-

Zona Industri Yinzhuang, daerah Mengcun, kota Cangzhou, provinsi Hebei, Cina

Tee Baja Karbon: Panduan untuk Perlengkapan Las Butt

Sorotan Utama

- Fitting tee baja karbon memberikan solusi yang andal untuk percabangan atau pengalihan aliran dalam sistem perpipaan, termasuk sambungan dengan ujung sisi paralel.

- Alat kelengkapan las butt ini dirancang untuk menangani lingkungan bersuhu dan bertekanan tinggi.

- Fitting tee yang sama ideal untuk menghubungkan tiga bagian pipa dengan diameter yang konsisten atau mengurangi ukuran.

- Spesifikasi standar seperti ASME, ASTM, dan ANSI mengatur alat kelengkapan ini dan memastikan kualitasnya.

- Pelanggan sering kali memiliki pertanyaan teknis tentang pemasangan, inspeksi, dan pemeliharaan, terutama untuk kasus penggunaan industri.

- Fitting tee baja karbon banyak digunakan dalam industri seperti HVAC, minyak dan gas, dan perpipaan industri.

Pendahuluan

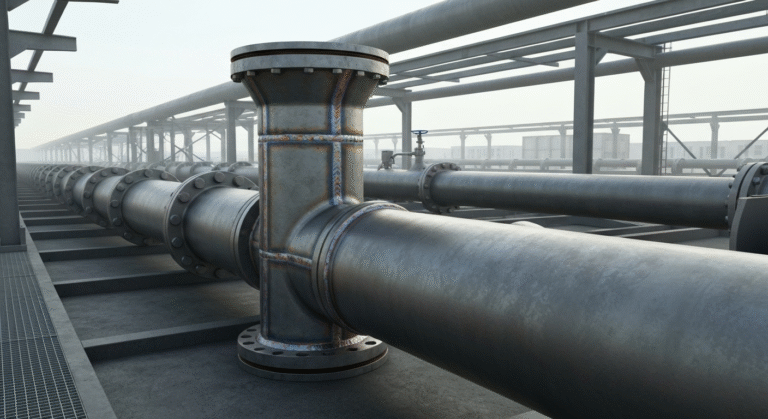

Fitting las pantat tee baja karbon memainkan peran penting dalam membuat sistem perpipaan Anda bekerja dengan baik dan bertahan lama. Anda dapat menggunakan alat kelengkapan ini di banyak tempat yang membutuhkan tekanan tinggi dan panas tinggi. Dengan desainnya yang mulus, alat kelengkapan ini membantu Anda bercabang atau mengurangi aliran dalam pipa Anda. Ini membantu perpipaan melakukan tugasnya dengan lebih baik. Orang-orang menggunakan fitting tee butt weld baja karbon di industri, di tempat kerja, atau bahkan di rumah. Jika Anda ingin pipa ledeng atau perpipaan Anda kuat dan dapat diandalkan, alat kelengkapan ini dapat membantu karena mengikuti standar yang tinggi. Kekuatan dan kecocokannya yang tepercaya membuatnya berguna untuk berbagai jenis pengaturan.

Tinjauan Umum Perlengkapan Las Tee Butt Baja Karbon

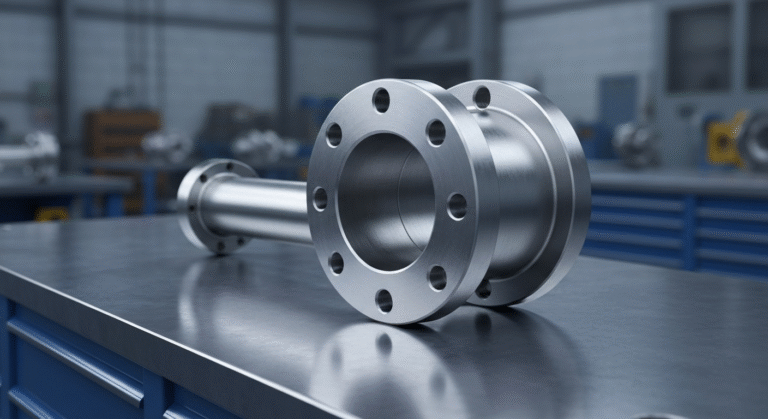

Fitting las pantat tee baja karbon dibuat untuk menyambung tiga bagian pipa. Dengan alat kelengkapan ini, Anda dapat membagi aliran secara merata atau menguranginya menjadi satu bagian. Bentuk T-nya memungkinkan bagian tengahnya pas dan bekerja dengan cara yang benar. Desain ini membuatnya digunakan dalam banyak pekerjaan.

Alat kelengkapan pipa ini kuat dan tahan lama. Mereka bekerja dengan baik ketika ada tekanan tinggi atau suhu panas. Anda dapat menggunakannya untuk koneksi yang sama dan mengurangi. Tee baja karbon membantu menyelesaikan kebutuhan perpipaan yang sulit dengan cara yang mudah dan cepat.

Fitur Utama dari Tee Baja Karbon

Tee baja karbon adalah pilihan populer untuk banyak pekerjaan perpipaan karena fitur-fitur hebat yang mereka tawarkan. Salah satu manfaat utamanya adalah dapat menangani tekanan air hingga 200 psi, bahkan ketika lingkungannya sulit. Hal ini membuat tee baja karbon sangat berguna untuk sistem bertekanan tinggi seperti saluran air atau berbagai jenis fasilitas industri.

Alasan lain untuk menggunakan baja karbon adalah karena baja karbon dapat menahan panas yang tinggi, sehingga dapat bekerja dengan baik di tempat-tempat yang suhunya dapat berubah banyak. Anda mungkin melihat tee baja karbon ini digunakan dengan sistem boiler atau penukar panas. Dalam pengaturan ini, alat kelengkapan yang terbuat dari bahan ini tetap memberikan kinerja yang stabil.

Perlengkapan seperti ini dibuat untuk tahan lama. Baja karbon kuat, aus secara perlahan, dan tidak mudah rusak oleh karat atau jenis tekanan lainnya. Karena itu, sistem perpipaan Anda akan tetap baik dan tahan bahkan ketika keadaan menjadi sulit. Hal ini membuat baja karbon menjadi pilihan cerdas untuk tempat mana pun yang membutuhkan perpipaan yang tangguh dan alat kelengkapan yang andal.

Standar dan Spesifikasi Umum

Memastikan kualitas dan kekuatan tee baja karbon yang baik berarti Anda harus mengikuti aturan industri yang penting. Di Amerika Serikat, aturan besarnya adalah ASME, ASTM, dan ANSI. Aturan-aturan ini membantu dalam memilih bahan yang tepat, ukuran, dan memastikannya berfungsi sebagaimana mestinya.

Misalnya, ASTM memeriksa kualitas bahan. Sesuatu seperti A234 WPB banyak digunakan dengan suhu tinggi atau pekerjaan panas sedang. ASME B16.9 adalah untuk ukuran dan aturan alat kelengkapan las butt. Penting untuk mengetahui dan mengikuti aturan-aturan ini jika Anda ingin segala sesuatunya aman dan bekerja dengan baik.

Standar | Badan Pengatur | Aplikasi |

|---|---|---|

ASME B16.9 | ASME (Persatuan Insinyur Mekanik Amerika) | Dimensi pemasangan las pantat |

ASTM A234 | ASTM (Masyarakat Amerika untuk Pengujian dan Material) | Kualitas dan spesifikasi material |

ANSI B36.10 | ANSI (Institut Standar Nasional Amerika) | Dimensi pipa untuk kompatibilitas |

Aturan-aturan ini memudahkan untuk memilih alat kelengkapan yang tepat untuk pekerjaan Anda. Aturan ini juga membantu memastikan bahwa alat kelengkapan bekerja dengan baik dan aman bagi orang yang menggunakannya.

Jenis dan Aplikasi Fitting Tee Baja Karbon

Fitting tee baja karbon memiliki dua jenis utama: fitting tee yang sama dan tee pereduksi. Fitting tee yang sama membagi aliran menjadi tiga bagian dengan ukuran yang sama. Mereka juga menyambung tiga pipa yang memiliki diameter yang sama. Sebaliknya, reducing tee menyambungkan pipa dengan diameter yang berbeda.

Alat kelengkapan ini sangat penting untuk sistem yang menggunakan tembaga, baja paduan, atau baja tahan karat. Apa pun jenis yang Anda gunakan, alat kelengkapan ini dapat menangani banyak tekanan dan melawan karat dengan sangat baik. Karena itu, orang menggunakannya di banyak area seperti pasokan air, minyak dan gas, dan sistem HVAC.

Tee yang Sama vs Tee Pengurang: Perbedaan dan Penggunaan

Mengetahui perbedaan antara fitting tee yang sama dan tee pengurang adalah kunci untuk memilih apa yang Anda butuhkan untuk pekerjaan perpipaan Anda.

- Semua outlet memiliki ukuran yang sama.

- Paling baik untuk membagi aliran secara merata di antara bagian pipa.

- Bagus apabila Anda ingin alirannya tetap sama ke segala arah.

Perlengkapan Tee yang Sama:

- Ada saluran keluar yang lebih kecil yang bercabang dari pipa utama.

- Digunakan ketika Anda menginginkan aliran yang lebih sedikit di satu bagian sistem.

- Sangat bagus apabila Anda perlu menyambung pipa dengan diameter yang berbeda.

Mengurangi Tees:

Fitting tee yang sama menonjol jika Anda menginginkan aliran yang lancar dan merata, tetapi fitting tee yang lebih kecil membantu jika ukuran dan jumlah aliran berubah. Bagian tengah fitting membantu menghubungkan semua bagian tee, membiarkan fitting melakukan tugasnya sehingga pemipaan bekerja dengan baik.

Industri dan Sistem Perpipaan yang Khas

Industri di seluruh dunia menggunakan tee baja karbon dalam banyak hal. Di Houston, TX, tee ini sering menjadi bagian dari perpipaan industri dan bagus untuk sistem saluran air bertekanan tinggi dan psi.

Tee baja karbon membantu memindahkan cairan di dalam pabrik dan pabrik kimia. Mereka memiliki kekuatan yang Anda butuhkan untuk pekerjaan semacam ini. Hal ini membuat mereka bekerja dengan baik di tempat-tempat tersebut.

Dalam minyak dan gas, tee ini memungkinkan minyak mentah, gas alam, dan produk lainnya mengalir dengan cara yang benar. Mereka bekerja dengan baik dengan gasket dan bagian pipa lainnya. Hal ini membantu membuatnya berguna untuk proyek-proyek besar di mana Anda membutuhkan sesuatu yang kuat dan stabil.

Manfaat Memilih Tee Las Butt Baja Karbon

Hal-hal yang baik tentang penggunaan butt weld tee baja karbon lebih dari sekadar kuat dan bekerja dengan baik. Alat kelengkapan ini cocok untuk banyak penggunaan dan bekerja dengan perpipaan standar dan perpipaan baja paduan. Mereka juga mampu menangani tekanan tinggi.

Selain itu, bahan yang kuat dari baja karbon membantunya bertahan dalam situasi yang sulit. Bahan ini dapat menahan panas yang tinggi dan hal-hal yang biasanya menyebabkan pipa berkarat. Jika Anda bekerja di industri yang membutuhkan sesuatu yang dapat Anda percayai, kaos ini akan bertahan lebih lama dan harganya lebih murah daripada kaos yang terbuat dari PVC atau bahan lainnya. Ada aturan pengembalian juga, jadi jika Anda mendapatkan barang yang buruk atau tidak terpakai, Anda bisa mengirimkannya kembali.

Keunggulan Kekuatan dan Daya Tahan

Baja karbon adalah pilihan yang baik ketika Anda membutuhkan bahan yang kuat dan tahan lama. Kekuatannya berarti kaos ini bekerja dengan baik bahkan pada suhu tinggi. Mereka tetap stabil dan tidak kehilangan bentuknya, terutama dalam jadwal XS dan STD. Mereka bertahan di bawah tekanan lebih baik daripada kebanyakan yang lain.

Fitting baja karbon ini lebih dari sekadar kuat. Mereka juga tahan terhadap kerusakan dan karat. Bahkan jika tempatnya kasar atau ada bahan kimia yang kuat di sekitarnya, tee ini tetap berfungsi sebagaimana mestinya. Mereka tidak mudah rusak.

Karena desain yang kuat ini, Anda akan lebih jarang memperbaiki atau menggantinya. Sistem perpipaan akan mengalami lebih sedikit waktu henti. Jadi, jika Anda membutuhkan alat kelengkapan butt weld untuk menangani pekerjaan yang berat, baja karbon adalah pilihan yang tepat untuk penggunaan yang lama dan kinerja yang kuat.

Efektivitas Biaya dan Keserbagunaan

Untuk industri yang perlu menghemat uang, tee baja karbon adalah pilihan yang baik. Harganya lebih murah di awal dan tahan lama. Ini berarti mereka adalah pembelian yang cerdas untuk pengaturan perpipaan apa pun. Alat kelengkapan ini memberi Anda nilai yang bagus tanpa kehilangan kemampuannya untuk bekerja dalam banyak situasi.

Alat kelengkapan ini bekerja dengan baik dengan banyak bahan lain, seperti pipa yang tidak terpakai, baja paduan, kuningan, dan bahkan PVC. Jadi, jika Anda ingin menghemat biaya atau membuat sistem Anda bekerja lebih baik, baja karbon dapat dibentuk agar sesuai dengan yang Anda butuhkan.

Selain itu, banyak penjual yang memiliki aturan pengembalian yang ramah. Jika Anda memiliki perlengkapan yang belum Anda gunakan, Anda bisa mengirim email ke layanan pelanggan untuk menanyakan tentang pengembalian uang Anda. Hal ini memastikan Anda hanya membayar apa yang sesuai dengan kebutuhan Anda.

Praktik Terbaik Pemasangan dan Pemeliharaan

Pemasangan dan perawatan yang baik untuk fitting tee baja karbon adalah kunci agar dapat bertahan lama dan bekerja dengan baik. Saat Anda memasang fitting, pastikan pengelasannya kuat dan rata. Hal ini akan membantu menghentikan kebocoran dan masalah lain pada pipa. Sering-seringlah memeriksa alat kelengkapannya. Dengan cara ini, Anda dapat menemukan karat atau kerusakan lebih awal.

Jika Anda memerlukan bantuan dengan pertanyaan teknis atau pengiriman, tim layanan pelanggan siap membantu Anda. Mereka dapat membuat seluruh proses menjadi lebih lancar. Dengan menggunakan langkah-langkah ini, Anda membuat pipa baja karbon dan alat kelengkapan tee bekerja lebih baik dan bertahan lebih lama. Untuk bantuan lebih lanjut, hubungi layanan pelanggan kami.

Teknik Pengelasan yang Tepat untuk Tee Baja Karbon

Untuk mendapatkan pengelasan terbaik untuk tee baja karbon membutuhkan pekerjaan yang cermat dan alat yang tepat. Gunakan palu dan soket untuk menyejajarkan bagian pipa sebelum Anda mengelasnya. Hal ini membantu mengurangi celah dan membuat sambungan menjadi lebih kuat.

Perhatikan sambungan flensa dan pastikan Anda menggunakan bahan yang disetujui ABLR. Ini akan menghentikan terbentuknya titik-titik lemah. Pastikan Anda mengontrol panas saat Anda bekerja sehingga logam tidak melengkung atau rapuh.

Jika Anda mahir dalam cara-cara pengelasan ini, Anda tidak hanya akan memiliki ikatan yang kuat tetapi juga membantu baja karbon tahan terhadap hal-hal seperti tekanan tinggi dan perubahan suhu dengan baik.

Kiat Inspeksi dan Umur Panjang

Inspeksi rutin adalah kunci untuk membuat fitting tee baja karbon bertahan lebih lama. Pada saat memesan, pastikan untuk meminta MTR. Simpan ini sebagai referensi. Selalu periksa catatan pesanan Anda. Ini membantu memastikan alat kelengkapan memenuhi spesifikasi yang tepat.

Selama perawatan rutin, cari tanda-tanda korosi atau keausan pada alat kelengkapan. Gunakan gasket dan sealant yang tepat. Ini akan membantu menghentikan kebocoran dan membuat sambungan menjadi lebih kuat. Jika Anda memiliki pertanyaan teknis tentang perpipaan atau fitting tee Anda, hubungi layanan pelanggan. Mereka dapat memberikan jawaban berdasarkan sistem Anda.

Mengambil langkah-langkah ini akan membantu memastikan alat kelengkapan tetap bekerja dengan baik untuk waktu yang lama. Hal ini membantu sistem perpipaan Anda bertahan lebih lama dan bekerja lebih baik.

Kesimpulan

Singkatnya, mengetahui tentang fitting las tee butt baja karbon penting untuk menjaga sistem perpipaan tetap kuat dan bekerja dengan baik di banyak area. Alat kelengkapan ini memiliki kekuatan yang besar dan tahan lama. Inilah sebabnya mengapa banyak orang suka menggunakannya untuk kebutuhan perpipaan mereka. Ketika Anda mempelajari tentang fitur-fitur utama, jenis, kegunaan, dan cara terbaik untuk memasang dan merawatnya, Anda dapat membuat pilihan yang lebih baik. Hal ini akan membantu sistem perpipaan Anda bertahan lebih lama dan bekerja lebih baik. Jika Anda memiliki pertanyaan lebih lanjut atau ingin bantuan khusus untuk Anda, hubungi kami untuk konsultasi.

Pertanyaan yang Sering Diajukan

Apa perbedaan utama antara equal tee dan reducing tee?

Fitting tee yang sama memiliki diameter yang sama pada setiap bukaan. Hal ini membantu menjaga aliran tetap merata ke segala arah. Tetapi reducing tee memiliki satu cabang yang lebih kecil. Fitting ini bekerja dengan baik ketika Anda perlu menyambungkan pipa dengan ukuran yang berbeda atau menginginkan aliran yang lebih sedikit dalam satu arah. Blog ini membahas bagaimana kedua jenis fitting tee ini mengikuti standar yang biasa dan dapat digunakan untuk berbagai pekerjaan.

Apakah tee baja karbon kompatibel dengan pipa baja tahan karat?

Ya, Anda dapat menggunakan tee baja karbon dengan pipa baja tahan karat. Pastikan untuk menggunakan gasket dan alat kelengkapan yang tepat untuk koneksi yang kuat. Selalu ikuti aturan standar, seperti dari ASME atau ASTM, untuk mendapatkan hasil yang baik di AS.

Bagaimana cara memilih ukuran yang tepat untuk butt weld tee?

Pilih ukuran butt weld tee dengan melihat kebutuhan aliran dan ukuran pipa sistem Anda. Periksa detail standar dan catat waktu pemesanan. Mintalah MTR untuk mendapatkan fakta yang benar. Jika Anda memiliki kebutuhan tambahan, cantumkan dalam catatan pesanan saat Anda check out pada hari Senin.

Standar apa yang mengatur alat kelengkapan las butt baja karbon di AS?

Di AS, alat kelengkapan las butt baja karbon dibuat untuk memenuhi standar ASME, ASTM, dan ANSI. ASME B16.9 digunakan untuk ukuran, termasuk opsi seperti 80S. Spesifikasi ASTM seperti WPB (A234) membantu memastikan bahwa kualitas bahan dan cara pembuatannya bagus.

Bagaimana cara mencegah korosi pada fitting tee baja karbon?

Untuk mencegah korosi, pastikan Anda memeriksa alat kelengkapan Anda secara teratur dan menjaganya tetap dalam kondisi yang baik. Gunakan gasket dan sealant yang tepat saat Anda mengatur segala sesuatunya. Jika Anda menemukan alat kelengkapan yang tidak terpakai yang tidak terlihat baik sejak awal, hubungi layanan pelanggan melalui email untuk mendapatkan bantuan atau meminta suku cadang baru. Saya akan memeriksa alat kelengkapan ini minggu depan. Merawat alat kelengkapan Anda dengan baik akan membantu alat tersebut bertahan lama.