-

Yinzhuang Industrial zone,Mengcun county,Cangzhou city,Hebei province,China

Want a custom configuration?

Carbon Steel Cap

Original price was: $7.70.$7.00Current price is: $7.00.

Size: 1/2”~80”,DN15~DN2000

Schedule: Sch 20, 40, STD, 80, 160, XXS

Designation: ASTM / ASME A234, A860, A420

Grade: WPB/C, WPHY 42, 46, 52, 60, 65, 70, WPL 3, 6, 9

- Premium Quality

- Secure Payments

- Satisfaction Guarantee

- Worldwide Shipping

- Money Back Guarantee

Carbon Steel Cap – Reliable Protection for Pipe Ends

It is a vital component designed to protect pipe ends in various piping systems. These caps, often referred to as pipe caps, pipe end caps, or buttweld caps, are essential for sealing pipelines, preventing leaks, contamination, and damage. Manufactured to high-quality standards like A234 WPB, these steel caps ensure durability, versatility, and reliability across diverse industries.

What is a Pipe Cap?

A pipe cap is a fitting used to seal the end of a pipe. Typically attached by welding or threading, these caps create a secure closure to withstand high pressure, temperature fluctuations, and corrosive environments. This makes them suitable for applications in oil and gas, chemical processing, power generation, and construction sectors.

Key Features of Pipe End Caps

- Material Strength:

Caps made from A234 WPB provide excellent tensile strength and durability, making them ideal for high-pressure systems. - Versatility:

Applicable across a wide range of pipelines, including industrial, commercial, and residential systems. - Corrosion Resistance:

With appropriate surface treatments, these caps resist corrosion, ensuring reliability in harsh conditions. - Customization Options:

Available in various sizes and thicknesses, buttweld caps can be tailored to specific pipeline needs.

Types of Steel Caps

- Welded Pipe Cap:

Welded pipe end caps are permanently attached to pipes through welding, ensuring a leak-proof seal. - Threaded Pipe End Cap:

Threaded caps are designed for systems requiring frequent removal or replacement, such as maintenance pipelines. - Buttweld A234 WPB Cap:

These caps are specifically manufactured to meet ASTM A234 WPB standards, ensuring high performance in moderate to high-temperature systems.

Applications of Pipe End Caps

- Oil and Gas Industry:

Used for sealing pipelines that transport crude oil, natural gas, and other resources. - Chemical Processing:

Protects pipe ends in systems exposed to corrosive chemicals. - Power Generation:

Provides reliable closures for high-pressure and high-temperature steam pipelines. - Construction:

Safeguards temporary pipelines or systems during inactive periods.

Why Choose Carbon Steel Caps?

- Cost-Effective:

Carbon steel is an economical choice, offering a balance of strength and affordability. - Durable and Reliable:

Designed for extreme conditions, these caps offer a long service life with minimal maintenance. - Compliance with Standards:

High-quality options like the A234 WPB cap meet industry standards, ensuring safety and dependable performance.

Conclusion

Cap is an indispensable solution for protecting pipe ends in various systems. Whether referred to as a pipe cap, pipe end cap, or buttweld cap, these fittings deliver superior performance in demanding environments. For pipelines requiring strength, durability, and compliance with A234 WPB standards, these steel caps are the ideal choice.

Contact us today to explore our extensive range of pipe end caps and find the perfect solution for your piping system needs.

| Weight | 7 kg |

|---|

Fast delivery

Our factory is equipped with fully automated production lines for pipe fittings, enabling us to efficiently meet customer requirements.

Located approximately 100 kilometers from Tianjin Port, we can swiftly deliver products to the port for shipment. This proximity allows for efficient logistics, reducing transit times and ensuring timely delivery to our clients.

Reliable and safe packaging

We prioritize the secure packaging of our products to ensure they arrive safely and in optimal condition. For small-sized pipe fittings, we utilize sturdy wooden boxes, providing robust protection during transit. For larger pipe fittings, we employ pallets wrapped tightly with PE stretch film, effectively safeguarding the items and preventing moisture ingress, which could lead to oxidation. This method ensures the reliability and safety of our packaging, maintaining the quality of the products throughout the shipping process.

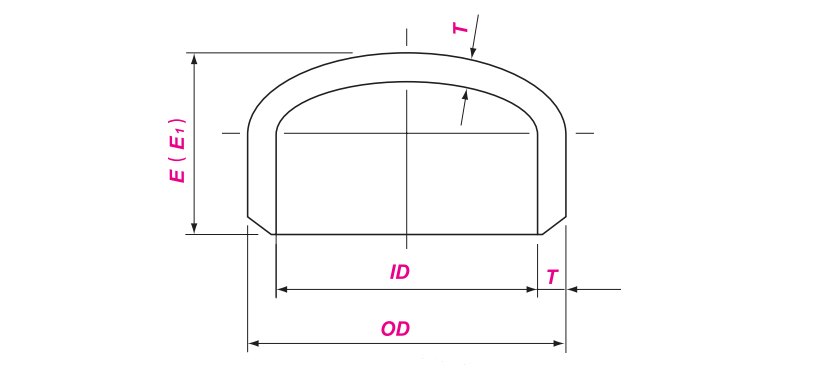

Buttwelding Cap Drawing

| DN | NPS | OD | E | E1 |

|---|---|---|---|---|

| 15 | 1/2 | 21.3 | 25 | 25 |

| 20 | 3/4 | 26.7 | 25 | 25 |

| 25 | 1 | 33.4 | 38 | 38 |

| 32 | 1 1/4 | 42.2 | 38 | 38 |

| 40 | 1 1/2 | 48.3 | 38 | 38 |

| 50 | 2 | 60.3 | 38 | 44 |

| 65 | 2 1/2 | 73 | 38 | 51 |

| 80 | 3 | 88.9 | 51 | 64 |

| 90 | 3 1/2 | 101.6 | 64 | 76 |

| 100 | 4 | 114.3 | 64 | 76 |

| 125 | 5 | 141.3 | 76 | 89 |

| 150 | 6 | 168.3 | 89 | 102 |

| 200 | 8 | 219.1 | 102 | 127 |

| 250 | 10 | 273 | 127 | 152 |

| 300 | 12 | 323.9 | 152 | 178 |

| 350 | 14 | 355.6 | 165 | 191 |

| 400 | 16 | 406.4 | 178 | 203 |

| 450 | 18 | 457 | 203 | 229 |

| 500 | 20 | 508 | 229 | 254 |

| 550 | 22 | 558.8 | 254 | 254 |

| 600 | 24 | 609.6 | 267 | 305 |

| 650 | 26 | 660.4 | 267 | – |

| 700 | 28 | 711.2 | 267 | – |

| 750 | 30 | 762 | 267 | – |

| 800 | 32 | 812.8 | 267 | – |

| 850 | 34 | 863.6 | 267 | – |

| 900 | 36 | 914.4 | 267 | – |

| 950 | 38 | 965.2 | 305 | – |

| 1000 | 40 | 1016 | 305 | – |

| 1050 | 42 | 1066.8 | 305 | – |

| 1100 | 44 | 1117.8 | 343 | – |

| 1150 | 46 | 1168.4 | 343 | – |

| 1200 | 48 | 1219.2 | 343 | – |

Reviews

There are no reviews yet.