-

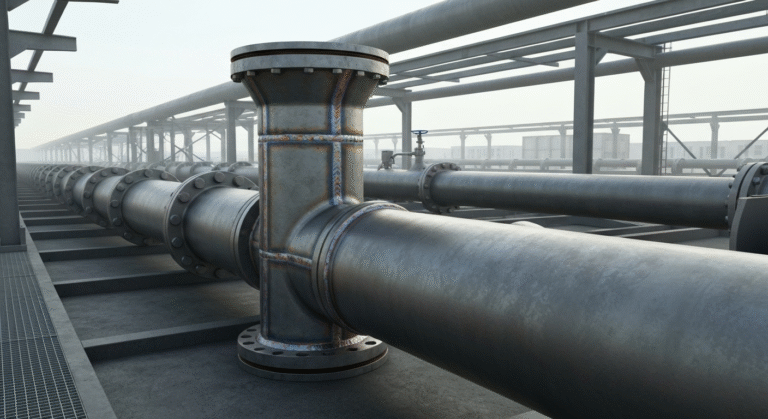

Zona industrial de Yinzhuang, concelho de Mengcun, cidade de Cangzhou, província de Hebei, China

Acessórios forjados: Guia para iniciantes sobre tipos e usos

Principais destaques

- Acessórios forjados são fabricados através de um processo de processo de forjamentogarantindo uma resistência e durabilidade de alto nível em aplicações industriais.

- Acessórios de soldadura de encaixe são ideais para ligações fortes e duradouras em sistemas de tubagem expostos a alta pressão.

- Disponível em diferentes tamanhos e especificaçõesEstes acessórios satisfazem diversos requisitos de tubagem em todas as indústrias.

- Materiais como aço inoxidável e liga de aço proporcionam uma resistência à corrosão e uma resiliência excepcionais.

- Estes acessórios são adaptávelA empresa tem uma vasta gama de produtos e serviços, que se destinam a instalações críticas nos sectores da produção de energia, sistemas de fluidos e química.

De seguida, vamos explorar o seu significado no mundo dos sistemas de tubagem.

Introdução

Conhecer a função dos acessórios para tubos é importante para quem trabalha com sistemas de tubagem industriais ou domésticos. Os acessórios forjados destacam-se dos outros devido à forma como são fabricados. O processo de fabrico utiliza calor elevado e muita pressão para dar forma à liga de aço. Isto torna estes acessórios fortes e capazes de durar em locais difíceis. Num sistema de tubagem, os acessórios forjados garantem que os fluidos ou gases se movem sem problemas. A sua construção ajudou a torná-los fiáveis para utilização em muitos campos diferentes.

Agora, vamos analisar mais de perto os acessórios forjados e o que os torna diferentes.

Compreender os acessórios forjados

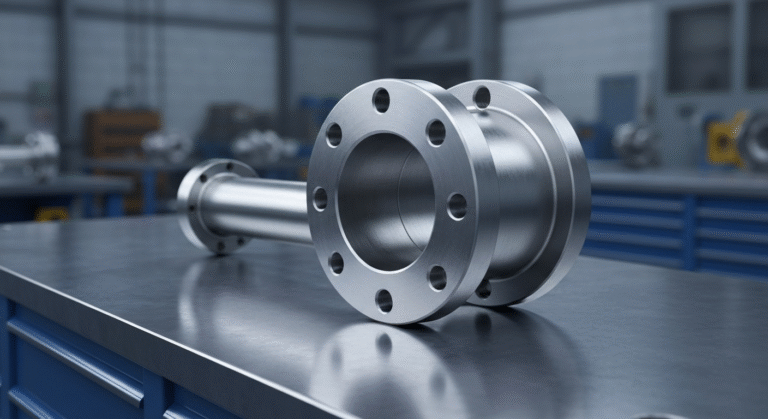

A palavra acessórios forjados é utilizado para peças especiais fabricadas com um forte processo de forjamento. Esta é uma forma em que o metal aquecido é moldado pressionando-o com força no lugar. Por este motivo, os acessórios finais têm mais densidade, grande resistência e duram muito mais tempo do que os acessórios fabricados de outras formas.

São frequentemente fabricados com liga de aço. Isto faz com que funcionem bem, mesmo em locais difíceis. Estas peças foram concebidas para resistir a uma utilização intensiva, pelo que são a melhor escolha quando necessita dos acessórios mais duradouros.

Abaixo, falaremos sobre as caraterísticas e os principais aspectos que deve saber sobre estes acessórios forjados.

O que são acessórios forjados?

Acessórios forjados são peças importantes utilizadas nos sistemas de tubagem. Ajudam a ligar os tubos de uma forma segura e fácil. São fabricados em aço resistente, como aço inoxidável e latão. Eles passam por um período difícil processo de forjamento para que cumpram todas as regras necessárias para o trabalho. A alta pressão de classe A classificação significa que estes acessórios funcionam bem quando é necessária muita força e é preciso confiar neles.

Existem dois tipos principais destes acessórios: soldadura de encaixe e acessórios roscados. Se pretender uma articulação forte e fixa, opte pela soldadura de encaixe tipo. Se o sistema precisar de ser desmontado um dia, utilize acessórios roscados.

Pode obter estes acessórios em muitos tamanhos e pressões nominais diferentes. Isto significa que se adaptam a muitas necessidades de trabalho e funcionam em diferentes domínios. Os acessórios são bons para parar corrosão. Assim, duram muito tempo, mesmo em locais duros, húmidos ou sujos.

Em seguida, vamos analisar as coisas e os pontos positivos que ajudam os acessórios forjados a serem especiais.

Principais caraterísticas e vantagens

As principais vantagens dos acessórios forjados distinguem-nos de outros acessórios para tubos. Estes acessórios têm uma grande resistência à corrosão. Isto significa que duram muito tempo, mesmo quando utilizados em locais com muita humidade ou com produtos químicos. A sua força para lidar com alta pressão também faz deles uma boa escolha. Por este motivo, vê-los-á muito na produção de energia e no trabalho em refinarias de petróleo.

Os acessórios forjados não são apenas fortes e duradouros. Também podem ser fabricados de acordo com especificações exactas, pelo que podem ser utilizados para muitos trabalhos diferentes. Os fabricantes utilizam materiais de qualidade, como ligas de aço, aço inoxidável e latão, o que ajuda a que durem mais tempo e a que possam ser utilizados em tarefas difíceis.

- Duradouro e resistente ao desgaste

- Funciona bem com muitos padrões industriais

- Alta resistência para utilizações grandes ou pesadas

- Design robusto feito para os trabalhos mais difíceis

Estas caraterísticas tornam os acessórios para tubos forjados importantes em qualquer trabalho de tubagem. Agora, vamos ver os tipos mais comuns que pode encontrar no mercado.

Tipos comuns de acessórios forjados

Quando se analisa os acessórios forjados, é importante conhecer os tipos mais comuns. As duas principais opções são os acessórios para soldadura de encaixe e os acessórios para tubos roscados NPT. Os acessórios de soldadura de encaixe utilizam uma soldadura de filete, pelo que são muito seguros. Os acessórios para tubos roscados NPT são fáceis de colocar e são frequentemente utilizados em sistemas que não são tão críticos.

Ambos os tipos de acessórios ajudam em diferentes configurações de tubagem, como redutores, cotovelos, tês, flanges e uniões. São fabricados em muitos tamanhos e podem corresponder a muitas especificações, o que é bom para muitas indústrias.

As próximas partes falarão mais sobre certos tipos, como cotovelos, uniões e tampões.

Cotovelos, Tês e Acoplamentos

Os cotovelos, tês e uniões são acessórios forjados comuns que têm uma grande utilidade num sistema de tubagem. Os cotovelos ajudam os tubos a alterar a forma como o fluido passa. Pode obter cotovelos com ângulos de 45° e 90°. Estes funcionam bem quando existe uma pressão elevada.

Os tês ajudam a fazer ligações de ramificação nos seus tubos. Encontrará diferentes tipos, como tês redutores e tês laterais, para muitas utilizações. A maioria dos tês une os tubos num ângulo claro de 90°. Esta configuração ajuda todos os fluidos a moverem-se bem em sistemas que podem ser complicados.

As uniões, como as uniões completas e as meias uniões, unem os tubos para que fiquem seguros e protegidos. Se for necessário ligar tubos de tamanhos diferentes, existem redutores para o efeito. Quando utilizados em conjunto, estes acessórios podem fazer com que um sistema de tubagem funcione sem problemas e se mantenha forte sob pressão.

Em seguida, falaremos sobre uniões, tampas e tampões que se encontram nos acessórios forjados.

Uniões, tampas e tampões

Os acessórios forjados têm muitas utilizações. As uniões são um tipo de acessório. São óptimos para unir tubos, especialmente quando é necessário desmontá-los frequentemente. As uniões proporcionam uma ligação forte, impedindo a corrosão entre diferentes materiais de tubos. Isto torna-os bons para utilizar em sistemas de tubagem com mais do que um material.

As tampas forjadas também são importantes. As pessoas utilizam-nas para selar a extremidade de um tubo, seja por um curto período de tempo ou para sempre, como quando é necessário efetuar reparações. Estas tampas ajudam a parar a corrosão e funcionam bem em muitas indústrias. O seu design simples permite-lhes encaixar sem problemas e fazer o trabalho corretamente.

Os tampões também têm a sua própria utilidade. Em sistemas de fluidos com secções, os tampões podem fechar partes para verificações ou reparações. Existem muitos tipos, como as cabeças hexagonais, quadradas e redondas. Pode colocá-los ou retirá-los de acordo com as especificações do trabalho.

Em seguida, mostraremos como as pessoas que são novas podem começar a utilizar acessórios forjados.

Guia para principiantes: Começando com acessórios forjados

Começar a utilizar acessórios forjados pode parecer difícil no início, mas quando se aprende o básico, torna-se muito mais fácil. Se estiver a trabalhar com padrões da indústria como ASME ou BSPPPara instalar uma casa de banho, é importante conhecer as especificações corretas e saber quais os materiais que combinam entre si. Isto ajuda a que todo o processo de instalação corra bem.

Sistema hidráulico RFS tem alguns bons guias para as pessoas que são novas neste domínio. Estes guias ajudam-no a escolher os acessórios certos para o seu sistema de tubagem. Quando se utilizam as ferramentas corretas e se compreende como funcionam materiais como o aço-liga e o latão, o trabalho torna-se muito mais simples. Verá que fazer uma boa instalação não é assim tão difícil.

Na próxima parte, falaremos sobre o que é necessário para começar se for novo neste trabalho.

O que é necessário para começar

Antes de colocar qualquer acessórios forjadosPara isso, é necessário ter consigo as ferramentas e os materiais adequados. A utilização de peças de alta qualidade pode ajudar o seu sistema de tubagem a funcionar bem. Eis algumas coisas de que vai precisar:

- Diferentes tipos de acessórios para soldadura de encaixe

- Tubos feitos de coisas como aço inoxidável ou latão que se adaptam aos seus acessórios

- Ferramentas que podem medir tamanhos para verificar o seu especificações

- Colas fortes ou vedantes feitos para tubos

Deve verificar o tamanho dos seus acessórios e prestar atenção às classificações de pressão. Estes pormenores devem corresponder às necessidades do seu projeto. Escolher peças feitas de liga de aço ajudará a sua tubagem a durar mais tempo, mesmo que a utilize todos os dias em locais movimentados.

Vejamos agora os passos que deve seguir para escolher e colocar acessórios forjados.

Processo passo-a-passo para selecionar e instalar acessórios forjados

Para instalar acessórios forjados da forma correta, é útil seguir alguns passos claros. Aqui está uma tabela simples que mostra como proceder:

Etapa | Detalhes |

|---|---|

Identificar os requisitos da tubagem | Veja o que o seu sistema de tubagem necessidades. Verifique a pressão, os materiais utilizados e se são adequados para a sua instalação. |

Selecionar o tipo de acessório | Escolha a melhor opção entre soldadura de encaixeou outros acessórios especiais para o seu sistema. |

Reunir ferramentas/materiais | Obter o que é necessário para o trabalho. Isto inclui aço inoxidável tubos, produtos de vedação e outros artigos necessários. |

Seguir as práticas de instalação | Utilize métodos regulares e seguros para obter bons resultados. Isto ajudará os seus acessórios a manterem-se fortes e a combaterem corrosão. |

Estes passos ajudam o seu projeto a corresponder a todos os especificações. De seguida, abordaremos mais pormenorizadamente cada passo.

Passo 1: Identificar os seus requisitos de tubagem

A primeira coisa a fazer com os acessórios forjados é descobrir quais as necessidades do seu sistema de tubagem. Deve verificar a pressão nominal que pretende, os diferentes tamanhos e certificar-se de que o material se adequa ao seu trabalho.

Alguns sistemas necessitam de ligas de aço que impedem a corrosão, enquanto outros necessitam de aço inoxidável se a pressão for elevada. É importante ter sempre em conta as especificações padrão da indústria, como a ASME. Isto ajuda-o a escolher o tamanho e a gama de pressão corretos.

Depois de conhecer todos estes requisitos, pode fazer uma lista de acessórios que correspondem às especificações do seu projeto. O passo seguinte é escolher o tipo de acessório que vai utilizar.

Passo 2: Escolher o tipo de acessório forjado adequado

A escolha do tipo de acessório correto ajuda-o a obter os melhores resultados. Se olhar para os tipos mais comuns, pode utilizar acessórios de soldadura de encaixe se quiser algo que fique no lugar. Para configurações que precisam de ser desmontadas, as flanges são uma boa escolha.

Se utilizar mais do que um tamanho de tubo, deve experimentar os redutores. Algumas configurações podem utilizar latão, por isso pode ter a certeza de que funciona bem com o que já existe. Verifique se existem acessórios como redutores, cotovelos e tês, porque estes são indispensáveis quando os tubos movem o fluido noutras direcções.

Escolher os acessórios forjados da forma correta traz força e flexibilidade ao seu design de tubagem, mesmo quando as coisas se tornam complicadas. Agora, continue a obter os materiais de que necessita para o próximo passo.

Etapa 3: Preparar ferramentas e materiais

Antes de começar a montar o seu equipamento, reúna todas as suas ferramentas e peças de alta qualidade. Eis o que precisa:

- Boas ferramentas de medição, como micrómetros

- Um forte conjunto de acessórios para soldadura de encaixe

- Equipamento de proteção quando se trabalha com aço inoxidável e latão

Certifique-se de que os seus materiais se adequam às necessidades especificações para a pressão correta e também para o tipo de sistema que possui. Se utilizar as ferramentas corretas e sólidas, pode parar os problemas antes que eles aconteçam. Isto é muito importante quando se lida com instalações de alta pressão.

Agora, vamos falar sobre as melhores formas de instalar acessórios forjados da maneira correta.

Passo 4: Melhores práticas de instalação

Instalação acessórios forjados A utilização correta dos acessórios ajuda-os a durar mais tempo e a funcionar melhor. Em primeiro lugar, deve olhar atentamente para os seus acessórios para que possa encontrar quaisquer problemas que o fabricante possa ter deixado para trás. Verifique a existência de corrosão e certifique-se de que podem resistir à ferrugem. Não aperte demasiado Roscas NPT pois isso pode afetar a sua resistência e provocar fugas.

Ao trabalhar com acessórios para soldadura de encaixeÉ necessária uma mão cuidadosa. Estes acessórios são pequenos e necessitam de um trabalho de soldadura exato. Se utilizar a forma correta de soldar, a junta será suave e forte. Isto é fundamental para evitar que a trepidação ou o estiramento prejudiquem o encaixe.

Se comprar acessórios de outros países, lembre-se de que Taiwan é conhecida por fabricar acessórios fortes e de primeira qualidade. É bom seguir todas as regras principais quando as coloca. Isso ajudá-lo-á a evitar erros e o encaixe será firme.

Resumindo, isto é o que precisa de saber sobre os acessórios forjados e a forma correta de os utilizar.

Conclusão

Em suma, é importante conhecer os acessórios forjados se quiser trabalhar com um sistema de tubagens. Estes acessórios forjados oferecem uma solução forte e estável para muitas utilizações. Pode utilizá-los tanto na indústria como em casa. Quando se aprende sobre os tipos de acessórios forjados e se segue um guia fácil para os escolher e colocar, obtém-se um resultado melhor e mais rápido. Os acessórios certos ajudam o seu sistema de tubagem a manter-se mais forte durante mais tempo. Também garantem o seu bom funcionamento. Se quiser iniciar o seu próprio projeto utilizando acessórios forjados, pode pedir uma conversa gratuita para o ajudar a começar.

Perguntas mais frequentes

Os acessórios forjados são diferentes dos acessórios para soldadura topo a topo?

Sim, os acessórios forjados não são o mesmo que os acessórios para soldadura topo a topo. São feitos de uma forma diferente durante o processo de fabrico. Os acessórios forjados têm normalmente uma maior resistência à tração. Isto significa que são fortes e podem suportar mais pressão. As pessoas utilizam frequentemente estes acessórios forjados para pequenos sistemas de tubagem. Por outro lado, os acessórios para soldadura de topo são mais utilizados para tubos de maiores dimensões. Estes utilizam frequentemente ligações de soldadura de encaixe para unir bem os tubos. Tanto o processo de fabrico como a utilização de soldadura de encaixe tornam estes acessórios bons para as suas próprias utilizações.

Que indústrias utilizam habitualmente acessórios forjados em Singapura?

As indústrias que trabalham na produção de energia, em trabalhos químicos e na movimentação de fluidos utilizam acessórios forjados no seu trabalho. Empresas como a rfs hydraulics tiram muito partido destes acessórios, porque os acessórios forjados são bons a lidar com alta pressão em sistemas de tubagem que podem ser complicados.

Como é que determino o tamanho e a pressão nominal?

Consulte as normas da indústria, como a ASME, para saber o tamanho e a classe de pressão de que necessita para o seu sistema de tubagem. Antes de escolher os acessórios, veja os diferentes tamanhos que vai utilizar e quais os limites necessários. Certifique-se de que as suas especificações correspondem ao que é necessário para o sistema.

Os acessórios forjados podem ser utilizados com todos os materiais de tubos?

Sim, os acessórios forjados podem ser utilizados com materiais de tubagem como o aço inoxidável, o latão e as ligas de aço. Isto torna-os adequados para muitas utilizações. Quando escolhe os acessórios certos, ajuda a garantir que a instalação decorre sem problemas e funciona bem.