-

Zona industrial de Yinzhuang, concelho de Mengcun, cidade de Cangzhou, província de Hebei, China

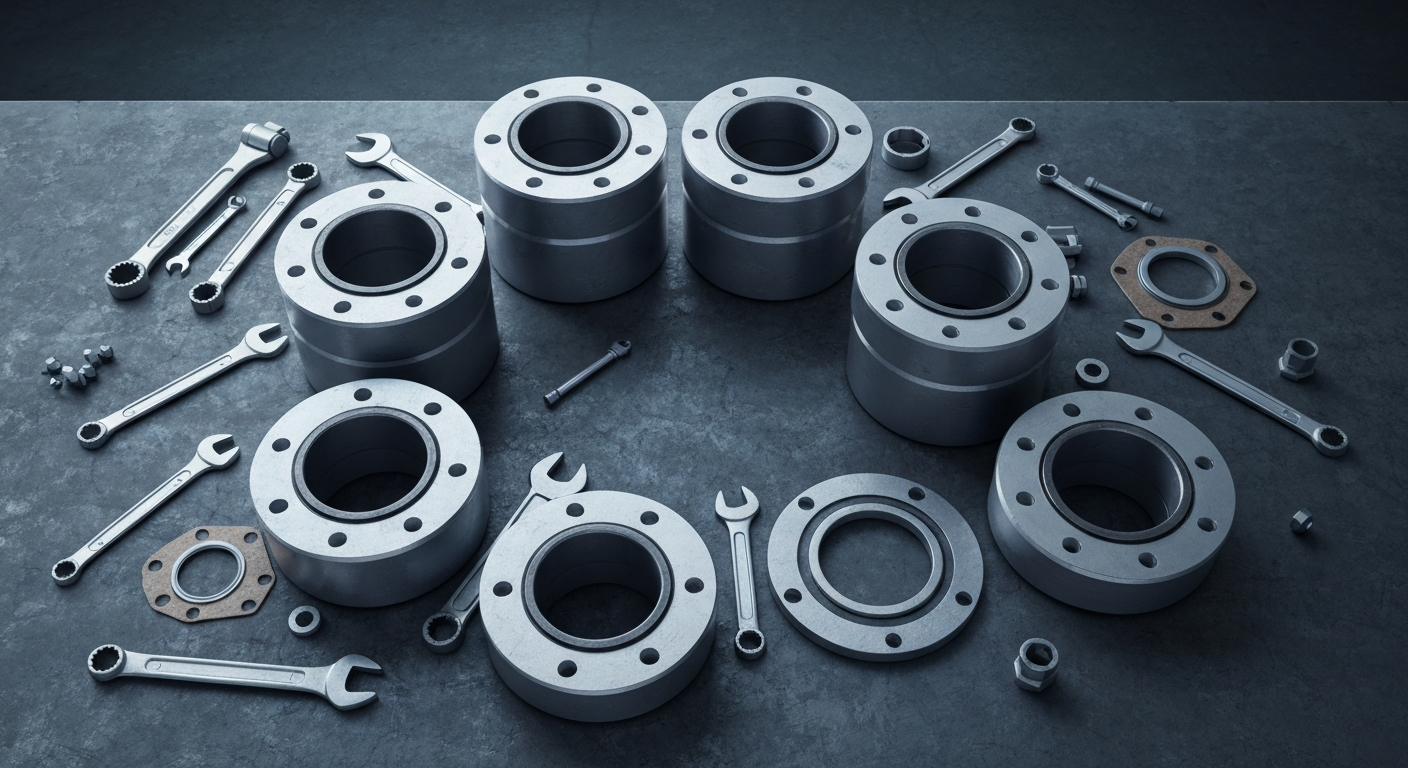

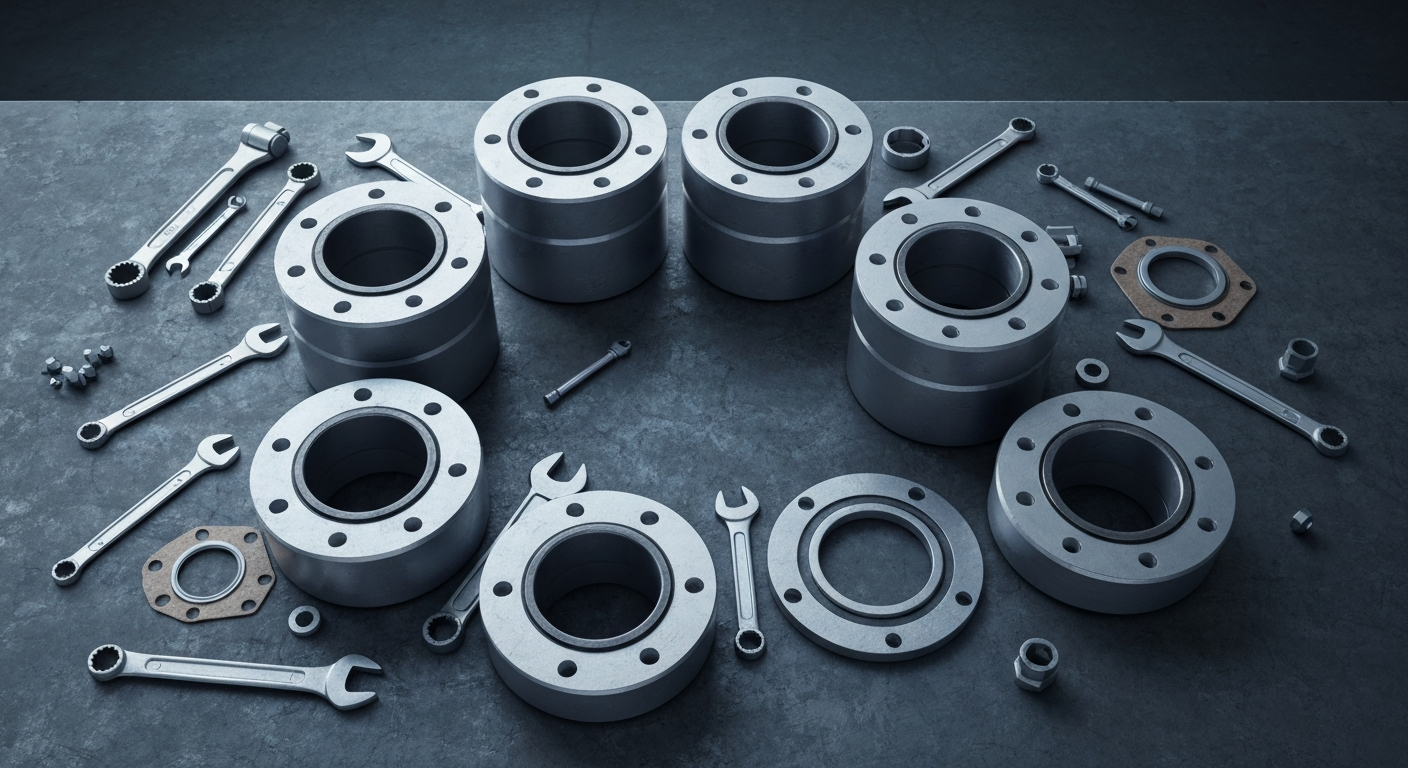

Instalações de flanges de alumínio: Dicas para o sucesso

Principais destaques

Aqui estão os principais pontos do nosso guia para instalações de flanges de alumínio:

- Os flanges de alumínio são leves, duráveis e oferecem excelente resistência à corrosão, tornando-os ideais para vários sistemas de tubulação.

- Os tipos comuns incluem flange com pescoço soldado, flange deslizante, flange com solda por encaixe e flanges cegas, cada um adequado para diferentes níveis de pressão e aplicações.

- Em comparação com materiais como aço inoxidável e ferro fundido, o alumínio oferece uma combinação única de baixo peso e alta durabilidade.

- Esses acessórios para tubos são amplamente utilizados em aplicações marítimas, na indústria de bebidas e em projetos estruturais devido ao seu desempenho em ambientes com água salgada.

- A instalação adequada requer um alinhamento cuidadoso, o uso correto de juntas e limpeza para garantir uma vedação firme e sem vazamentos.

Introdução

Quando se trata de conectar tubos, válvulas e outros equipamentos num sistema de tubulação, é fundamental escolher os componentes certos. Os flanges de alumínio são uma excelente opção para muitas aplicações industriais em que o peso e a corrosão são preocupações importantes. Esses conectores essenciais proporcionam uma junta segura, confiável e, muitas vezes, reutilizável. Nesta publicação do blog, exploraremos tudo o que precisa saber sobre a instalação de flanges de alumínio, desde a compreensão dos diferentes tipos até o seguimento das melhores práticas para um projeto bem-sucedido.

Compreender os flanges de alumínio

Uma flange de alumínio é uma borda ou colar saliente usado para conectar tubos, válvulas e outros equipamentos para formar um sistema de tubulação. Essas conexões são projetadas para serem aparafusadas, criando uma conexão forte e segura na extremidade do tubo. A principal vantagem de usar uma flange de tubo de alumínio é a sua combinação de leveza e durabilidade impressionante.

Diferentes projetos têm requisitos únicos, e é por isso que existem várias opções de tipos de flanges disponíveis. Compreender os principais tipos de flanges de alumínio e as suas utilizações comuns irá ajudá-lo a selecionar a opção perfeita para as suas necessidades específicas. Vejamos os diferentes designs e as suas aplicações mais adequadas.

Principais tipos de flanges de alumínio

Os flanges de alumínio estão disponíveis em vários modelos para atender às exigências de diferentes aplicações. Os tipos de flanges mais comuns que encontrará são os flanges com pescoço soldado, que apresentam um cubo cónico longo para uma excelente distribuição de tensão, tornando-os ideais para sistemas de alta pressão. Outra opção popular é o flange deslizante, que desliza sobre o tubo e é soldado no lugar para utilizações de baixa pressão.

Para sistemas de alta pressão com tubos de menor diâmetro, os flanges com solda de encaixe são uma opção confiável. Eles são soldados usando uma conexão de encaixe. Outros tipos importantes de flanges com gargalo incluem:

- Flanges cegas: Utilizado para vedar a extremidade de um tubo ou válvula, permitindo futura expansão ou manutenção.

- Flange com junta sobreposta: Utilizada com uma extremidade cega, esta flange pode ser rodada para facilitar o alinhamento dos parafusos e é ideal para sistemas que necessitam de desmontagem frequente.

- Flanges roscadas: Aparafusados a um tubo, são adequados para aplicações de baixa pressão onde a soldadura não é viável.

Cada tipo é projetado para criar uma conexão segura, geralmente com uma junta para garantir uma vedação à prova de vazamentos. A sua escolha dependerá da pressão do sistema, da temperatura e dos requisitos de manutenção.

Aplicações comuns em sistemas de tubagem

As propriedades únicas dos flanges de alumínio tornam-nos a escolha preferida em vários setores. A sua excepcional resistência à corrosão é particularmente valiosa em aplicações marítimas, onde a exposição a ambientes salinos degradaria rapidamente outros metais. É comum encontrá-los a ligar tubagens, válvulas e outros equipamentos em navios e plataformas offshore.

Na indústria de bebidas e processamento de alimentos, a higiene e a resistência à corrosão são fundamentais. Os flanges de alumínio proporcionam uma superfície durável e não reativa, garantindo a pureza dos produtos. Eles também são usados na indústria química para tubulações que transportam líquidos que exigem alta resistência à corrosão.

Além do transporte de fluidos, os flanges de alumínio também são utilizados em aplicações estruturais. A sua natureza leve torna-os ideais para fachadas de edifícios e sistemas de cobertura, onde a redução do peso total é uma consideração fundamental. Estes acessórios para tubos versáteis são uma solução fiável para uma ampla gama de projetos industriais e de construção.

Alumínio vs outros materiais para flanges

Ao selecionar um flange, tem várias opções de materiais, incluindo alumínio, aço inoxidável e ferro fundido. O alumínio destaca-se pelas suas propriedades leves e excelente resistência à corrosão, tornando-o um forte candidato para muitas aplicações. No entanto, compreender como ele se compara a outros materiais é fundamental para tomar a decisão certa para o seu projeto.

Cada material, seja uma liga especializada ou um metal comum, tem vantagens distintas. Comparar o alumínio com o aço inoxidável e o ferro fundido irá destacar os seus pontos fortes e ajudá-lo a determinar quando é a opção superior em termos de durabilidade e desempenho. Vamos examinar estas comparações mais de perto.

Comparando flanges de alumínio com flanges de aço inoxidável

Quando se compara o alumínio ao aço inoxidável, uma das diferenças mais significativas é o peso. O alumínio é substancialmente mais leve, o que pode simplificar a instalação e reduzir a carga estrutural. Em termos de resistência à corrosão, ambos os materiais têm um bom desempenho, mas o aço inoxidável é frequentemente ligado com crómio, o que lhe confere uma vantagem em determinados ambientes altamente corrosivos.

No entanto, flanges de alumínio são uma excelente opção quando há risco de corrosão sob tensão por cloretos. A durabilidade de ambos os materiais é alta, mas o tipo específico de cada liga determinará, em última instância, a sua resistência e vida útil. A escolha entre eles geralmente se resume a equilibrar peso, custo e os agentes corrosivos específicos do seu sistema. A soldagem em uma flange de alumínio também requer técnicas diferentes das utilizadas em uma flange de aço inoxidável.

Caraterística | Alumínio | Aço inoxidável |

|---|---|---|

Peso | Leve | Mais pesado |

Resistência à corrosão | Excelente, especialmente contra cloretos | Muito alto, varia de acordo com a nota |

Custo | Geralmente mais económico | Normalmente mais caro |

Soldabilidade | Requer técnicas especializadas | Mais fácil de soldar |

Diferenças entre flanges de alumínio e ferro fundido

A escolha entre flanges de alumínio e ferro fundido depende muito das exigências específicas da sua aplicação. O ferro fundido é conhecido pela sua resistência e é frequentemente utilizado em sistemas de água de alta pressão e pelas suas qualidades de amortecimento de vibrações. No entanto, é significativamente mais pesado e mais frágil do que o alumínio.

O alumínio oferece uma alternativa leve, mas durável. Embora os flanges de ferro fundido sejam comuns, a resistência superior do alumínio à corrosão torna-o uma escolha melhor para aplicações ao ar livre, marítimas ou químicas. O ferro fundido pode enferrujar e degradar-se quando exposto à humidade, enquanto o alumínio forma uma camada protetora de óxido.

Para aplicações estruturais em que o peso é um fator importante, o alumínio é claramente o vencedor. As especificações do seu projeto, incluindo pressão, temperatura e exposição a elementos corrosivos, irão orientar a sua decisão. Se precisar de uma solução durável, leve e resistente à corrosão, o alumínio é frequentemente a escolha mais prática em relação ao ferro fundido.

Principais vantagens dos flanges de liga de alumínio

Os flanges de liga de alumínio oferecem uma poderosa combinação de benefícios que os tornam a melhor escolha para sistemas de tubulação modernos. A sua característica mais elogiada é o facto de serem incrivelmente leves, o que simplifica o manuseamento e a instalação, reduzindo os custos de mão de obra e a tensão estrutural. Isso, combinado com a sua excelente resistência à corrosão, torna-os uma solução altamente prática e durável.

Além disso, essas flanges estão disponíveis em vários graus e podem atender a diferentes requisitos de classe de pressão, garantindo uma conexão confiável e sem vazamentos. Explorar as vantagens específicas, como seu desempenho leve e durabilidade, mostrará por que essa liga de alumínio é tão popular.

Benefícios do desempenho leve

Uma das vantagens mais significativas do alumínio é a sua baixa densidade. As flanges de alumínio são muito mais leves do que as suas contrapartes de aço ou ferro fundido, o que traz vários benefícios práticos durante a instalação e utilização. Esta natureza leve torna-as mais fáceis de manusear, transportar e instalar, muitas vezes exigindo menos maquinaria pesada e reduzindo o tempo de trabalho.

Este benefício é especialmente importante em aplicações onde o peso é um fator crítico, como nas indústrias aeroespacial, automóvel e naval. Um peso total mais baixo pode melhorar a eficiência de combustível em veículos ou reduzir a carga estrutural em edifícios e plataformas. Ao considerar conexões com um grande diâmetro externo, a redução de peso torna-se ainda mais substancial.

As principais vantagens do peso leve incluem:

- Instalação mais fácil e rápida

- Custos reduzidos de envio e manuseio

- Menores requisitos de suporte estrutural

Essas vantagens tornam o alumínio uma escolha inteligente para projetos em que a eficiência e a redução de peso são prioridades.

Resistência à corrosão e durabilidade

Os flanges de alumínio são muito apreciados pela sua capacidade natural de resistir à corrosão. Quando exposto ao ar, o alumínio forma uma camada fina e resistente de óxido de alumínio na sua superfície. Essa camada atua como uma barreira, protegendo o metal contra a ferrugem e a degradação causadas pela humidade e por muitos produtos químicos. Isso torna o alumínio uma opção incrivelmente durável para uso a longo prazo, especialmente em ambientes adversos.

Essa resistência inerente à corrosão é a razão pela qual o alumínio é a escolha preferida para aplicações marítimas e fábricas de processamento químico. Ao contrário de outros metais que requerem revestimentos especiais ou manutenção frequente, os flanges de alumínio mantêm a sua integridade com uma manutenção mínima. Essa durabilidade prolonga a vida útil do seu sistema de tubulação e reduz a necessidade de substituições dispendiosas.

Mesmo com componentes robustos, como um flange com pescoço soldado, a limpeza regular pode ajudar a manter o desempenho, mas o próprio material base oferece uma forte defesa contra elementos corrosivos. Isso torna o alumínio uma opção confiável, de baixa manutenção e durável para conexões críticas.

Escolhendo o flange de alumínio certo para o seu projeto

Selecionar o flange de alumínio correto é essencial para a segurança e eficiência do seu sistema de tubulação. Com vários tipos, tamanhos e especificações disponíveis, fazer a escolha certa envolve considerar as necessidades específicas do seu projeto. Fatores como pressão, temperatura, tipo de fluido transportado e frequência de manutenção necessária são importantes.

Desde o tipo de flange até o acabamento na parte superior da flange, todos os detalhes são importantes. Compreender os tamanhos comuns e as diferenças entre opções como flanges de base plana e ANSI ajudará a encontrar os acessórios de tubulação perfeitos para uma conexão segura e duradoura. Vejamos essas especificações.

Tamanhos e especificações comuns

Os flanges para tubos de alumínio são fabricados de acordo com dimensões padronizadas para garantir que sejam intercambiáveis e compatíveis com outros componentes de tubulação. Essas normas, como as estabelecidas pelo American National Standards Institute (ANSI), definem tudo, desde o diâmetro externo (OD) até o padrão dos orifícios dos parafusos. Os tamanhos podem variar de 1/2 polegada a 48 polegadas ou mais.

A classificação de pressão, ou classe, é outra especificação crítica. As classes de pressão comuns para flanges de alumínio incluem 150#, 300# e 600#, que indicam a pressão máxima que a flange pode suportar com segurança. Normas de rosca como NPTF (National Pipe Taper Fuel) também são especificadas para flanges roscadas para garantir uma vedação hermética.

Aqui estão algumas especificações comuns que poderá encontrar:

Especificação | Descrição |

|---|---|

Tamanho | Varia de 1/2″ a 48″ para corresponder ao tamanho nominal do tubo. |

Padrão | ANSI, ASME, DIN e EN são normas comuns da indústria. |

Classe de pressão | 150#, 300#, 600#, etc., indicando a capacidade de pressão. |

Grau | 6061, 5083, etc., indicando a liga de alumínio específica. |

Base plana vs. flanges de alumínio ANSI

Ao selecionar um flange de alumínio, poderá encontrar termos como “base plana” e “ANSI”. Compreender a diferença é fundamental para escolher a especificação correta para o seu projeto. Os flanges ANSI são fabricados de acordo com os rigorosos padrões dimensionais estabelecidos pelo American National Standards Institute, que agora são mantidos pela ASME (American Society of Mechanical Engineers). Esses padrões determinam dimensões, classificações de pressão e materiais para garantir segurança e intercambiabilidade.

Por outro lado, uma flange de base plana pode referir-se a uma flange com uma superfície de junta de face plana (FF), em oposição a uma face elevada (RF). Uma flange de face plana tem uma superfície de junta no mesmo plano que o círculo de aparafusamento. Este design é frequentemente utilizado em aplicações de baixa pressão e com ferro fundido ou outros materiais frágeis para evitar a deformação quando os parafusos são apertados.

Embora um flange de alumínio ANSI possa ter uma face plana, o termo “ANSI” em si refere-se à adesão geral a uma norma abrangente. Verifique sempre se o flange escolhido cumpre a especificação ASME/ANSI exigida para a sua aplicação, a fim de garantir o encaixe e o desempenho adequados.

Diretrizes de instalação para conexões com flange de alumínio

A instalação adequada é fundamental para garantir que a sua conexão de flange de alumínio seja segura e sem vazamentos. Uma flange mal instalada pode levar à falha do sistema, tempo de inatividade dispendioso e potenciais riscos à segurança. O processo envolve mais do que apenas apertar parafusos; requer preparação cuidadosa, alinhamento e o uso correto de uma junta.

Obter uma vedação perfeita é o objetivo final de qualquer instalação de flange. Seguir os passos corretos para a colocação e vedação, e compreender como as flanges de alumínio interagem com diferentes materiais de tubagem, ajudará a evitar fugas e a garantir a integridade a longo prazo do seu sistema de tubagem.

Passos para a colocação e vedação adequadas

Uma instalação bem-sucedida da flange começa com a preparação. Antes de começar, certifique-se de que as faces da flange estejam limpas e livres de detritos, riscos ou defeitos que possam comprometer a vedação. A limpeza adequada da flange e da junta é uma etapa simples, mas crucial. Uma superfície danificada pode impedir que a junta se encaixe corretamente, causando vazamentos.

Quando estiver pronto para montar a conexão, coloque a junta com cuidado, certificando-se de que ela esteja centralizada na face do flange. Uma junta desalinhada é uma causa comum de falha. Insira os parafusos e aperte-os em um padrão em estrela ou cruzado para aplicar pressão uniformemente em todo o flange. Esse aperto gradual e equilibrado é essencial para obter uma vedação firme sem deformar o flange.

Siga estes passos importantes para uma instalação segura:

- Inspecione e limpe todas as superfícies das flanges e juntas.

- Use uma junta nova e de alta qualidade adequada para a sua aplicação.

- Aperte os parafusos gradualmente, seguindo um padrão em estrela, para garantir uma pressão uniforme.

Seguir este processo irá ajudá-lo a criar uma conexão confiável, sem vazamentos e duradoura.

Compatibilidade com diferentes materiais de tubagem

Os flanges de alumínio são versáteis e podem ser usados com uma variedade de materiais de tubos. No entanto, ao conectar alumínio a um metal diferente, é importante considerar o potencial de corrosão galvânica. Essa reação pode ocorrer quando dois metais diferentes entram em contacto na presença de um eletrólito, como água, fazendo com que um metal corroa mais rapidamente.

Para evitar isso, pode-se usar kits de isolamento, que incluem juntas não condutoras e mangas para parafusos. Esses kits criam uma barreira entre os diferentes metais, impedindo a passagem da corrente elétrica que causa a corrosão. Essa é uma prática comum em encanamentos e tubulações industriais, onde materiais diferentes são unidos.

Em algumas configurações, pode ser utilizada uma flange de apoio (como uma flange de junta sobreposta). Aqui, a flange de alumínio não entra em contacto direto com o fluido no tubo. Em vez disso, uma extremidade feita de um material compatível é soldada ao tubo e a flange desliza sobre ela. Isso permite utilizar o alumínio por suas vantagens de leveza e custo, garantindo a compatibilidade do material para todos os encaixes e válvulas do sistema.

Conclusão

A instalação bem-sucedida de flanges de alumínio requer um sólido conhecimento das suas propriedades únicas e das melhores práticas para integração nos seus sistemas de tubagem. Desde a sua natureza leve até à sua resistência à corrosão, as flanges de alumínio oferecem inúmeras vantagens que podem aumentar a durabilidade e a eficiência dos seus projetos. Lembre-se de que a escolha certa do flange e as técnicas de instalação adequadas são cruciais para obter conexões confiáveis e evitar vazamentos. Seguindo as dicas descritas neste blog, pode garantir que as suas instalações de flanges de alumínio não só sejam bem-sucedidas, mas também contribuam positivamente para o desempenho geral dos seus sistemas de tubulação. Se tiver alguma dúvida ou precisar de mais ajuda, não hesite em entrar em contacto!

Perguntas mais frequentes

As flanges de alumínio são adequadas para instalações ao ar livre?

Sim, os flanges de alumínio são uma excelente escolha para instalações ao ar livre. A sua resistência natural à corrosão permite que resistam à exposição às intempéries e à humidade sem enferrujar. Isso torna-os altamente duráveis e confiáveis para aplicações ao ar livre, incluindo ambientes marinhos, onde resistem eficazmente aos danos causados pela água salgada.

Quais normas industriais se aplicam às flanges de alumínio?

Os flanges de alumínio são fabricados de acordo com várias normas industriais para garantir a qualidade e a intercambiabilidade. As normas mais comuns são as da ANSI (American National Standards Institute) e da ASME (American Society of Mechanical Engineers), como a ASME B16.5. Essas normas definem dimensões, materiais, especificações e classificações de classe de pressão.

Quando devo escolher flanges de alumínio em vez de outras opções?

Deve selecionar flanges de alumínio quando a sua aplicação exigir uma combinação de leveza e alta resistência à corrosão. Elas são ideais para projetos em que a redução da carga estrutural é importante ou em que os acessórios para tubos serão expostos à humidade ou a elementos corrosivos, tornando-as uma escolha melhor do que materiais mais pesados ou menos resistentes.