-

Yinzhuang Industrial zone,Mengcun county,Cangzhou city,Hebei province,China

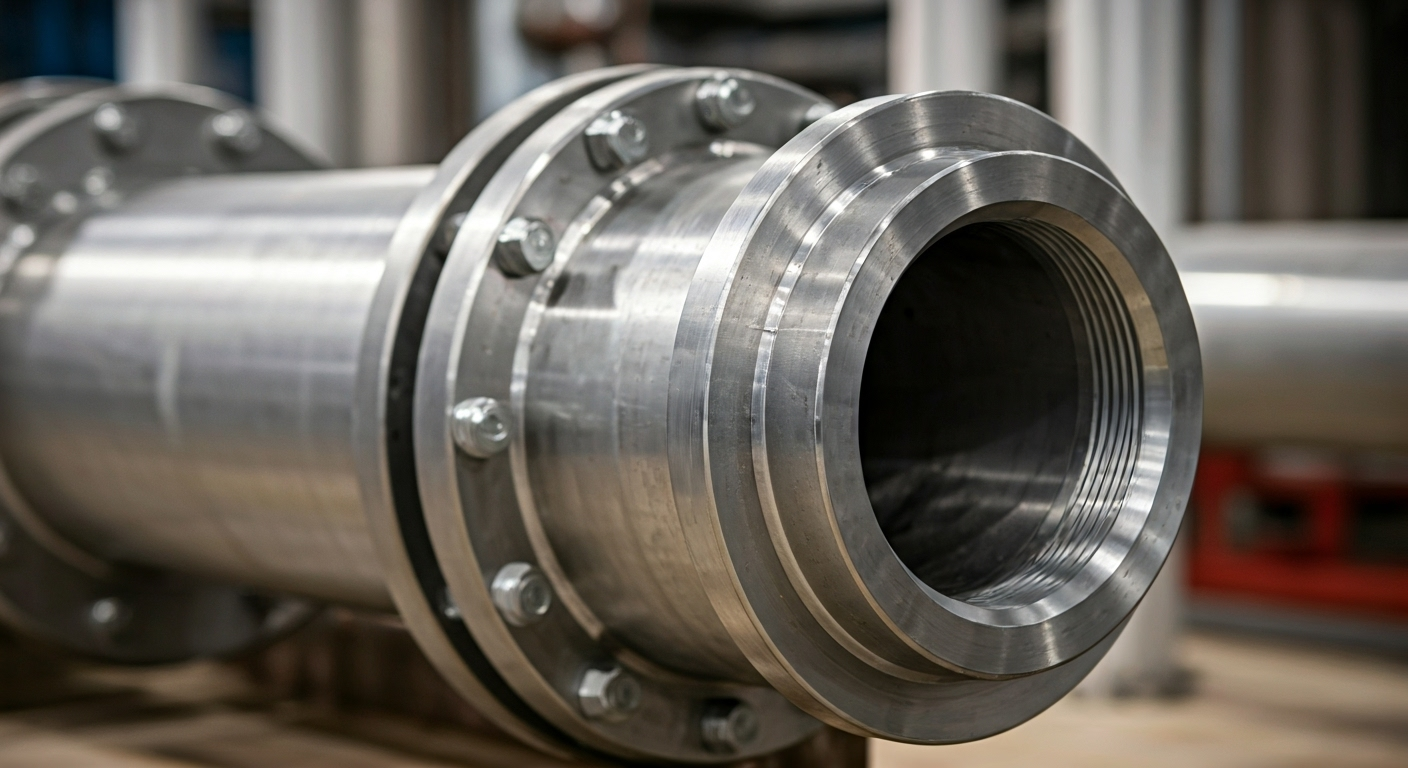

Carbon Steel Reducer: Essential for Butt Weld Fittings

Key Highlights

- Carbon steel pipe reducers play a key role in butt weld fittings. They help connect pipes that have different diameters.

- There are two types of these reducers. Concentric reducers keep the middle lines of the pipes the same. Eccentric reducers have an offset, which is needed in some setups.

- Their specs match top global rules like ASME, ASTM, and ANSI. This makes sure they are strong and last a long time.

- Pipe reducers bring down turbulence as liquids go from one pipe size to another. This helps keep the flow smooth in the pipes.

- You will also find these parts made from alloy steel and stainless steel, not just carbon steel, for plenty of uses in industry.

- These reducers meet exact needs for wall thickness and help keep pipes lined up the right way.

Introduction

Carbon steel reducers are important parts in the area of pipe fittings. They help connect pipes that have different sizes. These reducers make sure that pipes join together smoothly and also help with pressure control in butt weld fittings. People design these parts to fit many global needs. They are known for being strong and reliable.

Reducers can be concentric or eccentric. Their smart design helps keep the pipes lined up and meets the special needs of each use. When you look at what these carbon steel reducers can do, you see why they are a needed part of today’s piping systems.

Butt Weld Concentric Reducer Material , Size & Specification

Choosing the right materials and specifications for a butt weld concentric reducer is crucial for performance and durability. Typically crafted from carbon steel or alloy steel, these fittings must adhere to standard specifications like ASTM and ASME. The wall thickness is determined by the pipe size and application requirements, ensuring structural integrity under varying pressures. Available in different diameters, these reducers facilitate smooth transitions in piping systems, effectively managing flow and minimizing cavitation risks within the system.

Butt Weld Concentric Reducer Dimensions

Dimensions of butt weld concentric reducers are crucial for achieving optimal flow dynamics in piping systems. These fittings are commonly available in various sizes, ensuring compatibility with different pipe sizes and specifications such as ASME, ANSI, and ASTM standards. The precision in wall thickness and diameter variations allows for effective pressure management and reduces the risk of cavitation at the bottom of the pipe. Properly selecting the right dimensions ensures seamless integration within both carbon steel and stainless steel installations, enhancing overall system performance.

Butt Weld Concentric Reducer Project Reference List

Numerous projects across various sectors highlight the utility of butt weld concentric reducers. Notable examples include major petrochemical facilities in India where these fittings facilitated seamless transitions between differing pipe sizes, optimizing flow dynamics and minimizing cavitation risks. Additional references showcase installations in Chile, underscoring the versatility and reliability of carbon steel in diverse applications. Each project emphasizes adherence to stringent ASTM and ASME specifications, thus ensuring the integrity of the piping systems across different diameters and wall thicknesses.

Dynamic Forge & Fittings supplied Butt Weld Concentric Reducer in more then 37 countries in last 10 years

Dynamic Forge & Fittings has demonstrated remarkable global reach by supplying butt weld concentric reducers to over 37 countries in the last decade. Their commitment to quality and adherence to standard specifications such as ASME and ASTM ensures that these carbon steel and alloy steel fittings meet diverse industrial needs. Not only do they provide reducers in different diameters, but their extensive experience in the field positions them as a leader in the supply of high-performance pipe fittings worldwide.

Butt Weld Concentric Reducer Material of construction

Construction materials for butt weld concentric reducers are crucial in determining their performance and application. Typically, these reducers are manufactured from high-quality carbon steel, stainless steel, or alloy steel, each selected based on specific service requirements. The wall thickness and diameter play critical roles in ensuring structural integrity, particularly under pressure. Adhering to standard specifications such as ASME and ASTM guarantees reliability and durability, allowing for efficient fluid flow in pipe systems across various industries and environments.

Key Functions of Carbon Steel Reducers in Butt Weld Fittings

Carbon steel reducers help make butt weld fittings more adaptable and perform better. They let you join pipes that have different diameters, so everything flows smoothly in industrial piping. Their smart design helps stop problems in the flow and keeps pressure at the right level. This is important for systems that need to work with high efficiency.

On top of their ability to work with many sizes, these reducers are great for welding. They make a strong and smooth connection. This matches what is needed for butt weld fittings and makes them a key part of any piping system.

Ensuring Proper Pipe Alignment and Flow

Proper pipe alignment is very important in any piping network. Using a concentric reducer helps keep the centerlines of connected pipes the same. This helps fluid move smoothly, without extra turbulence. It is key to have this in systems where you need precision and the same flow every time.

Eccentric reducers, on the other hand, are best for situations where you need the pipe to be offset, like when the bottom of the pipe must be in a set spot to stop cavitation. These offset reducers help keep the pipeline working well. They also make sure nothing stops the flow, so the system works as well as possible.

Reducers also help when there are changes in pipe size or wall thickness. They can fit into many different work conditions with no problem. The role of these reducers, whether concentric or eccentric, is to keep the bottom of the pipe lined up while still letting flow work without trouble. This makes them very important in both simple and complex piping designs.

Applications in Chilean Industrial Sectors

Many companies in Chile use carbon steel reducers often because they are strong and can be used in many ways. The two main types, concentric reducers and eccentric reducers, help with moving liquids, gas, or solids through different factory systems and setups.

The main uses are:

- Mining: These reducers, made from carbon steel and alloy steel, help control pipelines under high pressure, especially in copper mining.

- Power Generation: Stainless steel reducers make sure steam and cooling systems keep running smoothly and also meet strict needs for each system.

- Petrochemical Plants: Durable welded reducers help fluids move easily through oil pipelines.

The reducers can be made with different special features to fit the needs of Chile’s industries. This makes sure they work well for each type of metallurgical job. Using materials like alloy steel and stainless steel with these reducers also helps Chile update its infrastructure. They also make sure operations stay reliable and meet strong requirements every day.

Conclusion

To sum up, carbon steel reducers are important parts of butt weld fittings. They help your pipeline stay smooth and lined up so everything flows well. You will find these components in many jobs in Chile, and people really see the value they bring. Knowing how they work and the ways concentric and eccentric reducers are different will help you pick what is right for your next project. When you focus on using good quality materials and follow the right rules, your pipeline will last longer and work better. If you want to get the most from your pipeline, it is a good idea to ask a professional for advice about carbon steel reducers that fit your needs.

Frequently Asked Questions

What is the difference between concentric and eccentric carbon steel reducers?

A concentric reducer helps keep the centerline of the pipe straight, so both pipes line up. An eccentric reducer does not do this. Instead, it gives an offset, so you can line up the bottom of the pipe. You can use both these reducers for many uses, and both are made from strong carbon steel. This makes it easy to match your fitting needs and any centerline changes you need, whether you want it concentric or eccentric.

Why is carbon steel preferred for butt weld reducers in Chile?

Chilean industries like to use carbon steel. This is because it is strong and easy to use in many sectors. Carbon steel also works well with butt weld fittings. It follows high rules, which makes it a good pick when you look at other materials like alloy steel. People in Chile find that carbon steel fits what they need in their local industries better than alloy steel.

How do you select the right size carbon steel reducer for a pipeline?

Picking the right size of carbon steel reducer depends on the pipe’s diameter, the standard specification, and the wall thickness. You should check the ANSI or ASME specification to make sure you choose the correct standards. This helps the carbon steel reducer fit well in your pipeline and keeps everything working as it should.

Are there specific standards for carbon steel reducers used in Chile?

Yes, many industries in Chile follow global rules. Some of these are ASME B16.9, ASTM A234, and ANSI guidelines. These are used to make sure that carbon steel reducers work well and last long. You will see these used the most in the mining, petrochemical, and energy fields.

What maintenance is required for carbon steel butt weld fittings?

Routine maintenance means looking out for any corrosion. People also need to check if there is good sealing. The welding points should be strong, so make sure to look at those as well. It is good to keep checking for any debris that might build up, or if the wall thickness is not right. By doing this, you help to make sure the carbon steel butt weld fittings keep working well.