-

中国河北省滄州市孟村県銀庄工業区

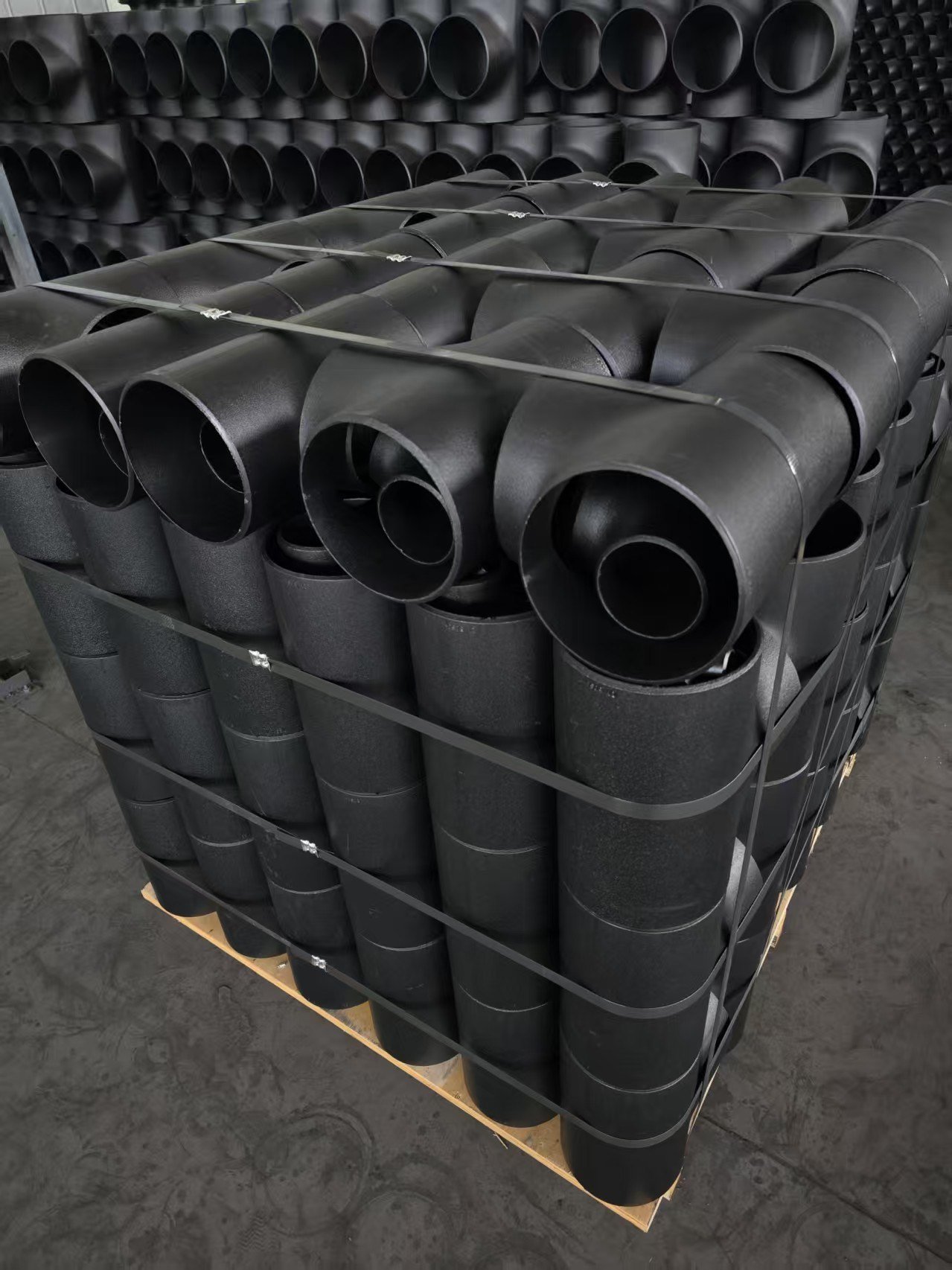

シームレス・ティ・バット溶接継手の完全ガイド

主なハイライト

- Butt weld fittings such as the A234 WPB equal tee are vital for connecting pipe sections with precise efficiency in pipeline systems.

- Constructed from durable alloy steel, these fittings handle moderate to high temperatures with ease, making them ideal for industrial applications.

- Pipe fittings like the equal tee optimise fluid flow rates while maintaining seamless connections in high-pressure environments.

- Designed to ASTM specifications, A234 WPB fittings ensure safety compliance and robust performance.

- Exceptional customer service, including tracking numbers and order notes, guarantees timely delivery and support for technical queries.

はじめに

Pipe fittings are a key part of any piping system. Parts like buttweld fittings and butt weld fittings help make smooth changes so the fluid can move well. The A234 WPB carbon steel is made from alloy steel and meets standard specification requirements. This makes it tough and ready to last in hard settings. These fittings work well in many places. You can use them in pipelines that carry oil, gas, water, or slurry. They are good for both warm and very hot uses. Good pipe fittings matter a lot. They keep your pipes working right and safe. You get great results from your system when you use strong alloy fittings like these.

Overview of Tee Butt Weld Fittings (A234 WPB)

Tee butt weld fittings (A234 WPB) are used in piping to link different pipe sections. They help change the path of flow between pipes with equal diameters. These tee fittings are mostly made out of alloy steel. This makes them good for high temperature uses and adds to their durability. The use of strong alloy means you get less defects during the work and over time. These tee butt weld fittings meet ASTM and ASME standards. So, you can use them in many kinds of work where safe and stable piping is needed. Their tough build helps make sure your system works well for a long time.

Key Features and Applications in Piping Systems

Tee butt weld fittings are made to give more flexibility and better working to piping systems. The main things to know about these fittings are:

- They help to control how fast the fluid moves, and you can do this without much effort.

- They stand up to very high heat and meet tough ASTM rules.

- They follow ANSI rules, so they can fit with many other parts.

In piping systems, these butt weld tee fittings are very important. They help change the way fluids go, and they do that without cutting down on how well the system works. You also keep the right pressure, which you need for big jobs. Their strong design means they last a long time, and you can trust them to keep things safe even when things get really hard.

You will see tee butt weld fittings in oil and gas work, chemical factories, and power plants. These places need piping that is strong, can handle rough use, and be exact. When you use fittings made from alloy steel, you get the extra trust that your system will keep going, even where there is very high heat or pressure. They show how important alloy and butt weld fittings are for durability and quality in any piping work.

Advantages of Using A234 WPB Material in the UK

The A234 WPB material is known for being strong and able to handle many jobs. Many people use it because it lasts a long time. It is a good choice for tough jobs in the UK where you need things to work well for a long time.

特徴 | メリット |

|---|---|

引張強度 | Gives 60,000 psi so it can take a lot of pressure in a timely manner. |

Alloy Composition | Makes it hard for rust and defects to form |

Refund Policy | You get your money back for unused and top-quality fittings |

Some of the good things about this material are that it handles high pressure very well, and it works smoothly in big places like power plants. The company also checks each fitting closely, so you don’t get items with defects. Plus, their customer service team is always ready to help with refund questions or technical issues about your fittings or other wpb products.

結論

To sum up, tee butt weld fittings, especially the ones made from A234 WPB material, are important in piping because of their strength and flexibility. Knowing about their features and where to use them can help you make your system last longer and work better. When you are looking at equal tees or comparing them to other fittings, you should see how they can be helpful in different cases. As you learn the basics of pipe fittings, be sure to think about what your project needs and talk to an expert if you want. If you want some help that is just for you, you can talk with our team and get advice on the best fittings, like pipe fittings and tees, for your project. This can make your work last a long time and be more useful.

イコール・ティーとは?

An equal tee is a key fitting people use in piping to join three sections of pipe. This tee has ends with the same diameter. This helps keep fluid flow the same through all parts of the pipeline. The midsection of the fitting goes across at a right angle and is made to fit well into the piping system. This lets the flow of fluid stay smooth and steady.

Many industries use these fittings when they need to move all kinds of fluids with control. This tee is known for spreading out liquids or gases evenly into other branches of the system. It is important in pipelines that carry oil, gas, water, or slurry, making these systems work well and safely.

Key Characteristics:

Equal tees have a few main features:

- The ends have equal diameters, which helps the fluid move smoothly through the stainless steel tee.

- The two sides are parallel. This helps keep the piping in a straight line.

- There is a middle section that is at a right angle to the sides. This part helps the fluid spread out in an even way.

- The tee is compact, so there is no unused space inside the piping.

These things help the tee stay steady and work well during any job. The simple design helps cut down on unwanted flow and keeps the right pressure in the pipes. This makes equal tees a good pick for tough use in big factories or other industrial places.

アプリケーション

Equal tees can be used in many industries. Here are some key uses:

- Piping systems that need an even flow rate at all points.

- Tubing that runs under high psi, like what you find in oil refineries and chemical plants.

- Fittings in gaskets where people want the branches to be stable.

These fittings work with many different specifications, including ASTM. This means they meet important industrial standards. Also, equal tees are good at keeping flow steady, even when there is a lot of pressure. This is why the fittings are chosen for strong and accurate pipeline and tubing systems.

Common Pipe Fittings

Pipe fittings, including steel pipe fittings, are made in many shapes and sizes to meet the needs of different industries. Some of the most common fittings are reducers, flanges, studs, and couplings. Each one has its own job.

A reducer helps change the size of pipe so that two pipes of different diameters can connect. Flanges are used to make sure connections are strong and secure. Studs make the system stronger, and couplings help join pipes together. These fittings are very important to keep the system running smoothly and to make everything work well. The right fittings help people manage the flow of oil, gas, water, and other things in big pipeline systems.

Equal Tee vs. Elbows

Equal tees and elbows have different but important jobs in a piping system. Equal tees are used when you need to split fluid into more than one branch, and all the branches are the same size, with equal diameters. Elbows help when the pipe needs to change direction at a certain angle.

These fittings are made to strict rules to make sure they work well, even under pressure. The one you pick depends on what you need for your project. You should choose equal tees for branching fluid to other pipes with equal diameters. Choose elbows if you have to change the way your piping goes.

イコール・ティー:

The equal tee is made to split fluid into more than one section. It comes with a few features.

- The equal diameters help the fluid stay the same all the way through.

- The tee has a midsection that is set at a right angle, making it easy to connect another pipe.

- It has a small and neat design, so the different pipes line up just right.

These fittings are good for systems that need everything to spread out evenly. They also work well and last long in tough industrial settings.

肘だ:

Elbows are great at changing the way liquid moves in a pipe. They do this without losing pressure or working less well. You use them most at corners in a piping system where a turn is needed.

Elbow fittings offer:

- Angles up to 90 degrees to help pipes change direction.

- Chrome construction that resists corrosion for better durability.

- Use on piping systems that go through high-pressure.

This is why they are important in round or curved pipeline paths. They help make smooth changes in direction.

Equal Tee vs. Reducers

Equal tees and reducing tees are not the same. Equal tees split pipe sections into more parts and keep all the diameters the same size. In contrast, reducers are used to connect pipe sections where one is wider and the other is narrower.

If you need to manage how much water or liquid goes through without making extra branches, it is better to use reducers instead of equal tees.

減速機:

Reducers have an important role in changing pipe size. They give several benefits:

- They help change the diameter, so it fits the needs of your pipeline.

- They use space well, so there is no unused area.

- They use ASTM materials, which help with durability.

These fittings help fluids, like water and oil, move better by giving the pipeline a smooth change in size. This way, the flow is more efficient.

Equal Tee vs. Couplings

Equal tees help make even branches in pipelines. Couplings, on the other hand, are used to join the ends of pipes in a safe way. These two parts do different things, so each one is important for its own use.

Couplings work well when you need to fix a pipe or connect pipes together in an easy way. They help hold everything in place for a long time.

Couplings:

Couplings are known for how well they connect pipes in a piping system. They have many benefits:

- They have good durability in tough conditions such as corrosion.

- They help use all of the fitting material, which means less goes unused.

- There are flexible refund options, so customers can be happy with what they get.

The use of couplings in repair jobs and quick connections makes pipelines work better and help them last longer. This shows why they are so important for many piping jobs.

Equal Tee vs. Crosses

Equal tees and crosses are used in different ways. Equal tees join three pipes that all have the same diameter. Crosses, on the other hand, link four pipes. This makes the pipeline set up more complex than when you use equal tees.

Crosses work best for setups where the flow needs to go through more than one branch. This is good when your system needs flow in many directions.

Crosses:

Crosses help control hard liquid movement in pipelines. They offer these features:

- Lets you connect many branches for tricky setups.

- Fits right into piping systems, which helps keep flow rate steady.

- Works with flanges to hold strong.

You can find these fittings in places where many fluid branches are used, like in chemical plants and refineries.

Advantages of Using Equal Tees

Equal tees offer many key benefits for piping systems. They are known for their strong durability, which helps pipes last a long time even under tough conditions. Because these trupply fittings, along with email customer service, are made to stick to set specifications, they keep the pipe work smooth and steady for fluid flow.

These fittings are a must-have because they can fit with many systems. This makes equal tees very important in pipelines that deal with high psi fluid movement, such as in oil and gas. Their strong design helps keep everything working well and prevents stops in work.

よくある質問

What is the difference between seamless and welded tee fittings?

Seamless fittings are made from seamless pipes. They do not have weak spots. This gives them higher durability. Welded fittings come from welded steel. People use these when they want a cost-effective option. Both types follow ASTM standards. All fittings get strict checks, so they do not have defects.

Are A234 WPB tee fittings suitable for high-pressure applications?

Yes, A234 WPB tee fittings are strong and made to handle high pressure. They can take up to 60,000 psi. The durability and how well they match the specification mean these tee fittings are good for the most important systems in big industries.

How do I select the right size and thickness for a tee butt weld fitting?

When you want to choose the right tee butt weld fitting, look at the diameter and wall thickness based on ASME standards. If you have more technical questions, think about your pipeline and how it will work to know what you need. You can email or call us for further help during business hours from Monday to Friday. Be sure to include these details in your order notes to get the right fit.