-

Zona industrial de Yinzhuang, concelho de Mengcun, cidade de Cangzhou, província de Hebei, China

Cotovelo de solda de topo sem costura de 90 graus importado | A234 WPB

Principais destaques

- Seamless 90-degree butt weld elbows are crafted to meet A234 WPB standard specifications.

- Specifically designed for demanding high-pressure and corrosive industrial applications in Singapore.

- Available in long radius (LR) and short radius (SR) options to suit diverse pipe layouts.

- Manufactured from premium-quality carbon steel, ensuring durability and robust performance.

- Fully compliant with ASTM, ANSI, and ASME international standards for reliable compatibility.

- Offered in an extensive range of nominal sizes and schedules to accommodate varied pipe fittings and dimensions.

Introdução

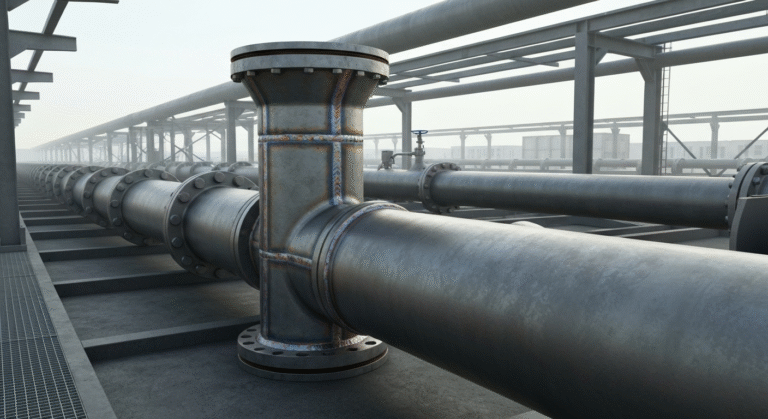

Seamless 90-degree butt weld elbows are key steel fittings for when you need to change the way a pipe goes. These butt weld pipe fittings help with smooth turns in a piping system. Made to meet A234 WPB specifications, these steel fittings fit the needs of many industries in Singapore. You can use them in places with high pressure or where pipes might deal with bad chemicals. They work well for both long and short radius uses. The seamless design helps make sure the joint will not leak, so you get a strong and safe connection. Because of this, these fittings are used in many kinds of jobs and places.

Key Features of 90 Degree Seamless Butt Weld Elbow (A234 WPB)

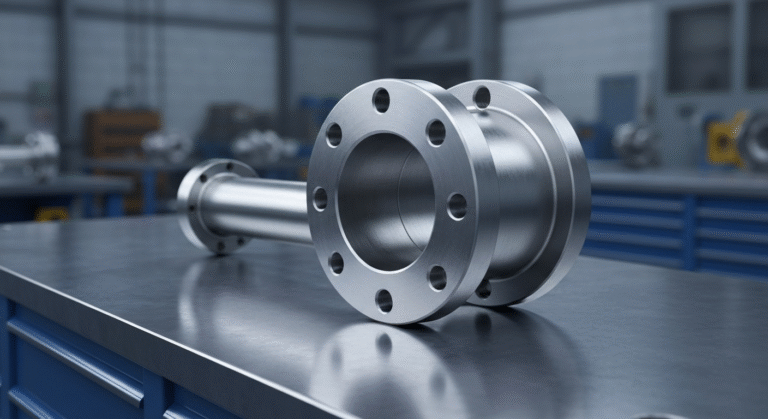

This elbow is made from strong carbon steel and is built to last. It gives a tight and safe fit for many uses. The seamless butt weld helps to give a smooth path for good flow. It is made with care so it can handle high pressure and high heat. The A234 WPB standard means you get something you can trust and is good quality.

Composição dos materiais e normas de fabrico

The integrity of seamless 90-degree elbows hinges on their high-quality material composition and adherence to recognized manufacturing standards. Crafted primarily from carbon steel, these elbows achieve outstanding tensile and shear strength while maintaining corrosion resistance under harsh conditions. Specialty applications might also utilize alloy steel for added stress resilience.

A detailed focus is placed on conforming to ASTM, ANSI, and ASME specifications, which ensure precise pipe fitting standards. Furthermore, each elbow undergoes rigorous non-destructive testing for quality assurance. Manufactures can provide Material Test Reports (MTR) for reference and compliance checks upon request.

Tipo de material | Conformidade com a norma | Caraterísticas principais |

|---|---|---|

Aço carbono | ASTM A234 WPB | High strength, durability |

Aço de liga leve | ASME specifications | Resilience in high-pressure settings |

Aço inoxidável | ANSI standards | Corrosion resistance in harsh environments |

These standards ensure the elbows meet international benchmarks and deliver continued industrial reliability.

Benefits of Seamless Construction for Singaporean Projects

What is the difference between seamless and welded pipe?

Seamless pipes are manufactured without any weld seam, providing higher strength and pressure ratings. Welded pipes are made by welding the edges of a steel plate or coil together, offering cost-effectiveness but slightly lower pressure handling capabilities compared to seamless pipes.

The seamless construction of 90-degree elbows is a big plus for industries in Singapore where accuracy is very important. Because there are no welds, these steel butt fittings are very strong. The surface of the pipe stays smooth and even. So, there is no risk of leaks, which helps avoid consequential damages or failures in the material.

Seamless steel butt fittings also make things easier when it comes to maintenance. You do not need to deal with as many problems over time, and there is less downtime. Since there are no joints, these fittings last longer. This also stops stress from building up like it can with welded fittings.

- Seamless fabrication cuts down on the chance of failure from unused items or after long installations.

- They work the same way, even when the temperature and pressure get really high.

- There are fewer technical questions, so things move along well with projects.

- They fit places where you may need further help or special changes.

With all these benefits, most people in Singapore pick seamless elbows for many important applications.

Typical Applications in Singapore’s Industrial Sector

Seamless 90-degree butt weld elbows play a key role in many industries in Singapore. They let the flow of pipelines change direction at a right angle, so everything keeps working without a stop. You often see these elbows in pipe fittings where they help the run of the pipe curve smoothly and keep things strong and safe.

Their shape makes them great for jobs that need exact turns in the pipe. They do this without losing their strength. It does not matter if you need them for high pressure, for pipes that do not rust, or for tough places. These butt weld fittings give a strong answer to many of Singapore’s top industries.

Usage in Oil & Gas, Petrochemical, and Marine Industries

Seamless 90-degree butt weld fittings are very important in the oil and gas, petrochemical, and marine industries. These steel fittings help change the direction of flow in areas that are busy and under a lot of stress.

In oil and gas, these fittings handle corrosive liquid and high pressure. This helps pipelines work well and last a long time, even over large distances. In the petrochemical field, people like these steel butt weld fittings because they are strong. They also work well with many kinds of pipeline layouts for moving chemicals.

For marine jobs, materials must be tough against water and salt. People often choose stainless steel butt or stainless steel fittings, because these do not rust easily. They meet international rules, so you can trust them. They help cut down on repairs and keep things running smoothly in these industries.

Performance in High-Pressure and Corrosive Environments

When used in places with a lot of pressure or where things can eat away at metal, seamless 90-degree fittings show great strength. The strong steel butt construction helps keep the system safe. This stability is important, so people can work even in tough settings.

Stainless steel types work well in places like the sea or factories that use chemicals. In these spots, stopping rust and damage is very important. These fittings also handle both high pressure and high heat.

Each one is made to match certain warranties and ways of working. This top design means there is less chance for money back or having to fix problems. You can count on these to last for a long time. Plus, you get technical help and support from the time of order through to when you set them up.

Conclusão

To sum up, knowing why mental health is important and making small changes in your day can really help how you feel. The way you sleep, what you eat and drink, what you do for fun, and how you think are all key parts of feeling better. You should see looking after your mind as something you must do, not just something nice to have. Put yourself and your well-being first, because having a healthy mind will make your life happier and better.

Perguntas mais frequentes

What is the difference between seamless and welded butt weld elbows?

Seamless butt weld elbows do not have any joints. This makes them stronger and better for tough situations. Welded elbows, on the other hand, have visible seams. They cost less but they are not as strong. Both types always meet ASTM and ASME standards. You will find that they each work better for different uses.

How do I select the right size and schedule for my piping system?

Pick the right one by looking at the nominal size and schedule that fit your system. Check your pipe specifications with care. Write these details in the order notes when you buy, so you get the exact fittings you need. If you need more help, the technical resources and customer service hours are there for you, including how to get a return email if needed.

Are these elbows compliant with Singapore’s import regulations?

Yes, the elbows meet international shipping rules because they follow ISO standards. These products come from trusted places like India or Houston, TX. So, they will match Singapore’s rules for bringing in industrial items.

What testing and certifications are available for A234 WPB elbows?

Each elbow meets ASTM, ANSI, and ASME standards. You can get a Material Test Report (MTR) if you ask at the time of order or by contacting customer support or email customer service in Houston TX. If you send back items that have not been used and are still good, within the right time, you will get a refund.

How should 90 degree butt weld elbows be installed and maintained?

To install and take care of 90-degree butt weld elbows, make sure you line them up right when you put them in. This will help to keep stress away from the elbows. It’s important to check them often for leaks or rust. You should follow what the manufacturer says about when and how to do maintenance. Always handle and store the elbows with care. This will help keep the butt weld elbows strong and working well.