-

Yinzhuang Industrial zone,Mengcun county,Cangzhou city,Hebei province,China

A234 WPB Reducer: Quality Butt Weld Fittings Explained

Key Highlights

Here’s a quick look at what you’ll learn about A234 WPB reducers:

- An A234 WPB reducer is a crucial butt weld fitting used to connect a larger steel pipe to a smaller one.

- These fittings are made from durable WPB carbon steel, ideal for moderate and high-temperature services.

- There are two main types: the concentric reducer, which is symmetrical, and the eccentric reducer, which is offset.

- They are essential for managing fluid flow and pressure in various industrial piping systems.

- Strict standards from organizations like ASTM and ASME govern their manufacturing to ensure quality and safety.

Introduction

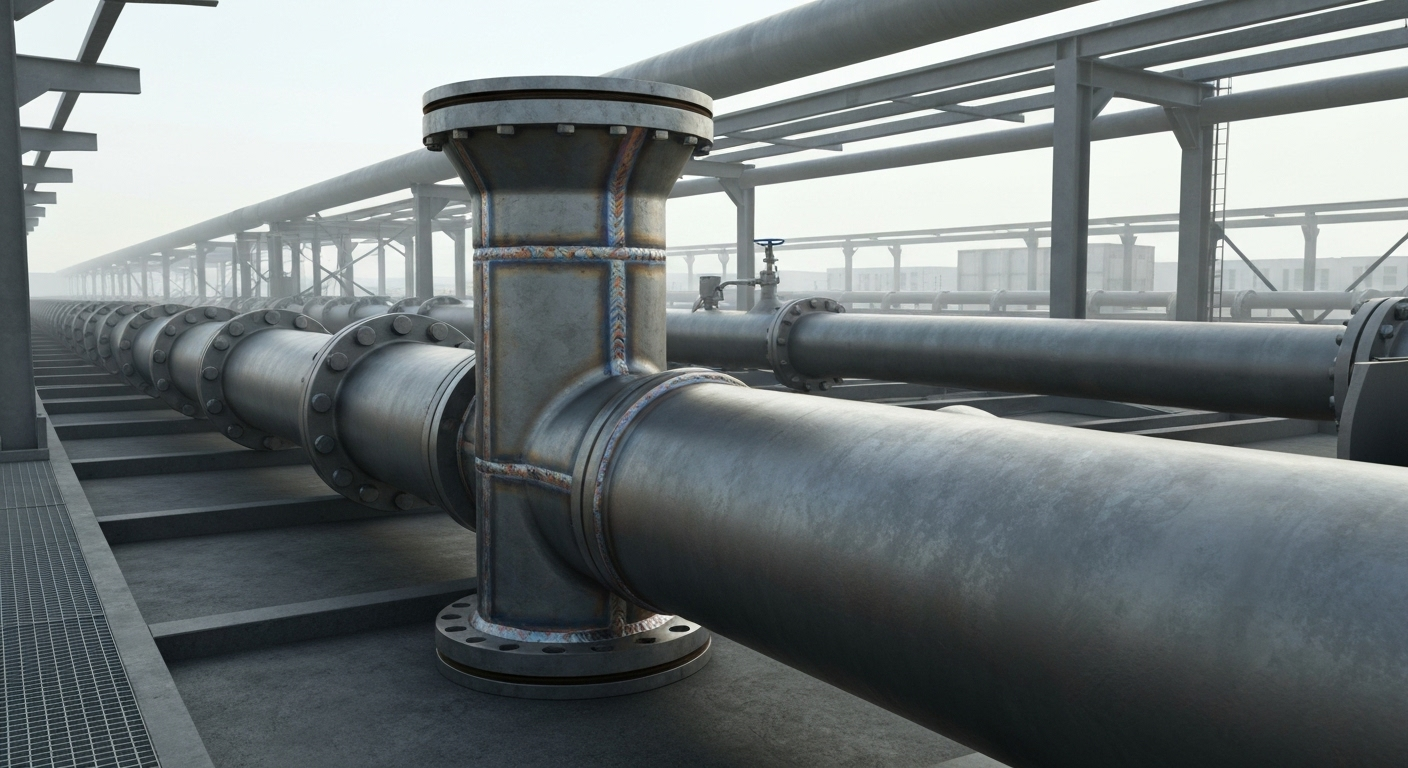

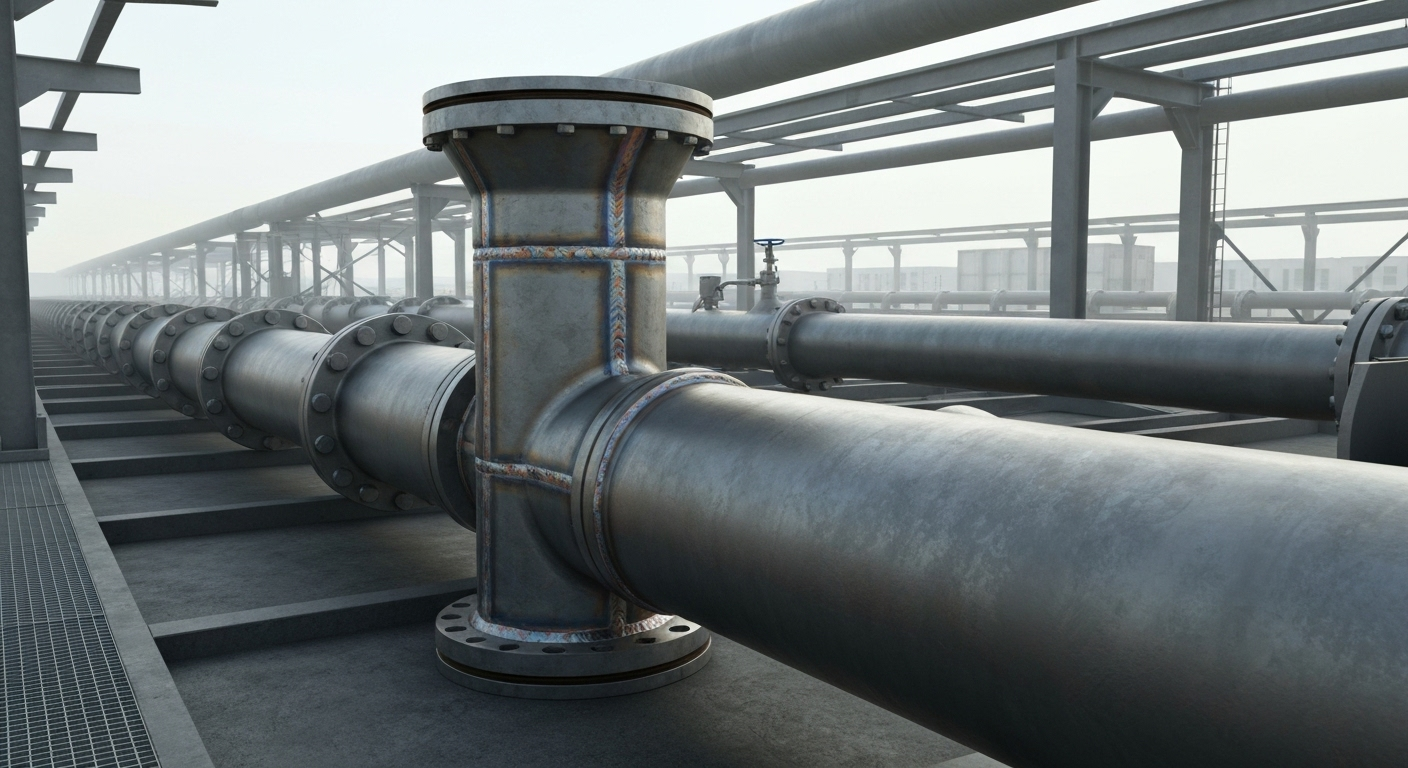

Have you ever wondered how different-sized pipes are connected in a complex piping system? The answer often lies in a component called an A234 WPB reducer. These essential butt weld fittings are designed to join a larger steel pipe to a smaller one, ensuring a smooth transition for the fluid or gas inside. A234 WPB is the standard specification for these steel fittings, indicating they are made of carbon steel suitable for moderate to high-temperature applications, making them a reliable choice for many industries. Because of their durability and ability to handle a wide range of temperatures and pressures, A234 WPB reducers are suitable for both industrial and some domestic applications where carbon steel fittings are required, although they are most commonly used in industrial settings.

Key Features and Materials of A234 WPB Reducers

A234 WPB reducers are known for their strength and durability, which comes from their material composition. The “WPB” in the name designates them as Grade B wrought carbon steel, making them strong enough for pressure piping systems. These butt weld fittings offer impressive tensile strength and can withstand significant stress, ensuring the integrity of your entire piping system.

The material and manufacturing process ensures these pipe fittings are perfect for high-temperature and high-pressure services. The specific chemical composition of WPB carbon steel and alloy steel provides resistance to corrosion and wear. The wall thickness is designed to match the connected steel pipe, creating a seamless and robust connection.

Let’s examine the exact material makeup and the standards that guarantee their performance.

Chemical Composition and Manufacturing Process

A234 WPB reducers are primarily made from wrought carbon steel and alloy steel. The WPB carbon steel grade is the most common, designed for performance in moderate to high temperatures. The chemical composition is carefully controlled to ensure the desired mechanical properties, such as strength and weldability. The manufacturing process can involve either hot or cold forming. In hot forming, the steel is shaped at high temperatures, while cold forming shapes the fitting at a temperature below 1150°F.

The precise blend of elements in the alloy steel defines its performance. According to the standard specification, the composition must adhere to strict limits to achieve the required durability for connecting a steel pipe.

Here is a breakdown of the typical chemical composition for A234 WPB carbon steel: | Element | Composition (%) | |———–|—————–| | Carbon (C) | 0.30 max | | Manganese (Mn)| 0.29-1.06 | | Phosphorus (P)| 0.05 max | | Sulfur (S) | 0.058 max | | Silicon (Si) | 0.10 min | | Chrome (Cr) | 0.40 max | | Molybdenum (Mo)| 0.15 max | | Nickel (Ni) | 0.40 max | | Copper (Cu) | 0.40 max | | Vanadium (V) | 0.08 max |

Standards Governing Quality and Performance

To ensure that every A234 WPB reducer is safe and reliable, manufacturing is governed by strict industry standards. These guidelines dictate everything from material composition and dimensions to testing procedures. They are crucial for anyone working with pressure piping, as adherence to these standards guarantees that the fittings can handle the specified operational demands. When you source an alloy steel pipe fitting, you should always check that it complies with these rules.

These standards are established by globally recognized organizations. Their goal is to create a universal language for manufacturers, engineers, and suppliers, ensuring consistency and quality across the board. For A234 WPB fittings, the most important standards come from bodies like ASTM and ASME.

Key standards include:

- ASTM A234/A234M: This is the primary standard specification covering wrought carbon steel and alloy steel fittings for moderate and high-temperature service. https://www.astm.org/a0234_a0234m-23.html

- ASME B16.9: This standard focuses on factory-made wrought buttwelding fittings, defining their dimensions and tolerances. https://www.asme.org/codes-standards/find-codes-standards/b16-9-factory-made-wrought-buttwelding-fittings

- ASME B16.25: This covers the preparation of buttwelding ends of piping components to be joined into a piping system by welding.

Types, Applications, and Sizing of Butt Weld Reducers

Butt weld reducers come in two main varieties: the concentric reducer and the eccentric reducer. Your choice between them depends on the specific needs of your piping system. A concentric reducer is cone-shaped and keeps the centerline of the steel pipe consistent, which is ideal for many vertical applications. An eccentric reducer has an offset shape, which is useful for keeping one side of the pipe level.

Selecting the right pipe reducer also involves matching it to the correct pipe sizes and wall thickness. These fittings are available in a wide range of dimensions to connect pipes of different diameters. The standard wall thickness is often denoted by a pipe schedule number, ensuring the reducer can handle the same pressure as the rest of the piping.

Understanding the differences between these types and their common uses is key to a successful project.

Concentric vs. Eccentric Reducer Differences

The primary difference between a concentric and an eccentric reducer is their shape and how it affects fluid flow. A concentric reducer has a symmetrical, cone-like shape with two parallel ends centered on the same axis. This design is perfect for vertical pipelines where maintaining a central flow is important.

An eccentric reducer, on the other hand, has an offset design where one side is flat. This is particularly useful in horizontal liquid reducers to prevent the gradual accumulation of air. By installing it with the flat side on top, you stop air pockets from forming, which could otherwise create a large bubble and cause issues like pump cavitation. For horizontal gas reducers, the flat side is often placed on the bottom of the pipe to allow condensation to drain easily.

Here’s a quick comparison:

- Concentric Reducer: Symmetrical cone shape, keeps the pipe on the same centerline. Best for vertical pipes.

- Eccentric Reducer: Offset shape with a flat side. Prevents air trapping in horizontal liquid lines.

- Application: Concentric reducers are widely used, while eccentric reducers are chosen for specific needs, like on the suction side of pumps.

- Flow: The eccentric design is crucial for avoiding turbulence and blockages from air or liquid pooling.

Industrial vs. Domestic Uses and Pressure Ratings

A234 WPB reducers are workhorses in a wide range of industrial applications. You will find them in high-stress environments like oil and gas refineries, chemical processing facilities, and power plants. Their ability to handle high temperature and high-pressure piping makes them indispensable for these sectors. While their primary role is industrial, they are not typically found in standard domestic uses like home plumbing, which operates at much lower pressures.

The strength of these reducers is categorized by pressure ratings, which indicate the maximum pressure they can safely withstand. These ratings are crucial for ensuring the safety and longevity of the entire system. Engineers select a reducer with a pressure rating that meets or exceeds the operational demands of the pipeline.

Common pressure ratings for these fittings, also known as “class,” include: | Rating Class | Common Name | |————–|—————| | 3000# | Class 3000 | | 6000# | Class 6000 | | 9000# | Class 9000 |

Installation and Selection Guidelines for A234 WPB Butt Weld Fittings

Choosing and installing your A234 WPB butt weld fittings correctly is just as important as selecting the right material. Proper selection ensures that the reducer matches the existing pipe sizes and can handle the system’s pressure. A mistake in sizing or connection type could compromise the entire piping system, leading to leaks or failures down the line.

The installation process requires precision to create a strong, durable bond. The ends of the reducer and pipe must be properly prepared and aligned before welding. Following best practices for installation guarantees an optimal fit that maintains the integrity and efficiency of your fluid or gas transport system.

Let’s look at how to choose the right fitting and install it for peak performance.

Choosing the Correct Size and Connection Type

To choose the right size for an A234 WPB concentric reducer, you need to match it to the two pipes you are connecting. This means identifying the nominal pipe sizes (diameter) of both the larger and smaller pipes. You also must match the wall thickness, which is indicated by the pipe schedule number (e.g., STD-40, XH-80). Using a reducer with the same schedule as your pipe ensures a consistent standard wall thickness and pressure capacity.

The connection type is another key factor. A234 WPB reducers are primarily butt weld fittings, meaning they are welded directly to the pipe ends. This creates a strong, leak-proof seal suitable for high-pressure systems. Threaded reducers, on the other hand, screw onto pipes. While easier to install, threaded connections are generally used for smaller diameter pipes and lower pressure applications, as they are not as robust as a butt weld.

Here’s what to confirm when selecting a reducer:

- Large End Diameter: Must match the larger pipe’s nominal size.

- Small End Diameter: Must match the smaller pipe’s nominal size.

- Pipe Schedule Number: Must match the wall thickness of your pipes.

- Connection Type: Ensure you get a butt weld fitting for high-pressure welded systems.

Installation Best Practices for Optimal Fit

Proper installation is critical for ensuring your A234 WPB reducer performs correctly and safely within your piping system. To achieve an optimal fit, the process must be handled with care and precision. The goal is to create a seamless, leak-proof connection that is as strong as the pipe itself. Any misalignment or improper welding can create weak points.

Before welding, ensure the ends of the fitting and the pipes are clean, free of debris, and properly beveled according to the standard specification (ASME B16.25). This preparation allows the welding material to penetrate fully and create a solid bond. The alignment of the reducer with the pipes is equally important to prevent flow disruption and stress points.

Follow these best practices for a perfect installation:

- Align Carefully: Ensure the reducer and pipes are perfectly aligned before tack welding them in place.

- Maintain the Gap: Leave a small, uniform gap between the ends of the pipe and the fitting to allow for proper weld penetration.

- Use Qualified Welders: The welding process should be performed by a certified welder following a qualified welding procedure.

- Post-Weld Inspection: After welding, inspect the connection for any defects to ensure it meets all safety and quality standards.

Conclusion

In conclusion, A234 WPB reducers are essential components that play a crucial role in various pipeline systems. Their quality and durability ensure that they can withstand different pressures and applications, making them suitable for both industrial and domestic uses. By understanding the key features, materials, and installation guidelines, you can make informed decisions that enhance the performance of your projects. Always remember to choose the correct size and connection type for optimal results. If you’re looking to upgrade your fittings or have any questions about A234 WPB reducers, feel free to reach out for personalized advice and support!

Frequently Asked Questions

What are the main benefits of using A234 WPB reducers in pipeline systems?

The main benefits of an A234 WPB reducer include its high strength and durability, making it ideal for high-pressure piping systems. These butt weld fittings create a permanent, leak-proof connection. Manufactured to a strict standard specification, they ensure a reliable transition between steel pipe sizes, reduce noise, and absorb vibration.

Are A234 WPB reducers suitable for both industrial and domestic applications?

A234 WPB reducers are primarily designed for demanding industrial applications due to their high-pressure ratings and durable alloy steel construction. They are rarely used in typical domestic uses, as home plumbing systems operate at much lower pressures and do not require such robust fittings for the piping system.

How do you choose the right size for an A234 WPB concentric reducer?

To choose the right size for a concentric reducer, you must match the fitting to your pipes. Identify the nominal pipe sizes (diameter) of both the larger and smaller pipes. You also need to match the wall thickness by selecting a reducer with the same schedule number as your pipes.