-

Zone industrielle de Yinzhuang, comté de Mengcun, ville de Cangzhou, province de Hebei, Chine

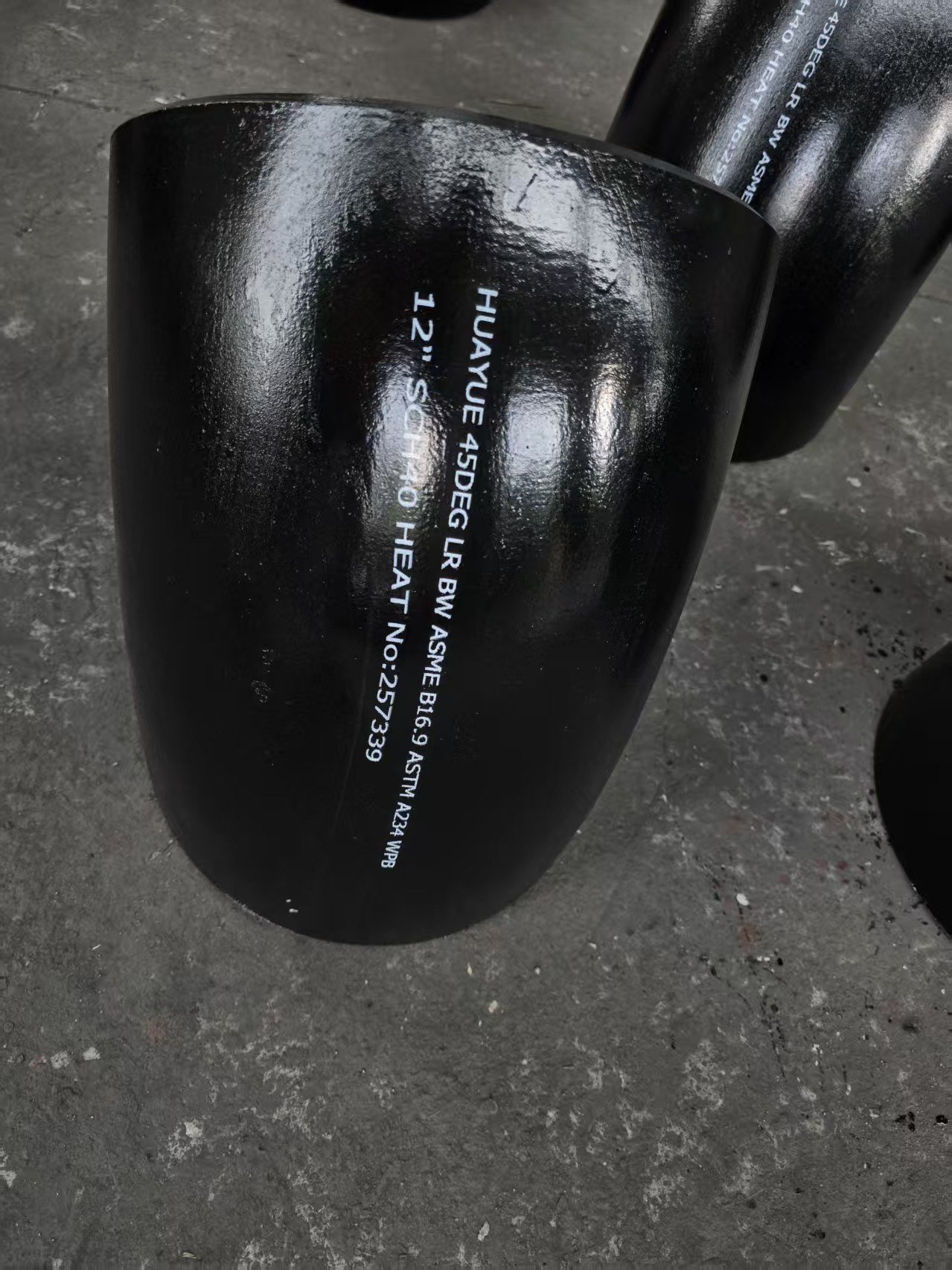

Coude en acier au carbone : guide essentiel pour les raccords de tuyauterie

Faits marquants

- Carbon steel elbows are vital components in piping systems, offering durability and versatility for various applications.

- Long radius and short radius options help adapt to different pipe routing requirements with ease and efficiency.

- Manufactured according to ASME and ASTM standards, these pipe fittings ensure quality and safety.

- Butt weld fittings provide a seamless connection, minimizing leakage risks and enhancing system reliability.

- Available in multiple sizes, thicknesses, and angles like 45°, 90°, and 180° to meet diverse specifications.

- Carbon steel elbows’ affordability and resistance to corrosion make them an industry-favorite solution.

Introduction

Carbon steel elbows have an important place in pipe fittings. They help fluids move well through the pipes. Many choose them in homes and in heavy work areas because they last a long time and are strong. You use the elbows to join pipes that go in different directions. These simple fittings help make a firm and flexible system. No matter if there is a high push of liquid or the heat is not too much, carbon steel elbows give your piping network a solid and long-lasting base.

Types of Carbon Steel Elbows Used in Singapore Pipe Fittings

In the piping industry in Singapore, you will find many kinds of elbows used for building and making things. The carbon steel elbows are some of the most popular because they are strong and stand up well to corrosion. People often use them with stainless steel fittings, especially when the job has to deal with chemicals. This helps the pipes stay strong and last longer.

Buttweld fittings are used a lot in different jobs. These include both long radius and short radius elbow types. These elbow styles work with many kinds of pipe layouts. They help make sure the pipes do not leak and stay connected the right way.

Coudes à rayon long ou à rayon court

The main difference between a long radius elbow and a short radius elbow is in how they curve. A long radius elbow has a curve where the center is 1.5 times the pipe’s size. This makes it good for letting fluid flow smoothly. The gentle curve also leads to less pressure drop. You will find long radius elbows useful in longer pipelines. They help when you need a smooth change in direction.

A short radius elbow has a tighter curve. Its center is the same as the pipe’s size. This design comes in handy when you do not have much space, like in small or tight spots. But this sharp curve can make fluid run into more resistance. You should think about this problem when you install it.

You have to choose between a long radius and short radius elbow by looking at the pipeline’s pressure, the wall thickness you need, and how much space you have. Both give good ways to solve different needs. Each one just fits a certain challenge or what the job calls for.

45°, 90°, and 180° Elbow Options

Carbon steel elbows come in three main angles—45°, 90°, and 180°. These different angles help meet all types of piping needs. The 45° socket weld elbow makes the pipe turn a little bit. It is good for changing the flow in a gentle way. This elbow works well in places where you do not want many changes in direction.

The 90° elbow, which many people call a right-angle fitting, lets the pipeline make a sharp turn. This elbow is the one most people use the most. It fits in with standard plumbing setups well. You can find it in different thicknesses like XS, so it is strong enough for high-pressure jobs.

The 180° elbow, also called the return elbow, makes the pipe go back in the opposite direction. It is best for setups where you need the fluid to move back, like in heat exchangers. Take a look at this simple overview:

Elbow Angle | Typical Applications | Available in Materials like |

|---|---|---|

45° | Slight directional changes | PVC, Carbon Steel |

90° | Right-angle pipelines | XS, Standard |

180° | Full directional reversal systems | Tee, Stainless Steel |

Key Standards and Specifications for Carbon Steel Elbows

When companies make carbon steel elbows, they need to follow rules like ASME and ASTM. ASME B16.9 gives the sizes and shapes needed for each fitting so that every piece fits well. ASTM rules decide what kind of material is used, such as A234 WPB.

These steps help make sure each fitting is safe and works well. This is very important in places with high pressure and heat, such as in the USA. By using these rules, companies can give people strong and dependable elbow fittings. These fittings meet the high needs of the market around the world.

ASME and ASTM Requirements

ASME and ASTM are trusted names when it comes to setting quality rules for making carbon steel pipe fittings, including brass fittings. ASME (American Society of Mechanical Engineers) shares guides such as B16.9. This guide talks about sizes, how things need to be built, and how elbows can fit well and easy into other pipes.

ASTM rules, like A234 WPB, focus on the mix of materials used and how strong the fitting is. These rules help make sure that degree elbow fittings are tough enough to handle different pressure in a system. When used together, these two standards let people make great butt weld fittings all over the world.

Many times, someone from outside the company checks things to make sure the fitting or weld is actually good and safe. This helps people trust that their elbows will work well, even during hard jobs. Whether it’s thick XS butt weld fittings or other kinds of carbon steel builds, using both ASME and ASTM rules means you get good, safe, and strong fittings for every job.

Sizing and Dimension Guidelines

Carbon steel elbows come in many different sizes. It is important to follow the right sizing steps so the elbow will fit the pipe you have. The size of the elbow starts with its nominal diameter, which matches the pipes it connects to. These sizes usually go from 1/2 inch up to 80 inches in most fittings.

Wall thickness also matters a lot. There are types like XS and Sch 120 that are made for setups that get a lot of pressure. To have proper, standard connections, the radius and center-to-end lengths need to be right according to ASME B16.9 guidelines.

You should use the correct size and always follow the guidelines. This will help stop leaks or breaks. Most of the time, manufacturers make this easy for people by giving charts with every needed measurement. This helps engineers and contractors pick the right carbon steel elbow. These details, which include wall thickness and radius, are also shown in inches and written in line with ASME rules.

Conclusion

To sum up, knowing about the different types and details of carbon steel elbows helps you make better choices when working with pipe fitting. These fittings are very important. They help keep your piping strong and improve the way it works, even if you use it for water or gas pipes.

When you think about things like the radius, the angle, and if the fittings meet certain standards, you can make your project safer and work more smoothly.

If you want more advice or need help picking the right carbon steel elbows for your job, you can ask for a free talk. Having the best fitting and parts for your system can make a big difference in how well it works!

Questions fréquemment posées

What are the main benefits of using carbon steel elbows in piping systems?

Carbon steel elbows are a good choice if you want to save money. They give you great protection from corrosion. You can find them in many sizes, so they fit many needs. The wall thickness is strong. This means they last a long time, even with high pressure. You also get good pricing with these elbows. That’s why they are the best for joining pipes safely.

How do I choose between long radius and short radius elbows?

If you have space, pick long radius elbows. These will let the fluid flow more smoothly and will lower pressure drops. Short radius elbows fit better in tight places. But, they have a sharper bend, so the fluid may have a bit more resistance. Look at the radius and fitting angle to choose the best option.

Are carbon steel elbows suitable for high-pressure applications?

Yes, carbon steel elbows are made for high-pressure systems. The wall thickness is strong and they meet ASME standards. Butt weld fittings in XS and Sch 80 schedules are able to handle extreme pressure. You can use these in many industrial applications. The weld is strong and the wall thickness is made to last. This means butt weld carbon steel elbows are a good choice for jobs that need extra strength.

Can carbon steel elbows be used for both water and gas pipelines?

Yes, carbon steel elbows are very good because they do not rust easily. This makes them great for water and gas pipes. PVC elbows can work in some places, but carbon steel is better when you need something strong. Carbon steel holds up well, even when the pressure changes.

How do I ensure proper installation and maintenance of carbon steel elbows?

To make sure you get things right when you set up your pipe, use certified butt weld fittings. Check that the size is right for your pipe job. For maintenance, check the weld now and then to see if there is any corrosion or if things look worn out. If you have any trouble or need to ask about refund, shipping through a third party, or replacements, always look at what the maker says.