-

Yinzhuang Industrial zone,Mengcun county,Cangzhou city,Hebei province,China

Butt Weld Fittings: Essential Insights for Your Projects

Key Highlights

- Butt weld fittings are the backbone of many piping systems, offering seamless connections through continuous metal structures.

- Available in various materials, including carbon steel, stainless steel, and alloy steel, to match project specifications.

- Long radius designs in elbows enhance efficiency and fluid flow in industrial applications.

- Durability ensures high performance under extreme temperatures and pressures in Australian industries.

- Ideal for cost-effective solutions, these fittings cater to sizes ranging from ½ inch to 72 inches.

- Compatible with ASME and ASTM standards, providing reliability and compliance for demanding projects.

Introduction

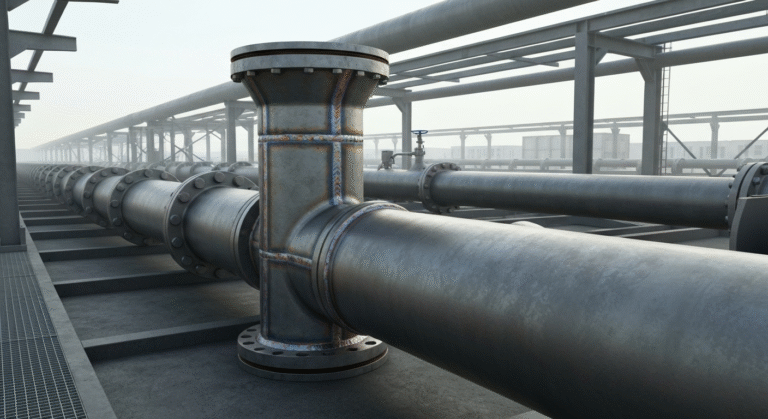

Butt weld fittings play an important role in today’s piping systems. Many people choose these pipe fittings because they are easy to weld and have a strong build. They help make sure connections are tight and long-lasting, whether you use them in homes or big factories. The smooth, all-metal build of these fittings means there is less risk for leaks. They can also handle high pressure better than many other fittings. You will find a range of choices, so you can get the right size and material to suit your piping needs. Because of this, butt weld fittings make it easier to work with complex designs, and they help the whole job get done well. See how these pipe fittings can give your next piping project a boost.

Understanding Butt Weld Fittings and Their Applications

Butt weld fittings are used a lot in piping because they are strong and can do many things. These fittings get welded right onto the ends of the pipes. This way, they make a continuous metal structure, and it helps cut down on problems like leaking or parts breaking. They are very important for keeping the system working well, mostly when something important is being done.

People use these fittings in fields like building, oil and gas, and water work. When the job needs to handle high pressure or hot temperatures, butt weld fittings are often picked first. They help with good, steady flow and are trusted in different projects.

Key Characteristics of Butt Weld Fittings

Butt weld fittings are well-known because they have no seams. The way they be made is by joining the ends of two pipes or fittings, so they form one smooth piece of metal. This extra step makes a piping system stronger. It is very important in places with high pressure.

When people make these fittings, they follow standards like ASTM. This shows the fittings meet strict rules for being tough and working well. Butt weld fittings can fit many pipe sizes and thickness, so they are good for lots of different jobs in piping.

If a piping system needs to send fluid in different directions, these fittings help do it right every time. They also fit pipes with different schedules, like SCH 10 and SCH 40. Butt weld fittings are made to be steady and strong, so there is less chance of problems as time goes by. All these things make them a clear first choice for hard jobs in industry.

Common Uses in Australian Industries

Australian industries like construction, oil and gas, and shipping need piping parts that work well and last long. That is why they often use butt weld fittings. You can find these in pipelines where strong fluid flow is important. These fittings are especially good for high-pressure uses.

Butt weld fittings meet hard standards, like ASME and ASTM, which is what makes them reliable in tough places. People often use them in water treatment plants. Here, their strong build helps everything last longer and means less downtime. Their flexible use also works in multi-level industrial setups, helping different systems work together with no issues.

There are many jobs for butt weld fittings. They connect water pipelines in cities, and they also help oil rigs run without trouble. The piping fittings are a must-have in places where you need steady work and toughness. Their flexibility helps with many piping plans, and they keep the piping systems strong every time.

Types and Materials of Butt Weld Fittings

Butt weld fittings come in different types. These include elbows, tees, reducers, and caps. Each one has its own role in a piping system. The different variants help meet all sorts of project needs. They make sure the fluid moves smoothly and that the system stays strong.

These fittings are often made using carbon steel, alloy steel, and stainless steel. Carbon steel is strong and costs less. Alloy steel offers better resistance to heat and high pressure. Stainless steel keeps the fittings safe from rust and works well with many piping systems.

Popular Types: Elbows, Tees, and Reducers

Among butt weld fittings, elbows, tees, and reducers are in high demand because of how well they work and last. Each one is made for a certain job in a piping system.

- Long radius elbow: Helps the fluid change direction in a piping system without slowing it down.

- Equal tee: Makes it easy to split a pipeline so you can send fluids to different places at the same rate.

- Eccentric reducer: Lets you change the pipe size. This helps control the flow in the piping by letting it move smoothly from one size to another.

These fittings come in lots of different variants to match what your project needs. You get the best performance for your piping system this way. Their strong build and the way they meet top standards like ASTM and ASME is why people choose them.

Material Options: Carbon Steel, Alloy Steel, and Stainless Steel

The kind of material you pick is very important for how well butt weld fittings work. Carbon steel, alloy steel, and stainless steel all have their own benefits for many types of jobs.

Carbon steel is strong and does not cost a lot. This is why you see it a lot in big jobs that need tough parts. Alloy steel is very good for withstanding heat and pressure. If you want something to last in tough places, this could be a good choice. Stainless steel is great if your system handles water or anything wet. It stops rust, so it lasts longer and keeps looking nice.

Material Type | Key Characteristics |

|---|---|

Carbon Steel | Strength, affordability, and pressure resistance |

Alloy Steel | Temperature durability and long service life |

Stainless Steel | Corrosion resistance and aesthetic finish |

When you choose the right material, you help your project work better and last longer.

Types for Buttweld Fittings

There are different types of buttweld fittings used in a piping system, and each one has its own job. Long radius elbow and short radius elbow help change the direction of the piping. They do this while keeping rushes in the flow as low as possible. The equal tee is another type of buttweld fitting. It is often used for making new branch lines in a way that does not change the size of the pipe. The eccentric reducer is important when you want to taper down part of the piping in an easy way. Knowing about these variants, like the long radius elbow, buttweld tee, and eccentric reducer, helps you choose the right buttweld fittings and keep your piping system in good shape. This makes sure your project has good flow, safety, and strong pipes.

Butt Weld Elbow (Buttweld Elbow)

Butt weld elbows play an important role in any piping system. They help the pipes change direction without trouble. You can get them in angles like 45-degree, 90-degree, and 18-degree. These fittings help the flow move easy across the piping connections.

They are made from strong materials like carbon steel and stainless steel. There are long radius and short radius variants, so they work for many designs and uses. Because of their solid build, they handle high pressure well. They give a strong and leak-free join, so many people choose them for big jobs in piping work.

45 Degree BW Elbow

The 45-degree butt weld elbow is a useful and efficient fitting for making smooth turns in piping systems. This part is important because it lets the fluid flow at the right angle without making too much turbulence. This helps the system work better. The elbow is usually made out of carbon steel or stainless steel, which are strong materials. This helps the piping keep a continuous metal structure. When you use a long radius design, it helps the liquid flow even more smoothly. That is why this fitting is good for both industry jobs and homes.

90 Degree BW Elbow

A 90-degree buttweld elbow is used to change the direction of piping systems. It comes in long radius and short radius variants. These variants help the flow and reduce resistance in the pipe. Most of the time, people make this fitting from carbon steel, stainless steel, or sometimes alloy steel. This gives the buttweld fitting a strong and continuous metal structure, so it lasts long and works well.

When you pick a 90-degree elbow for your piping, you need to look at things like ASTM standards, the kind of pipe you have, and the needs of your job.

18 Degree BW Elbow

The 18-degree butt weld elbow is a type of fitting that is used a lot in special piping setups. It is made to help fluid move well through the pipes and also keep the pipes strong. This fitting has a smoother curve than those with sharp corners. Because of this, the flow inside the piping is better, and there is less turbulence. Most of the time, it is made from carbon steel or stainless steel. The long radius design helps the fitting last longer and work well over time. You can use this fitting for many different jobs. It matches well with standards like ASTM and ASME. This makes it a good and trusted choice for engineers and contractors.

Butt Weld Tee (Buttweld Tee)

The butt weld tee, also known as a buttweld tee, is used often in many piping systems. It is an important fitting, as it helps to split the flow. You can get it in equal or reducing types. This lets you make a smooth change for liquid or gas to move through pipes. These tees are made from things like carbon steel, stainless steel, and alloy steel. Because of these strong materials, they can handle many tough jobs. If you learn how to use buttweld tees in the right way, your work will be stronger and better. These tees help your piping jobs perform well every time.

Butt Weld Equal Tee

Whether you are adding it to a piping system or a more complex setup, the butt weld equal tee has a big part in keeping everything flowing smoothly. This tee helps you join three pipes at once. It gives you a continuous metal structure, which makes the whole setup stronger and more stable. You can get these tees in different materials like carbon steel and stainless steel. They follow strict ASTM and ASME standards. When you pick the right type—like an eccentric reducer or a regular equal tee—you make sure the tee will give your project the best results. You can match it to what you need for your piping.

Butt Weld Reducing Tee

A butt weld reducing tee is an important fitting in a piping system. It lets you join two pipes that are not the same size, making it easy to move from one size to the other. This tee keeps the metal continuous, which helps reduce turbulence and keeps things flowing smoothly. The fitting is usually made from carbon steel or stainless steel. These materials are strong and help stop rust from forming. The reducing tee can be used in many ways and works well in lots of places. It gives you both function and flexibility, so it is a key part of any piping network that needs to be reliable.

Butt Weld Reducer

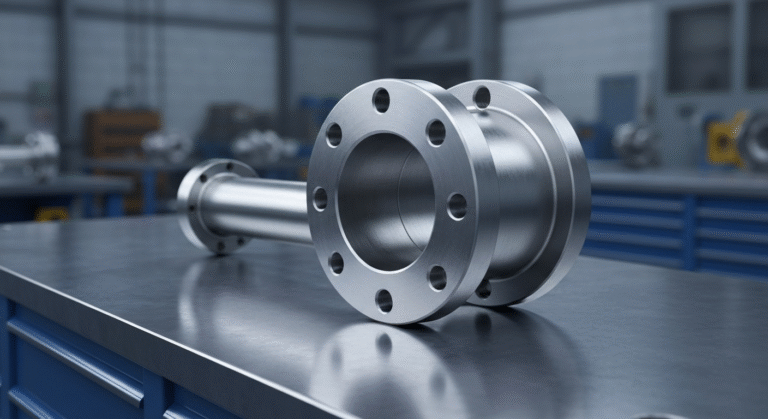

A butt weld reducer is an important part of a piping system. It helps connect pipes that have different diameters. The reducer is usually made from carbon steel, stainless steel, or other steel materials. These fittings offer a strong and tight connection to keep the piping leak-proof. In a continuous metal structure, this is very important.

There are two main variants of butt weld reducers. You can find them in concentric and eccentric shapes. Engineers use these different types to meet their needs for different ways to install the piping. This helps the system work better and allows it to run smoothly and efficiently with good flow rates. By using the right variant, engineers can make sure the piping system will be dependable every time.

Materials of Carbon Steel Buttweld Fittings

The materials used in carbon steel butt weld fittings are very important for the strength and performance of piping systems. Most often, these fittings are made from ASTM A234 and A420. These materials let the fittings handle high pressure and high heat. The way they join together makes a continuous metal structure. This helps lower stress and keeps the piping strong. Carbon steel fittings also come in different variants, like long radius and short radius elbows, so you can get what you need for your project.

Materials of Alloy Steel Welded Pipe Fittings

Alloy steel welded pipe fittings are made to be strong and last a long time. They use iron as the main metal, and add nickel, chromium, and molybdenum. These other metals help the fitting work well in places with high heat or pressure. ASTM standards help pick the right mix for the metal, so the pipe fittings can do their job well in the piping system. The continuous metal structure in these alloy steel fittings gives them the strength they need for many kinds of work. So, these fittings are a good choice for places that need something tough and reliable. Durability is very important in these situations, and these fittings offer it.

Stainless Steel Butt Weld (Buttweld) Fittings

Stainless steel butt weld fittings are known for being strong and for not rusting easily. This makes them a good pick for many types of piping systems. You can use these fittings to join pipes together so you get a continuous metal structure. They work well under high pressure and high temperature.

These fittings meet ASTM and ASME standards. You can find them in different types, like long radius and short radius elbows. They work well in many settings, from big factories to homes.

Their use helps to improve how fluids move through pipes. This also makes the whole piping system better and more efficient.

Buttweld Fittings Dimensions

Knowing the size of buttweld fittings is important for smooth fit in your piping system. These buttweld fittings often follow standards like ASTM and ASME. These standards set the size and details for different uses. You will see common sizes listed as different schedules (sch) and nominal pipe sizes. These sizes work for long radius elbows, short radius elbows, and also tees and reducers. When you use the right size, you get good flow in the piping. It also helps protect the continuous metal structure of your piping system.

Benefits of Butt Weld Fittings

Butt weld fittings are strong and last a long time. These fittings work well in many piping systems. The continuous metal structure in them helps lower stress in the pipes. This makes the pipes last longer and do a better job. A smooth, seamless design also means there is less turbulence and less flow resistance. This is true, especially with long radius fittings. You can get them in carbon steel, stainless steel, and other materials. This lets people pick the best option for their job. The way you connect these fittings by welding means you get leak-proof joints. This makes them a top choice in many industrial places and for a range of piping uses.

Octal supplies Buttweld Pipe Fittings with competitive price and urgent delivery.

Octal has a wide range of butt weld pipe fittings that are known for being good value and getting to you quickly. There is always a full stock of long radius and short radius elbows. You will also find equal tees and eccentric reducers here. This means you can get the right fitting for any piping system you have. Octal works hard to keep the quality high and the prices low. Because of this, your projects can stay on track, and you do not have to worry about the materials. The supply chain at Octal also makes sure everything runs well, so your pipe fittings ship fast. These fittings are ready for many different jobs in the piping world.

Conclusion

Butt weld fittings are important in building a strong and continuous metal structure in piping systems. There are different types, like elbows, tees, and reducers, so you can pick what fits your project. These fittings are made using materials such as carbon steel, stainless steel, and also alloy steel. This helps make them last and do their job well. If you know about the types and the sizes, you can make good choices for what you need. This lets your system work better and stay strong for a long time. For the best results, it is a good idea to use quality butt weld fittings every time.

Frequently Asked Questions

What are the benefits of using butt weld fittings?

Butt weld fittings are known for their strong and long-lasting joints. The way they join together helps to keep fluids moving smoothly with little or no turbulence. These fittings work well in high-pressure situations, so many industries choose them when they need a trusted way to connect pipes.

How do I select the right material for my project?

Choosing the right material for your project means you have to check things like how strong the material is, if it can resist rust, and if it can handle heat. You should also think about the needs of your application, which can include where it will be used and how much you can spend. By doing this, you can make sure that your butt weld fittings work well and last a long time.

Are there specific standards for butt weld fittings in Australia?

Yes, Australia uses certain rules for butt weld fittings. The main ones are AS 2885 and AS/NZS 1163. These rules help to keep quality, safety, and how well things work the same in all kinds of jobs. This helps everyone feel sure about the pipes in buildings and industry. It is very important for people who make and put in these fittings to follow these rules.

What’s the difference between butt weld and socket weld fittings?

Butt weld fittings are joined by welding each piece right together. This way, you get a strong and lasting connection. It works well in systems that have high pressure. On the other hand, socket weld fittings slip over the pipe end. People usually use these for pipes with smaller diameters. They are easier to put in, but they do not be as strong as butt weld fittings.

Can butt weld fittings be used for high-pressure applications?

Yes, butt weld fittings work well for high-pressure uses. This is because they are made in one piece without seams. The strong joints help them last in tough places. You will find them in the oil and gas industry, water supply lines, and places that handle chemicals. For the best safety, always pick the right materials for the job.