-

Zona Industri Yinzhuang, daerah Mengcun, kota Cangzhou, provinsi Hebei, Cina

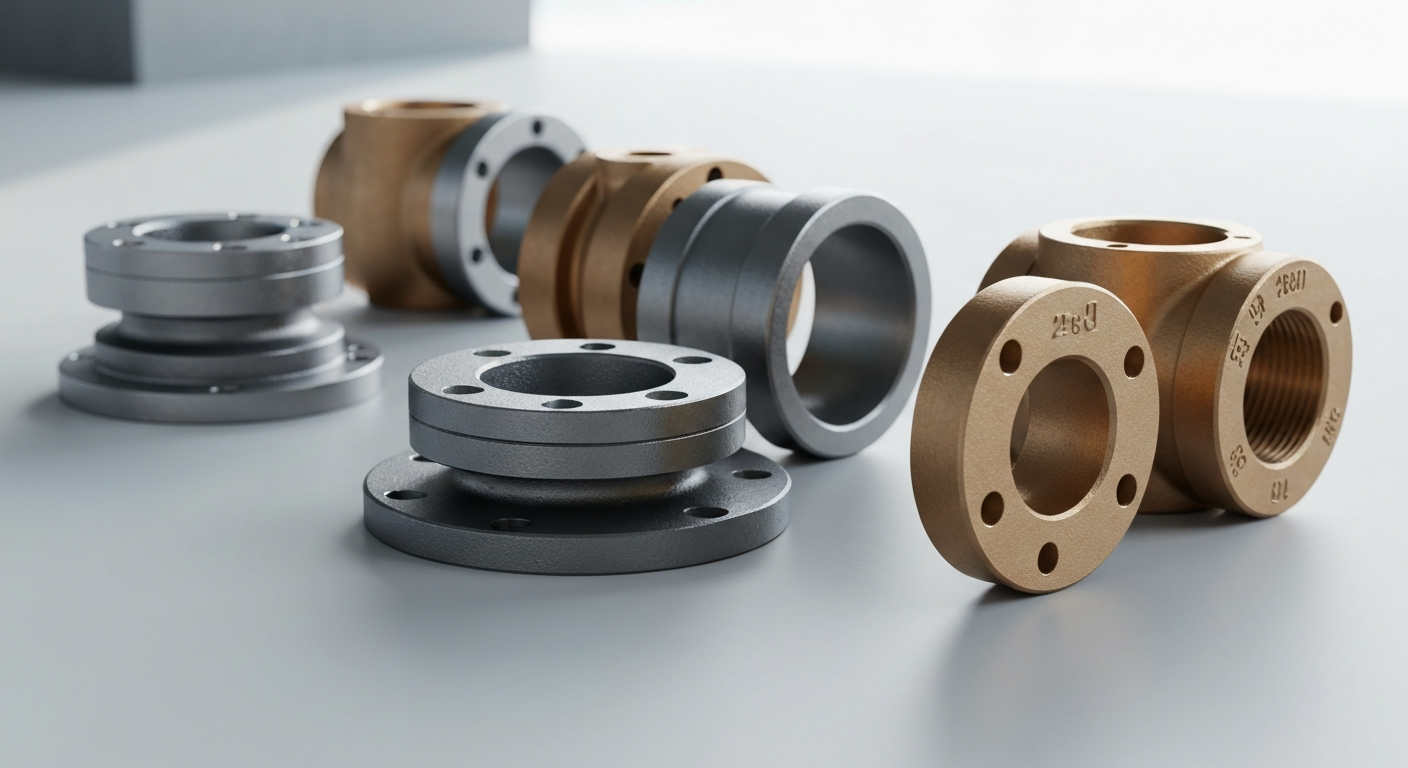

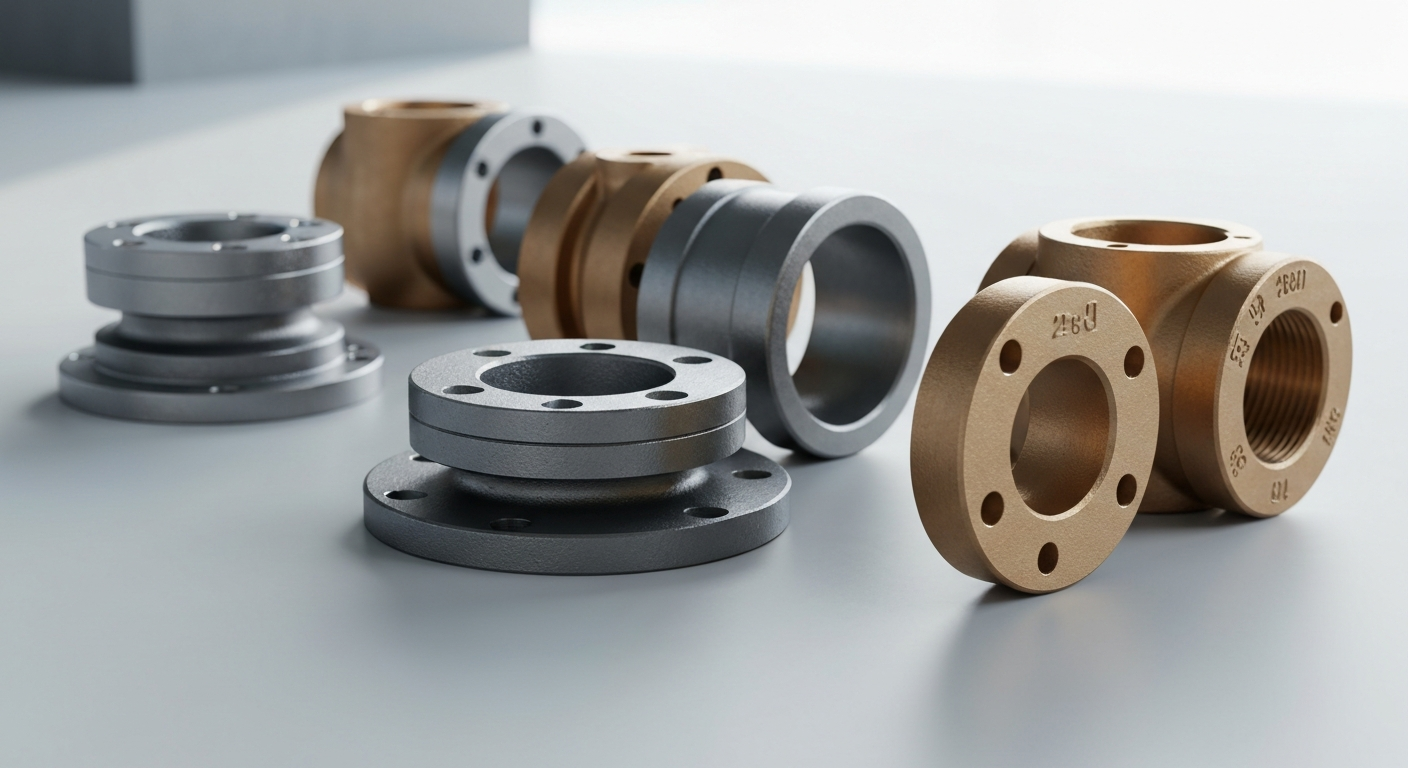

Bahan Flensa SO Atas: Memilih Opsi yang Tepat

Sorotan Utama

- ASTM A105 is the standard specification for carbon steel forgings used in flange materials and pipe fittings.

- These flanges are designed for use in ambient and high-temperature service within pressure systems.

- While carbon steel is economical and strong, other options like stainless steel offer superior corrosion resistance.

Compliance with ASME standards is crucial for ensuring the correct dimensions, pressure ratings, and safety. If you are looking to buy standard A105 flanges online, many reputable industrial supply websites and authorized distributors offer a range of carbon steel and stainless steel flanges that meet ASME standards.

- Compliance with ASME standards is crucial for ensuring the correct dimensions, pressure ratings, and safety.

- A105 flanges possess excellent mechanical properties, making them a reliable choice for industrial applications.

- Heat treatment, such as normalizing, can further improve the toughness and uniformity of A105 flanges.

Pendahuluan

Choosing the right components for your piping system is essential for safety and efficiency. A slip on flange is a popular type of pipe fitting that slides over the end of a pipe before being welded in place. These steel pipe flanges, including the neck flange variants, offer a reliable connection, but their performance heavily depends on the material you select. Understanding the different materials available, especially for high-pressure and high-temperature environments, ensures your system operates smoothly and securely for years to come. If you are looking to buy standard A105 flanges online, many industrial suppliers and specialized piping distributors offer these products through their websites, often allowing you to browse specifications and place orders directly online.

Key A105 Flange Materials for Slip-On Flanges

When it comes to flange materials, ASTM A105 is a top contender, specifically for carbon steel forgings. This specification covers carbon steel pipe fittings and similar parts that are built for demanding conditions, offering excellent mechanical properties and toughness. The primary advantage of using A105 carbon steel is its combination of high strength, good ductility, and cost-effectiveness, making it a go-to choice for many industrial applications.

These carbon steel forgings are engineered for ambient and higher-temperature service in pressure systems, and they often undergo slow furnace cooling. While A105 is a popular choice, it’s just one of several options. Let’s look closer at its properties and compare it to other materials like alloy and stainless steel.

Carbon Steel Flange Options and Their Properties

ASTM A105 carbon steel blind flange is a material engineered for strength and reliability in pressure systems. Governed by ASME standards, these carbon steel forgings are limited to a maximum weight of 10,000 lbs, ensuring consistent quality. This material is particularly valued for its good weldability, allowing it to be easily integrated into various piping configurations.

However, it’s important to note its limitations. A105 carbon steel has poor corrosion resistance, so it may not be suitable for use with certain chemicals or in corrosive environments without protective coatings. The key to its performance lies in the sum of chromium and its specific mechanical properties, which guarantee its ability to handle pressure and temperature.

Here is a summary of the key mechanical properties you should know:

Properti | Minimum/Maximum Value |

|---|---|

Kekuatan Tarik | Elongation (in 2 in.) forged at precise temperatures between 1,700 degrees Fahrenheit and 2,200 degrees Fahrenheit. |

Yield Strength | 36 ksi [250 MPa] min |

Elongation (in 2 in.) | 22% min |

Reduction of Area | 30% min |

Kekerasan | 197 HBW max |

Alloy Steel and Stainless Steel Choices for SO Flanges

While A105 carbon steel is a workhorse in many industries, certain applications demand different material properties. This is where alloy steel and stainless steel enter the picture. Unlike A105, which is primarily carbon and manganese, these alternatives include elements like chromium, nickel, molybdenum, and vanadium. These additions significantly improve specific characteristics, most notably corrosion resistance.

The forging manufacture and heat treatment processes for these materials, including considerations for design temperature, are just as critical as they are for A105 flanges. An A105 slip on flange differs from a stainless steel one mainly in its ability to withstand corrosive fluids. If your system handles aggressive chemicals, stainless steel is a much safer and more durable choice.

Consider these points when comparing materials:

- Corrosion Resistance: Stainless steel offers superior resistance to rust, corrosion, and chemical attack compared to carbon steel, particularly in environments where copper is present.

- Temperature Range: Certain alloy steels are designed for extremely high or cryogenic temperatures where A105 might falter.

- Cost: A105 carbon steel is generally more economical than alloy or stainless steel flanges.

Important Specifications for A105 Slip-On Flanges

When selecting an A105 slip on flange, you can’t just pick one off the shelf. Each flange must adhere to a strict specification to ensure it is safe and compatible with your system. Standards from organizations like ASME, MSS, and API, including insights from industry experts like Curtis, define everything from dimensions to material composition. These specifications are not just guidelines; they are mandatory for pressure vessel components to prevent leaks and failures.

Understanding these details is key to making the right choice for your project. Two of the most critical specifications to consider are the pressure rating of the flange and the type of face it has, as these directly impact how it seals according to the pressure vessel code section IX.

Pressure Ratings and Face Types (Raised Face vs Flat Face)

Pressure ratings, or classes, indicate the maximum pressure a flange can withstand at increasing temperatures. For A105 flanges, these classes are standardized to ensure you can match the flange to your system’s design pressure. Choosing a flange with a lower pressure rating than your system requires is a major safety risk, and understanding the applied methods is essential for optimal performance.

Another crucial feature is the flange face. The two most common types are raised face (RF) and flat face (FF). A raised face flange has a small, raised surface around the bore where the gasket sits, creating a concentrated, high-pressure seal. A flat face flange has a contact surface on the same plane as the bolting circle. The difference lies in how they compress the gasket to create a seal. RF flanges, often with great pricing, are common in industrial applications, while FF flanges are often used in lower-pressure situations.

Available A105 flange pressure ratings include:

- Class 150

- Class 300

- Class 600

- Class 900

- Class 1500

- Class 2500

Certifications and Compliance When Selecting SO Flanges

How can you be sure the flange, such as a socket weld flange, you’re buying meets the required standards? The answer is through certifications. Verifying compliance is a mandatory requirement to guarantee that the flange has been manufactured and tested according to specifications. A certificate of conformity from the manufacturer details the material properties and test results, proving it meets standards like ASTM A105.

Without this documentation, you have no assurance of the flange’s good quality or safety. When you purchase standard A105 flanges, you should look for suppliers who provide complete documentation. Reputable online suppliers will always offer certified products that adhere to industry standards.

When buying A105 flanges from Trupply, look for these key certifications:

- ASTM A105: Certifies the carbon steel material requirements.

- ASME B16.5 or B16.47: Confirms the flange dimensions, tolerances, and markings.

- MSS Standards: May apply for specific dimensional or quality requirements.

- Manufacturer’s Test Report (MTR): Provides specific chemical and mechanical test results for the heat lot.

Pertanyaan yang Sering Diajukan

Navigating the world of SO flanges and flanges of special design can raise various questions. Common queries often include which material offers excellent mechanical properties for specific applications, like carbon steel versus stainless steel options. Another frequent concern pertains to the compatibility of raised face or flat face designs with specific gaskets for optimal sealing. Understanding the manufacturing process, such as heat treatment and forging, is essential to ensure durability under the applicable design pressure and temperature. Don’t hesitate to reach out with any more questions you may have!

Where are A105 slip-on flanges commonly used?

A105 slip-on flanges are widely used in industrial pressure systems due to their excellent mechanical properties. You will find these steel pipe flanges, known as high-hub flanges, in the oil and gas, chemical processing, and power generation industries, where they are valued for their strength and reliability in high-temperature, high-pressure applications governed by ASME standards.

How do I choose the right size and type of carbon steel flange?

To choose the correct flange size, you must refer to your project’s piping specification. This will define the nominal pipe size (NPS), pressure class, and required wall thickness. Always ensure the flange’s mechanical properties, including any necessary tempering, and dimensions align with both the pipe it connects to and the overall system requirements outlined in ASME standards.

Are A105 flanges suitable for industrial and domestic piping systems?

A105 carbon steel flanges are designed primarily for industrial pressure systems that operate at high pressures and temperatures, and they may also undergo processes like normalize and temper. While they are incredibly robust, they are generally considered overkill for typical domestic plumbing, where pressure and temperature demands are much lower and other materials like brass or PVC are more common.

Kesimpulan

Choosing the right flange material, such as the 12 inch butt weld cap, is essential for ensuring the integrity and efficiency of your piping systems. A105 slip-on flanges offer a versatile solution, adaptable for various applications with different material options available such as carbon steel, alloy steel, and stainless steel. By considering specifications like pressure ratings and compliance certifications, you can make an informed decision that meets both industry standards and your project requirements. Remember, selecting the appropriate flange not only impacts the performance of your system but also contributes to its longevity. If you have any questions or need assistance in making your selection, don’t hesitate to reach out!