-

Industriegebiet Yinzhuang, Kreis Mengcun, Stadt Cangzhou, Provinz Hebei, China

Nahtlose Bögen: Verstehen ASTM A234 WPB 90 Grad

Wichtigste Highlights

- Crafted with premium carbon steel, these elbows provide exceptional strength and durability.

- Engineered for secure butt weld connections in a wide variety of pipeline applications ranging from industrial setups to infrastructure projects.

- Fully compliant with global standards, ensuring optimal product safety and reliable performance under tough conditions.

- Designed to function seamlessly in both above-ground and underground piping installations.

- Offered in a broad spectrum of sizes and configurations, catering to diverse industry requirements.

- The long radius feature of the elbow significantly enhances flow efficiency and curtails pressure loss, benefiting fluid dynamics.

Einführung

The ASTM A234 WPB Seamless Elbow 90 Degree Long Radius Elbow is a key part used in many piping jobs. It lets steel pipe turn smoothly at a new angle while keeping the full strength of the pipe. This elbow is made with good carbon steel and meets tough industry standards. It is a top pick for people who need strong and good-quality pipe fittings. Its seamless build makes it even more steady and trustworthy. You will see this kind of fittings in the work of today’s engineers, who want the best piping, durability, and a steady radius in their projects.

Key Specifications of ASTM A234 WPB Seamless 90 Degree Long Radius Elbows

ASTM A234 WPB seamless 90-degree long radius elbows are made to meet the set rules for many industry areas. These fittings go with carbon steel pipes, flanges, and couplings. This helps make sure things connect well. They are made to take on hard work and can be found in a wide range of sizes, from ½ inch to 80 inches. This lets the elbows fit different needs in a pipeline.

You can get these elbows in many thickness schedules, like SCH 10, 20, 40, STD, XS, and XXS. They can also be changed to fit many kinds of pipeline designs people might use. Their smart design and strong following of rules mean you get fittings made with care, so they work well and last. In the next part, we will talk about the materials used and look closer at the way these elbows are made.

Material Composition and Manufacturing Process

Premium-grade carbon steel is the main material used to make ASTM A234 WPB elbows. This gives the fittings great strength and helps them resist corrosion. These elbows are made without any welds, so they are seamless. Because of this, they do not have the weak spots that welded areas often have. This feature makes them a good choice for high-pressure jobs in many types of industrial pipelines.

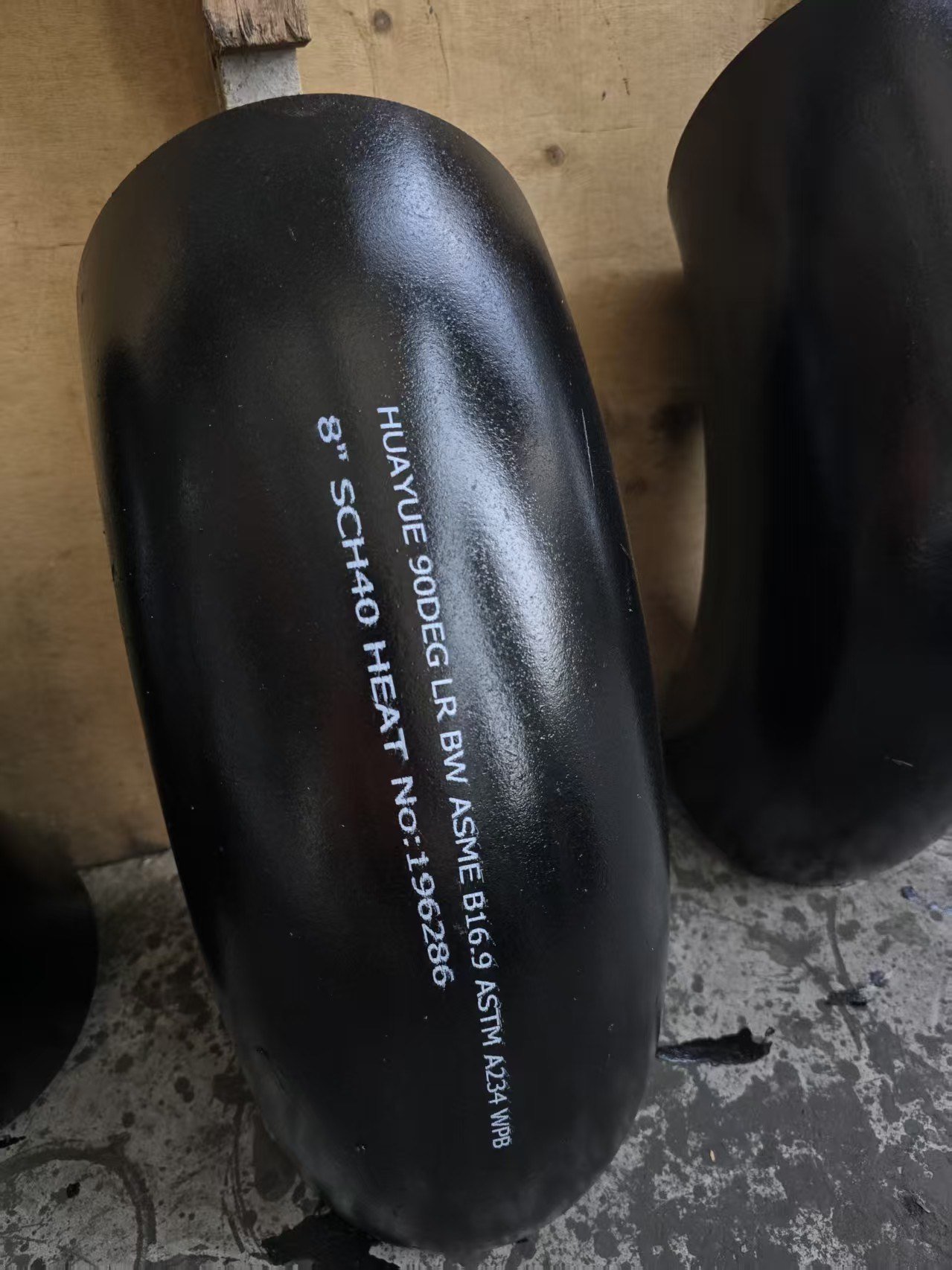

Every fitting gets marked right during production. The marking follows ASTM and ASME rules. Important details like grade, size, and heat number are easy to find on each fitting. This marking helps to keep track of products. Detailed documentation is given each time, most often as a pdf. That supports all parts of quality assurance.

Eigentum | Spezifikation |

|---|---|

Material | Carbon Steel (WPB) |

Herstellung | Seamless |

Marking | As per ASTM/ASME |

Documentation | PDF, Accessible |

This careful process makes sure each pipe fitting comes out with the same, good quality. This is why these fittings are must-haves in many tough industrial jobs.

Compliance with ASME B16.9 and British Standards

ASTM A234 WPB seamless elbows stand out from other pipe fittings because they meet ASME B16.9 and the right British Standards. This careful standardisation makes sure of the same sizes, proper fit, and top product safety in every market.

For packaging and marking, each fitting gets handled with care. Packages are marked in a way that is easy to see and understand. This helps people check the size and grade fast. Good markings and packaging help protect the fittings during shipping, keep up safety, and stop mistakes from happening.

Every piece is clearly marked with details that match what the industry asks for. This makes it easy to track where pipes come from. It also shows that the fittings meet tough international standards for product safety and performance. All of this gives people more trust in these pipe fittings and how well they work in different jobs. Now, let’s look at how these elbows are used in UK industries.

Applications and Advantages in UK Industrial Settings

ASTM A234 WPB seamless elbows are used a lot in the UK, especially in pipelines and plumbing systems. These steel pipe fittings play a key part where strong fittings are needed. Their simple and flexible design makes them a good fit for oil, gas, and water systems. These fittings can work in many different settings.

The pipe fittings are known for good performance. They are easy to install because of the simple design. The build is strong, so they last a long time. This helps save money, which is important for businesses in the UK. The next part talks more about where these fittings are used most in different pipelines.

Common Uses in Oil, Gas, and Water Pipelines

ASTM A234 WPB seamless elbows are important in oil, gas, and water pipelines. These pipe fittings are made strong to take on high pressure. This quality helps them last a long time, even in tough places.

- These fittings can change the flow of the pipeline in a smooth way. They help to make the flow better and keep the system working well.

- The fittings connect different parts of the pipeline, which keeps each segment steady and safe.

- They lower the chance of leaks, so the pipeline works better for a long time.

This kind of fitting is good for big projects and helps pipelines around the world keep up with hard work. They are the ones that let pipeline systems stay strong and keep running.

Benefits of Long Radius Design for Flow and Durability

The long radius shape of ASTM A234 WPB elbows helps fluid move through the piping without much trouble. This design lowers pressure drops. You get smooth and easy flow, even when the pipeline has many bends. This helps the system run better.

- Smooth inside surfaces help reduce the risk of rust and erosion. You keep better flow over time.

- High durability means these elbows can hold up in tough workplaces, where other pipe parts might wear down quickly.

- These elbows can work well in extreme places, helping extend the life of the whole pipeline.

Because of all this, long radius elbows are a good choice for pipelines. They help the system work well and last longer, even when things get tough.

Schlussfolgerung

To sum up, ASTM A234 WPB seamless 90-degree long radius elbows play a big role in many industrial jobs. You often see these fittings used in oil, gas, and water pipelines. Their shape helps the flow go smoother and makes them last longer in high-pressure systems. When you follow rules like ASME B16.9 and British Standards, you keep things safe and running well. If you work with installing or taking care of piping, knowing the details and good points of these elbows will help make your pipeline work better. If there is anything you want to know about picking the right fittings or you want to check out more from us, please get in touch—we are here to help!

Häufig gestellte Fragen

What is the difference between a seamless and welded 90 degree elbow?

Seamless elbows are shaped from one solid piece of carbon steel. They do not have any welded parts, so their structure is stronger than welded elbows. Welded elbows are made by joining different sections together. Seamless pipe fittings work well in high-pressure settings. They are reliable and will last a long time. If you need good strong fittings, these are a good choice.

How do I choose the right size and radius for my piping system?

To pick the right inch size and radius, you need to look at what your pipeline needs for water flow and how much space you have. Pipe fittings have clear markings to help you choose the right ones. You can also ask plumbing experts to make sure your fittings will work together. Doing this will help everything in your plumbing run well and fit as it should.

Are ASTM A234 WPB elbows suitable for high-pressure applications?

ASTM A234 WPB elbows are made using strong steel pipe. These elbows are built to handle high-pressure situations. The way they are made helps them last a long time. They meet safety rules, so you can use them in tough places and trust they will work well.

How are elbows inspected and tested for quality assurance?

Inspection is about checking the surface quality, measuring the size, and looking at the materials. All the testing results are put into easy-to-read PDFs, so people can see them later. The packaging helps keep the product safe when it is moved or handled.

Can these elbows be used for both above-ground and underground installations?

Yes, these pipe fittings work well for both above-ground and underground systems. They have good rust resistance and are strong. This makes them work well in many kinds of weather and places.