-

Yinzhuang Industrial zone,Mengcun county,Cangzhou city,Hebei province,China

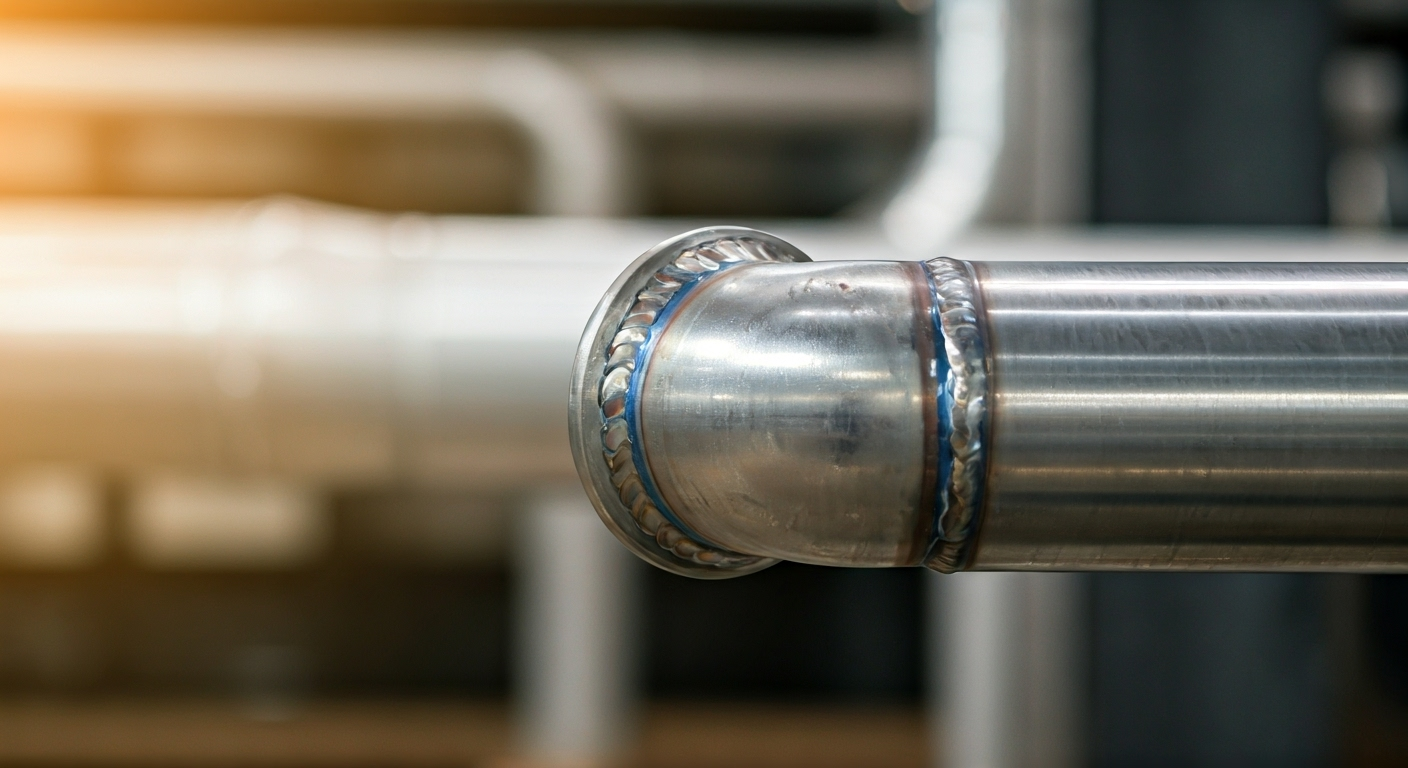

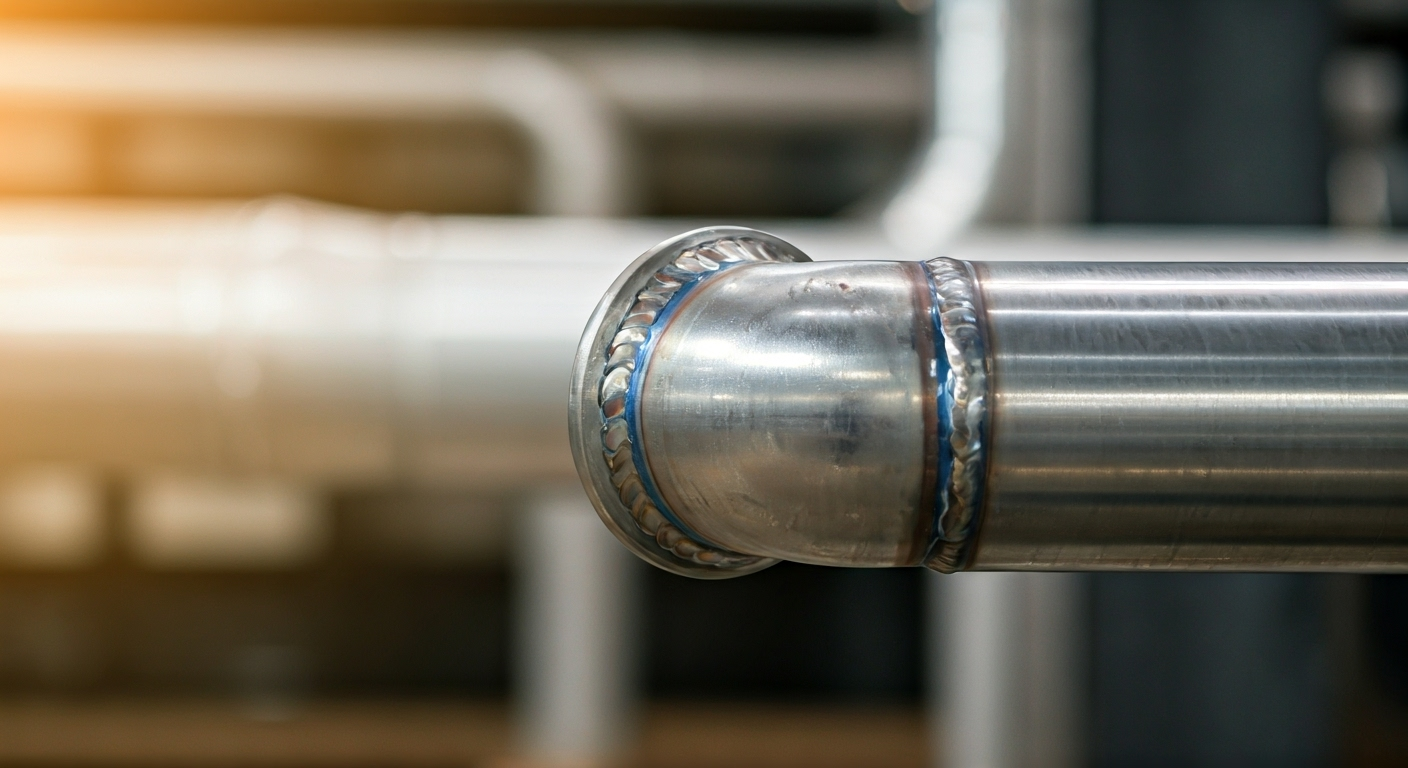

Butt Weld Elbows: Key Benefits for Pipe Fitting

Key Highlights

- Butt weld fittings, including pipe elbows, are integral for seamless fluid flow control in pressure piping systems.

- Crafted from carbon and stainless steel, these fittings ensure corrosion resistance and durability under varied conditions.

- The fusion welding technique guarantees leak prevention and enhanced strength across piping joints.

- Elbows designed with precise angles ensure efficient direction changes and reduced pressure drops in pipelines.

- Commonly found in plumbing, pressure vessel fabrication, and industrial applications requiring dependable steel pipe fittings.

- Available in alloy steel types for elevated temperature services, catering to diverse specifications and angles.

Introduction

Butt weld elbows play an important part in building systems that move liquids. They are used to join pipes and change the way flow moves. Most of these are made from steel pipe. You will see them a lot in jobs where there is high pressure, like pipelines or pressure tanks. The pipe elbow is shaped so flow goes around corners easily and does not get blocked. Their strong butt weld joins and use with steel fittings help them last long. These fittings also help keep the whole system working well. In the end, you get pipe elbow and butt weld parts that bring trust and good performance to the work.

Overview of Butt Weld Elbows in Pipe Fitting

Butt weld elbows are very important in joining sections of piping systems. They help keep fluid moving well and make the pipes strong. These pipe fittings use fusion welding to join pipes together and make sure the connections are strong.

Butt weld elbows do more than just change the way fluid moves. These fittings are made to handle high-pressure uses. They work well for regular jobs and also for setups made to fit special needs. Butt weld elbows help pipes work well for a long time, even in big and busy piping systems that use welding and fusion.

What Are Butt Weld Elbows?

Butt weld elbows stand out because of how they connect pipes and change the direction of flow in a piping system. These pipe fittings use a pipe elbow made with smooth curves. This lets liquids and gases move smoothly and stops any big change in pressure.

With butt weld elbows, the welding process uses fusion to join steel pipes with strong bonds. There will not be leaks because the weld holds it all together. You can find these fittings made from stainless steel, carbon steel, or alloy steel. This design keeps the system in good shape, even if there is a lot of pressure or stress on it.

Butt weld elbows have a range of options, such as different angles from 45° to 90° for steering the flow in vacuum tubing. They let you guide fluids while still giving you strong flow and not slowing things down. Industries that use pressure piping often pick these fittings because they are a cost-effective and tough choice for hard pipeline jobs. All over the world, butt weld elbows keep pipes working well and lasting longer.

Common Applications in Australian Industries

Australia’s industries use butt weld elbows in many ways. These pipe fittings are needed in places where strong and efficient work is important.

- Pressure Vessel Fabrication: Butt weld elbows help create pressure piping. You can use these in places with both normal and high heat.

- Plumbing Systems: These are key to connect steel pipes for homes, businesses, and factories, making water systems work right.

- Stainless Steel Applications: People use stainless steel fittings in jobs where they need parts that don’t rust. This makes the work strong and steady.

- Pressure Piping Operations: These heavy-duty jobs need seamless pipe fittings. They make sure fluids move well even under pressure.

By meeting the different needs of each industry, businesses in Australia get the right pipe elbows and steel fittings. The result is dependable fabrication and work that does not stop, even when environments get tough. Stainless steel and other strong weld fittings help fight corrosion and keep systems running smoothly.

Types of Butt Weld Elbows

Butt weld elbows are made in many types to meet different needs for the industry. They are made from carbon steel, alloy steel, and stainless steel. These fittings are strong, so they can last in many working conditions.

You can get these in long radius or short radius options, which help steer fluids in different ways. Some have seamless construction, and others are welded. This means you have good choices for systems that need to handle a lot of pressure. No matter what you need, there are many types to pick from, so they work well in tough pipeline jobs.

Long Radius vs. Short Radius Elbows

The difference between long radius and short radius pipe elbows comes from the way they bend and the way it changes flow in a piping system. A long radius elbow helps fluid move better by giving it a smooth curve, almost like a river bend. The short radius elbow lets you make tight turns in the piping, but it’s sharper.

Feature | Long Radius Elbows | Short Radius Elbows |

|---|---|---|

Degree Elbow Radius | The radius is 1.5 times the diameter of the steel pipe | The radius is the same as the diameter of the steel pipe |

Applications | This type helps to reduce pressure drop in big systems | It is best to use in areas where there is not much space |

Benefits | There is improved flow with less turbulence | It gives you a lower price but means more resistance |

You should pick a long radius or short radius elbow based on what the job needs. Think about the amount of space you have and what kind of flow you want in the pipe. If you know about the radius and other features, you can choose the one that works best in your steel pipe system.

Standard Angles and Custom Configurations

Butt weld elbows are not just made in standard shapes like 45° or 90°. You can get pipe elbow fittings made to fit special needs in the pipeline. Some pipelines may need a right angle, and custom options make this possible.

Manufacturers design these so they match different ways fluids move in the workplace. They make sure the fittings meet all the right safety and quality checks for good use. If the space is small or if the flow goes in a strange way, custom weld fittings help the system work well.

When a company needs something exact, being able to create custom pipe elbow fittings is a big help. It makes the movement of liquids or gases in the pipelines smooth and easy.

Core Benefits of Using Butt Weld Elbows

Butt weld elbows give many advantages to new pipeline systems. First, their smooth fusion gives leak-proof connections and strong steel fittings. They also help stop corrosion, so your system will last longer.

When you use these fittings, you can get rid of usual pipeline problems like pressure drops. This helps the fluid flow better. With the right way to weld and connect, they handle high-pressure jobs well. So, these butt weld fittings are good for many types of projects.

Enhanced Strength and Leak Prevention

Pipeline systems must have strong joints, and butt weld techniques help with that. This kind of welding uses heat to join the materials, which stops leaks from happening. With this method, you get steel pipes that fit together without gaps. This is different from threaded connections.

Using butt weld elbows stops leaks, which helps you save money on work and also keeps you from hurting the environment. Whether it’s plumbing or pressure vessel fabrication, these elbows are made with care, so things stay safe and work well.

Also, these strong welds help the fittings last a long time. They keep working even when there is a lot of pressure. That’s why you see these designs used in pressure piping, where you need to know things will keep working right.

Improved Flow Efficiency and Reduced Pressure Drop

Good fluid movement depends a lot on good design. Butt weld elbows help pipes connect without stopping the flow. Their smooth bends let water or gas move along better. This helps keep the speed steady and means there is less loss of pressure in the system.

When you use the right welding for these pipe fittings, you get a system that handles high and low pressure well. Liquids and gases can go through easily. Many people in businesses that use stainless steel or alloy steel want these kinds of steel fittings. That is because they help keep everything running the way it should.

If you pick strong pipe elbows, you will have steady flow for a long time. You save energy, too. This shows why these fittings are a smart idea in any kind of building or big repair job where steel fittings, welding, stainless, and alloy parts are needed.

What is Steel pipe fittings

Steel pipe fittings, including brass fittings, are important because they help control how things flow through pipes. They can change the speed or the direction of the flow in the pipeline system. There are different types of fittings like reducers, nipples, flanges, and caps. These be used to move liquids the way you want in plumbing or in things used for work.

These fittings, including steel elbow types, are made with carbon or alloy steel. They are built strong, so they last a long time, even when there is a lot of pressure. Some fittings like tees and elbows let pipes bend or turn as needed. Also, they be great at fighting problems like corrosion and can handle a lot of pressure. This means you can use them for more than just regular steel pipes.

If you work in an industry and need your flow systems to work well all the time, using good quality pipe fittings is a smart move. It will make your system last longer and work better.

What is ASTM A234 WPB

The ASTM A234 WPB rules cover how pipe fittings made from carbon and alloy steel should be used for places with both high and moderate temperatures. These fittings are made from seamless or welded steel pipe, often with filler metal added. They are known for being strong and reliable.

ASTM-approved fittings come in different types, like elbows, tees, reducers, and more. They are used in work like HVAC systems and other jobs that need pipe fittings to take a lot of pressure. The WPB materials are known to be strong and hold up well under heavy use, which is why many use them for high-pressure piping.

Using fittings that follow these specifications means you get good, steady work, even when your project needs to handle changes in temperature around the world.

Grades in ASTM A234

ASTM A234 gives us many grades. These include WPB, WP11, and WPC. Each one is best for different heat levels and how much you need the fitting to bend. Alloy steel grades in astm are used for pipelines when things get very hot or are very tough. These alloy fittings, like the WPB and WPC, are made to last in hard places.

WP91 is one of the grades people choose when they want fittings with good strength and do not want rust or problems from corrosion. These fittings come from steel pipes or plates. They work well, because they keep the right balance between being strong and handling the outside world.

It is important to pick the right grade in ASTM if you want your alloy steel pipelines to fit industry standards. The right timing and choice help your fittings and pipelines work well in any hard use or tough condition.

ASTM A234 WPB steel pipe fitting chemical and mechanical features

WPB pipe fittings that meet ASTM standards are known for being top quality. The amount of carbon in these fittings is kept low at 0.35%. This helps keep them strong and also flexible. Other elements like silicon and molybdenum help the fittings resist corrosion and last longer.

These pipe fittings also have a tensile strength of 60,000 psi. This means they work well in high-pressure systems. The grades of the fittings can be used for many engineering projects, especially in fluid pipelines that need to be strong.

Knowing about what is inside these WPB fittings and how they work shows why they are important. You will find them in places where people need pipe fittings or fittings that always meet set standards for quality.

Mechanical properties of ASTM A234 WPB pipe fittings

Mechanical integrity in WPB fittings means taking great care with calculations. For example, these fittings have a tensile strength of 60,000 psi, which comes from making the right changes in chemicals. This level of work is needed to meet the demands that pipelines have. Following ASME rules also helps with this.

ASTM fittings work at a higher standard than most, by going past normal limits. This is true for both seamless and welded options. The fittings can handle different types of stress from the outside. Because of this, makers can meet the needs of many industries in a good and efficient way.

All this hard work helps people trust the products. Industries that want strong mechanical and structural support in their piping networks look for this kind of promise in their fittings.

ASTM A234 includes seamless and welded pipe fittings

ASTM A234 fittings can be either seamless or welded. Seamless fittings are made to keep the strength of the pipe with no breaks. Welded fittings give you more ways to use them when there are tricky areas in the pipeline.

This choice of fittings helps engineers balance how strong the pipeline is and how much room there is. They also help meet rules from ASME for the environment.

With both seamless and welded fittings, ASTM shows that its standards are needed in many industries. These options give people what they need for pipe systems that can change and work well.

Steel pipe fittings manufacturing forming processes

Making steel pipe fittings takes many steps. These include forging and casting, which help make them strong. People use pressing, hammering, bending, extruding, and welding to shape the steel pipe. These ways help make sure the fittings are smooth and fit well.

It is important to watch for problems in welding and to control how fast the steel cools. This is done to make sure the pipe fittings always meet strict rules. After making them, more checks like hydrostatic tests are done. This is to make sure the fittings are high quality and will work well when in use, even with lots of pressure.

ASTM A234 steel pipe fittings dimensions

Dimensions for ASTM fittings change based on how and where they be used. The outer diameter can go from 1/2” up to 48”. Thickness runs from SCH 10 to SCH XXS, and this does include SCH 80 and SCH 160. Standards are based on ANSI/ASME codes from B16.9 and also include MSS-SP details.

This range gives you fittings that fit different uses and set-ups. It helps people match what they need and makes sure everything meets ASTM and ASME requirements. This way, you get good fit and strong work for any piping job.

Alloy steel pipe fittings grades in ASTM A234

Alloy fittings that meet ASTM standards come in high-strength types such as WP5 and WP91. These fittings work well in places with very high or low temperatures. The metal molybdenum is used in these fittings, and it helps give them great strength, even when under a lot of pressure.

People use these alloy fittings in big pipelines for oil and in nuclear plants. They trust their chemical makeup to be strong and safe. WP22 grade alloy fittings can handle tough jobs in many industries that need bending and pulling strength during work.

Chemical Composition

The chemical makeup for ASTM alloy fittings has layers of chromium and molybdenum. There is also nickel and copper. These are added to help the steel fittings fight against corrosion in server conditions. At the same time, silicon in the alloy helps to protect the fittings from breaking down over time.

Because of this mix, the alloy stays strong. This makes these steel fittings good to use in tough places that need to meet specification rules.

Tensile Requirements

Industrial codes say that tensile ranges can be checked according to ASTM standards.

Property Feature | Reading Range |

|---|---|

Strength WPB | Tensile Yield: 60Ksi [Pressure Durability] |

The astm codes help to show how strong the wpb material used will be.

Conclusion

To sum up, butt weld elbows are a good choice for many pipe fitting needs. Their seamless design and strength help them last longer. These steel fittings work well in places with high pressure. This means they stay strong and help stop defects or corrosion. Because they use fusion welding, there is more integrity. This makes them a good choice for critical range jobs like pressure vessel fabrication and plumbing. You can find butt weld fittings in different alloys, like stainless or alloy steel. This helps them meet the needs of many industries. With these steel fittings, you get good results and long-lasting piping.

Frequently Asked Questions

What materials are commonly used for butt weld elbows in Australia?

In Australia, people often use carbon steel, stainless steel, and alloy steel to make butt weld elbows. Each one has its own good points. For example, stainless steel stands out because it helps protect against corrosion. Carbon steel and alloy steel are strong. Because of these features, you can use them in many piping systems for different types of work across industries.

How do you select the right size and angle for a butt weld elbow?

To pick the right size and angle for a butt weld elbow, you have to look at the pipe size, how much pressure will be in the system, and what type of fluid will go through it. Doing this helps make sure the flow is good and that there will not be too much stress on weld joints. This can help your pipes last longer. Always check the right specs before you get started.

Are butt weld elbows suitable for high-pressure applications?

Butt weld elbows work well for high-pressure jobs. Their strong build and seamless weld help keep the pressure steady. They are a good choice when you need more strength, like in oil, gas, and chemical companies. Because of their tough design, the piping system stays safe and works well for a long time.

What maintenance is required for butt weld elbows?

Regular maintenance for butt weld elbows is important. You should look for signs of corrosion. Check that the weld is set right. Look for any leaks in the joints. It is good to clean the joints, so dirt does not build up and slow down the flow. If you keep a close eye on these things over time, the elbows will last longer and stay strong in the system.

Can butt weld elbows be used for both above-ground and underground piping?

Yes, butt weld elbows can be used for pipes that are above the ground and also for pipes that go under the ground. They are strong and make a tight, safe weld connection. This helps the pipes stay together well, even when the weather or environment changes. Because of this, people can use them in many places and for different kinds of jobs. Butt weld elbows help keep the pipes solid and in good shape.