-

Zona industrial de Yinzhuang, condado de Mengcun, ciudad de Cangzhou, provincia de Hebei, China

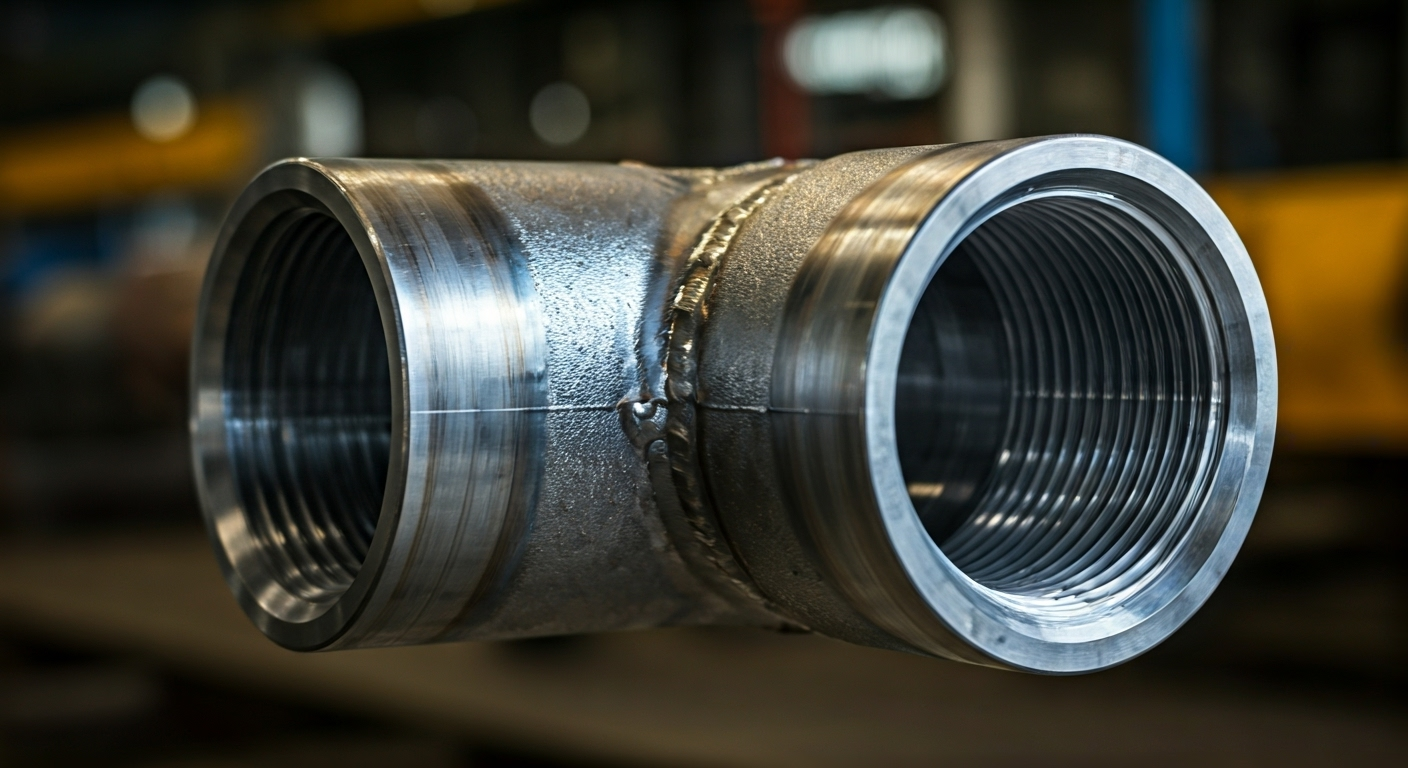

SA234 WPB Tee: Quality Standards for Steel Pipe Fittings

Aspectos más destacados

- SA234 WPB Tee fittings are crafted from carbon steel and alloy steel, designed to handle moderate and high-temperature conditions.

- These pipe fittings adhere to stringent ASTM, ASME, and ANSI standard specifications, ensuring reliable performance.

- Available in seamless and welded versions, they are widely applied across industries requiring durable and high-pressure capabilities.

- Their key mechanical properties include notable tensile strength and yield strength.

- Detailed inspection and certification processes guarantee quality, eliminating defects before shipping.

- Dimensional versatility caters to various industrial requirements, with options for reducers, unequal tees, and standardised fittings.

Introducción

Pipe fittings play a big part in pretty much any pipeline setup. They help keep things moving and let you change the direction of what flows inside. The SA234 WPB Tee is one example made from carbon steel. It follows the standard specification from ASTM.

This strong wpb tee can handle both high temperature and heavy pressure, so it does a good job where you need the best results. Thanks to its tough build and following of strict rules, the WPB Tee belongs in pipelines where you want things to last and to be done right.

Now, let’s take a look at its structure, what you can use it for, and the main reasons people pick this kind of fitting.

Overview of SA234 WPB Tee Fittings

SA234 WPB Tee fittings are well-liked in the industry because they are strong and easy to use. These pipe fittings are made from WPB carbon steel. You will find them in many places that handle both hot and warm pipes. People use these carbon steel tees in different types of projects and jobs.

The fittings can come in seamless or welded styles. This makes them flexible. They stay strong, even when under a lot of pressure.

WPB pipe fittings, like the tee, are made to need less maintenance. They help by keeping the right thickness and size every time. With WPB carbon fittings, you can also fit them easily with reducers or adjust them for other needs. That is why these pipe fittings are so important for pressure piping systems and making large tanks or pressure vessels.

Key Applications in Singapore’s Industries

Singapore’s industries depend a lot on SA234 WPB Tee fittings to keep things running well. In the petrochemical industry, these wpb pipe fittings help move gases and liquids safely even at high heat. They do this without the pipes losing strength or shape.

The construction and marine industries also use these carbon steel tee fittings often. They help manage pipes and control how things flow in and out of different systems. SA234 WPB tees be very good at handling changes in fluid direction and flow speed, which keeps the work going smoothly.

Power plants in Singapore trust WPB Tee fittings as well. These pipe fittings last long and can take a lot of heat. Their good performance and strength make them a must-have for industries where you need strong pipeline systems that can keep working in tough situations.

Advantages Over Other Steel Pipe Fittings

SA234 WPB Tee fittings stand out compared to fittings made from alloy steel or stainless steel. This is because WPB carbon steel has very good tensile strength. It helps these pipe fittings handle high pressure without problems.

WPB tees are also more affordable than many fittings made from alloy steel. Even though they cost less, they do not lose performance. The manganese that is in the WPB carbon steel adds more strength and helps the tees be flexible. This means they work well across different temperatures and hold up over time.

WPB pipe fittings come in both seamless and welded types, so you can pick what fits your needs. If you need something safe and strong under heavy use, WPB grades do a better job than others. This is why many companies in oil, gas, and construction trust these fittings like the WPB tee, for their lasting strength and ease of use.

Normas de calidad y requisitos de conformidad

To make sure you get safety and top performance, SA234 WPB Tee fittings need to meet the highest quality standards. These rules come from ASTM, ASME, and ANSI. They tell what the tee fittings should be made of, what size they should be, and how they need to work.

It is not just about the rules. Makers carry out many checks, like hydrostatic and tensile tests, so they can find and remove all defects from the fittings. When you get a shipment, it comes with Material Test Reports (MTRs) that show it passes the industry’s strict rules. This careful method helps every WPB tee fitting work well and last long, even when there is high pressure and heat.

ASTM and ASME Specifications for SA234 WPB

ASTM and ASME specifications form the backbone of SA234 WPB Tee fittings. These standards regulate material composition, dimensional tolerances, and manufacturing processes.

Specification Type | Descripción |

|---|---|

ASTM A234 WPB | Covers carbon and alloy steel fittings for moderate to high temperatures. |

ASME B16.9 | Defines butt-welding fittings dimensions and tolerances. |

ANSI Standards | Ensures compatibility with pipe systems and pressure requirements. |

Manufacturers follow ASTM specifications to ensure the fittings are seamless or welded, forged from killed steel, and free of harmful defects. ASME B16.9 complements this by ensuring they meet precise dimensional requirements for reliable pipeline integration.

Inspection, Testing, and Certification Processes

Making SA234 WPB Tee fittings needs careful checks and tests. These steps help find and remove defects. Workers use tests like the hydrostatic test and check the size and shape. This way, the fittings can handle high pressure and hot or cold temperatures.

When it comes time for shipping, you can get Material Test Reports (MTRs) if you ask for them. MTRs show that the wpb tee fittings meet ASTM and ASME rules. All shipments come with tracking numbers. This lets you track your order.

Workers do many things like checking wpb tee fittings for defects and doing tensile strength tests. They also look at the surface of the tees. These steps help make sure you get good quality fittings every time, no matter where you are in the world.

Conclusión

To sum up, it is important to know the quality standards for SA234 WPB tee fittings if you work with steel. This matters even more when you need the fittings to be strong and up to code. In Singapore, these fittings are used in many key industries. It is important to follow ASTM and ASME standards for every project. Knowing what makes these tees special helps you make better choices. Inspection, tests, and proper paperwork help make sure the SA234 WPB tee fittings will work well, even with high pressure. When you start a new job, think about using SA234 WPB fittings. This will help keep your work safe and up to standard. If you want to know even more about how these tee fittings can help, you can get in touch and ask for a consultation!

Qué son los accesorios de tubería de acero

Steel pipe fittings are important parts you need in a pipeline system. They help control the way liquids move and change direction. These fittings are made from carbon steel or alloy steel. They let you manage how fluids travel and work in many factory jobs.

Some common types of these pipe fittings are reducers, flanges, elbows, and tees. Each one helps move fluids in the way you want. SA234 WPB fittings stand out because they are strong and still can bend a bit when needed. So, if the job is moving oil, gas, water, or even slurry, these fittings will help you with accuracy and speed in every step.

Qué es ASTM A234 WPB

ASTM A234 WPB is a standard that describes what you need for carbon and alloy steel fittings. These fittings work for jobs with moderate to high temperatures. You will find both seamless and welded types. This includes elbows, tees, and reducers.

The standard makes sure all fittings use top-quality materials, such as wrought steel and killed steel. WPB fittings that meet ASTM rules are great for places with high pressure. They are a good choice for pipelines and when you have to make or repair a pressure vessel. These alloy steel fittings give different options for many kinds of work.

Grados en ASTM A234

The ASTM A234 standard has many grades made for different uses in industry. WPB is the most popular of these grades. It is made for pipelines that work in medium and high heat. This grade uses carbon steel, which gives it good yield and strong tensile strength.

Some other grades, like WP5 and WP12, have extra alloy materials. This helps them last longer in places with a lot of pressure or where things can eat away at metal. These carbon steel grades are often used in things like power plants or in oil pipelines where the work can be tough on pipes.

Accesorios de tubería de acero ASTM A234 WPB características químicas y mecánicas

The chemical mix in ASTM A234 WPB fittings has set amounts of carbon and manganese. These levels are controlled to give the right strength and flexibility. If there is less carbon in these fittings, there will be more manganese. This change helps make them stronger and last longer.

WPB steel fittings also have good mechanical strength. Their tensile strength can be as much as 60,000 psi, and their yield strength is about 35,000 psi. They even have extra pressure ratings that go up to 9000 lbs. All these strong features make WPB a top choice for many in the industry.

Propiedades mecánicas de los accesorios de tubería ASTM A234 WPB

ASTM A234 WPB pipe fittings have good mechanical properties, which are important for many industries. The tensile strength of these wpb pipe fittings is between 415 and 655 MPa. Their yield strength is at least 240 MPa.

These fittings can handle high pressure and work with many pressure ratings, including 150, 300, 600, and higher. This strong and durable design means the fittings work well in pipelines that move fluids even in tough conditions.

La norma ASTM A234 incluye accesorios de tubería sin soldadura y soldados

The ASTM A234 specification covers seamless and welded pipe fittings. Seamless fittings are made from a tubular material. This gives them strong structure and better reliability.

On the other hand, welded fittings are made by joining pipes together. This method helps add more options with pipe fittings. ASTM has strict rules for both kinds. This makes sure all fittings follow the high standards and can be used well in many jobs.

Procesos de conformado para la fabricación de accesorios de tubería de acero

Steel pipe fittings go through careful processes like forging, hammering, and bending. These steps help shape the pipe fittings with the right precision, so there are no defects.

After this, the fittings are cooled down in a controlled way to stop heat damage. Then, they are checked with things like hydrostatic tests or strength tests to make sure their quality is good.

Dimensiones de los accesorios de tubería de acero ASTM A234

SA234 pipe fittings follow ANSI and ASME dimension guidelines, guaranteeing standardization.

Parameters | Measurement Range |

|---|---|

Diameter | ½ inch to 48 inches |

Espesor | SCH 10, 20, 40, 80, XS |

These fittings adapt easily to various pipeline setups, meeting industry-wide needs.

Grados de accesorios de tuberías de acero aleado en ASTM A234

Alloy steel pipe fittings are made by mixing metals like chrome and molybdenum. This blend makes them last longer. Grades such as WP5 and WP11 are strong. They work well in oil pipelines and nuclear sites.

You can get these alloy steel pipe fittings in both seamless and welded types. This helps them fit many uses. When they meet ASTM rules, it shows they are high-quality and safe to use. These fittings are trusted in the field for their strength and reliability.

Composición química

ASTM A234 fittings be made with exact amounts of chemicals to work their best. The carbon and manganese in these fittings are balanced to make them strong. There are limits for things like silicon and nickel in the fittings.

These careful choices mean the fittings can last a long time and stay strong, even when the environment gets tough.

Requisitos de tracción

The tensile requirements for ASTM A234 WPB fittings show how strong they are. The tensile strength for these fittings is between 415 and 655 MPa. This strength helps the fittings handle a lot of stress.

The yield strength for them is at least 240 MPa. This gives good protection against bending or changing shape. Because of these specs, the wpb fittings can handle high pressures in many uses.

Preguntas frecuentes

What does WPB mean in SA234 WPB Tee?

WPB means Weldable Pressure Grade B. It is a type of carbon steel pipe fittings. These grade b fittings are made to meet high standards. You can use these wpb fittings in places that need to handle heat or pressure. They work well in pressure pipelines and when making a vessel.

How is the quality of SA234 WPB Tee fittings ensured?

Quality is checked with careful inspections, certifications, and a lot of testing. Material Test Reports (MTRs) show that things meet ASTM standards. Inspections also look for defects to make sure that everything works the same every time.

Are SA234 WPB tees suitable for high-pressure systems?

Yes, SA234 WPB tees are a good choice for high-pressure systems. They are made of carbon steel, which gives them strong tensile strength. They also meet the standard specification, so you can trust them to work well even when the temperature gets high. These features help them to be steady and safe in tough environments.

What are the common sizes available in Singapore?

SA234 WPB Tee fittings in Singapore are available in many sizes. These pipe fittings usually range from 0.75 inches up to 24 inches in size. The thickness of each wpb tee fits common SCH standards like STD, SCH 30, and SCH 40.

How do SA234 WPB Tees compare to stainless steel alternatives?

SA234 WPB tees are a good choice when you want strength and reliability but need to save on cost. Carbon steel and WPB carbon steel fittings can handle pressure and heat well in many applications. Stainless steel is great for places with a lot of corrosion, but WPB carbon fittings still keep their tensile strength for most uses. With these WPB fittings, people get a strong and dependable option without spending more money.