-

Yinzhuang Industrial zone,Mengcun county,Cangzhou city,Hebei province,China

Want a custom configuration?

Carbon Steel Tee

Original price was: $7.70.$7.00Current price is: $7.00.

Size: 1/2”~80”,DN15~DN2000

Schedule: Sch 20, 40, STD, 80, 160, XXS

Designation: ASTM / ASME A234, A860, A420

Grade: WPB/C, WPHY 42, 46, 52, 60, 65, 70, WPL 3, 6, 9

Type: Seamless Elbow and Weld Elbow

- Premium Quality

- Secure Payments

- Satisfaction Guarantee

- Worldwide Shipping

- Money Back Guarantee

Carbon Steel Tee – High-Quality Pipe Fittings for Efficient Flow Management

Tees are essential pipe fittings used to join three sections of pipes, allowing the fluid or gas to either split into different directions or combine from multiple lines. Made from high-strength carbon steel, these tees are known for their durability, resistance to wear, and excellent performance in both high-pressure and high-temperature environments. They are widely used in industries such as oil and gas, chemical processing, water treatment, and construction.

What is a Pipe Tee?

A pipe tee is a fitting that connects three sections of pipe, typically at a 90-degree angle. This allows fluid or gas to flow in different directions, making tees vital in branching or combining pipework systems. Available in various sizes, materials, and configurations, tees provide reliable and robust solutions for managing the flow of media through pipelines. These tees are engineered to withstand high pressures, heavy loads, and extreme conditions, making them an ideal choice for demanding industrial applications.

Tees are manufactured to meet high industry standards such as ASTM A234 WPB, ensuring that they can handle the pressure and temperature requirements of most pipeline systems.

Types of Tees

- Seamless Tee

Seamless tees are produced from a single piece of carbon steel, with no welds or joints. This construction method offers superior strength and resistance to corrosion, making them ideal for high-pressure systems. Seamless tees are often used in applications where mechanical strength is a critical requirement, such as in power plants or heavy industrial systems. - Weld Tee

Weld tees are formed by welding together three sections of pipe. This construction method offers flexibility and cost savings compared to seamless tees, though it may be more suitable for lower-pressure applications. Weld tees come in various configurations, including 90-degree tees and reducing tees, to accommodate different flow requirements. - Equal Tee

An equal tee is used when all three branches of the pipe are the same size. This type of tee ensures that the flow of fluid is evenly distributed between the three sections, and it is commonly used in systems where balance is important, such as water distribution systems or fire sprinkler networks. - Reducing Tee

A reducing tee is used to connect pipes of different sizes. This type of tee allows for a smooth transition between large and small pipes while maintaining consistent flow rates and minimizing pressure drops. Reducing tees are commonly used in systems where different flow rates or pipe diameters are required, such as in chemical processing or HVAC systems. - Barred Tee

Barred tees have an internal screen (or bar) that helps prevent backflow and protects equipment downstream. These tees are used in critical systems where preventing backflow or particulate contamination is essential, such as in water treatment or oil refining processes.

Coating Options for Tees

To enhance their performance and lifespan, tees can be coated to improve their corrosion resistance. Some common coating options include:

- Black Painting Tee

Black painting is a common coating option used to protect carbon steel tees from corrosion, dirt, and moisture in general industrial applications. This cost-effective option is ideal for applications where the tees are exposed to mild environmental conditions. - PE Coating Tee

PE (Polyethylene) coating provides a strong protective barrier against moisture, chemicals, and physical damage. This coating is commonly used in outdoor or buried piping systems, where the tees may be exposed to harsh weather or corrosive environments. - Galvanized Tee

Galvanization involves coating the carbon steel tee with a layer of zinc, which prevents rust and corrosion. Galvanized tees are perfect for applications in wet, humid, or chemically aggressive environments, extending the lifespan of the fitting and minimizing maintenance needs.

Benefits of Tees

- Durability: Tees are designed to withstand high pressure, temperature, and wear, providing long-term performance in demanding environments.

- Cost-Effective: Compared to more expensive materials like stainless steel or alloy steel, carbon steel are a more affordable solution that still delivers reliable performance.

- Versatility: Available in multiple sizes, configurations, and coatings, tees can be tailored to meet the specific needs of various piping systems.

- Corrosion Resistance: Coating options like galvanization and PE coating help improve the corrosion resistance of tees, making them suitable for outdoor and corrosive applications.

- Flexibility: Tees come in different configurations, including equal, reducing, and barred tees, allowing for easy integration into various systems.

Standards and Certifications

To ensure that our tees meet high-quality standards, we manufacture them in accordance with internationally recognized specifications:

- ASTM A234 WPB: This specification covers the production of tees and fittings used in pressure piping systems. It ensures that the tees meet strict mechanical and dimensional requirements for reliability and performance.

- ASME B16.9: This standard outlines the requirements for factory-made butt-welding fittings, including tees. It provides essential guidelines on dimensions, tolerances, and pressure-temperature ratings to ensure consistency and quality.

Applications of Tees

Tees are used in a wide range of industries, including:

- Oil & Gas: Tees are used to branch or combine pipelines in oil and gas transportation systems.

- Power Generation: In power plants, tees are employed to connect various piping systems that carry steam, water, or other fluids.

- Water Treatment: Tees are used in water and sewage processing systems to direct flow or combine multiple pipeline branches.

- Construction: Tees are commonly used in HVAC systems, plumbing, and other mechanical installations to manage fluid flow.

Conclusion

Tees are critical fittings in piping systems that provide strength, durability, and flexibility. Whether you need equal tees, reducing tees, or weld tees, these fittings are designed to meet the demands of high-pressure, high-temperature environments. With coating options like black painting, PE coating, and galvanization, tees offer enhanced corrosion resistance and extended service life.

If you’re looking for high-quality tees that meet industry standards such as ASTM A234 WPB and ASME B16.9, choose a trusted supplier who can provide a range of sizes, configurations, and coatings to fit your specific needs. Tees continue to be an excellent choice for reliable, cost-effective, and high-performance pipe systems across various industries.

Fast delivery

Our factory is equipped with fully automated production lines for pipe fittings, enabling us to efficiently meet customer requirements.

Located approximately 100 kilometers from Tianjin Port, we can swiftly deliver products to the port for shipment. This proximity allows for efficient logistics, reducing transit times and ensuring timely delivery to our clients.

Reliable and safe packaging

We prioritize the secure packaging of our products to ensure they arrive safely and in optimal condition. For small-sized pipe fittings, we utilize sturdy wooden boxes, providing robust protection during transit. For larger pipe fittings, we employ pallets wrapped tightly with PE stretch film, effectively safeguarding the items and preventing moisture ingress, which could lead to oxidation. This method ensures the reliability and safety of our packaging, maintaining the quality of the products throughout the shipping process.

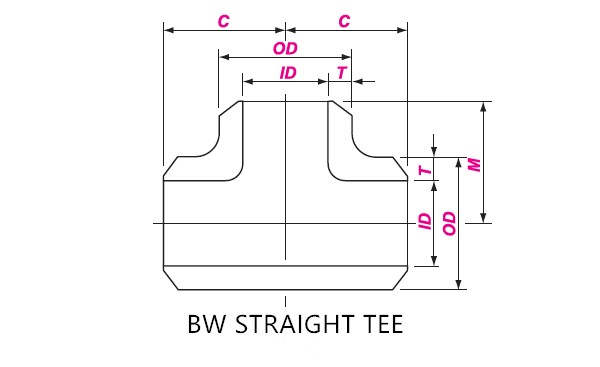

BW EQUAL TEE DRAWING

| Nominal Size | Outside Diameter at Bevel | Center to End | ||

| DN | NPS | OD | C | M |

| 15 | 1/2 | 21.3 | 25 | 25 |

| 20 | 3/4 | 26.7 | 29 | 29 |

| 25 | 1 | 33.4 | 38 | 38 |

| 32 | 1 1/4 | 42.2 | 48 | 48 |

| 40 | 1 1/2 | 48.3 | 57 | 57 |

| 50 | 2 | 60.3 | 64 | 64 |

| 65 | 2 1/2 | 73 | 76 | 76 |

| 80 | 3 | 88.9 | 86 | 86 |

| 125 | 5 | 141.3 | 124 | 124 |

| 150 | 6 | 168.3 | 143 | 143 |

| 200 | 8 | 219.1 | 178 | 178 |

| 250 | 10 | 273 | 216 | 216 |

| 300 | 12 | 323.8 | 254 | 254 |

| 350 | 14 | 355.6 | 279 | 279 |

| 400 | 16 | 406.4 | 305 | 305 |

| 450 | 18 | 457 | 343 | 343 |

| 500 | 20 | 508 | 381 | 381 |

| 550 | 22 | 559 | 419 | 419 |

| 600 | 24 | 610 | 432 | 432 |

| 650 | 26 | 660 | 495 | 495 |

| 700 | 28 | 711 | 521 | 521 |

| 750 | 30 | 762 | 559 | 559 |

| 800 | 32 | 813 | 597 | 597 |

| 850 | 34 | 864 | 635 | 635 |

| 900 | 36 | 914 | 673 | 673 |

| 950 | 38 | 965 | 711 | 711 |

| 1000 | 40 | 1016 | 749 | 749 |

| 1050 | 42 | 1067 | 762 | 711 |

| 1100 | 44 | 1118 | 813 | 762 |

| 1150 | 46 | 1168 | 851 | 800 |

| 1200 | 48 | 1219 | 889 | 838 |

| 1300 | 52 | 1321 | 965 | 914 |

| 1400 | 56 | 1422 | 1041 | 965 |

| 1500 | 60 | 1524 | 1118 | 1016 |

| 1600 | 64 | 1626 | 1194 | 1092 |

| 1700 | 68 | 1727 | 1270 | 1168 |

| 1800 | 72 | 1829 | 1320 | 1245 |

| 1900 | 76 | 1930 | 1422 | 1320 |

| 2000 | 80 | 2032 | 1499 | 1397 |

Reviews

There are no reviews yet.