-

Industriegebiet Yinzhuang, Kreis Mengcun, Stadt Cangzhou, Provinz Hebei, China

Herstellung von 3PE-Stahlrohren: Qualität und Normen

Wichtigste Highlights

- Steel pipe importance: Utilized across industries, these pipes gain extended lifespan and durability with advanced coatings.

- 3PE coating benefits: A three-layer system offering robust protection against corrosion and mechanical damage.

- Fusion bond epoxy usage: The primer ensures strong adhesion to enhance the pipeline’s mechanical properties.

- Corrosion resistance: The polyethylene layer shields pipes in aggressive environments.

- Protection against mechanical damage: It adds impact resistance, supporting secure operations even in challenging conditions.

- Adhesive layer role: A critical bond ensuring seamless integration of all protective layers.

Einführung

Steel pipes are used in many types of work, like oil and gas lines, water systems, and moving chemicals. But, there is a big problem with corrosion. This can make the pipes less safe and not last as long. To fix this, the 3PE coating is used. This coating has three layers: fusion bond epoxy, adhesive, and polyethylene (PE layers), which provide many advantages of FBE. These layers give strong protection. The fusion and epoxy part help to stop corrosion. The outer polyethylene coating gives extra safety. Using this coating cuts down the money you have to spend on fixes. It also helps pipes last for more years, even when things get tough. So, pipelines can work well and be safe for a long time, including in pipeline’s transporting of oil and gas.

Overview of 3PE Steel Pipes

3PE steel pipes are a big step forward when it comes to stopping rust. They have a coating system that uses three layers to protect the pipes. This keeps them safe in tough places, like underwater or underground. The coating steel pipe design helps stop damage from the outside and keeps out harmful chemicals, so the pipes last longer.

These pipes use smart engineering by putting together the strength of fusion bond epoxy, an adhesive layer, and polyethylene. This coating system gives strong protection, so the pipes need less fixing over time. By using this design, there can be good, steady work with the steel pipe even in hard conditions.

What Is 3PE Coating and How Does It Work?

The 3PE coating is made to stop corrosion on a steel pipe. It has three layers that help protect the pipe from things in nature that can cause damage. The first part is fusion bonded epoxy. In this step, a layer of epoxy powder goes on the heated steel pipe surface. This creates a strong bond that makes it hard for corrosion to start.

After this comes the adhesive layer. This layer acts as a bridge. It helps the epoxy and polyethylene layers stick together so there are no gaps. It also helps keep the steel pipe strong and safe from things outside like moisture.

The last layer is called the polyethylene layer. It sits on the outside of the pipe. This adds extra toughness. It helps the coating stand up to hits, water, and tough weather conditions. All these three layers work well together. They make the coating last a lot longer, so the steel pipe will hold up better and will be ready for heavy use in big jobs.

Key Applications of 3PE Steel Pipes in Singapore

3PE steel pipes are used in many industries in Singapore because of their strong protection features. They help keep different systems running well, from moving oil to handling sewage:

- Öl- und Gaspipelines: These pipes have corrosion resistance that helps keep oil and gas lines safe. That means less rust and damage in pipelines that carry petroleum or natural gas.

- Water supply networks: Their strength stops contamination, so water stays clean and safe as it moves through the pipes in the city network.

- Sewage systems: These pipes can handle strong chemicals and a lot of moisture, so drainage keeps working even in tough conditions.

- Marine uses: These are great for use in underwater pipelines. Their corrosion resistance helps protect them from saltwater or damage from marine organisms.

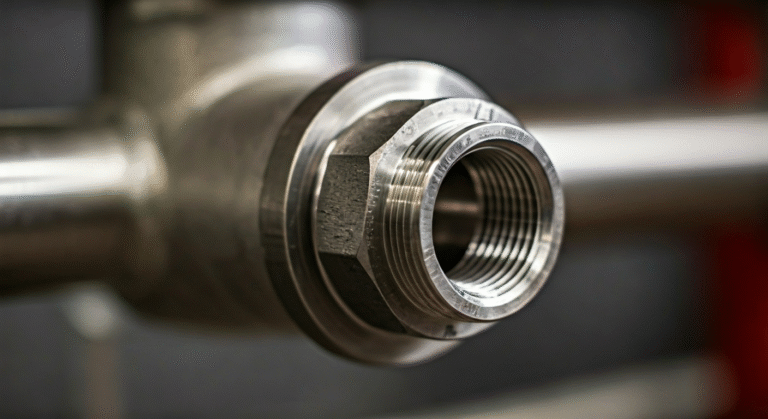

These pipes also help to protect valves and fittings from mechanical damage. That can give good support for building strong, long-lasting infrastructure in Singapore.

The Manufacturing Process of 3PE Steel Pipes

Creating 3PE steel pipes uses steps that help these pipes last a long time. First, the steel pipe goes through a surface treatment. This part of the process has the pipeline cleaned with abrasive tools. It gives the pipe a smooth and polished outside.

The next step is putting on several coating layers to protect the pipe. The process starts with a layer of FBE coating pipe, or fusion bonded epoxy, as the first layers of coating. After this, an adhesive layer and then a polyethylene layer are put over the epoxy. Controlled heat is used so all the coatings stick well to the pipe through fusion. This way helps to make sure the pipe is strong against corrosion. The result is a steel pipe that you can use in many different industries because it resists corrosion and lasts a long time.

Preparation and Surface Treatment of Steel Pipes

The first step to make steel pipes is to clean their surface and get rid of impurities. A solvent emulsion is used to wash away things like grease, oil, and dirt. This makes the surface smooth.

After cleaning, tools with wire brushes are used. These take off rust, oxides, and slag from the pipes. To get even better results, people use a mix of steel grit and shot as abrasives. This combo is blasted onto the surface, which is useful when finishing with epoxy coatings.

The last step is chemical pickling. This process helps make the pipe cleaner and a bit rougher. It also gets the pipe ready to resist mechanical damage. Pickling works well but needs to be handled with care. If not done right, it can cause corrosion and harm the environment.

Application of the Three-Layer Polyethylene Coating

After the steel pipes get treated, the three-layer polyethylene coating goes on. First, there is a fusion bond epoxy primer. It gets heated and sprayed on to make the first protective layer. This gives very good sticking power.

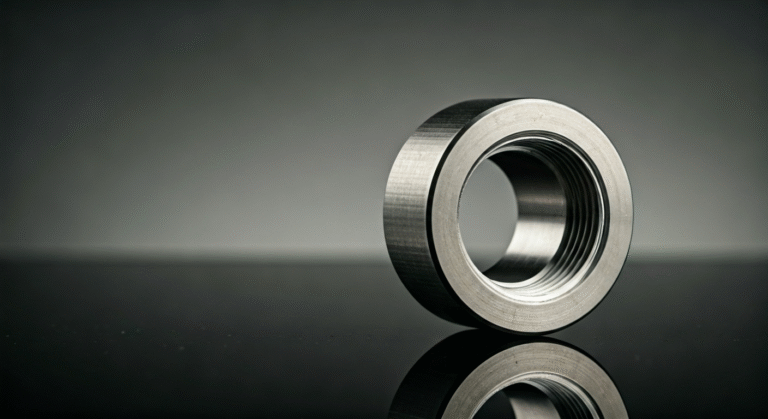

Die second layer has a copolymer adhesive. This middle layer helps the epoxy stick to the polyethylene. This makes everything strong. The adhesive’s thickness is often between 170μm and 250μm.

Die third layer is made with polyethylene. This layer gives the pipe mechanical protection and helps with corrosion resistance. It is flexible and thick, usually between 300mm and 1020mm. This makes it a good shield. The thickness of this coating protects pipes from damage and outside stress.

Quality Standards and Testing for 3PE Steel Pipes

Making sure that steel pipelines are used safely means you need to follow quality rules and to test them in detail. Each 3PE-coated pipe has to meet the standards that prove it can last and work well.

During testing, people check if the pipes can fight off corrosion. They also look at how strong the pipes are and if the coating stays in place when under pressure conditions. This helps to show that the pipes can handle different work settings and keep doing their job, even when the Korrosion or outside conditions are tough.

International and Singaporean Standards Compliance

Compliance with industry standards is key to ensuring pipeline reliability. Below is a summary of essential standards adhered to globally and in Singapore:

|

Standard |

Requirement |

|---|---|

|

ASTM |

Ensures advanced coating protection under extreme pressure conditions. |

|

ISO 21809 |

Specifies external coatings for submerged pipelines including cement-based options. |

|

GB/T 3091 |

Validates suitability for transporting water and sewage. |

|

DIN 30670 |

Mandates polyethylene coatings for enhanced corrosion resistance. |

|

API 5L |

Regulates standards for steel pipelines used across oil and gas industries. |

By meeting these benchmarks, 3PE steel pipes offer dependable operations while securing environmental safety.

Inspection, Testing, and Certification Procedures

A thorough inspection helps make sure that the pipe will last and be strong. The process starts with electrical resistance tests. These tests check to see if the pipe has high electrical resistance, which is very important for stopping corrosion. This step also looks at the fbe coating to make sure the whole pipe is covered in the same way.

Next, mechanical tests come in. These tests show how the pipe stands up under pressure or if it gets damaged. Bending and pulling tests are used to find out if the pipeline can stay strong and be steady.

After this, there is official certification. Experts give certificates once it is shown that the pipe meets all the standards. These include certificates for each fbe coating layer, pipeline insulation, and how safe it is for the environment. With such strong quality control, people can trust the pipeline to work well and last for a long time.

Schlussfolgerung

To sum up, knowing how 3PE steel pipe is made is important. It helps make sure the product is strong and lasts a long time. Each step, from cleaning the surface to adding the three-layer polyethylene coating, is key. This process protects the steel pipe from corrosion and tough weather. Following international and Singapore standards makes sure the pipes are safe and work well. When you look to buy steel pipe, check they have the needed quality certificates. This helps you feel sure about your choice. If you want more details or help about polyethylene coating, feel free to ask for a consultation today!

Häufig gestellte Fragen

What are the main advantages of 3PE-coated steel pipes?

3PE coating gives steel pipes great protection from corrosion. It helps guard against rust and damage from outside stress. This coating also stops mechanical damage, which helps make the pipes last longer. By using this coating, you can cut down on repair costs. It keeps pipes working well for many years, even in tough places.

How does the 3PE coating protect against corrosion?

The 3PE coating has three main parts. First, there is an epoxy layer. This layer stops corrosion, so the pipeline stays strong for a long time, providing tough, durable protection. Next, an adhesive layer sticks all the layers together. After that, the polyethylene layer and polypropylene layer go on top. This layer keeps the pipeline safe from scratching and damage. It also helps protect the pipe from water, dirt, and other things found outside. All these layers work together to shield the pipeline.

Are 3PE steel pipes suitable for marine environments in Singapore?

Yes, 3PE steel pipes are a good choice for Singapore’s marine areas. They have very good corrosion resistance and good stability. The pipes can work well in low temperatures. They hold up to saltwater and help keep underwater pipelines safe.

What quality certifications should I look for when sourcing 3PE steel pipes?

When you buy steel pipelines, it is important to ask for certifications from well-known standards like ASTM, ISO 21809, and API 5L. You should also make sure the inspection of FBE coatings is done properly. This helps make sure the pipelines will work well and be safe for the environment, as a reputable supplier like United Steel Industry Co., Ltd would ensure compliance.

How long can 3PE steel pipes last with proper maintenance?

With the right care, 3PE-coated pipes can last from 30 to more than 50 years. These pipes stay strong because of their great corrosion resistance. They also help to lower heat loss. Because of these features, the pipes keep working well and steady for many years while fighting against corrosion.