-

Yinzhuang Industrial zone,Mengcun county,Cangzhou city,Hebei province,China

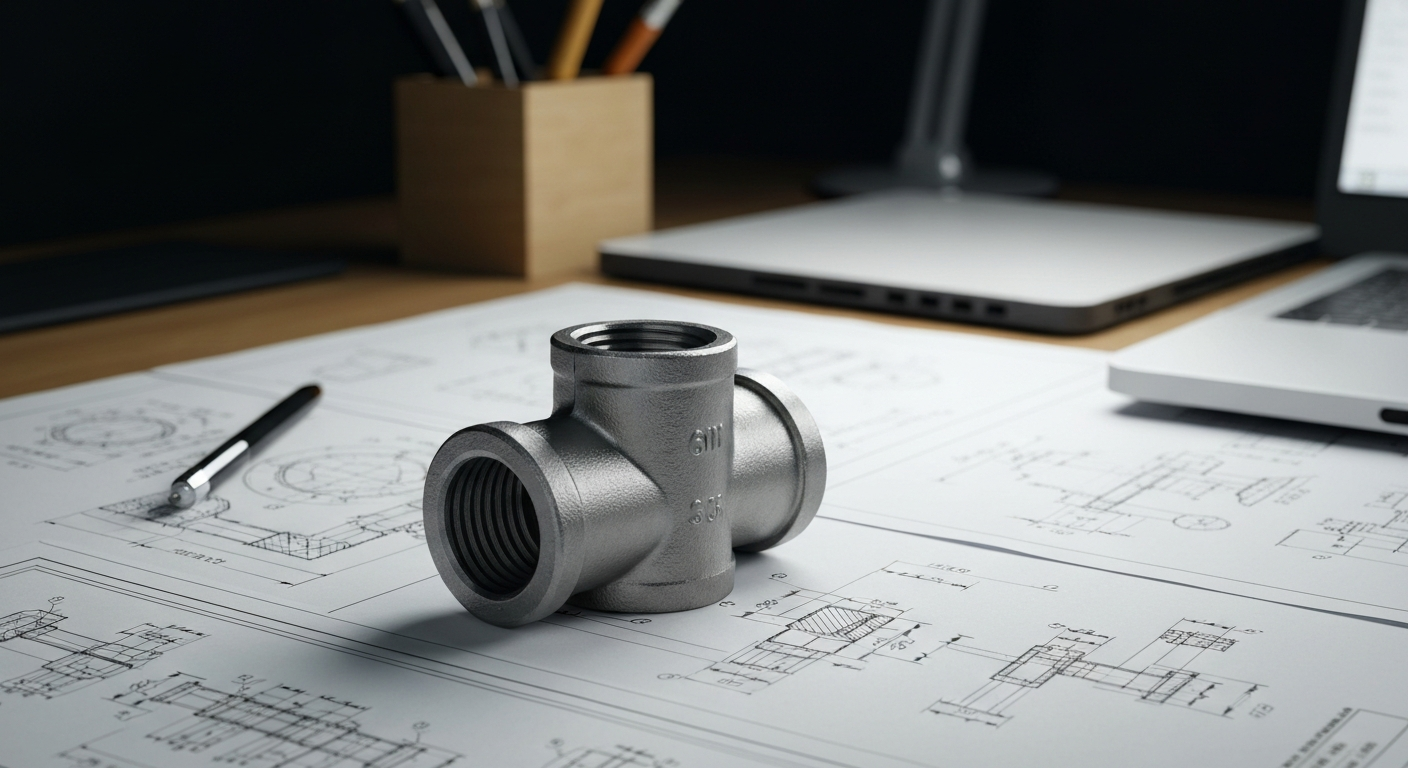

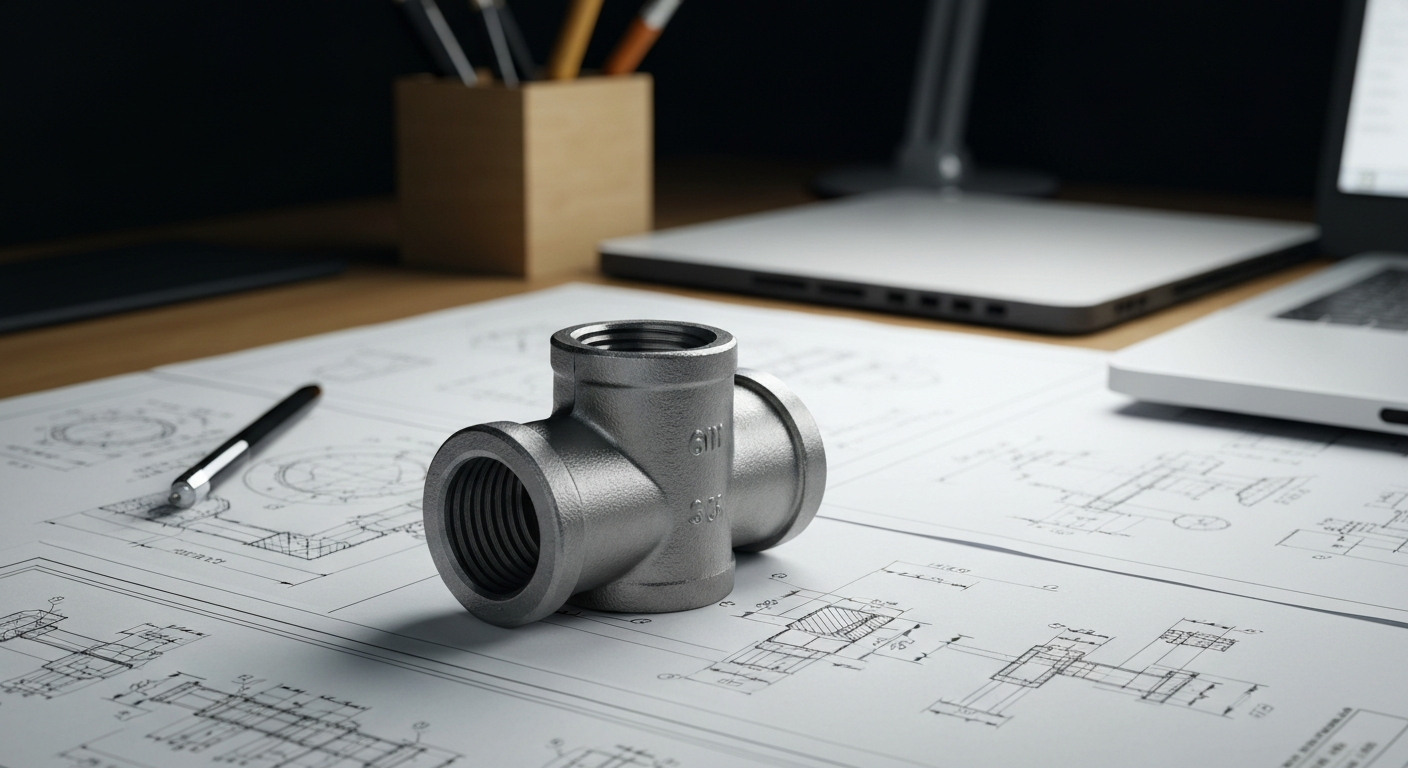

6 Inch Carbon Steel Tee: A Guide for Professionals

Key Highlights

- A 6-inch carbon steel pipe tee is a T-shaped fitting used to change fluid direction in pipelines.

- Tee fittings come in two main forms: the equal tee, where all branches are the same size, and the reducing tee, or tee reducer.

- Connection types vary, with butt weld designs being common for larger sizes like 6 inches due to their strength. Typical lead time for ordering a 6 inch carbon steel butt weld steel tee generally ranges from 2 to 4 weeks, depending on availability and manufacturer specifics. Material grades and standards, such as ASTM A234, ensure the quality and performance of carbon steel tees.

- Material grades and standards, such as ASTM A234, ensure the quality and performance of carbon steel tees.

- Wall thickness is defined by a schedule number, like Schedule 40 or Extra Heavy (XH).

Introduction

Welcome to your professional guide on the 6-inch carbon steel tee. If you work with piping systems, you know how crucial the right fittings are. A steel tee is a T-shaped pipe fitting with three branches, designed to combine or divide fluid flow. This type of pipe tee is an essential component in networks that convey liquids and gases across various industries. Whether you’re in oil and gas or power generation, understanding these fittings is key to a successful project.

When compared to similar fittings made from other materials or in different size classes, the 6 inch carbon steel tee generally conforms to standard dimensions specified by ASME or ANSI. These dimensions include the outside diameter, wall thickness, and branch size, which are consistent with comparable tees in the same nominal pipe size but may differ in terms of pressure ratings and material strength when compared to tees made from stainless steel or PVC.

Understanding 6 Inch Carbon Steel Tee Specifications

When selecting a 6-inch carbon steel tee, knowing its specifications is critical. Key details include the Nominal Pipe Size (NPS), which is 6 inches in this case, the wall thickness, and the pipe schedule number (sch). These specifications ensure the tee fits perfectly with the corresponding steel pipe and can handle the system’s operational pressures. The main line pipe diameter and branch diameter define whether it’s an equal or reducing tee.

Compliance with industry standards is equally important for these steel pipe fittings. Look for markings indicating adherence to standards from organizations like ASME, ANSI, and ASTM. For example, a common grade for carbon steel butt weld fittings is ASTM A234 WPB. These standards guarantee the material quality, dimensions, and durability of the fittings, ensuring safety and reliability in your piping infrastructure.

Material Grades and Standards (ASTM A234, ASTM A105, etc.)

Material grades and standards are the backbone of reliable pipe fittings. They dictate the chemical composition, mechanical properties, and manufacturing process. For carbon steel tees, standards from ASTM and ASME are the most recognized, ensuring your fittings meet strict quality requirements for industrial use.

Different material types are governed by specific standards. The right standard depends on the connection type and material. Here is a quick breakdown of common material types and their associated standards.

Material Type | Applicable Standard |

|---|---|

Carbon & Alloy Steel (Butt Weld Fittings) | ASTM A234 |

Carbon Steel (Forged/Socket Weld Fittings) | ASTM A105 |

Stainless Steel (Butt Weld Fittings) | ASTM A403 |

For a 6-inch carbon steel tee, ASTM A234 is the primary standard for butt weld designs, with WPB being a common grade. While carbon steel is widely used, you may also encounter alloy steel material for specialized applications or stainless steel for environments requiring good corrosion resistance.

Schedule 40 vs Extra Heavy (XH) Tee Dimensions

Understanding the difference in dimensions between schedule 40 and extra heavy (xh) tees is essential for selecting the right fittings for your project. Schedule 40 tees generally have a lighter wall thickness, making them ideal for standard applications. Conversely, extra heavy tees are designed for higher pressure systems, offering increased durability and strength. Both dimensions impact the overall pressure ratings and performance in industrial pipelines, ensuring that applications are well-suited to the right connection types and material specifications.

Types and Connections of 6 Inch Carbon Steel Tees

A 6-inch carbon steel steel tee can be connected to a pipeline in several ways. The primary connection types for tee fittings are butt weld, socket weld, and threaded. Each method is suited for different applications, pipe sizes, and pressure levels. Choosing the right connection is fundamental to a secure and leak-free system.

For a 6-inch pipe nps, butt weld connections are the most common and robust option. Socket weld and threaded fittings, which involve female NPT threads or male NPT threads, are generally used for smaller diameter pipes, typically 4 inches and under. Let’s explore the differences between butt weld and socket weld designs, as well as equal versus reducing tees.

Butt Weld vs Socket Weld Designs

When it comes to steel pipe fittings, the welding method plays a huge role in the system’s integrity. Butt weld and socket weld are two distinct connection types, each with its own advantages and ideal use cases. For a 6-inch carbon steel tee, one design is far more prevalent than the other.

To make the right choice, it’s helpful to understand how they differ in installation and performance.

- Butt Weld Tee: This butt weld pipe fitting has ends that are beveled to match the pipe. The tee is welded directly to the pipe, creating a strong, continuous seam. This design is ideal for larger pipes and systems that experience higher pressure and temperature.

- Socket Weld Tee: With a socket weld tee, the pipe is inserted into a recessed area in the fitting. It is then fillet-welded around the outside. This connection type is easier to align but is typically used for smaller pipe diameters.

For a 6-inch pipeline, the butt weld design is the industry standard. Its ability to withstand higher pressure and stress makes it a more reliable choice for large-scale applications. The smooth internal surface also reduces friction and allows for better flow.

Equal Tee vs Reducing Tee – Functional Differences

Beyond connection types, pipe tee fittings are categorized by the size of their outlets. The two main functional types are the equal tee and the reducing tee. Your choice depends entirely on whether you need to maintain the pipe size or change it at the branch connection.

Here’s a look at the functional differences between these essential steel pipe fittings.

- Equal Tee: Also known as a straight tee, an equal tee has three branches of the tee that are all the same diameter. A 6-inch equal tee, for example, will have three 6-inch openings to connect pipes of the same size.

- Reducing Tee: This fitting, also called a tee reducer, has a smaller diameter on its branch outlet. For instance, a 6x6x4-inch reducing tee has a 4-inch reducing branch coming off a 6-inch main line.

An equal tee is used to split the flow into two streams of the same size or combine two streams into one main line. In contrast, a reducing tee is used when you need to branch off to a smaller pipe, making it a versatile fitting for adjusting flow rate and direction in complex systems.

Conclusion

In summary, understanding the specifications and types of 6-inch carbon steel tees is essential for professionals looking to make informed decisions in their projects. From material grades and standards to the differences between butt weld and socket weld designs, this guide has highlighted key factors that can impact both the performance and longevity of your installations. By selecting the appropriate tee and ensuring proper connections, you enhance not only the efficiency of your piping systems but also ensure compliance with industry standards. For those ready to dive deeper into the world of carbon steel tees or seeking quality products, don’t hesitate to explore your options online.

Frequently Asked Questions

How do I choose the correct weld type for installation?

To choose the correct weld type, consider your pipe size and pressure ratings. For a 6-inch steel pipe, a butt weld is the standard choice because it creates a stronger connection suitable for larger diameters and higher pressures. Socket weld connections are typically reserved for smaller pipes, usually under 2 inches.

What are the common uses for 6 inch carbon steel straight tees?

A 6-inch carbon steel straight tee is primarily used in industrial pipelines to divide or merge fluid flow without changing the pipe diameter. These fittings are essential in the oil and gas, chemical processing, and power generation industries, where maintaining consistent flow volume through the main line and branch is crucial.

Where can professionals in the United States purchase 6 inch carbon steel tees online?

Professionals in the United States can buy 6-inch carbon steel fittings from numerous online industrial suppliers and distributors. When purchasing online, ensure the supplier provides detailed specifications and material certifications. Many offer nationwide shipping, making it convenient to get the exact fittings you need for your project delivered directly to your site.

What are carbon steel forged fittings?

Carbon steel forged fittings are high-strength components made from carbon steel, designed to connect pipes in various applications. They undergo a forging process, enhancing their durability and resistance to pressure and temperature changes. Common types include tees, elbows, and couplings, essential for efficient and secure piping systems.

What are carbon steel forged fittings?

Carbon steel forged fittings are durable components made from carbon steel through a forging process, ensuring strength and resilience. These fittings, including 6 inch carbon steel tees, are crucial in piping systems for connecting, redirecting, or terminating pipes while withstanding high pressure and temperature conditions effectively.