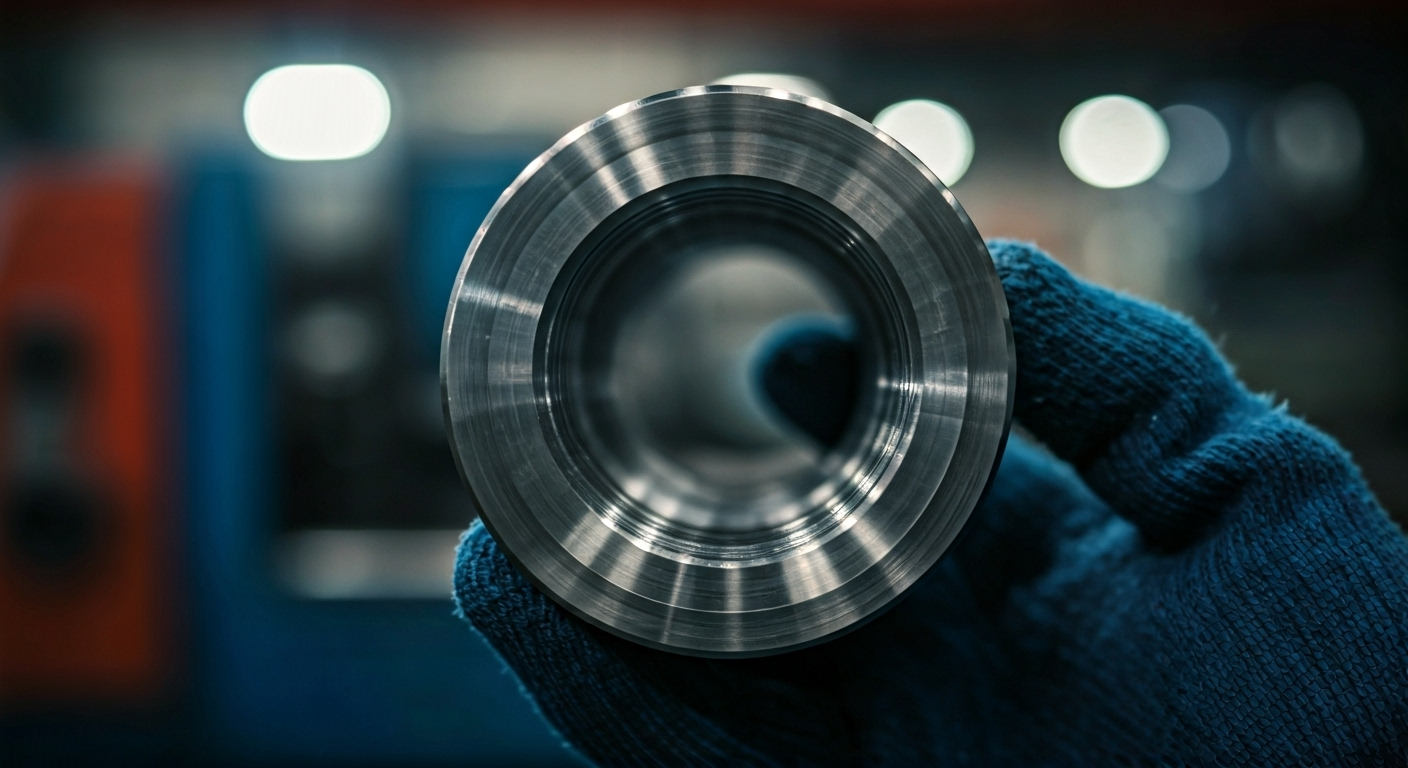

A forma como os acessórios de aço funcionam depende da qualidade do seu fabrico e dos materiais utilizados. Marcas como a Jones Stephens estabelecem um padrão, seguindo regras rigorosas que garantem que cada acessório é forte e fiável.

Coisas como o tipo de material, a forma cuidadosa como cada peça é moldada e a qualidade da vedação fazem a diferença na qualidade dos acessórios de aço-carbono. Se os acessórios não forem fabricados da forma correta, podem não funcionar tão bem, especialmente em locais onde existe muita pressão. Se prestar atenção a estes pormenores, pode ter a certeza de que o aço-carbono e os acessórios em aço durarão muito tempo e funcionarão bem em todo o tipo de situações.

Classes de materiais e normas de fabrico

A qualidade do material e o cumprimento das regras de fabrico estabelecidas são muito importantes quando se trata da confiança que se deposita nos acessórios de aço-carbono.

- Qualidade do aço-carbono: O aço-carbono de alta qualidade resiste ao desgaste. Suporta uma utilização difícil e mantém-se durante muito tempo em locais difíceis.

- Normas: Quando os acessórios seguem normas conhecidas, como o NPS, proporcionam uma melhor precisão de encaixe e ajudam a lidar com a pressão.

- Maquinação de precisão: As formas corretas de fabricar os acessórios de aço impedem as falhas ou misturas, o que é fundamental para bloquear as fugas.

- Ensaios: Testes cuidadosos significam que surgem menos problemas quando os sistemas estão a funcionar.

Quando escolhe marcas bem conhecidas que seguem todas as regras, ajuda a proteger os seus acessórios de aço. O aço-carbono continua a ser uma das principais escolhas para trabalhos que necessitam de acessórios resistentes e fortes, porque funciona bem e pode confiar nele. Os acessórios de aço-carbono e as normas NPS em conjunto proporcionam fiabilidade ao seu sistema.

Testes, certificação e requisitos de conformidade

Para garantir que os acessórios para tubos são seguros e fiáveis, os testes e a certificação são muito importantes. Os acessórios de aço-carbono são submetidos a testes de pressão e de calor. Estes testes ajudam a verificar se são adequados para utilização em diferentes tipos de trabalho.

A maioria dos locais utiliza produtos que seguem as regras da Austrália. Por exemplo, alguns acessórios, tais como acoplamentos e conectores de soldadura de encaixe, têm de passar por controlos rigorosos. As pessoas verificam-nas para se certificarem de que cumprem todas as regras.

Critérios | Processo de teste |

|---|---|

Normas australianas | Indica o tipo de material a utilizar e as dimensões corretas |

Certificações | Verificar se o produto funciona bem em diferentes condições |

Ensaios de pressão | Certificar-se de que os acessórios dos tubos suportam o esforço do trabalho sem se partirem |

As certificações de qualidade dão confiança a todos. Tanto os fabricantes como os utilizadores podem confiar que estes acessórios de aço e acessórios de aço-carbono são bons para utilizar. Estes sinais mostram que os acessórios irão cumprir a sua função, mesmo em situações de trabalho árduo.

Conclusão

Resumindo, escolher os acessórios para tubos de aço carbono corretos é fundamental para obter qualidade e bons resultados em qualquer trabalho. É preciso conhecer os vários tipos de acessórios, como cotovelos e flanges. Também é importante olhar para os graus do material e certificar-se de que cada um cumpre as normas corretas. Todas estas coisas ajudam a fazer com que o seu sistema dure mais tempo. Também ajudam a manter as coisas seguras e a funcionar bem. Deve dedicar algum tempo a procurar esta informação e verificar a qualidade. Desta forma, o seu projeto com acessórios para tubos e aço-carbono terá melhores resultados. Se quiser melhorar o seu projeto com bons acessórios para tubos ou flanges em aço-carbono, entre em contacto connosco. Estamos aqui para ajudar e responder às suas perguntas.

Perguntas mais frequentes

Quais são as principais vantagens dos acessórios para tubos de aço-carbono?

Os acessórios de aço-carbono são fortes e duram muito tempo. Aguentam bem a alta pressão. Isto torna-os bons para trabalhos difíceis. Pode encontrar acessórios como flanges e acoplamentos feitos de aço-carbono. Estes acessórios de aço ligam partes de um sistema e mantêm-nas seguras. Não enferrujam facilmente. Os acessórios de aço-carbono resistem ao desgaste e às rupturas. Isto dá-lhes uma vida mais longa em muitas situações de trabalho.

Como escolher o acessório de aço-carbono adequado para o meu projeto?

Escolha os acessórios de aço-carbono tendo em conta o tamanho do seu sistema, a pressão de que necessita e o tipo de trabalho que está a fazer. Se tiver um trabalho de alta pressão, então os acessórios de soldadura de encaixe funcionam melhor. Utilize tês e válvulas quando precisar de dividir tubos ou de controlar o fluxo. Antes de tomar uma decisão, certifique-se de que os acessórios de aço, como as soldaduras de encaixe ou os tês, correspondem às necessidades do seu sistema.

Os acessórios de aço-carbono são adequados para sistemas de alta pressão?

Sim, os acessórios de aço-carbono, como os acoplamentos e os estilos de soldadura de encaixe, fazem um bom trabalho em sistemas de alta pressão. Estes acessórios de aço são fortes e podem lidar com trabalhos difíceis. Cumprem as normas NPS corretas, pelo que pode utilizá-los quando mais precisa de segurança e resistência. Os acessórios de aço-carbono como estes ajudam a garantir que o seu sistema funciona bem, mesmo em condições difíceis.

Que certificações devo procurar nos acessórios para tubos australianos?

Procure certificações que mostrem que os acessórios seguem as regras australianas. Escolha artigos de fabricantes de confiança, como a Jones Stephens. Estas marcas deixam claro que as ferragens passam por controlos de qualidade rigorosos. Isto ajuda a mostrar que são fortes e que vão durar em diferentes trabalhos e locais.

Como posso manter os acessórios para tubos de aço-carbono para um desempenho a longo prazo?

A manutenção de rotina significa que é necessário limpar as fichas e os acessórios. Também é necessário utilizar produtos anti-corrosão. É importante procurar o desgaste, especialmente em objectos como os tampões e as mangueiras. Quando se efectuam verificações regulares, ajuda-se a proteger a resistência dos acessórios de aço-carbono. Isto permite que os seus acessórios de aço continuem a funcionar bem, mesmo quando o trabalho é duro.