-

منطقة ينزوانغ الصناعية، مقاطعة منغكون، مدينة تشانغتشو، مقاطعة خبي، الصين

أنابيب الصلب غير الملحومة FBE

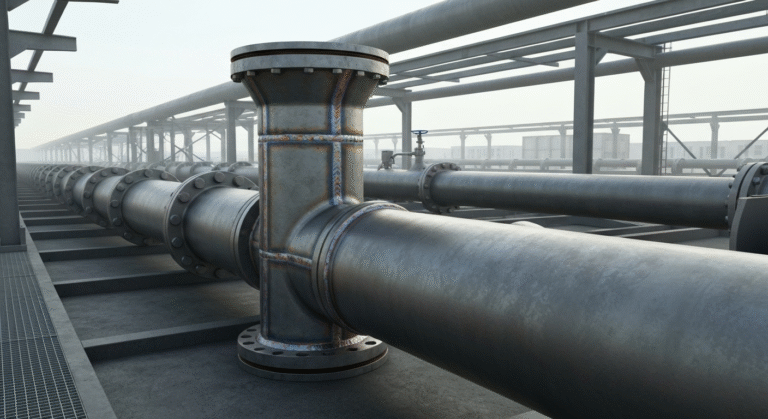

FBE Seamless Steel Pipe: The Unsung Hero of Modern Infrastructure

In an era where infrastructure resilience is paramount, Fusion Bonded Epoxy (FBE) coated seamless steel pipes have emerged as the backbone of critical systems worldwide. These engineering marvels silently power our modern lives—from transporting the oil and gas that fuels our economies to delivering clean water to our homes. But what makes these specialized pipes capable of withstanding the harshest environments while maintaining structural integrity for up to 50 years? The secret lies in their revolutionary coating technology that combines superior corrosion resistance with exceptional mechanical strength, creating a virtually impenetrable barrier against environmental threats. 💪

As industries push the boundaries of what’s possible in challenging terrains and harsh conditions, the demand for more durable, reliable piping solutions continues to grow. FBE coated seamless steel pipes stand at the forefront of this evolution, offering a compelling answer to the age-old problems of pipe degradation and maintenance costs. Whether buried deep underground, submerged in corrosive waters, or exposed to extreme temperatures, these pipes deliver unmatched performance through their innovative multi-layer protection systems. In this comprehensive guide, we’ll explore the fascinating world of FBE seamless steel pipes—from understanding their fundamental properties and diverse types to examining their sophisticated manufacturing processes, technical specifications, remarkable advantages, and the cutting-edge innovations shaping their future. 🔍

Understanding FBE Coated Seamless Steel Pipes

A. Definition and Core Benefits of Fusion Bonded Epoxy Coating

Fusion Bonded Epoxy (FBE) coated pipes are steel pipes treated with a specialized protective layer of fusion bonded epoxy. This coating serves multiple critical functions, primarily to mitigate corrosion that would otherwise compromise the pipe’s integrity. Beyond corrosion protection, FBE coatings enhance the mechanical strength of the pipes and significantly extend their service life.

The core benefits of FBE coatings include:

- Superior Adhesion: The epoxy bonds firmly to the steel substrate, creating a durable protective layer

- متانة محسّنة: Provides excellent resistance to wear and tear in demanding environments

- Environmental Resistance: Helps pipes withstand exposure to various environmental conditions

- Mechanical Strength: Reinforces the pipe structure against physical damage

- مقاومة المواد الكيميائية: Protects against corrosive substances that pipes may encounter

B. Key Applications in Oil, Gas, Water, and Industrial Sectors

FBE coated seamless steel pipes find extensive application across multiple industries due to their exceptional performance characteristics:

Oil and Gas Sector:

- Transportation of crude oil and natural gas

- Offshore and onshore pipeline networks

- Processing facilities where corrosion resistance is critical

Water Pipeline Systems:

- Municipal water distribution networks

- Wastewater management systems

- Irrigation infrastructure

Industrial Applications:

- Chemical processing plants

- Manufacturing facilities

- Power generation systems

The widespread adoption of FBE coated pipes in these sectors stems from their ability to maintain integrity under varying conditions while ensuring safe and efficient fluid transport.

C. Service Life Expectations (30-50 Years) and Performance Factors

FBE coated seamless steel pipes deliver impressive longevity, with a typical service life ranging from 30 to 50 years. However, achieving this extended lifespan depends on several critical performance factors:

Key Factors Affecting Service Life:

- Quality of Surface Preparation: Proper cleaning and abrasive blasting ensure optimal adhesion

- Coating Application Precision: The uniformity and thoroughness of the coating process

- Regular Maintenance: Periodic inspection and maintenance protocols

- الظروف البيئية: Exposure to extreme temperatures, chemicals, or mechanical stress

- Installation Quality: Proper handling and installation techniques

When manufactured and maintained according to industry standards, FBE coated pipes provide decades of reliable service while requiring minimal maintenance interventions, making them a cost-effective solution for demanding applications.

With this understanding of FBE coated seamless steel pipes, their benefits, applications, and longevity factors, let’s explore the various types of FBE coated seamless steel pipes available in the market and their specific advantages for different applications.

Types of FBE Coated Seamless Steel Pipes

Now that we have explored the fundamentals of FBE coated seamless steel pipes and their importance in various industries, let’s examine the different types available to meet specific application requirements. The selection of the appropriate FBE coating system depends largely on the environmental conditions and operational demands the pipes will face.

A. Single-layer FBE systems for moderate conditions

Single-layer FBE coating systems represent the standard application in the industry and are widely used for moderate operational conditions. These systems involve applying a single layer of fusion bonded epoxy directly to the properly prepared steel surface. The thickness typically ranges from 100 to 500 microns, depending on the specific requirements of the application.

Single-layer FBE coatings excel in providing excellent corrosion resistance in environments with lower temperatures and moderate exposure to environmental factors. They offer good cost-performance benefits and are particularly effective for:

- Standard oil and gas transportation systems

- Water supply infrastructure

- Chemical transportation in non-harsh environments

- Applications where high-temperature resistance is required but mechanical stress is minimal

The application process involves cleaning the pipe surface, heating it to temperatures between 350 to 500°F, and then applying the electrically charged epoxy powder, which melts and fuses to create a uniform protective barrier.

B. Dual-layer FBE for harsh environments

When pipes are expected to operate in more challenging conditions, dual-layer FBE systems provide enhanced protection. These systems consist of a base layer of standard FBE coating followed by a second layer of specialized FBE formulation designed to resist specific environmental threats.

Dual-layer FBE systems offer:

- Improved abrasion resistance

- Enhanced chemical resistance

- Better protection against extreme temperature fluctuations

- Greater durability in soil with varying pH levels or salt content

This type of coating is particularly beneficial for pipelines in coastal areas, regions with aggressive soil conditions, or applications involving transportation of corrosive materials where a single layer might be insufficient.

C. Three-layer polyethylene (3LPE) pipes for buried or submerged applications

For the most demanding applications, especially those involving buried or submerged pipelines, three-layer polyethylene (3LPE) systems represent the highest level of protection. While technically not a pure FBE system, 3LPE builds upon FBE technology as its foundation.

The structure of 3LPE includes:

- A base layer of FBE coating that provides the primary corrosion protection

- An intermediate adhesive layer

- An outer layer of polyethylene that offers superior mechanical protection

3LPE systems excel in:

- Underground pipeline applications where soil stress and movement are concerns

- Submerged applications including offshore pipelines

- Environments with high mechanical stress or abrasion risk

- Situations requiring maximum protection against moisture intrusion

Compared to single-layer FBE, 3LPE offers enhanced mechanical resilience, though it may have different temperature limitations. While FBE alone provides excellent corrosion resistance, the additional layers in 3LPE significantly improve mechanical protection against external damage.

With these different types of FBE coating systems available, engineers can select the most appropriate solution based on specific project requirements, balancing factors such as environmental conditions, mechanical stress, temperature ranges, and budget constraints.

With this understanding of the various types of FBE coated seamless steel pipes, we’ll next explore the manufacturing process of these specialized pipes to gain insight into how these protective coatings are applied and what makes them so effective in their respective applications.

Manufacturing Process of FBE Seamless Steel Pipes

Now that we have explored the various types of FBE coated seamless steel pipes, let’s delve into the sophisticated manufacturing process that brings these essential industrial components to life. The production involves several critical stages, from creating the base pipe to the final coating application.

A. Seamless steel pipe production methods

Seamless steel pipes form the foundation of FBE coated pipes used in oil and gas applications. Unlike welded pipes, seamless pipes are manufactured without seams, offering superior structural integrity. The production process typically begins with solid steel billets that undergo piercing and rolling to create the hollow pipe structure. This seamless construction provides the necessary strength and durability required for high-pressure pipeline systems.

B. Surface preparation and cleaning techniques

Surface preparation is perhaps the most vital step in the FBE coating process. Before coating application, the steel pipe must undergo rigorous cleaning to ensure proper adhesion. The industry standard includes abrasive blasting techniques to remove all contaminants, mill scale, and oxidation from the pipe surface. This meticulous cleaning creates the ideal surface profile for the epoxy coating to bond with the steel substrate. As noted in industry practices, inadequate surface preparation is a leading cause of coating failures, making this step crucial for long-term pipeline integrity.

C. Pre-heating requirements (180°C-250°C)

Following surface preparation, the seamless steel pipes must undergo pre-heating to a specific temperature range of 180°C to 250°C. This critical temperature window ensures optimal conditions for the subsequent FBE application. Pre-heating serves multiple purposes:

- Eliminates any remaining moisture from the pipe surface

- Raises the steel temperature to facilitate proper powder melting

- Creates the necessary thermal conditions for chemical bonding

- Ensures consistent coating quality throughout the pipe

Temperature control during this phase is carefully monitored to prevent issues that could compromise coating performance.

D. FBE powder application and curing process

Once the pipe reaches the appropriate temperature, FBE powder is applied using specialized methods such as powder coating spray guns or electrostatic fluidized beds. These application techniques ensure uniform coverage across the entire pipe surface. The electrostatic method is particularly effective as it creates an attraction between the charged powder particles and the grounded pipe, resulting in consistent coating thickness.

After application, the coating enters the critical curing phase. During curing, the epoxy undergoes chemical cross-linking to form a strong, durable bond with the steel substrate. This process requires precise temperature control and timing to achieve the desired coating properties. Quality control inspections occur throughout this stage to identify and address any defects or inconsistencies in the coating.

The completed FBE coating provides a protective barrier that shields the pipeline from corrosion, chemicals, and mechanical damage. This protection significantly extends the service life of the pipeline while reducing maintenance costs and environmental risks.

With this understanding of the manufacturing process, we’ll next examine the technical specifications and standards that govern FBE seamless steel pipes, ensuring they meet the rigorous requirements for various industrial applications.

Technical Specifications and Standards

Now that we’ve explored the manufacturing process of FBE seamless steel pipes, it’s essential to understand the technical specifications and standards that govern their quality and performance. These specifications ensure that FBE coated pipes meet industry requirements for various applications across different environments.

A. Coating thickness requirements for different environments

The thickness of FBE coating is a critical parameter that directly affects the pipe’s performance and longevity in various environments. Typically, FBE coating thickness ranges from 100 to 500 microns, with specific requirements determined by the operating conditions:

- Standard environments: Basic protection typically requires 300-350 microns

- Harsh environments: More aggressive conditions may necessitate thicknesses of 400-500 microns

- Underwater applications: Special considerations for thickness to prevent water penetration

- High-temperature applications: Thickness requirements adjusted for thermal expansion/contraction

The coating thickness must be carefully controlled during application, as inadequate thickness can lead to premature failure while excessive thickness may impact flexibility and adhesion properties. The application temperature range of 180 to 250°C (356 to 482°F) must be precisely maintained to ensure proper fusion bonding to the steel surface.

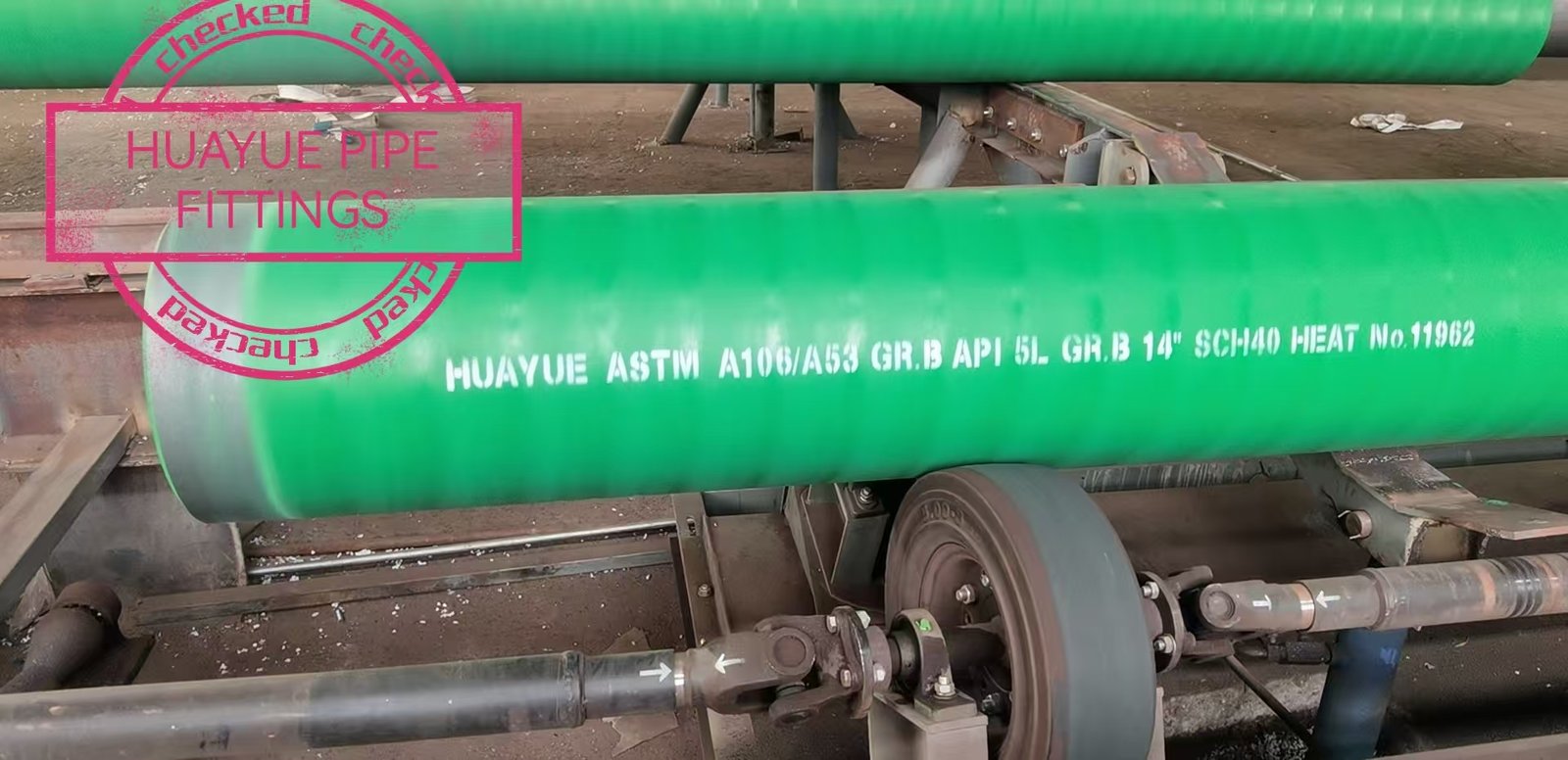

B. Industry standards (DIN, ISO, API) for quality assurance

FBE coated seamless steel pipes must comply with stringent international standards to ensure quality and reliability:

- ISO 21809 Part 2: The primary international standard specifically governing FBE coating of pipelines, detailing requirements for materials, application procedures, and performance testing

- AWWA C213: Standard for fusion-bonded epoxy coating for water pipelines

- API Standards: American Petroleum Institute specifications for oil and gas applications

- DIN Standards: German industrial standards applicable to coated steel pipes in various industries

These standards define testing protocols for adhesion strength, impact resistance, cathodic disbondment, and chemical resistance. Compliance with these standards is verified through rigorous quality control procedures throughout the manufacturing process.

C. Mechanical and physical property requirements

FBE coated seamless steel pipes must meet specific mechanical and physical property requirements:

| الممتلكات | المتطلبات |

|---|---|

| Adhesion strength | Must withstand predetermined pull-off forces |

| مقاومة الصدمات | Ability to absorb impact without coating damage |

| Flexibility | Coating must remain intact when pipe is bent to specified radii |

| Cathodic disbondment resistance | Minimal coating detachment under cathodic protection |

| Chemical resistance | Withstand exposure to specific chemicals without degradation |

| UV resistance | Limited degradation when exposed to ultraviolet light |

| Temperature resistance | Maintain integrity at specified operating temperatures |

The thermoset nature of FBE coatings provides excellent chemical cross-linking, resulting in superior adherence to the steel substrate compared to conventional liquid coatings. This creates a solid coating that cannot be remelted, offering enhanced protection against corrosion.

With these technical specifications and standards in mind, next, we’ll explore the advantages of FBE coated seamless steel pipes, including their performance benefits in various applications and how they compare to alternative coating technologies.

Advantages of FBE Coated Seamless Steel Pipes

Superior corrosion and chemical resistance properties

Ever wondered why FBE coated seamless steel pipes are the top choice for harsh environments? The fusion-bonded epoxy coating creates an almost impenetrable barrier that shields the steel from corrosive elements like acids, alkalis, saltwater, and aggressive soils.

Unlike traditional coatings, FBE doesn’t just sit on the surface – it forms a chemical bond with the steel substrate. This means no water or corrosive agents can creep between the coating and pipe, eliminating the starting point for most corrosion failures.

The coating maintains its protective properties across a wide temperature range (-40°F to 200°F), making it perfect for everything from arctic pipelines to desert installations. And while other coatings degrade when exposed to UV radiation, FBE stands strong with minimal chalking or degradation.

Exceptional adhesion and mechanical strength

The marriage between FBE coating and steel is no casual affair – it’s a powerful bond that refuses to break under pressure. The fusion process creates a molecular connection that withstands extreme physical abuse during installation and service.

FBE coated pipes can take a beating without showing it. They resist:

- Impact damage during transportation

- Abrasion when pulling through rough terrain

- Point loading from rocks and debris

- Soil stress from ground movement

These pipes maintain their structural integrity even when bent, stretched, or compressed. The coating flexes with the pipe rather than cracking or peeling away.

Environmental safety (no solvents or VOCs)

The green credentials of FBE coatings are impressive. Unlike liquid-applied coatings that release harmful volatile organic compounds (VOCs) into the atmosphere, FBE is a 100% solids formulation. This means everything in the powder ends up in the coating – nothing evaporates.

During application, there’s:

- No solvent smell

- No harmful emissions

- No flammable compounds

- No groundwater contamination risk

Workers don’t need to worry about breathing harmful fumes, and nearby communities aren’t exposed to airborne toxins. This makes FBE coating operations safer for both people and planet.

Reduced maintenance costs and extended pipeline integrity

The math is simple: better protection equals fewer failures equals massive savings. FBE coated seamless steel pipes dramatically cut maintenance expenses through their exceptional durability.

A typical uncoated or poorly coated pipeline might need inspection and repair every 3-5 years. With FBE coating, that stretches to 15-20 years or more. This translates to:

- Fewer excavations and repairs

- Reduced downtime and production losses

- Lower labor costs for maintenance crews

- Extended overall pipeline lifespan

When you factor in the cost of emergency repairs, environmental cleanup after failures, and regulatory fines, the initial investment in FBE coating pays for itself many times over. Companies report ROI within just a few years of installation, with continued savings throughout the pipeline’s extended service life.

Related Innovations in Steel Pipe Technology

Now that we have covered the numerous advantages of FBE coated seamless steel pipes, let’s explore some related innovations that have emerged in steel pipe technology. These advancements complement FBE coated pipes and offer additional solutions for specialized applications across various industries.

A. Induction Bends with Standard and Custom Angles (45°, 90°)

Induction bending technology has revolutionized how steel pipes are configured for complex pipeline systems. This innovative process allows for the creation of precise bends in FBE coated seamless steel pipes without compromising the integrity of the coating or the pipe itself. The most common standard angles include 45° and 90°, though custom angles can be manufactured to meet specific project requirements.

The induction bending process works in harmony with FBE coating technology, as both involve careful temperature control. Similar to how FBE coating requires heating to 180-250°C for proper application, induction bending uses controlled heat to shape the pipe while maintaining the protective properties of the coating. This synergy ensures that even bent sections of pipelines maintain excellent corrosion resistance and durability.

B. Specialized Coatings for Corrosive Environments (ASTM A847, A423 GR 1)

While FBE coating offers superior protection in many environments, certain extremely corrosive conditions require additional specialized coatings. Standards such as ASTM A847 and A423 GR 1 have been developed to address these challenging scenarios.

These specialized coatings build upon the foundation of FBE technology, often incorporating additional elements or modified formulations to enhance specific properties:

- Enhanced chemical resistance for industrial applications

- Improved performance in high-humidity environments where standard FBE might be less effective

- Specialized formulations for extreme temperature variations

- Coatings designed for specific soil compositions or underwater applications

These innovations represent advancements in the thermoset polymer coating technology that FBE pioneered, adapting it for increasingly demanding industrial applications.

C. Integration with Other Protective Systems (HDPE Liners, AWWA C210 Epoxy)

Modern pipeline systems often employ multiple protective technologies working in concert. FBE coated seamless steel pipes can be further enhanced through integration with complementary protective systems:

- HDPE Liners: High-density polyethylene liners can be installed inside FBE coated pipes to provide an additional barrier against internal corrosion, particularly useful in water transport applications.

- AWWA C210 Epoxy Systems: This liquid-applied epoxy system can be used in conjunction with FBE coatings to provide reinforced protection at joints, connections, and other vulnerable points in a pipeline system.

These integrated approaches represent the cutting edge of corrosion prevention technology, combining the strengths of multiple protective systems. The resultant multi-layer protection systems offer superior performance compared to single-layer solutions, particularly in applications where mechanical damage is a concern alongside chemical corrosion.

The integration of these technologies follows the same principles that have made FBE coatings successful – creating robust barriers against environmental factors while maintaining the structural integrity and performance of the steel pipe itself.

الخاتمة

FBE coated seamless steel pipes represent a significant advancement in pipeline technology, offering exceptional protection against corrosion while enhancing mechanical strength across various industrial applications. From single-layer FBE solutions for moderate conditions to sophisticated three-layer polyethylene systems for harsh environments, these pipes deliver remarkable performance with service lifespans of 30 to 50 years when properly maintained. The rigorous manufacturing process—involving meticulous surface preparation, precise pre-heating, and uniform coating application—ensures consistent quality that meets international standards established by organizations like ISO, DIN, and the American Petroleum Institute.

The advantages of implementing FBE coated seamless steel pipes extend far beyond corrosion resistance. Their strong adhesion properties, mechanical durability, chemical resistance, and environmental safety make them an ideal choice for critical infrastructure in oil and gas, water systems, and various industrial settings. As innovations in steel pipe technology continue to evolve, FBE coated seamless steel pipes remain at the forefront, offering reliable solutions that significantly reduce maintenance costs while maximizing pipeline integrity and operational efficiency. For projects demanding exceptional performance under challenging conditions, these specialized pipes deliver unmatched value and dependability.