-

منطقة ينزوانغ الصناعية، مقاطعة منغكون، مدينة تشانغتشو، مقاطعة خبي، الصين

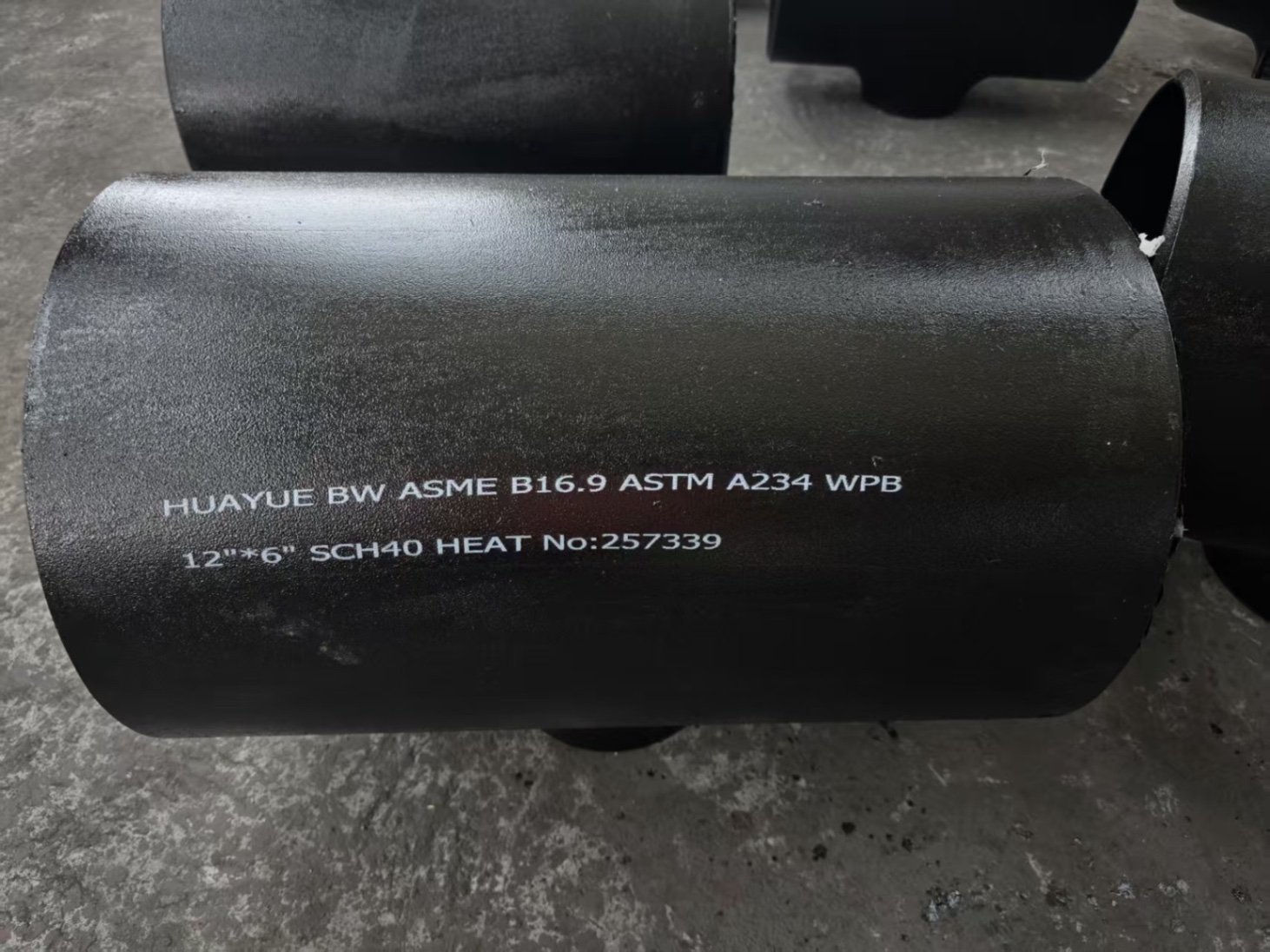

وصلة اللحام التناكبي A234 WPB: دليلك لتجهيزات اللحام التناكبي

أبرز الملامح الرئيسية

- تُعد الأنبوبة A234 WPB Tee ضرورية في توصيل الأنابيب في أنظمة خطوط الأنابيب من خلال اللحام التناكبي، مما يوفر موثوقية وكفاءة هيكلية.

- توفر تجهيزات اللحام التناكبي متانة لا مثيل لها بسبب بنيتها غير الملحومة وتوافقها مع مختلف مواد خطوط الأنابيب.

- هذه التركيبات مصنوعة من سبائك الفولاذ، وهي مصممة لتتحمل درجات الحرارة العالية، مما يجعلها مناسبة للاستخدامات المتنوعة.

- وهي تُستخدم في مختلف الصناعات على مستوى العالم، بما في ذلك تلك الموجودة في سنغافورة، نظرًا لتعدد استخداماتها وأدائها.

- تخدم المحملات المتساوية والمحملات المختزلة استخدامات مختلفة، مما يلبي متطلبات أنظمة خطوط الأنابيب المتنوعة.

- يتم الرد على الاستفسارات الشائعة حول الجوانب الفنية والمواصفات الخاصة بهذه التركيبات لتعزيز الوضوح.

مقدمة

في عالم الأنابيب، من المهم معرفة كيفية عمل التجهيزات. تعتبر التجهيزات A234 WPB الإنشائية جزءًا أساسيًا من هذا الإعداد، خاصةً عند استخدامها في أعمال اللحام التناكبي. تساعدك هذه التركيبات على ربط أقسام الأنابيب المختلفة بطريقة تحافظ على تدفق كل شيء بشكل جيد. يستخدم العديد من الأشخاص هذه المحملات لأنها قوية ويمكنها تحمل الضغط العالي ودرجة الحرارة العالية. تساعد نقطة الإنطلاق A234 WPB على صنع أنظمة أنابيب تدوم طويلاً وتفي بالمعايير الصارمة. وهذا يجعلها اختيارًا جيدًا عندما تحتاج إلى أنابيب أو تجهيزات للقيام بأعمال ثقيلة.

فهم المحمل A234 WPB Tee وتطبيقاته

تحتاج الكثير من الصناعات إلى نقطة الإنطلاق A234 WPB للحفاظ على عمل أنظمة خطوط الأنابيب بشكل جيد. تعتبر نقطة الإنطلاق هذه مهمة لنقل السوائل المختلفة بالطريقة الصحيحة، حتى عند التعامل مع درجات الحرارة العالية أو أعمال الأنابيب العادية. وغالبًا ما تستخدم لتوصيل الأنابيب بأقطار متساوية. وهذا يساعد على التأكد من أن السوائل أو الغازات تذهب إلى حيث تحتاج، ويمكن إرسالها في اتجاهات جديدة إذا لزم الأمر.

يستخدم الناس نقطة الإنطلاق A234 WPB في أشياء مثل أعمال النفط والغاز، والمصانع الكيميائية، ومعالجة المياه. تصميمها يمنحها متانة جيدة ويجعلها تعمل بشكل جيد. ولهذا السبب، أصبح جزءًا ضروريًا في العديد من الأعمال الهندسية الجديدة.

ما هي تي شيرتات A234 WPB؟

التَرْكِيبة A234 WPB ذات الأطراف الجانبية المتوازية هي تَرْكِيبة تستخدم في الأنابيب لربط ثلاثة أنابيب معًا في مكان واحد. تُصنع نقطة الإنطلاق هذه من مادة ASTM A234 WPB. وهي تعطي متانة جيدة وتساعد على الحفاظ على التدفق بشكل صحيح في العديد من الأعمال. تُستخدم هذه التَرْكِيبة في العديد من أنواع الأعمال الصناعية حيث يجب أن تدوم الأنابيب بما في ذلك التطبيقات التي تتضمن الجزء الأوسط من التَرْكِيبة ويجب أن يظل النظام قويًا.

الاستخدامات الشائعة لمحملات اللحام التناكبي في صناعات سنغافورة

تستخدم المحملات الملحومة بعقبية كثيرًا في المصانع ومواقع البناء في سنغافورة. فهي تساعد في توصيل أقسام الأنابيب في أنظمة الأنابيب. هذه التجهيزات تجعل من السهل تغيير اتجاه الأنابيب أو إنشاء فروع جديدة في خطوط الأنابيب. النفط والغاز، والمياه، وأعمال البناء هي بعض من المجالات الرئيسية التي تستخدم فيها المحملات A234 WPB. ويختارها الناس لقوتها ومتانتها. تعمل هذه التركيبات بشكل جيد، حتى عندما يكون الجو حارًا أو عندما يكون هناك ضغط مرتفع. تتناسب المحملات الملحومة بعقبية مع كل من أنابيب السبائك والفولاذ المقاوم للصدأ. وهذا يجعلها خيارًا جيدًا لأنواع كثيرة من الأعمال وتساعد على إنجاز العمل بعدة طرق.

الميزات والفوائد الرئيسية لتجهيزات اللحام التناكبي A234 WPB A234

إن تجهيزات اللحام التناكبي A234 WPB قوية وتدوم طويلاً. وهذا يجعلها خيارًا جيدًا للاستخدام في الحرارة العالية. يمكنك استخدام هذه التجهيزات مع العديد من أنظمة الأنابيب. بعض هذه الأنابيب مصنوعة من الفولاذ المقاوم للصدأ أو سبائك الفولاذ، لذا يمكنك استخدامها بطرق عديدة. تتصل هذه التجهيزات بشكل جيد وتقلل من فرصة حدوث تسربات. وهذا يساعد على بقاء النظام بأكمله آمنًا وقويًا. تلبي تجهيزات A234 WPB القواعد المطلوبة وهي سهلة التركيب. ولهذا السبب، فهي تساعد على جعل العمل بسيطًا وسريعًا، ولكنها أيضًا ثابتة في العديد من المشروعات التي تحتاج إلى أنابيب وتجهيزات جيدة.

متانة وقوة مادة A234 WPB A234 WPB

مادة A234 WPB مصنوعة من سبائك الفولاذ عالية الجودة، وهي معروفة بقوتها ومتانتها الكبيرة. يمكن أن تعمل تجهيزات اللحام التناكبي هذه بشكل جيد تحت حرارة عالية وضغط قوي. وهذا يجعلها موثوقة للغاية لأنظمة خطوط الأنابيب القوية. وتسمح الطبيعة القوية لمادة WPB باستخدام هذه التركيبات في العديد من أنواع الصناعة، لذلك غالبًا ما يتم اختيارها في أعمال الأنابيب الرئيسية. وبفضل بنيتها القوية وخصائصها الميكانيكية الجيدة، تدوم WPB أيضًا لفترة أطول من معظم مواد الأنابيب. وهذا يقلل من عدد المرات التي يتعين فيها استبدال أو إصلاح أنظمة الأنابيب التي تحتاج إلى تجهيزات قوية وثابتة.

التوافق مع أنظمة الأنابيب المختلفة

تبرز نقطة الإنطلاق A234 WPB لأنها تعمل بشكل جيد مع العديد من أنواع أنظمة الأنابيب. يمكنك استخدام هذه الأنبوبة مع أنابيب الفولاذ المقاوم للصدأ وسبائك الفولاذ والنحاس. وهي رائعة لمختلف الأعمال بسبب مرونتها. تتبع نقطة الإنطلاق معايير قوية. يمكنها التعامل مع الحرارة العالية وتحافظ على شكلها حتى عند تعرضها لقوة كبيرة. الاستخدام الرئيسي لقمزة WPB هو ربط أقسام الأنابيب المختلفة معًا. وهذا يجعل من السهل تركيب أنظمة خطوط الأنابيب. وهي ضرورية لكل من المصانع الكبيرة والشركات الأخرى.

الخاتمة

باختصار، تعتبر نقطة الإنطلاق A234 WPB جزءًا مهمًا يستخدم في العديد من أنظمة الأنابيب. فهي قوية ويمكن استخدامها بطرق مختلفة. تعمل نقطة الإنطلاق هذه بشكل جيد في تركيبات الأنابيب، حتى في أماكن مثل سنغافورة. تبرز نقطة الإنطلاق اللحام التناكبي بسبب متانتها الجيدة وكيف يمكن تغييرها لتناسب الوظائف المختلفة. فهي تساعد الأنابيب وخطوط الأنابيب على العمل بشكل أفضل ويمكنها تحمل درجات الحرارة العالية لفترة طويلة. عندما تعرف ميزات هذه المحملات WPB، يمكنك اتخاذ خيارات أفضل لمشروعك واحتياجات الأنابيب الخاصة بك.

ما هي تجهيزات الأنابيب الفولاذية

تجهيزات الأنابيب الفولاذية، بما في ذلك الفلنجات، هي أجزاء مهمة تستخدم في أنظمة السباكة وخطوط الأنابيب. فهي تساعد على توصيل أو إنهاء أو تغيير مكان تدفق الأنابيب. هذه التركيبات مصنوعة من أنواع عديدة من السبائك والفولاذ المقاوم للصدأ، وهي قوية وتدوم طويلاً. وهي تعمل بشكل جيد حتى عندما تكون درجة الحرارة مرتفعة. هناك قواعد مشتركة، مثل ASTM و ANSI، تنص على كيفية صنع هذه التجهيزات وتصميمها. يمكنك العثور على تجهيزات الأنابيب الفولاذية بأشكال مختلفة مثل المرفقين والمحملات والمخفضات والأزرار. كما أنها تأتي في العديد من الأحجام. وهذا يعني أنه يمكنك استخدامها لوظائف مختلفة. مع هذه التجهيزات، سوف ينقل نظام الأنابيب الخاص بك السوائل بشكل جيد ويبقى قوياً.

ما هو ASTM A234 WPB

ASTM A234 WPB هي مواصفات قياسية لتجهيزات الأنابيب المصنوعة من الفولاذ الكربوني أو سبائك الفولاذ. وتستخدم هذه التجهيزات، مثل المرفقين والمحملات والمخفضات، في أنابيب الضغط وبناء أوعية الضغط. تساعد هذه الأنواع من التركيبات في الحفاظ على قوة وسلامة أنظمة خطوط الأنابيب. تُصنع تجهيزات WPB، التي يمكن أن تشمل خيارات الانحناء بالدرجات، في الغالب من الفولاذ الكربوني، لذا فهي جيدة للاستخدام في أعمال الضغط العالي ودرجات الحرارة العالية. ولهذا السبب ستراها في العديد من الأماكن، مثل حقول النفط والغاز ومحطات الطاقة. إن بنيتها القوية ومتانتها تجعلها خيارًا جيدًا للأعمال الشاقة.

الدرجات في ASTM A234

تغطي ASTM A234 العديد من درجات التجهيزات المصنعة وفقًا لمعايير ASME. تُصنع هذه التجهيزات في الغالب من سبائك الصلب والفولاذ الكربوني. وتساعد هذه الأنواع من الفولاذ على استمرار التركيبات. فهي قوية حتى عندما تكون ساخنة أو عندما يكون الضغط مرتفعًا في أنظمة خطوط الأنابيب. ويتم تصنيع درجات مختلفة، مثل WPB وWPC، لتلبية الاحتياجات المختلفة. وهذا يتيح للناس استخدامها مع العديد من أنواع الأنابيب وأنظمة خطوط الأنابيب. تساعدك معرفة هذه الدرجات على اختيار تجهيزات اللحام التناكبي المناسبة لمشروعك. ويضمن لك الحصول على المواصفات المناسبة للأعمال الصناعية. وبهذه الطريقة، فإنك تساعد في الحفاظ على سلامة العمل وجعل كل شيء يعمل بشكل جيد. تُعد متانة سبائك الصلب السبائكي والفولاذ الكربوني سببًا كبيرًا في أنها تعمل بشكل جيد في معظم التطبيقات.

ASTM A234 WPB أنابيب الصلب ASTM A234 WPB تركيبات الأنابيب الفولاذية الخصائص الكيميائية والميكانيكية

تجهيزات الأنابيب الفولاذية ASTM A234 WPB مصنوعة من الفولاذ الكربوني. وتشتهر هذه التجهيزات بقوتها ومتانتها. فهي تتحمل الحرارة العالية، وهو أمر مهم في العديد من أنظمة خطوط الأنابيب. تفي التركيبات بمعايير الصناعة لأشياء مثل مقدار الوزن الذي يمكن أن تتحمله قبل أن تنكسر ومقدار ثنيها دون أن تتلف.

تشمل التركيبة الكيميائية لهذه التجهيزات الحديد والكربون، إلى جانب كميات صغيرة من عناصر أخرى. ويساعد هذا المزيج تجهيزات الأنابيب على مقاومة الصدأ والعمل في أماكن مختلفة. وبسبب هذه الخصائص، تُعد تجهيزات الأنابيب ASTM WPB خيارًا جيدًا للعديد من الاستخدامات ويمكنها التعامل مع المهام الصعبة في أنظمة خطوط الأنابيب المختلفة.

الخواص الميكانيكية لتجهيزات الأنابيب ASTM A234 WPB

تلعب الخواص الميكانيكية دورًا كبيرًا في مدى جودة عمل تجهيزات الأنابيب ASTM A234 WPB في المواقف المختلفة. تتمتع هذه التجهيزات بالقوة والمتانة اللازمة لأنظمة خطوط الأنابيب عالية الضغط. ويمكنها تحمل درجات الحرارة العالية، مما يجعلها جيدة للأماكن الصعبة. وتعني قوة الخضوع العالية أن هذه التجهيزات يمكنها تحمل الكثير من الضغط دون أن تنحني خارج الشكل. كما أن ليونتها الجيدة تجعل من السهل تركيبها ومواءمتها مع الأنابيب الأخرى. كل هذه الميزات تجعل من تجهيزات ASTM A234 WPB أحد أفضل الخيارات للعديد من الصناعات التي تستخدم تجهيزات الأنابيب في أنظمتها.

تتضمن ASTM A234 تجهيزات الأنابيب غير الملحومة وغير الملحومة

تقدم ASTM A234 العديد من الخيارات لأنظمة خطوط الأنابيب. تحتوي على تجهيزات الأنابيب الملحومة وغير الملحومة. تصنع التجهيزات غير الملحومة من قطعة واحدة من سبائك الصلب. وهذا يساعدها على أن تكون أقوى وتدوم لفترة أطول في المناطق ذات درجات الحرارة العالية. من ناحية أخرى، تصنع التجهيزات الملحومة عن طريق ربط الأجزاء باللحام. وهي جيدة للعديد من الاستخدامات والأشكال المختلفة. تساعد كلتا التجهيزات على عمل الأنابيب بشكل جيد وتدوم لفترة طويلة. ولهذا السبب فهي مهمة عندما تحتاج إلى تلبية القواعد والمعايير المختلفة في الصناعة. يضمن استخدام هذه التجهيزات أن تكون أنظمة الأنابيب قوية وتفي بالمواصفات المطلوبة. فهي تُظهر المتانة الجيدة لسبائك الفولاذ في الأنابيب وإعدادات درجات الحرارة العالية.

عمليات تشكيل تصنيع تجهيزات الأنابيب الفولاذية

تستخدم في صناعة تجهيزات الأنابيب الفولاذية بعض طرق التشكيل الخاصة للتأكد من أن التجهيزات قوية ومصنوعة بشكل صحيح. ويستخدم العمال التشكيل على الساخن والشغل على البارد للتأكد من أن كل تركيبات تفي بالحجم والسُمك المطلوبين. وهذا يساعد كل جزء، سواء كانت تركيبات اللحام التناكبي أو المخفض اللامتراكز، على الحفاظ على قوتها عند استخدامها في حالات درجات الحرارة العالية. تتم فحوصات الجودة أثناء العملية بأكملها. وتتأكد هذه الفحوصات من أن كل تَرْكِيبة تتبع قواعد ASTM وستعمل بشكل جيد في أنظمة خطوط الأنابيب. وهذا أمر مهم لمتانة تجهيزات الأنابيب والمخفضات.

أبعاد تجهيزات الأنابيب الفولاذية ASTM A234

أبعاد تجهيزات الأنابيب ASTM A234 تتبع قواعد الصناعة المحددة، بما في ذلك السماكات المختلفة مثل SCH 10 و SCH 40. وهذا يساعدها على ملاءمتها بشكل جيد في أنظمة الأنابيب المختلفة. تأتي هذه التجهيزات بأحجام عديدة. يمكن أن يكون حجم الأنبوب صغيرًا مثل 1/2 بوصة، أو يمكن أن يكون الحجم أكبر بكثير، حتى أكثر من 48 بوصة. توضح التفاصيل سُمك الجدار ومقدار الضغط الذي يمكن أن تتحمله كل تجهيزات. هذه التجهيزات جيدة للأعمال ذات الحرارة العالية. يتم تصنيعها بعناية بحيث تصطف كل واحدة منها بشكل وثيق مع أقسام خط الأنابيب. وهذا يضيف قوة ويساعد إعداد الأنابيب بالكامل على العمل بشكل أفضل، حتى في الأماكن الصعبة.

الكلمات الدالة: تجهيزات الأنابيب، والتجهيزات، والأنابيب، والأستم

درجات تجهيزات الأنابيب الفولاذية السبائكية في ASTM A234

هناك العديد من أنواع الدرجات في ASTM A234 لتجهيزات أنابيب سبائك الصلب. هذه الدرجات مصنوعة لتناسب الاحتياجات المختلفة في العديد من أنظمة خطوط الأنابيب أو الاستخدامات الصناعية. تشتهر درجات مثل WPB ببنيتها القوية ومتانتها الجيدة. وهذا يجعلها جيدة للبيئات الساخنة أو أعمال الأنابيب الصعبة.

من المهم معرفة تفاصيل هذه التركيبات، مثل ما إذا كانت الأفضل لخط الأنابيب الخاص بك. عليك التأكد من أنها تعمل بشكل جيد مع المواد الأخرى، مثل الفولاذ المقاوم للصدأ أو الفولاذ الكربوني. إذا كان لديك المزيد من الأسئلة التقنية حول اختيار الدرجة المناسبة، فهذا يساعد النظام بأكمله على الاستمرار لفترة أطول. كما أنها تحافظ على سلامة كل شيء وتعمل بشكل جيد في الأماكن الصعبة. وبهذه الطريقة، يمكن أن تعطي تجهيزات الأنابيب وأنظمة خطوط الأنابيب أفضل النتائج.

التركيب الكيميائي

في تجهيزات A234 WPB، يكون ما يدخل في المعدن مهمًا جدًا لمدى جودة عمله في العديد من المواقف. في معظم الأحيان، تصنع التجهيزات من سبائك الصلب. تحتوي السبيكة على الكربون والمنجنيز والفوسفور والكبريت والسيليكون. هذا المزيج يجعل التجهيزات قوية ويساعدها على الاستمرار لفترة طويلة. وهذا يجعل التركيبات جيدة لأنظمة خطوط الأنابيب حيث تصبح ساخنة. كما أن استيفاء قواعد ASTM يعني أن السبيكة ستتمتع بالقوة اللازمة للوظيفة. وهذا يساعد على إبقاء الأشياء آمنة وتعمل بشكل جيد. عندما تعرف ما هو موجود في هذه التجهيزات، يمكنك اختيار المناسب لاحتياجاتك في العمل أو في أنظمة خطوط الأنابيب.

متطلبات الشد

تعتبر احتياجات الشد لتجهيزات A234 WPB مهمة جدًا لاستخدامها الآمن في العديد من الوظائف. توضح هذه القواعد نوع القوة ومقدار التمدد الذي يجب أن تتمتع به التجهيزات. هذا الأمر مهم للغاية في أعمال الضغط العالي، مثل داخل أنظمة خطوط الأنابيب. بالنسبة للتركيبات A234 WPB، يجب أن تكون أقل قوة شد حوالي 60,000 رطل لكل بوصة مربعة (413 ميجا باسكال). كما يجب أن تكون قوة الخضوع أعلى من 35,000 رطل رطل لكل بوصة مربعة (241 ميجا باسكال). عند اتباع هذه القواعد، يمكنك التأكد من أن التجهيزات ستتحمل الأحمال الكبيرة. وهذا يجعلها اختيارًا جيدًا للأشخاص الذين يستخدمون سبائك الصلب والفولاذ المقاوم للصدأ. تعمل التركيبات بشكل جيد في الأماكن التي تحتاج إلى تركيبات قوية، مثل خطوط الأنابيب التي تستخدم الفولاذ المقاوم للصدأ والسبائك.

مقدمة في تركيبات الأنابيب

تعتبر تجهيزات الأنابيب أجزاء مهمة في العديد من الأنظمة. فهي تربط بين القطع داخل خطوط الأنابيب وتساعد على إبقاء الأشياء تتحرك. تسمح هذه التركيبات للأنابيب بتغيير الاتجاه أو الحجم أو طريقة تدفق الأشياء. يمكنك أن تجد التجهيزات مصنوعة من مواد مختلفة، مثل سبائك الصلب والفولاذ المقاوم للصدأ. وهذا يعني أنها تعمل بشكل جيد لدرجات الحرارة العالية ويمكن أن تلبي الاحتياجات العادية أيضًا. من المهم أن تعرف المواصفات الصحيحة لـ astm و ansi للتأكد من أن التجهيزات ستدوم وتعمل مع ما هو موجود بالفعل. إن اختيار تجهيزات الأنابيب المناسبة سيساعد خط الأنابيب بأكمله على العمل بشكل أفضل ويدوم لفترة أطول.

ما هو التي شيرت المتساوي؟

نقطة الإنطلاق المتساوية هي نوع من تركيبات الأنابيب التي تساعدك على توصيل ثلاثة أنابيب بأقطار متساوية. تسمح هذه التَرْبة للسوائل أو الغازات بالتحرك في أكثر من اتجاه. يستخدمها الناس كثيراً في الأنابيب لأنواع مختلفة من أعمال التصنيع والبناء.

وظيفة نقطة الإنطلاق متساوية

تعتبر المحملات المتساوية أجزاء مهمة في أنظمة خطوط الأنابيب. فهي تربط ثلاثة أقسام من الأنابيب التي لها أقطار متساوية. تتيح هذه التركيبات ذات المحملات للسائل أو الغاز المرور عبر الأنابيب بطريقة متوازنة. وبسبب ذلك، يتحرك كل شيء بسلاسة في جميع أنحاء نظام الأنابيب. ويساعد تصميم أنبوب الإنطلاق المتساوي في الحفاظ على ثبات الضغط. فهي توقف الكثير من الاضطراب وانخفاض الضغط الذي يمكن أن يحدث في الأنابيب.

غالباً ما تحتاج إلى هذه التجهيزات في كل من المصانع الكبيرة والمنازل. عند استخدامها، يعمل نظام الأنابيب بأكمله بشكل أفضل. وتستخدم في العديد من الأماكن لأنها تساعد في الحفاظ على تدفق السوائل بشكل متساوٍ وتجعل أنظمة الأنابيب أكثر موثوقية.

تطبيقات متساوي القامة المتساوية

تعتبر المحملات المتساوية أجزاء مهمة في العديد من أنظمة خطوط الأنابيب. فهي تساعد على نقل وتبادل السوائل بين أقسام الأنابيب التي لها نفس الحجم. غالبًا ما يستخدم الناس هذه التركيبات في صناعات مثل النفط والغاز والمصانع الكيميائية ومعالجة المياه. إذا كانت لديك أسئلة، يمكنك إرسال بريد إلكتروني إلى خدمة العملاء للحصول على مزيد من المساعدة والمزيد من المعلومات خلال أيام العمل من الاثنين إلى الجمعة. تحافظ هذه التركيبات على حركة السوائل بشكل جيد مع القليل من المتاعب. يتيح التصميم الخاص تفرع الأنابيب بسلاسة. يمكنك أيضًا استخدامها في الأماكن ذات الحرارة العالية، وتظل قوية، خاصةً في تركيبات يوم الجمعة. إن متانتها الجيدة واستخداماتها العديدة تجعلها شائعة في كل من أعمال الأنابيب المنزلية والعملية. يثق الناس في هذه التركيبات للأداء الثابت الذي يصمد مع مرور الوقت.

فوائد استخدام تركيبات الأنبوبة المتساوية

تُستخدم تركيبات التجهيزات المتساوية في أنظمة خطوط الأنابيب لتوصيل الأجزاء التي لها نفس القطر أو حتى أحجام مختلفة. تساعد هذه التركيبات على بقاء التدفق متساويًا بين كل فرع متساوي الحجم، وبالتالي يقل الاضطراب ويقل انخفاض الضغط. وهذا يساعد في الحفاظ على عمل النظام بأكمله بشكل جيد. تُصنع العديد من المحملات المتساوية من السبائك أو الفولاذ المقاوم للصدأ. وهذا يعطي التجهيزات متانة أكبر. ويمكنها أن تتحمل الحرارة العالية والأماكن التي قد يكون فيها صدأ أو تلف. وبسبب هذا التصميم القوي، تدوم أنظمة خطوط الأنابيب التي تستخدم المحملات المتساوية المصنوعة من الفولاذ المقاوم للصدأ أو المحملات المصنوعة من السبائك لفترة أطول وتكلفة أقل لإصلاحها بمرور الوقت. وهذا يجعلها خيارًا جيدًا للعديد من أنواع الأعمال والصناعات المختلفة.

الفروق بين نقطة الإنطلاق المتساوية ونقطة الإنطلاق المخفضة

هناك اختلافات واضحة يجب ملاحظتها بين المحملات المتساوية والمحملات المختزلة عندما يتعلق الأمر بتجهيزات الأنابيب. تصنع المحملات المتساوية لتوصيل أقسام الأنابيب التي لها نفس القطر. وهذا يساعد على التأكد من تدفق السوائل بالتساوي إلى كلا الجانبين. ولهذا السبب، فإنها تعمل على تحسين كفاءة عمل أنظمة خطوط الأنابيب.

وعلى النقيض من ذلك، تربط الأنابيب ذات الأقطار المختلفة. فهي تساعد في نقل السوائل من حجم أنبوب إلى آخر، ولكنها تسمح للسائل بالتدفق بشكل جيد. إن تصميم هذه التركيبات يمنحها العديد من الاستخدامات في تركيبات الأنابيب غير البسيطة. فهي تلعب دورًا كبيرًا في مدى جودة أداء تجهيزات اللحام التناكبي لوظيفتها في الصناعات المختلفة.

متساوٍ

نقطة الإنطلاق المتساوية هي نوع من تركيبات اللحام التناكبي التي تساعدك على عمل وصلات متفرعة في نظام الأنابيب. نقطة الإنطلاق لها شكل متماثل، لذا فإن الأنابيب التي تتصل بها جميعها بأقطار متساوية. يساعد هذا الإعداد في الحفاظ على التدفق ثابتًا ومتساويًا. يستخدم الناس المحملات المتساوية في العديد من الأماكن، مثل الأنابيب الصناعية والمنازل. وتساعد نقطة الإنطلاق هذه الأنابيب على تجميع الأنابيب معًا بسلاسة وتحافظ على الضغط من الانخفاض الشديد. وغالباً ما تكون نقطة الإنطلاق مصنوعة من سبائك الفولاذ أو الفولاذ المقاوم للصدأ. هذه المواد تكون قوية، لذلك تدوم التجهيزات لفترة طويلة. تتبع المحملات المتساوية قواعد محددة للتأكد من أنها تعمل بشكل جيد وتدوم لفترة أطول. وبسبب كل هذا، فإن استخدام نقطة الإنطلاق المتساوية المصنوعة من مواد قوية، مثل سبائك الفولاذ أو الفولاذ المقاوم للصدأ، يساعد نظام الأنابيب على العمل بشكل أفضل ويدوم لفترة أطول.

تصغير المحمل المخفض:

تُعرف نقطة الإنطلاق المختزلة بتصميمها الفريد من نوعه. وهي جزء مهم في أي خط أنابيب. تساعد هذه التركيبات على ربط أقسام الأنابيب التي ليست بنفس الحجم. تتيح لك نقطة الإنطلاق المختزلة الانتقال من أنبوب كبير إلى أنبوب صغير بسهولة. في معظم الأحيان، تُصنع هذه المحملات من مواد قوية مثل سبائك الفولاذ أو الفولاذ المقاوم للصدأ. تساعد هذه المواد في الحفاظ على قوتها حتى عند تعرضها لدرجات حرارة عالية. توجد المحملات المختزلة في العديد من الوظائف لأنها مفيدة للغاية. فهي تجعل تركيبات اللحام التناكبي أفضل لجميع أنواع أعمال الأنابيب اليوم. مع نقطة الإنطلاق المختزلة باللحام التناكبي، يحصل نظامك على المزيد من الطرق لتناسب ما تحتاجه فقط. يتيح لك ذلك استخدام الأنابيب والتجهيزات الخاصة بك للعمل مع المزيد من الأحجام والوظائف.

الأسئلة الشائعة

ما الذي يرمز إليه A234 WPB؟

A234 WPB هو نوع من الفولاذ الكربوني يستخدم لصنع تجهيزات اللحام التناكبي. تم تعيينها من قبل ASTM، والتي تعني الجمعية الأمريكية للاختبار والمواد. تُظهر هذه الدرجة أن التجهيزات جيدة لوظائف الأنابيب عالية الضغط في العديد من الصناعات. صُنعت تجهيزات اللحام التناكبي A234 WPB لتتمتع بالقوة وتدوم لفترة طويلة، مما يضمن بقاء الأنابيب آمنة وقوية. وهذا يتيح للناس استخدام هذه التركيبات عندما يريدون متانة جيدة وأداءً قويًا في أعمال الأنابيب.

كيف يتم تركيب نقطة الإنطلاق A234 WPB؟

لتركيب أنبوبة A234 WPB، تأكد أولاً من أنها محاذاة جيداً مع الأنابيب الأخرى. نظف أطراف الأنابيب حتى تكون جاهزة. ضع مادة حشو اللحام المناسبة. استخدم ماكينة لحام لربط الأجزاء. اتبع دائمًا خطوات السلامة وتحقق من عملك للتأكد من وضع نقطة الإنطلاق بالطريقة الصحيحة.

ما هي مزايا تركيبات اللحام التناكبي على التركيبات الملولبة؟

تجهيزات اللحام التناكبي قوية وتدوم طويلاً. وهي تعمل بشكل أفضل من التجهيزات الملولبة لأنها تتصل بدون أي فجوات. وهذا يعني أنه يمكنها تحمل المزيد من الضغط دون أي مشكلة. وأيضًا، مع تركيبات اللحام التناكبي، تقل فرصة حدوث تسرب. كما أنها تقاوم الصدأ بشكل أفضل أيضًا. تجهيزات اللحام التناكبي هذه جيدة للأعمال الصعبة في الصناعات المختلفة. إذا كنت تريد كلاً من القوة والمتانة، فإن تجهيزات اللحام التناكبي هي خيار جيد.

هل يمكن استخدام المحملات A234 WPB في تطبيقات درجات الحرارة العالية والمنخفضة؟

نعم، تُصنع المحملات A234 WPB للتعامل مع درجات الحرارة الساخنة والباردة على حد سواء. يمكنك استخدامها في العديد من أنواع أنظمة الأنابيب. كما أن بنيتها القوية تساعدها على الاستمرار لفترة طويلة. كما أنها تعمل بشكل جيد وتحافظ على متانتها في العديد من الإعدادات الصعبة، لذا فهي خيار جيد للكثير من الأعمال الصناعية.

هل المحملات A234 WPB مناسبة للاستخدام في أنظمة مياه الشرب؟

تعتبر المحملات A234 WPB خيارًا جيدًا لأنظمة مياه الشرب. فهي تتمتع بمتانة جيدة وتقاوم التآكل، لذا يمكن أن تدوم لفترة طويلة. للحفاظ على سلامة النظام، من المهم تركيبها بالطريقة الصحيحة واتباع جميع القواعد المحلية. تحدث دائماً مع متخصص قبل استخدامها.