-

Zone industrielle de Yinzhuang, comté de Mengcun, ville de Cangzhou, province de Hebei, Chine

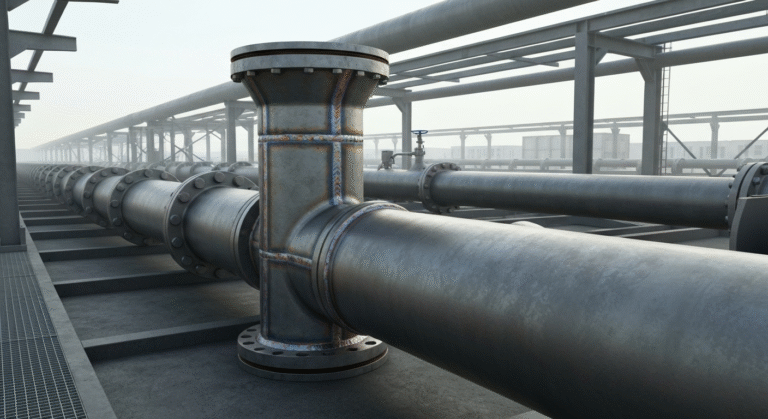

Codo sin soldadura : Conexiones eficientes para tuberías

Faits marquants

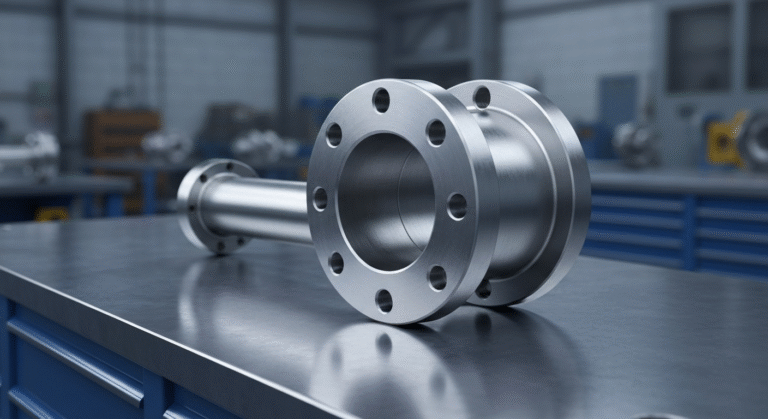

- Seamless elbows, crafted from high-quality steel, provide efficient solutions for pipe system connections, ensuring durability and precision.

- They are available in various materials like acier au carbone et acier inoxydable, catering to diverse industrial applications.

- Common angles of 45° and 90° enable flexibility in designing fluid and gas flow systems.

- Using seamless elbows reduces installation time, costs, and ensures robust, long-lasting systems.

- Compliant with ASTM standards and local certifications, they meet stringent quality requirements for Chilean markets.

- Their resilience against high pressure and corrosion makes them ideal for industries like water, gas, and petrochemical sectors.

Introduction

Pipe systems need to have high-quality parts like codos de acero sin soldadura de 1 1/2 pulgada to keep everything working safe and smooth. These steel elbows are made for many kinds of aplicaciones. They have top calidad that helps build strong networks for liquids and gases. Because these parts are seamless, they are strong and there are fewer spots in the bodega where leaks could happen. This makes them key pieces in many industries. People use them for moving fluids and fixing pipelines. Their great design and the fact that you can use them in many ways is why you see them so much in important lugares, y facilitar la entrega de tu pedido.

Tipos de codos sin soldadura para tuberías

The world of codos de acero sin soldadura is wide and very useful. There are many choices to fit what a project needs. You can get these pipe parts in materials like acero de carbono et acero inoxidable. That way, different industries get what they need. If you use elbows made from acero de carbono, you get high strength and long life. If you pick those made from acero inoxidable, you also get more protection from rust. This is key for food systems or where there are chemicals.

These elbows come in many grados and angles, catering to diversas necesidades. This helps make sure fluids or gas flow the right way. Codos de acero de carbono standard work in everything from big industry spots to small setups. You can find long-radius or short-radius designs so you have the right match for your job. Thanks to how strong they are and their many options, these elbows are a top pick for most pipe systems that need acero, carbono, and tough builds.

Codo 45º sin soldadura: aplicaciones y ventajas

Codos de 45º sin soldadura are needed when you want to change the way a pipeline goes, but you want it to be smooth. The special ángulo design of these elbows lets the flow turn slowly. This helps lower stress on the pipes. It also makes the movement of water, gas, or other fluids work better in the pipes. Because of this, people pick them for many aplicaciones, incluyendo reparaciones de manera eficiente. You can find them in water supply pipes and gas systems.

These elbows are strong because they are made from high-quality materials like carbon steel. They are made to last long and fight off rust and high pressure, so many people use them in homes and factories. You can also get these elbows in different sizes. This means they fit well in old or new pipe setups, making sure that your project goes smoothly.

It does not matter if you are doing repairs, working on new pipelines, or making bigger networks. The great calidad and good resistencia of these elbows give you both safety and long life. Because they work well in many ways, having some for your projects is always a good idea when you need something that is safe, lasting, and reliable.

Codo 90º sin soldadura: usos frecuentes en instalaciones

Les codo 90º sin soldadura is used to help pipes make a smooth 90-degree turn. This helps the pipeline go around things in its path or join two pipe sections at the exact right angle. People use these elbows a lot in water, gas, and petrochemical work. Here, safety and good flow are very important.

Much like popular produits you see on redes sociales, these pipe fittings are very common. They have a strong build and are useful in many situations. They come in different sizes, so they fit well for big jobs and small ones. Because of their seamless make, there is less risk of leaks. This gives everyone more peace of mind.

It is like how companies use the uso de cookies online to make things better for you. In the same way, these elbows help the pipeline work better. They can handle high-pressure flows without bending and add value to your setup.

Beneficios de utilizar codos sin soldadura en sistemas de tuberías

Choisir codos sin soldadura for your pipes gives you a lot of clear benefits. They have haute résistance, which means the system stays strong even when it’s under a lot of pressure or heat. There are no weak spots where leaks may start, unlike with welded options. This makes them a good and reliable choice when things get tough.

Also, these elbows have great durabilité. Their longer life makes the prix worth it, since you don’t have to replace them often or spend much on repairs. It does not matter if you use them in a factory or in a home. These choices give you a strong system that works well for a long time, so you get more for your money.

Seguridad y durabilidad en las conexiones

When it comes to making sure there is sécurité in piping systems, seamless elbows stand out for their design. Their seamless build means there are no weak joints. This gives you smooth flow and helps lower the risk of leaks or getting blocked. These things matter in casos of high-pressure systems, where bad fittings could cause major problemas.

It’s not just about safety. The strong focus on durabilité lets these elbows handle harsh conditions. They work well in areas that have corrosion or a lot of heat changes. Made from carbon steel or stainless steel, they last a long time. This longer life means you will need fewer changes and get more lastingINSTALLED systems.

When you pick these fittings, you cut down on risk and help follow rules. They make things reliable now and later on. If you are fixing or making a pipeline, these elbows put calidad at the center of what they do.

Reducción de tiempos y costos de instalación

Choosing codos sin soldadura helps people save a lot in both tiempos et costo when making installations. They are simple to put in because you do not need to do any heavy welding. This helps you finish the work faster, and it makes sure that you will get your project done on time.

- Seamless fittings cut out a lot of prep work. You need less labor time.

- They work well with what is already in the pipeline, so you have an easy time setting things up.

- The high trust you can have in them means you do not have to replace them much. It also means you will have less to repair later.

- The links with empresas de despacho give you more delivery choices, so things get there faster and the wait is less.

Suppliers also help with smooth steps so you get your order on time. This helps everyone keep working and avoids any wasted time. When you look at how fast they work and how long they last, seamless elbows are a smart way to save money for different usuarios.

Materiales y certificaciones de codos sin soldadura en Chile

The materials used in making codos sin soldadura are important for how well they work. Many people use both acero inoxidable and carbon steel. When you need something that does not rust, higher grados de acero inoxidable are better. These grades help the parts last longer and keep the system strong.

In Chile, it is important that industries follow certifications that are strict, including those related to investor relations, and to stay updated by following relevant blog discussions. These rules make sure the products are safe and will last a long time. Certifications help to show that the materials, like acero and different grados, are good. They help keep the parts reliable in any tough situation.

Acero al carbono y acero inoxidable: diferencias clave

Understanding the distinctions between acero al carbono and acero inoxidable is essential in choosing the right pipe fittings for your system. While carbon steel prioritizes strength and affordability, stainless steel stands out for its corrosion resistance and long-term calidad in demanding environments. Para más información, puede contactarnos a nuestro correo.

Aspecto | Acero al Carbono | Acero Inoxidable |

|---|---|---|

Durabilidad | Resistente pero susceptible a la corrosión | Resistente a la corrosión |

Applications | Alta presión y temperatura | Sistemas alimentarios y químicos |

Costo | Económico | Más costoso |

For installations requiring a robust build and lower prix, carbon steel is ideal. However, for pipelines exposed to moisture or corrosive agents, stainless steel is the preferred choice.

Normas ASTM y certificaciones requeridas en el país

Compliance with normas like ASTM and ansi is important when you choose piping parts in chile. These standards help to make sure the certificados you get with the products can show their reliability and estado. This is very important in demanding work areas.

Seamless elbows that have an ASTM A234 certificate give people trust in the material. They hold up well under pressure, and their material works with high-level requirements. ansi standards also make sure the size and shape of these products match what is needed around the world.

When you meet these needs, seamless elbows can make the job safer and work better. They follow both local and international normas that are very important for chile.

Conclusion

En resumen, los codos sin soldadura son una opción que ayuda a hacer conexiones de tuberías de forma eficiente y segura. El diseño de estos productos hace que la instalación sea más rápida y barata. Esto lleva a que los costos y los tiempos de trabajo sean menores. Además, la seguridad y la durabilidad que dan estos productos son importantes para que todo el sistema de tuberías se mantenga bien y funcione por más tiempo.

Es importante elegir productos de calidad y asegurarse de que tengan los espesores y certificaciones necesarias en Chile, especialmente en procesos de procesamiento. Así, puedes tener la confianza de que tu instalación será segura y cumplirá con lo que piden los estándares. Si quieres saber más o necesitas ayuda sobre cómo comprar codos sin soldadura con certificación y buena durabilidad, puedes contactarnos. Te ofrecemos una consulta gratuita sobre esto y estaremos listos para ayudarte.

Questions fréquemment posées

¿Cuáles son las principales ventajas de los codos sin soldadura frente a los soldados?

Los codos sin soldadura tienen algunas ventajas importantes. Tienen mayor calidad y mejor resistencia cuando se enfrentan a mucha presión. Su durabilité es superior. Estos codos son buenos para applications industriales donde no puede haber errores. Al usarlos, se reducen los puntos débiles en los produits. También, se elimina el riesgo que puede haber por soldaduras que no son fuertes.

¿En qué tipos de sistemas se recomienda el uso de codos sin soldadura?

Son recomendados para sistemas en los que la seguridad y la resistencia son muy importantes. Puedes usarlos en redes de agua, gas y petróleo. De acuerdo al grado de acero, los codos de radio largo sirven para tuberías de diferentes metros. Estas tuberías necesitan ser estables y soportar altas presiones.

¿Cómo se realiza la instalación de un codo sin soldadura?

La instalación es muy fácil, ya que no se necesita soldar nada. Los productos se pueden poner en las tuberías usando herramientas comunes. Hay empresas de despacho que se encargan de que lleguen a tiempo, y el pago del despacho va a cuenta del cliente, permitiendo cuotas sin interés. Además, su equipo técnico da ayuda si tienes cualquier consulta.

¿Qué mantenimiento requieren los codos sin soldadura?

El mantenimiento de este producto es muy pequeño, ya que tiene alta calidad y gran durabilidad. Solo hay que revisar a menudo para ver si existen problemas, como daños mecánicos o corrosión. Este simple cuidado ayuda a que el uso del producto dure por más tiempo en las instalaciones.

¿Dónde puedo adquirir codos sin soldadura certificados en Chile?

En Chile, es posible encontrar codos sin soldadura certificados en mercados de confianza como Mercado Libre o tiendas especializadas. También, hay empresas que tienen buenas políticas de despacho que aseguran que los productos lleguen rápido y sean de calidad, cumpliendo con los estándares del mercado y considerando la entrega sobre 100.000 pesos netos, incluso los días hábiles como el sábado, domingo y lunes.