-

Yinzhuang Industrial zone,Mengcun county,Cangzhou city,Hebei province,China

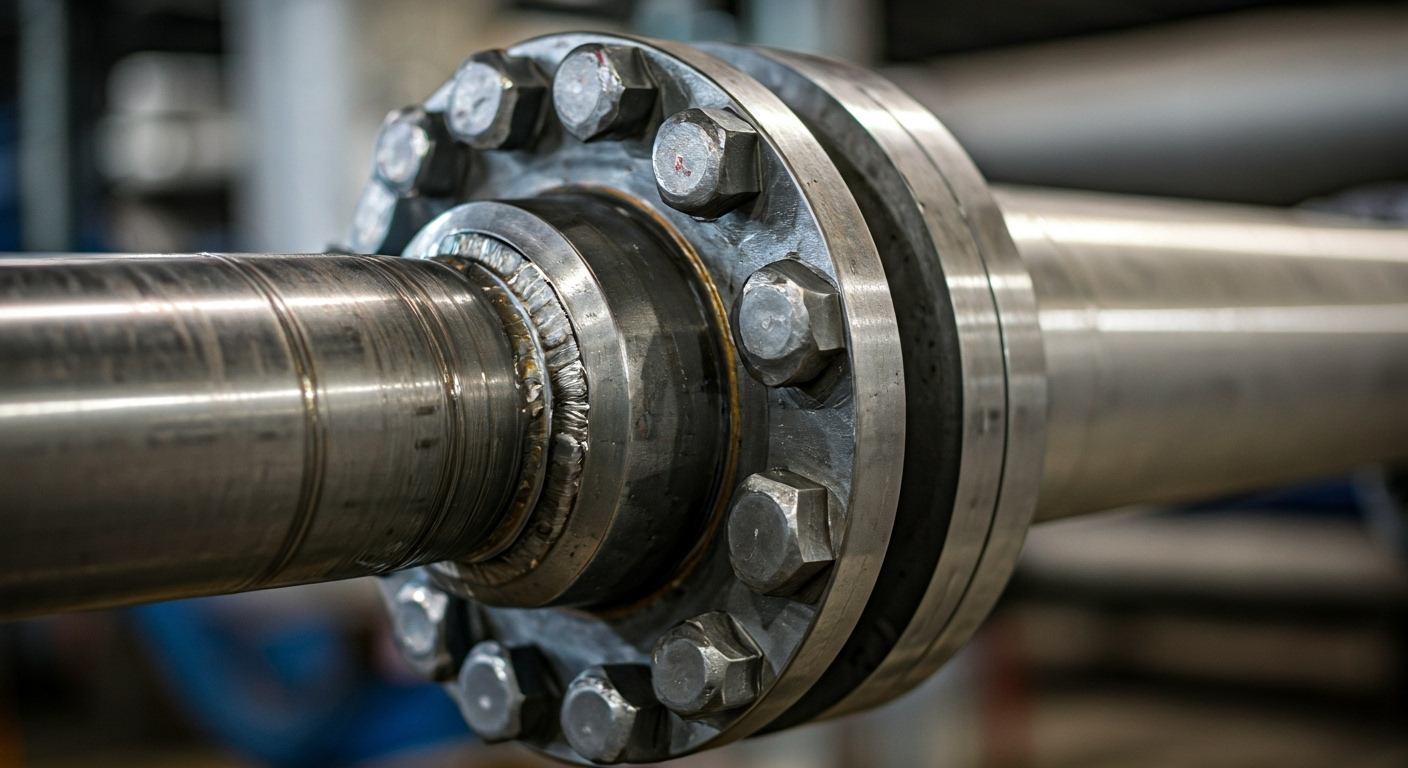

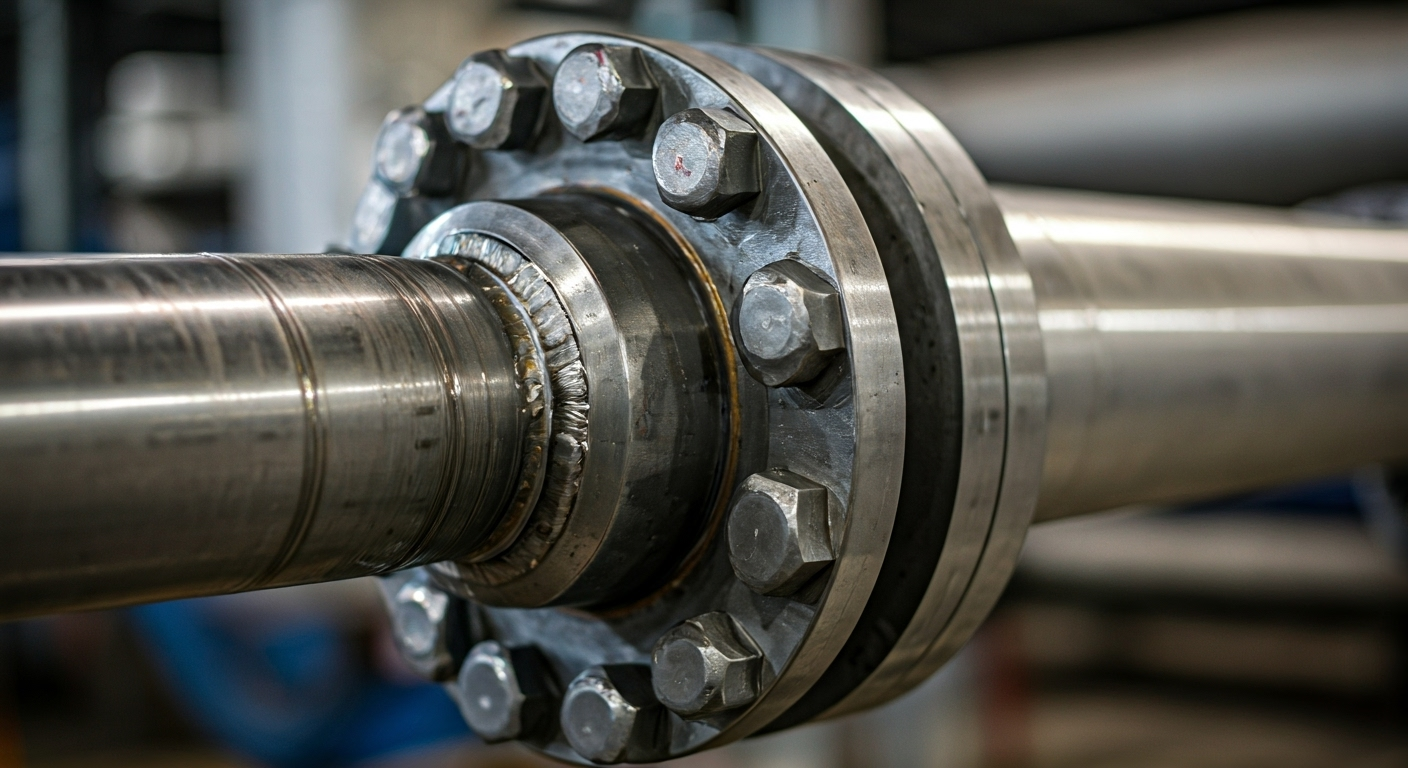

A234 WPB Fittings: Standards and Material Properties

Key Highlights

- ASTM A234 WPB buttweld fittings are critical components in U.S. pipeline systems, providing strength and flexibility for moderate to high-temperature applications.

- These fittings are made from carbon steel, alloy steel, or stainless steel, offering options based on material strength and corrosion resistance.

- Popular types such as elbows, tees, and reducers come in varying degrees of bends and wall thickness to meet diverse pipeline configurations.

- Compliance with ANSI, ASME, and ASTM ensures reliable functionality and seamless integration into pressure piping systems.

- Ideal for high-pressure use and pressure vessel fabrication, these fittings handle critical industrial processes effectively.

- Selecting appropriate fittings requires understanding specifications, ensuring timely delivery, and considering customer support.

Introduction

Buttweld fittings are used to connect and support steel pipe systems in a smooth way. ASTM A234 WPB fittings, in a special way, are made for times when the temperature is moderate or high. These fittings are needed in many big pipeline setups. You can get them in carbon steel, alloy steel, or stainless steel. With these, you get a strong system for moving fluids. These fittings are made to follow very strict specification rules. They are built to be tough and work well even when things get hard. Because they can be used in many ways, these fittings are a must-have for any place that uses pressure piping or builds vessels out of steel pipe.

Understanding ASTM A234 WPB Fittings

ASTM A234 WPB fittings are known for their strong material and careful making process. They are made to be used in places with regular or high heat. These steel fittings follow the strict standards set by ASTM, ASME, and MSS. You can get them as either seamless or welded types.

These fittings play a key role when you want to make safe and solid connections in pressure pipelines or vessel making, including instrumentation tubing. They are usually made from killed steel and fusion-welded tubular products, so you get good and lasting quality. These fittings also come in many shapes and sizes. This means there is always a good option for the tough needs you may find in busy industrial sites.

Definition and Significance of A234 WPB

ASTM A234 WPB is a standard specification made for steel pipe fittings that use carbon and alloy steel, with filler metal often added during fabrication. You will find these fittings in jobs where temperatures can be moderate or very high. These fittings are built to give strong, seamless, and welded choices for building pressure pipelines and making pressure vessels. The name WPB means “Weldable Pressure Grade B,” which shows that they are made for handling pressure and are tough in these settings.

People choose these fittings because the fittings can fit many jobs, and they meet top manufacturing rules like ASTM B16.9 and MSS-SP-75. These steel pipe fittings get their strength from killed steel metals that are formed using methods like forging, pressing, and fusion welding. Since A234 WPB fittings hold up well against high heat and changing pressure, you will usually see them in places like oil refineries, the chemical industry, and power plants. What makes them important is how reliable the fittings are and how the fittings help in keeping pipeline systems safe and working well.

Common Types and Applications in the US Industry

Industries in the U.S. get many benefits from using ASTM A234 WPB fittings, especially for pressure piping and steel pipe jobs. The main types of these fittings are:

- Elbows: These help change the direction of flow in a pipe. You can find them in both short and long radius shapes.

- Tees: These are used to let the flow go off in another direction, helping to split and move fluids in different ways.

- Reducers: These fittings help make one pipe size fit into another. They control the flow rate by managing the speed and force of the flow in the pipes.

The fittings are needed for high-pressure piping jobs in places like oil refineries, chemical plants, and power generation sites. These spots must have things that work well even in tough conditions. ASTM WPB fittings are made strong by forging and welding. That makes them work at high temperatures too. Picking the right type of fittings will help keep everything working well, avoid issues, and keep things running. When you know about these main fittings, you can also start to look at more shapes like buttweld elbows and tees that might fit your needs.

Types for Buttweld Fittings

Buttweld fittings come in many different shapes to fit different pipeline needs. You will find elbows, tees, reducers, and stub ends among these fittings. They give you the flexibility to build a system that works well for you. You can get buttweld fittings with either beveled ends or plain ends. This makes it easy to join pipes and helps things flow smoothly through the system.

There are different materials used for these fittings, like carbon steel, alloy steel, and stainless steel. Using these materials helps take care of many different jobs in different industries. Each fitting can have a different angle bend, pipe thickness, diameter, and studs. This helps make sure you get what you need for the job. Next, we will look at some types of buttweld fittings, including elbows and tees.

Butt Weld Elbow (Buttweld Elbow)

The butt weld elbow is made to help pipes in pipeline systems join smoothly, just like a socket weld fitting. It helps to make the flow rate better and keeps pressure drops low. You can get this fitting in many different angles, like short radius and long radius. These fittings let steel pipes connect right to each other, so you will not need extra flanges or gaskets. They follow important standards like ASTM and ASME, so you know they are safe and good for your work. The fittings are made with strong materials, like carbon steel, alloy steel, and stainless steel. This makes them last a long time, even when there is a lot of heat or pressure in the system.

45 Degree BW Elbow

45-degree butt weld elbows help change the way a pipeline goes while letting things flow through easily. They are used in piping systems to keep the flow rate high, as these elbows do not slow down the fluid much. Most of the time, you will find these elbows with a long radius, and this is good because it helps stop too much wear and keeps there from being big drops in pressure.

When you see their details, they will often look like this: “Elbow, BW, 45 Degree, LR, SCH 40.” This tells you the angle, the radius type, and the thickness. These butt weld elbows are often used in places where liquids need to move a lot, such as in chemical plants or oil refineries. They can deal with different temperatures and conditions where there is a lot of pressure, so they are very reliable. After talking about these 45-degree elbows, we can move on and talk about elbows with a 90-degree angle next.

90 Degree BW Elbow

90-degree BW elbows are a key part of pressure piping. These fittings help the fluid make sharp turns without breaking the flow. You can get these elbows in two types: long-radius and short-radius. Long-radius elbows are good when you want less pressure drop. Short-radius elbows are best to use when there is not much space.

A common way to describe one is, “Elbow, BW, 90 Degree, SR, SCH 80.” This tells you the angle, the radius type, and thickness of the fitting. Because they are strong and designed for a degree bend, you can use them in places with high pressure and high heat. People in power plants and other big jobs often use these for changing the direction of the flow. Next, we’ll talk about the use of 180-degree BW elbows.

18 Degree BW Elbow

The 180-degree butt weld elbow is used as a return bend. It helps to change the direction of fluids in steel pipe systems, making the flow move back the other way. You can get this elbow in a long radius or a short radius design. This means you can pick the one that fits your space, or that works with the pressure you need. This design is best when you need to get smooth flow in a small area within your pipeline systems.

These elbows are usually named by their radius, the pipe size, and how thick they are, like “Elbow, BW, 180 Degree, LR, SCH 60.” They are very important when you need to control the way fluids move inside steel pipe setups. Many industries use them in complicated systems, such as oil refineries and chemical plants, to make sure things work right. Next, we will talk about why buttweld tees matter in pipelines and the types you can get.

Butt Weld Tee (Buttweld Tee)

The butt weld tee is known for being very useful in pipeline systems. This important piece helps guide the flow in the best way. It connects three pipes together. This link lets you move liquids to different areas, and it does this with little drop in pressure.

Butt weld tees come in different types. You can get them as concentric or eccentric reducers. You can also find them in many sizes and wall thicknesses to fit what you need. They are made to be strong, so they work well in places with high heat and high pressure. Because of their strong build, these fittings and tees are needed when you weld parts together to make a pressure vessel. They help keep everything working well in the pipeline systems.

Butt Weld Equal Tee

The butt weld equal tee is used to split or join flow in pipeline systems. It makes a branch that is the same size on all three sides. This equal shape helps to spread the fluid evenly. You might see it called something like “Equal tee, NPS 6, SCH 40,” which tells you the pipe size and wall thickness.

This fitting is strong. It can handle pressure in places like oil and gas plants. These tees help keep the pipeline system strong and steady. They let fluid move well through the pipelines. The tee can fit into many complicated pipeline systems. After learning about this kind of weld tee, it is good to know that there are also reducing tees used when you need to work with pipes of different thicknesses or sizes.

Butt Weld Reducing Tee

Reducing tees are used in pipelines when the branch has a different diameter from the main line. This type of tee lets fluid move easily from one pipe size to another. It also helps to keep the flow rate steady. You can find these fittings in concentric or eccentric shapes, depending on how you want the pipes to line up.

A description may look like this: “Reducing Tee, Concentric, SCH 20.” Here, the description lists the type, shape, and pipe thickness. Many industries use these tees to control flow rate, like in chemical plants. Their strong build helps manage pressure and keeps fluid moving well through the pipeline. Next, we will talk more about why reducers are helpful in pipeline systems.

Butt Weld Reducer

Reducers are used in pipeline systems to help change pipe sizes when needed. These fittings let larger pipes connect to smaller ones, which helps control flow speed and manage pressure. There are two main types of reducers. Concentric reducers keep the pipes in line. Eccentric reducers connect pipes that do not line up perfectly.

The fittings are known for being strong and easy to fit into your system. This means the pipeline stays safe when you change the flow. You can get reducers in many different sizes and materials. This makes them important pieces when you want your system to work well. Now, let’s talk about the materials used in buttweld fittings for specific jobs.

Materials of Carbon Steel Buttweld Fittings

Carbon steel buttweld fittings are used in many ways. These fittings are made from low to medium carbon steel. The materials have good weldability and strong mechanical features. Because of this, they are right for different pipeline systems. The fittings do well in high-pressure jobs, so they are trusted in important places such as pressure vessel fabrication. Meeting ASTM and ASME standards shows that they are good in quality. They also come in different wall thickness options. This lets them meet many engineering needs. The fittings are useful and work well in many kinds of industries.

Materials of Alloy Steel Welded Pipe Fittings

Alloy steel welded pipe fittings are made from materials that mix high carbon with chromium, molybdenum, and nickel. This mix gives the fittings more strength, helps them resist corrosion, and lets them handle high pressure in pipeline systems. These chrome fittings can work in a critical range of both heat and pressure. Because of this, they are a good choice for many uses, like pressure vessel fabrication. When fittings are made under ASTM and ASME standards, you know they meet the needed specifications for steel pipe setups, which makes sure about quality and performance every time.

Stainless Steel Butt Weld (Buttweld) Fittings

Stainless steel butt weld fittings are used in many pipeline systems. These fittings have great corrosion resistance and high strength. They work well in places where there is heat or when making a pressure vessel. You can find them in several grades, like 304 and 316. This gives you the right option for different places so the fittings can do their job well. These butt weld fittings fit different wall thicknesses and sizes. They can blend into any setup and help keep the flow rate just right.

Buttweld Fittings Dimensions

The size and shape of buttweld fittings are important because they help the fittings work well with different pipeline systems. Usually, these fittings follow standard rules like ASTM and ASME. These rules set things like the outer diameter (OD), wall thickness, and how much the pipe bends. The fittings can come in long radius or short radius shapes. This helps control the flow rate in the system. When you measure parts like tees and elbows just right, it helps keep the joints strong. This is very important for pipeline systems that carry stuff at high temperatures or under a lot of stress, so the pressure stays steady and safe.

Benefits of Butt Weld Fittings

Butt weld fittings are known for their strength and long-lasting use, with sizes ranging from 1/4 inch to 24 inch. They are great for high-pressure pipeline systems because of this. The smooth design of these butt weld fittings helps to lower the risk of leaks. It also keeps the flow rate high, which is very important in jobs like pressure vessel fabrication.

These fittings can be made with many material types, including stainless steel, carbon, and alloy. This means they can be used in many situations. When fittings follow formats like ASTM and ASME, you get the same results every time, even in a critical range where defects must work well.

Butt weld fittings help to keep customers happy by making sure you get your order on time and with good customer service and shipping. This makes them a top pick for those who want safe, strong, and easy-to-use parts for their work and projects.

Conclusion

To sum up, using A234 WPB fittings is key for making strong and efficient pipeline systems. It is important to know about their specifications, the properties of their material, and how to use them. This helps you pick the best fittings for different places. Mixing materials like carbon steel, stainless steel, and alloy steel with each fitting helps them last longer. These fittings can handle different levels of pressure and temperature, which makes them reliable. When you choose good-quality fittings for your pipeline systems, you make sure everything works well and the systems stay strong over time.

Frequently Asked Questions

What does WPB stand for in ASTM A234 WPB fittings?

WPB in ASTM A234 WPB fittings means “Wrought Pipe Bend.” This shows that the fittings are made from carbon steel that is shaped by working the metal. These fittings be used for pipes in places where there can be high heat and pressure. That makes them strong and dependable in all sorts of piping systems.

How do A234 WPB fittings differ from other grades?

A234 WPB fittings are made for use in places with high temperature and high pressure. This makes them stand out from other grades. They are made from carbon and alloy steel. This mix gives them strength and helps them last a long time. Other grades of fittings may be made for different uses in piping systems or may have other things they focus on.

What are the main chemical properties required for A234 WPB fittings?

The main things you need in A234 WPB fittings are carbon, manganese, phosphorus, sulfur, silicon, and copper. These make the fittings strong and help them stop rust. The different elements, including copper, also help the fittings last longer. Because of these materials, WPB fittings work well and keep doing a good job in many uses.

Are A234 WPB fittings suitable for high-pressure applications?

A234 WPB fittings are great for high-pressure jobs because they are strong and last a long time. These fittings are made with carbon steel and can handle pressures typically found in a 200 PSI water main. They meet strict industry standards, so you can trust them in tough places. It is a good idea to check the details to make sure the fittings are right for your needs.

What should be considered when selecting A234 WPB fittings for specific projects?

When you pick A234 WPB fittings for your projects, you need to think about a few things. Check the material to make sure it works well with what you need. Look at the pressure ratings and temperature limits too. Think about the place where it will be used and if it fits with the environment there. You should also look at what the fittings will do and if they meet the right industry rules. This helps you get the best results and keep things safe.

What are A234 WPB fittings and what applications are they commonly used for?

A234 WPB fittings are carbon steel pipe fittings used in various industries, such as oil and gas, chemical processing, and power generation. These fittings are designed to withstand high pressure and temperature, making them ideal for connecting pipes in demanding environments while ensuring structural integrity and reliability.