-

Yinzhuang Industrial zone,Mengcun county,Cangzhou city,Hebei province,China

Pipe Elbow Weight Chart and Calculation Formula

Elbow weight:How to calculate the theoretical weight of 90 degree elbow?

Pipe elbows, including long radius elbows, are important components in various industries. Calculating their weight is crucial for logistical purposes such as freight and container usage. While this guide primarily focuses on the calculation of 90-degree elbows, it’s worth noting that other fittings like tees, reducers, caps, bends, and flanges also have calculable weights and weight charts. Understanding the calculation process for butt weld elbows is a practical skill that can assist in efficient planning and management.

These products are also calculable and have weight charts. Now let’s first learn how to calculate the butt weld elbow.

Table of Contents

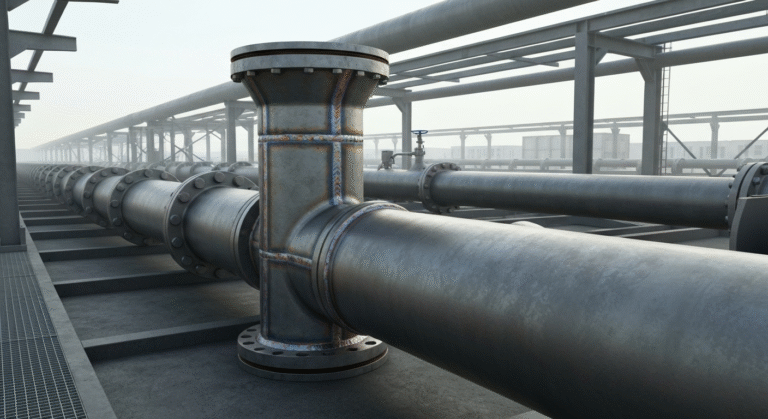

Introduction to steel pipe elbow.

In pipeline systems, elbows are fittings used to change the direction of the pipeline. Based on the angle, the most commonly used types are 45°, 90°, and 180°.

materials of elbow

Elbows are typically made from a variety of materials, including carbon steel elbow, stainless steel elbow, alloy steel elbow, and other suitable materials based on the specific application requirements. The choice of material depends on factors such as the type of fluid or gas being transported, the temperature and pressure conditions, corrosion resistance, and overall durability. It is important to select the appropriate material to ensure the longevity and performance of the elbow in the pipeline system.

Connection methods of elbow

Butt Weld Elbow, Threaded Pipe Elbow, Flanged elbow, and Socket Elbow are the common connection methods used for elbows in pipeline systems. Each method has its own advantages and is chosen based on factors such as the pipe material, operating conditions, and installation requirements. It is crucial to select the appropriate connection method to ensure a secure and leak-free joint between the elbow and the pipeline.

Manufacturing processes of elbow

The manufacturing processes of elbows include welded elbows, seamless elbows, mandrel-bent elbows, cast elbows, and butt-weld elbows. These processes are used to form the desired shape and structure of the elbow, ensuring its integrity and strength in the pipeline system. The choice of manufacturing process depends on factors such as the material, application requirements, and desired level of precision.

Radius of elbow

Long radius (1.5D) elbows and short radius (1D) elbows are two common types of elbows used in piping systems. The radius of an elbow refers to the curvature of the elbow bend. Long radius elbows have a larger radius of curvature, specifically 1.5 times the diameter of the pipe, while short radius elbows have a smaller radius, equivalent to the diameter of the pipe. The choice between long radius and short radius elbows depends on factors such as the specific application, pipe material, and installation requirements.

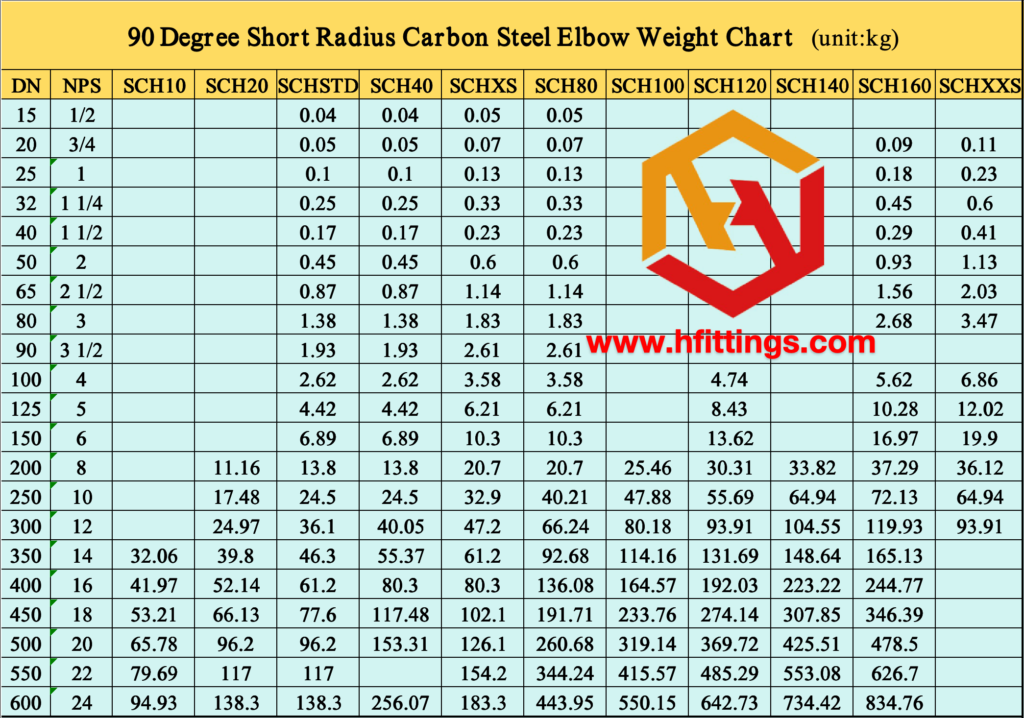

90 Degree Carbon Steel Long Radius Elbow Weight Chart

We have made the commonly used weight chart of the elbow and compared it according to diameter and thickness. Please note that the chart shows the weight of the carbon steel elbow.

90 Degree Long Radius Carbon steel Elbow weight chart

(OD:1/2”~24” Thickness:SCH10,SCH20,SCHSTD,SCH40,SCHXS,SCH80,SCH100,SCH120,SCH140,SCH160,SCHXXS)

(OD:1/2”~24” Thickness:SCH10,SCH20,SCHSTD,SCH40,SCHXS,SCH80,SCH100,SCH120,SCH140,SCH160,SCHXXS)

Elbow Diameter and Thickness Chart

Formula of Carbon Steel Elbow Weight

The formula : 90 degree carbon steel elbow is W=(D – S) * S*R *0.0387/ 1000, the unit is kg/pc.

· W : Weight (kg)

· D : Outside Diameter (mm)

· S : Thickness (mm)

· R : Radius LR=1.5D(DN), SR=1D(DN).

· 0.0387 : A factor for carbon steel fittings.It cannot be applied to other materials.

For example : 90 Degree Long Radius Carbon Steel Elbow LR Seamless 8″ Sch 40 BW ASTM A234 WPB

Elbow diameter and thickness chart show that D=219.1mm,S=8.18mm,R=1.5DN=1.5×200

W=( 219.1 – 8.18 )x 8.18x 1.5 x 200 x 0.0387 / 1000 = 20.03kg/pc.