-

Industriegebiet Yinzhuang, Kreis Mengcun, Stadt Cangzhou, Provinz Hebei, China

Nahtlose Winkel 90 Grad A234 WPB ASME B16.9 | Fittings

Wichtigste Highlights

- Seamless elbows are vital components for changing fluid flow direction in piping systems, ensuring precise engineering solutions.

- Made from Kohlenstoffstahl, these fittings offer exceptional durability and strength for demanding applications.

- The Standard ASME B16.9 guarantees uniform specifications for manufacturing, enhancing compatibility in pipeline setups.

- Crafted from ASTM A234 WPB, the material ensures reliable performance under varying degrees of pressure and temperature.

- These fittings come in different radius options, including kurzer Radius und langer Radius, for versatile system designs.

- With exceptional quality and reliability, these elbows deliver efficient solutions across diverse industries.

Transitioning from highlights, let’s explore the detailed introduction.

Einführung

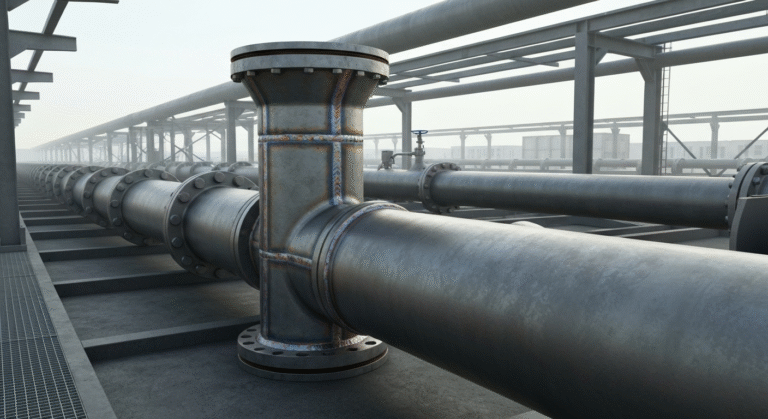

Seamless elbow fittings are now a must-have in modern piping systems. The main job of these carbon steel fittings is to let fluid easily change direction. They help keep the system running well and smooth. Because these elbows are made from carbon steel, you can use them where high pressure is a big concern. People count on their solid build and how well they work under stress. It does not matter if you are working on big industrial pipelines or smaller home systems—these seamless elbows offer real dependability and are easy to put in. Let’s take a closer look at Seamless Elbow 90 Degree A234 WPB ASME B16.9 fittings so you can know more about what they do and why they are helpful.

Overview of Seamless Elbow 90 Degree A234 WPB ASME B16.9 Fittings

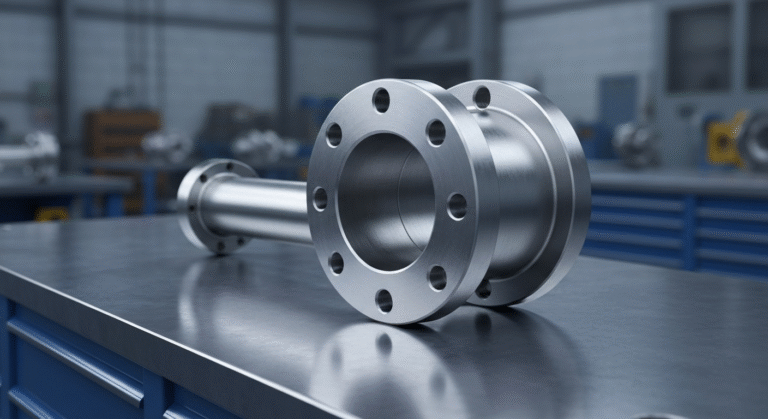

These carbon steel elbows be made to meet tough industry rules like ASME B16.9. They come in a 90-degree shape that can change the direction of fluids fast and well. These elbows are great to use in many types of piping systems. They are made without seams, so they last a long time and have less chance to leak, even when the pressure is high.

These fittings be built to give high-quality performance for both short and long radius setups. If you want a small setup or one that moves a lot of flow, these elbows work well. You can trust them to fit your piping system needs.

Hauptmerkmale und Vorteile

Carbon steel elbow fittings use strong material that helps them stand up to daily use and tough conditions. These have been made with high-quality welding processes, like butt welding, so you get a smooth finish and steady results every time. Some important features are:

- Made with durable carbon steel, these elbows can handle both pressure and very hot or cold temperatures.

- Die Stumpfschweißkrümmer shape gives a firm seal, which helps stop leaks and keeps your pipeline running well.

- Die smooth interior surface lets liquids and gases move with less resistance, making the whole system work better.

- Because they resist chemical reactions, these Beschläge work in many fields, like oil, gas, and chemical plants.

With great manufacturing, these carbon steel elbows offer long life, strong performance, and are flexible for different tough places.

Typical Applications in U.S. Industries

The versatility of seamless elbows makes them great for many uses. They show their value in different ways:

- These elbows are used in piping systems for oil and gas facilities. They handle high-pressure flows very well.

- When used in carbon steel and stainless steel pipe networks, they work well with different materials.

- You will often find them in chemical plants, refineries, and water-treatment systems. They help change the direction of flows often, which is needed in these places.

- Their design lets people use them in small spaces. This is why they are needed in tight industrial setups.

Because they can be used in so many places, these degree elbows help make sure your steel pipe and stainless steel pipe stay working well and trouble-free. They keep different pipelines running smoothly for everyone involved.

Material Specifications and Manufacturing Standards

These fittings are made to meet ASTM A234 WPB und ASME B16.9 standards. The way they are made helps them be reliable. It also makes sure these fittings follow all the needed technical requirements in a pipeline. When making these fittings, thickness and safety rules are followed. This will help give the fittings the strength that people need for their work.

You can get these fittings in both short-radius and long-radius options. This lets them fit many types of flow rates and pressures. There are strong checks with inspections. Also, great care is given to the packaging. All fittings come to you ready to be set up right away in your system.

ASTM A234 WPB Material Properties

Die ASTM A234 WPB standard is known for having strong and high-quality material. These elbows are made with Kohlenstoffstahl, so they handle heavy pulls and hits very well.

- The grades let them work well in many temperatures and pressures.

- Thickness helps make them last longer. You can rely on them in places where things wear out fast or where there is a lot of pressure.

- They are made to the right thickness, so the walls stay strong and safe even after lots of use.

- The material is always steady and works smoothly in both commercial setups and big plants.

Because of all this, ASTM A234 WPB elbows are a good choice when you need strong parts for the industry.

Compliance with ASME B16.9 Standards

ASME B16.9 standards help make sure that seamless elbows keep their top quality and strength. The standards set the rules for the size of the pipe’s diameter, how big the bend’s Radius is, and the Dicke. This lets all fittings work well together.

Elbows made under these rules always perform the same way, so you can use them in different pipeline systems. Because they follow these standards, it is easy to fit them with many setups, even if the pipeline is tricky or goes under high pressure.

By sticking close to ASME rules, these fittings are a good, trusted choice in any job where you need things to be just right and work well.

Schlussfolgerung

To sum up, it is important to know about Seamless Elbow 90 Degree A234 WPB ASME B16.9 fittings if you work with pipelines. These fittings have strong build and can be trusted, which is why people use them in many U.S. industries. They meet strict ASME and material rules, so you get good performance, even when the pressure is high. When you choose the right fittings for your pipeline, you help it work better and last longer. If you want personal help or advice about WPB or fittings, get in touch with our team. You can get a free consultation from our experts.

90 Degree Seamless Elbow Short Radius

Short-radius elbows help change the way a pipeline goes when there is not much space to move. This short radius elbow has a bend where the radius is the same as the pipe’s diameter. Because they are small, they work well in spots with low pressure.

With no seams, they are strong and easy to work with, even in tough pipeline setups. Most people use these elbows in gas pipelines, chemical plants, and small areas in factories. They let the pipeline turn around corners without using much room, so they are a good choice for tight spots.

10 Inch 90 Degree Elbow Dimensions

Navigating the dimensions of seamless elbows involves understanding key specifications. Below is a detailed text table:

Diameter | Dicke | Schedule (Sch) | Pipe Diameter | Standard (Std) |

|---|---|---|---|---|

10 inches | 9 mm | Sch 120 | DN250 | ASME B16.9 |

This dimensional data allows better planning and precise installation in Rohrleitungssysteme.

How to Calculate Weight of 90 Degree Elbow

Calculating the weight of a 90 degree elbow needs to be done with care. The formula to use is:

W = 0.0387 S (D – S) R / 1000

Here is what the letters in the formula mean:

- W is the weight for one piece in kilograms.

- S stands for the thickness.

- D is the size across, or diameter.

- R means the radius.

You must always use the correct measurements for degree elbow parts. Sticking to the right standards helps the pipelines work well.

90 Degree Short Radius Elbow Weight

Short-radius elbows are good choices when there is not much room, as they fit well in small spaces. The weight of the elbow can change depending on what it is made from and the sch, or schedule, that it has. With the right assessment and proper packaging, you help make sure the elbows get moved and set up safely.

Material Grades of Seamless Elbow

Seamless elbows can be made from a mix of material grades like carbon steel and stainless steel. These elbows fit different custom jobs. The way they are built helps them handle big changes in temperature and high pressure. You can count on them to work well in many tough situations.

Carbon Steel Elbows Suppliers

A strong network of carbon steel elbows suppliers helps make sure that you get good products that fit the needs of different piping systems. These suppliers are important because they give you the fittings you need, including 90-degree elbows and long-radius shapes. These parts follow both ASTM and ASME rules. The suppliers offer many types of carbon steel, which means you can use them for different jobs and pipe sizes. When you work with trusted suppliers, you get strong and reliable carbon steel parts that help your pipeline work well. This makes your pipeline last longer and be more efficient.

Drawing & Specification for Seamless Elbow

Detailed specifications for a seamless elbow include things like material type, wall thickness, and diameter. The ASTM A234 WPB standard sets the rules for making this carbon steel fitting. This helps ensure high quality and long-lasting parts in any piping system. The inside of a seamless elbow is smooth, so things can flow better through the pipeline. Careful drawings show how engineering and design come together to make seamless elbows important for any complex pipeline system.

Large Diameter Steel Pipe Cap

Large diameter steel pipe caps are used to close the ends of pipes in many systems. You can find them in both carbon steel and stainless steel. These caps can handle high pressure and different weather or work conditions. They work well with many welding methods, like butt weld and socket weld. This helps make sure your steel pipe stays sealed tight. The caps come in different thicknesses and diameters. They can be used in many types of pipeline jobs and help keep the whole system strong. The packaging is well made, so you can move and install the caps without any trouble.

90 Degree Threaded Elbow

The 90-degree threaded elbow helps move things smoothly in a piping system. It is a key part of any pipeline. Made from strong carbon steel, this piece is built to last. It be tough enough to handle pressure and keeps up high quality all the way.

If you use the right threading for it, you get a good, secure fit. That means the pipeline will hold together well. This simple design cuts down on flow problems and keeps things moving easy.

This elbow is a good fit if you work with pipelines made of carbon steel or stainless steel. It will work well in many kinds of jobs, giving you something you can count on.

Sch 80 Concentric Reducer

In many piping systems, the sch 80 concentric reducer is important because it helps connect pipes of different sizes. You can use it with both carbon steel and stainless steel pipes. This part helps make sure that water, gas, or other fluids move smoothly from one pipe to the other with less turbulence. These reducers are made to follow high standards set by ASTM. This keeps the system strong and safe. The way it is built also makes welding easier and helps connections stay strong for a long time, no matter what the job needs.

Ellbogen aus Edelstahl mit langem Radius

Stainless steel long radius elbows are important parts used in many piping systems. They help the flow move better and there is less turbulence. The way these fittings are made lets them handle pressure and corrosion. This is why they can be used in so many ways. The larger radius in these fittings lets the direction change slowly in the pipeline. This helps to cut down friction loss and makes the tubing work better. These elbows come in many sizes, with different diameters and thicknesses. Long radius elbows are needed to make strong and lasting connections in any pipeline or tubing network.

45 Degree Long Radius Elbow

Manufacturers of high-quality 45 degree long radius elbows give the important parts needed for good piping systems. These fittings are usually made of carbon steel or stainless steel. They help the flow of liquids or gases stay smooth and lower the chance of trouble inside the pipes. The way they are made follows strong ASTM and ASME rules for extra strength and long-lasting use. There are many choices for pipe diameter and thickness, so they work well in many areas, like factories and other businesses. Good suppliers use safe packaging and deliver on time, making it easier for people to get what they need.

A234 WP91 Stahlbiegung

A234 WP91 steel bends are made to be strong and to work well in piping systems with high pressure. They have good strength and can bend without breaking, so the flow moves smoothly in many types of jobs. These bends work well for the hard jobs that big pipelines need to do. People know these bends last a long time. You can get A234 WP91 bends in different radius designs. This means you can pick what fits your pipe’s diameter best. The way these bends are made follows tight industry rules. This makes sure you get good quality connections, whether you use carbon steel or stainless steel in your project. These bends help make your system work better, too.

Häufig gestellte Fragen

What is the difference between seamless and welded elbows?

Seamless elbows are made from one whole piece of metal. This gives them more strength. There are no joints, so they last longer. Welded elbows are made by joining two pieces together. They are usually less expensive, but they may not work as well when there is a lot of pressure. Both of these types are used for different jobs.

How do I select the right size and radius for my piping system?

To choose the right size and radius for your piping system, you need to think about the flow rate, how much pressure is needed, and how much space there is. Also, check the right specifications to make sure the piping system works well with the current fittings. This helps the system work well and last a long time.

Are A234 WPB elbows suitable for high-pressure applications?

Yes, A234 WPB elbows are made to handle high pressure. These elbows use carbon steel and follow ASME B16.9 rules. This helps them deal with a lot of stress and changes in temperature. Because of this, you will find them used in tough places in many industries.

How should seamless elbows be installed for best performance?

To get the best results, make sure you install seamless elbows as the manufacturer says. You need to line them up the right way and give proper support. Use the right fittings, and try not to make sharp bends in the piping. After you put everything in, check it on a regular basis. This can help stop leaks and make the system last longer.

Can these elbows be used with different types of pipes (carbon steel, stainless steel)?

Yes, seamless elbows made for carbon steel pipes can also be used with many other pipes, like stainless steel. But you have to check things like pressure ratings and the way the materials work together. It is a good idea to look at the right fittings specs before you use them. This helps you stop leaks or other problems from showing up.