-

Yinzhuang Industrial zone,Mengcun county,Cangzhou city,Hebei province,China

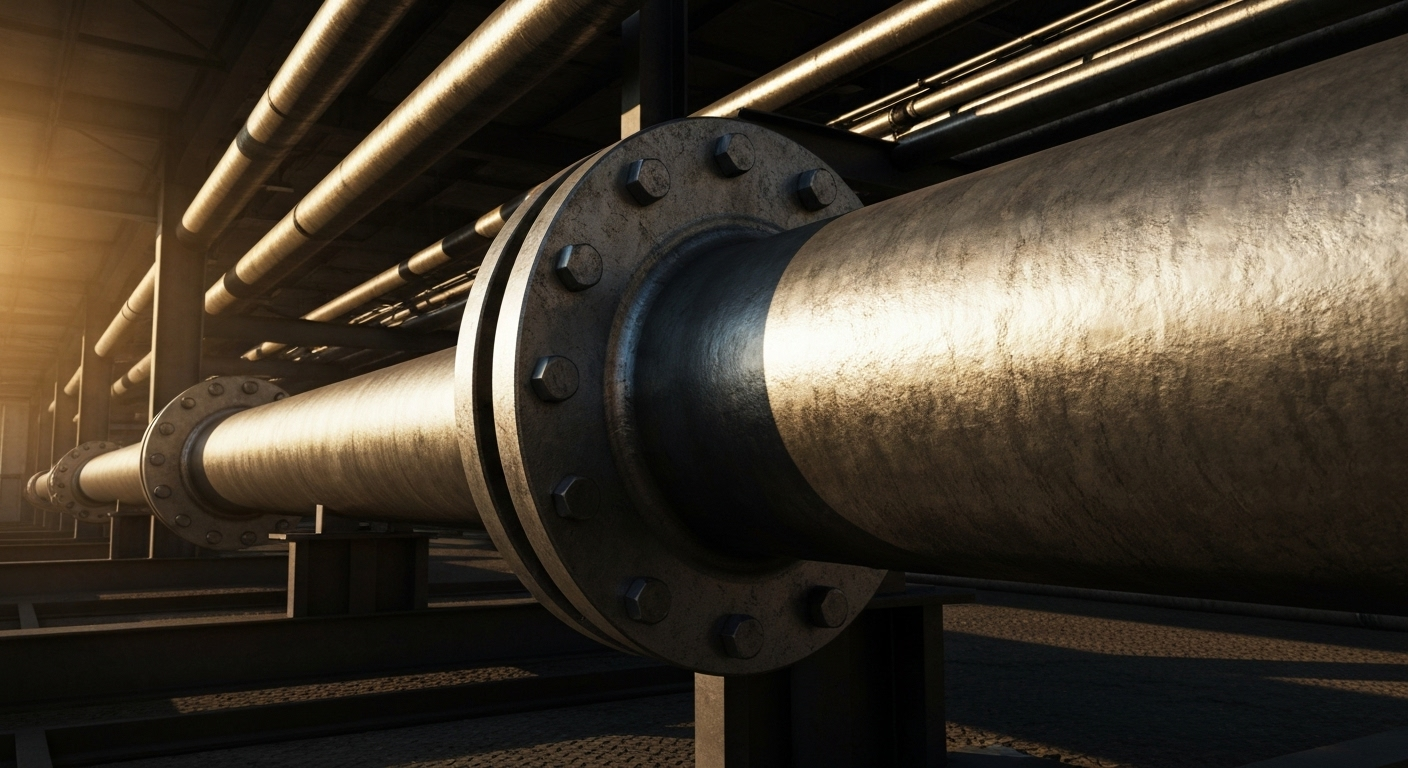

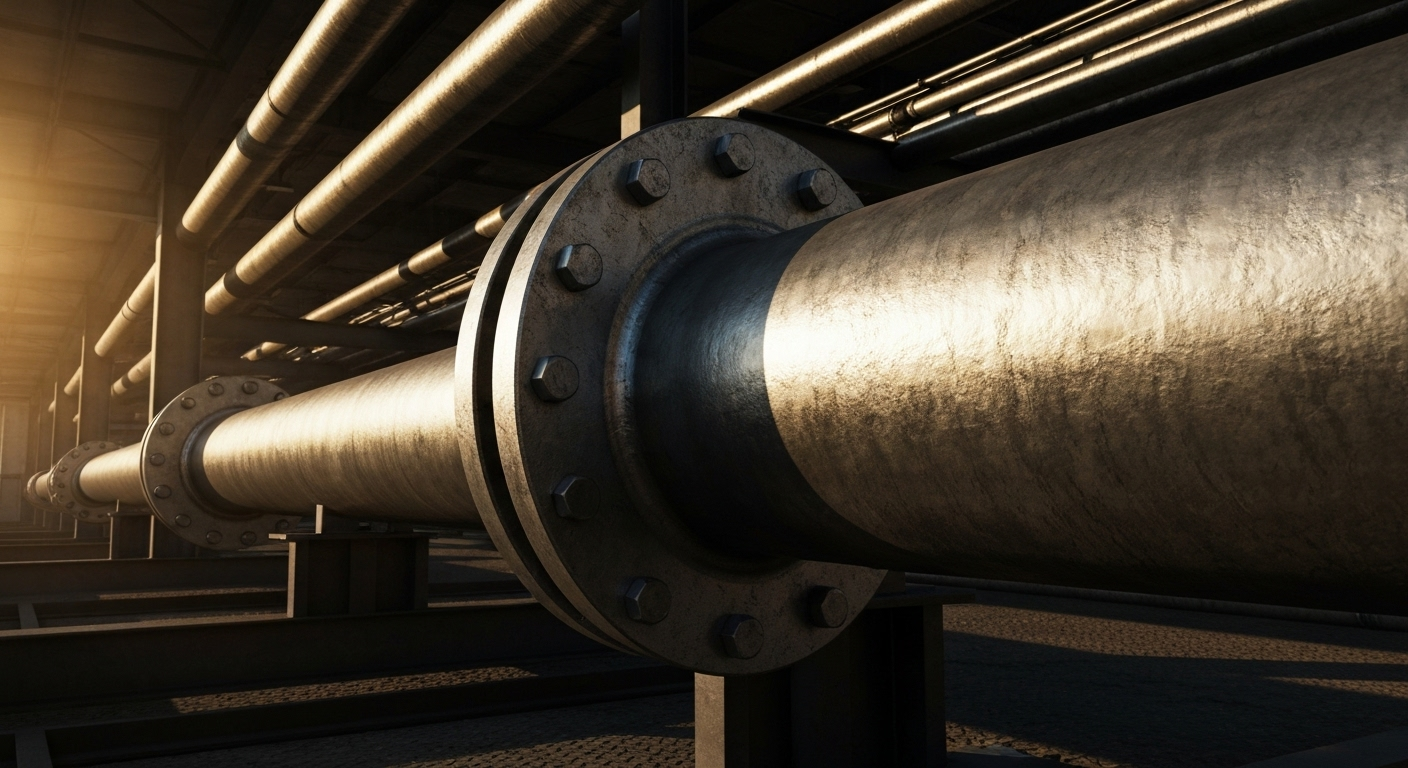

Blind Flange: Essential Guide for Pipe Fittings

Key Highlights

Here’s a quick look at what you’ll learn about the blind flange:

- A blind flange is a solid disk used to seal the end of a piping system, a valve, or an equipment nozzle.

- Unlike other pipe flanges, it has no central bore, effectively stopping the flow of fluids or gases.

- These fittings are bolted, not welded, allowing for easy access for maintenance, inspection, or future expansion.

- Using a gasket with a blind flange is crucial for creating a tight, leak-proof seal.

- They are essential for pressure testing lines and isolating sections of a piping network.

Introduction

Welcome to your essential guide on blind flanges! When working with industrial piping, you’ll encounter a wide variety of pipe fittings, each with a unique purpose. One of the most important components for sealing and terminating a system is the blind flange. This solid, reliable fitting plays a critical role in safety and maintenance. Whether you’re dealing with standards like ASME or simply need to close off a pipe, understanding how a blind flange works is key to a successful project.

Understanding Blind Flanges in Piping Systems

A blind flange serves a very different purpose from most other pipe flanges. While a weld neck flange or slip-on flange is designed to connect pipes and allow flow, the blind flange is built to stop it. It acts as a solid cover, sealing the end of a pipe or a port on a valve.

These essential fittings are a fundamental part of managing any piping network. They provide a secure and reliable way to terminate a line or isolate equipment. Let’s explore exactly what a blind flange is and where you’ll typically find it used.

What Is a Blind Flange?

So, what exactly is a blind flange? Think of it as a solid, circular plate with bolt holes but no center opening. Its primary function is to act as a lid or cover, completely sealing the end of a pipe or an unused nozzle on a piece of equipment. This design distinguishes it from all other types of pipe flanges that are designed to let media pass through.

These fittings are typically available in various face styles, with the most common being Raised Face (RF) and Flat Face (FF). The choice of face depends on the connecting flange and the type of gasket used to create the seal. Because it is bolted on, it provides a detachable solution, unlike a permanent welded cap.

This makes the blind flange an incredibly versatile component in any piping system. It provides a strong, non-permanent seal that can be easily removed when you need access to the line for maintenance, inspection, or future system modifications, making it one of the most useful fittings available.

Typical Uses and Advantages in Pipe Networks

You might be wondering where a blind flange is most effective. Its design makes it perfect for several key applications within a pipe network. It’s not just for permanently closing a line; it offers flexibility for a variety of operational needs.

The main advantage of a blind flange is that it provides easy access. Since it is bolted rather than welded, maintenance crews can quickly remove it to inspect or modify the piping. When paired with the correct gasket, it creates a secure seal that prevents leaks, a critical factor for safety and efficiency. Some of its most common uses include:

- Pressure Testing: Sealing the end of a pipe to safely test the system’s pressure.

- Temporary Sealing: Closing off a line during modifications or repairs on other sections of the piping.

- Creating Access Points: Installing a blind flange on a nozzle provides a convenient entry point for inspection or cleaning.

- Permanent Termination: Ending a pipeline that is no longer needed or is being reserved for future expansion.

This versatility makes the blind flange a go-to solution for isolating piping and valves according to various industry standards, including ANSI specifications.

Key Features and Materials of Blind Flanges

Blind flanges have some distinct features that set them apart from other flanges. One of the most notable is their thickness. To withstand the high stress and pressure that builds up at the center of the flange, they are typically thicker than a weld neck flange of the same size and pressure rating.

The material used is another critical feature. Your choice will depend on the application’s requirements for strength and corrosion resistance. Common options include carbon steel, stainless steel, and various alloys containing elements like molybdenum for added durability. Let’s look closer at these characteristics and the materials you can choose from.

Essential Characteristics and Benefits

The design of a blind flange is simple yet highly effective. Unlike flow-through fittings such as a weld neck flange, its solid construction is its defining characteristic. This design is what allows it to securely close off the end of a piping system.

The primary benefit is the combination of a strong seal with easy accessibility. When you need to perform maintenance, test a line, or make modifications, a bolted blind flange can be removed far more easily than a welded cap. This saves significant time and labor. To ensure a perfect seal, a gasket is always installed between the flange faces, preventing any gas or liquid from escaping.

Key benefits of using a blind flange include:

- Secure Closure: Provides a robust and reliable seal for high-pressure applications.

- Easy Access: Bolted design allows for simple removal for inspection or system expansion.

- Versatility: Can be used for temporary or permanent pipe termination.

- Leak Prevention: When used with the proper gasket, it creates a tight seal.

Common Materials and Material Grades (ASTM, Carbon Steel, etc.)

Choosing the right material for your blind flange is crucial for ensuring the safety and longevity of your piping system. Generally, the flange material should match the material of the connecting pipe. The most common choices are carbon steel, prized for its strength, and stainless steel, known for its excellent corrosion resistance.

Industrial standards from organizations like ASTM and ASME define the specific material grades. For example, an ASTM A105 blind flange is made from carbon steel and is ideal for high-temperature service. In contrast, ASTM A182 covers alloy and stainless steel flanges, including grades with molybdenum for enhanced resistance to corrosion, making them suitable for more demanding chemical environments.

Here are some common material standards for blind flanges:

Material Type | ASTM Standard | Common Grades |

|---|---|---|

Carbon Steel | ASTM A105 | N/A |

Alloy Steel | ASTM A182 | F5, F9, F11, F22, F91 |

Stainless Steel | ASTM A182 | F304/L, F316/L |

Selecting and Installing Blind Flanges

Once you understand what a blind flange is, the next step is selecting the right one for your job and installing it correctly. Proper selection involves considering the size, pressure rating, and the specific standards your piping system must adhere to, such as those from ASME or ANSI. Choosing the wrong flange can compromise the safety and integrity of the entire system.

Correct installation is just as important as proper selection. A poorly installed blind flange can lead to leaks and potential failures. Below, we’ll cover the key considerations for choosing the right fittings for your valves and piping, as well as best practices for installation.

Size, Rating, and Standards Considerations

To select the correct blind flange, you must match its specifications to your system’s requirements. This includes the outer diameter (OD), bolt hole pattern, and thickness. Blind flanges are made to match the dimensions of other flange types, but they are often thicker to handle the pressure at the center.

Standards from organizations like ASME and ANSI provide detailed specifications. For example, ASME B16.5 covers flanges up to 24 inches. You also need to consider the pressure class, such as Class 150 or Class 300. A higher class rating is needed for applications with higher pressures or temperatures. The flange face, commonly RF (Raised Face), is another key consideration to ensure compatibility.

Here are the available size ranges for common ANSI blind flanges:

ANSI Spec | Class Rating | Available Size Range |

|---|---|---|

B16.5 | 150 | 0.5” – 24” |

B16.5 | 300 | 0.5” – 24” |

B16.47 | 150 | 26” – 60” |

B16.47 | 300 | 26” – 60” |

Installation Tips and Best Practices

Proper installation is essential for a secure and leak-free seal. Since a blind flange is a bolted fitting, the process is straightforward but requires attention to detail. The most critical part of the installation is ensuring a tight seal with the gasket.

Before you begin, always make sure the flange faces are clean and free of debris. Use a new, high-quality gasket that is compatible with the fluid or gas in the piping. When tightening the bolts, do so in a star or crisscross pattern to ensure even pressure is applied across the flange face. This prevents warping the flange and ensures the gasket is compressed uniformly.

Here are a few best practices to keep in mind during installation:

- Use the Right Gasket: Always select a gasket material suitable for the system’s temperature, pressure, and media.

- Check Alignment: Ensure the blind flange is properly aligned with the connecting pipe or valve before tightening the bolts.

- Even Bolt Tightening: Tighten bolts gradually in a crisscross pattern to the correct torque specification.

- Mark the Flange: In some systems, it’s helpful to mark the blind flange to indicate if it’s for a normally open or normally closed line.

Conclusion

In summary, understanding blind flanges is crucial for anyone involved in piping systems. These essential components offer unique advantages, such as blocking off pipe ends and facilitating maintenance without disrupting flow. By selecting the right materials and adhering to proper installation practices, you ensure the integrity and efficiency of your piping network. Whether you’re new to this topic or a seasoned professional, always remember that knowledgeable choices lead to more reliable and effective systems. If you have any questions or need personalized guidance, don’t hesitate to reach out for a consultation. Your piping projects deserve the best expertise!

Frequently Asked Questions

How does a blind flange differ from other flange types?

The primary difference is that a blind flange has no central opening. While pipe flanges like the weld neck flange are designed to connect pipes and allow flow, a blind flange is a solid plate used to seal or block off a pipeline or nozzle, effectively stopping the flow.

When should I choose a blind flange for my piping project?

You should choose a blind flange when you need to terminate the end of a piping run, isolate a section of a pipe or a valve for maintenance or repair, create an access point for inspection, or seal a line for pressure testing. It’s the ideal fitting for securely closing a system.

What are the main applications for carbon steel blind flanges?

Carbon steel blind flanges are primarily used in applications where strength and durability are critical, such as in high-pressure and high-temperature piping systems. They are commonly used to seal the ends of pipes, block off equipment nozzles, and provide secure isolation points in industrial processing and energy applications.