-

Yinzhuang Industrial zone,Mengcun county,Cangzhou city,Hebei province,China

3PE Coating Steel Pipe: A Comprehensive Guide

Key Highlights

Here’s a quick look at what makes 3PE coating a top choice for steel pipes:

- A 3PE coating steel pipe features three layers: an epoxy layer, an adhesive layer, and a polyethylene layer.

- This system offers excellent corrosion resistance against moisture and the chemical of soil.

- It provides superior mechanical protection, shielding pipes from mechanical damage.

- The coating has good impact resistance, making it ideal for tough environments.

- By protecting the steel pipe, it significantly extends its service life beyond 50 years.

Introduction

When you need to protect pipelines from the elements, choosing the right coating is crucial. Have you ever wondered what makes certain pipes last for decades underground? For many projects involving the transport of oil, gas, or water, the answer is a 3PE coating steel pipe. This advanced coating system is a popular choice because it provides exceptional corrosion resistance and durability. It ensures your steel pipe infrastructure remains safe and functional for years to come, protecting it from environmental threats.

Understanding 3PE Coating for Steel Pipes

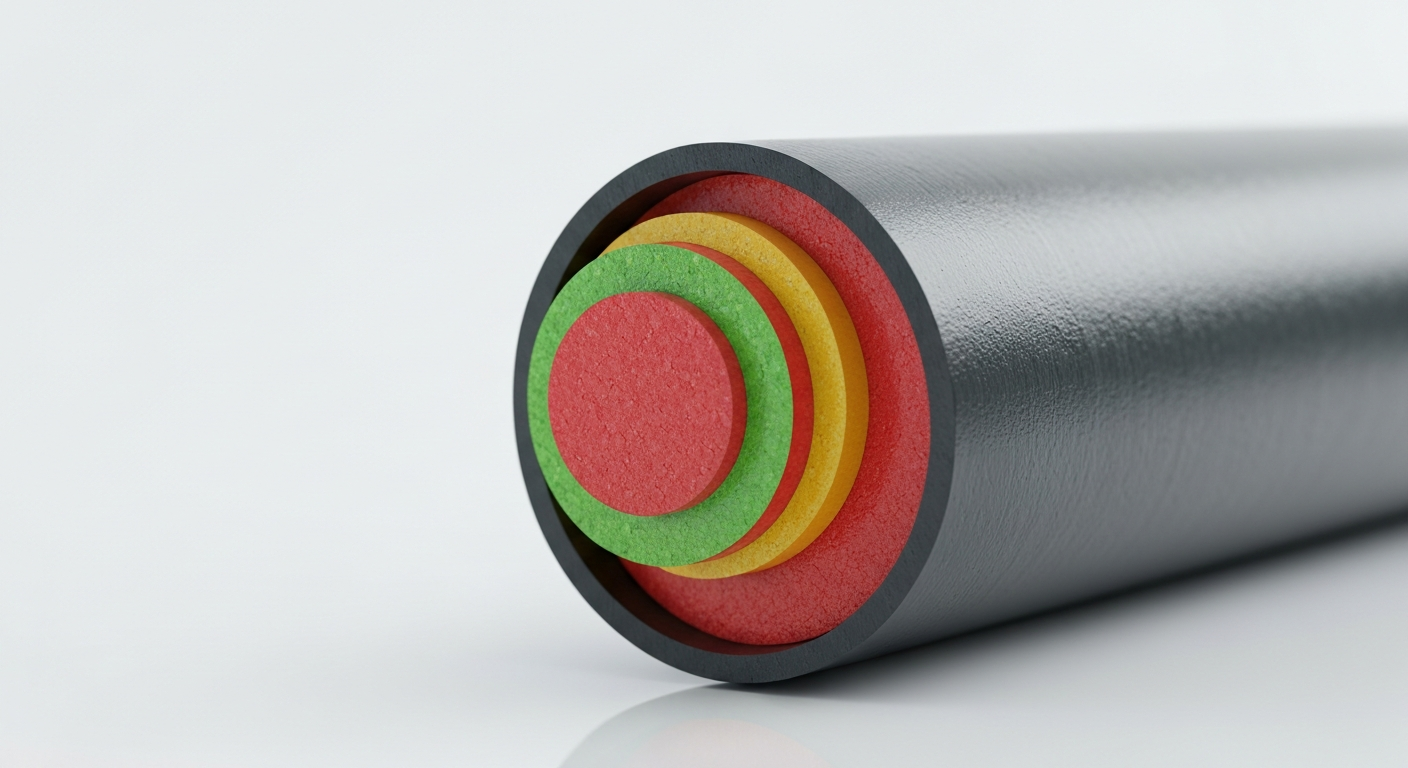

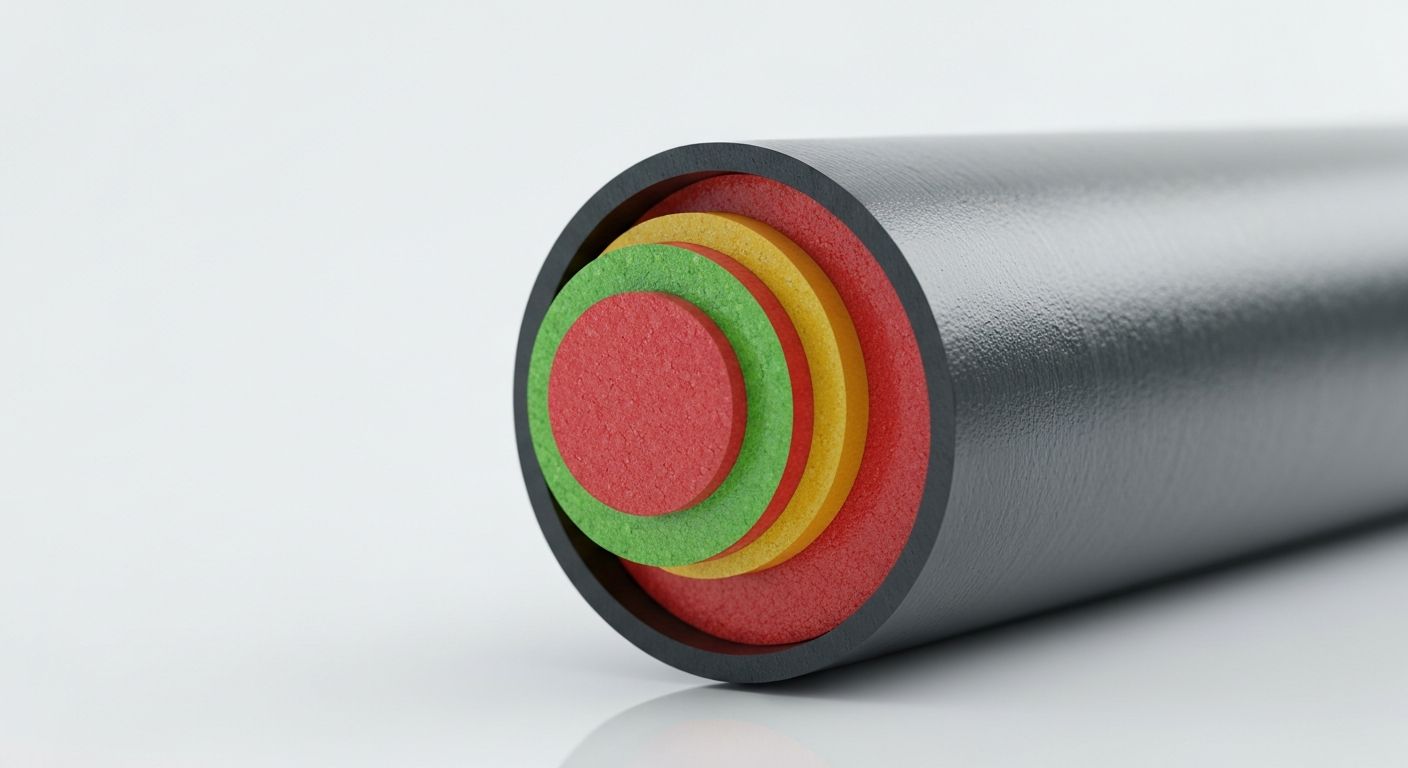

A 3PE coating is a multi-layer system applied to a steel pipe to protect it from corrosion. The “3PE” stands for three-layer polyethylene, which highlights its unique structure. This coating consists of a fusion-bonded epoxy, an adhesive, and an outer polyethylene layer.

The primary goal of this coating steel pipe is to deliver robust corrosion resistance and durability. It shields the pipe from mechanical damage and harsh environmental factors, ensuring a long service life. Thanks to its good impact resistance, it is a reliable solution for pipelines in demanding conditions. Let’s explore the specific layers and how they differ from other coatings.

Structure and Composition of 3-Layer Polyethylene (3PE) Coating

The effectiveness of a 3PE coating steel pipe comes from its three distinct layers working together. Each layer serves a specific purpose, creating a powerful protective barrier. The structure is designed to maximize adhesion, durability, and resistance.

The first layer is a fusion-bonded epoxy (FBE) primer. This epoxy layer bonds directly to the steel pipe, providing the primary defense against corrosion and creating a strong foundation. Its thickness is typically greater than 100 micrometers.

Next, the second layer is a copolymer adhesive. Its job is to create a solid bond between the inner epoxy layer and the outer polyethylene coating. This adhesive layer is crucial for the integrity of the entire system. Finally, the third layer is a rugged polyethylene coating, which provides excellent mechanical protection against impacts, abrasion, and harsh environmental conditions.

How 3PE Coating Protects Against Corrosion and Environmental Factors

A 3PE coating offers comprehensive protection by combining the strengths of its three layers. The system creates a barrier that isolates the steel surface from corrosive elements, ensuring a long service life for your pipeline.

The outer polyethylene coating is the first line of defense, offering superior mechanical protection. It stands up to abrasion, impacts, and other physical stresses that can occur during installation or operation. This layer is also highly resistant to moisture and the chemical of soil, preventing them from reaching the pipe.

Internally, the FBE layer provides excellent corrosion resistance by bonding tightly to the steel. The combination of these layers results in a system with several key protective qualities:

- High electrical resistance

- Low water absorption

- Resistance to chemical subjects

- Protection against soil stress and wear

Comparing 3PE Coated Steel Pipes with FBE and 2PE Pipes

When selecting a coating for a steel pipe, you’ll often encounter options like 3PE, FBE, and 2PE. While all are designed to provide corrosion resistance, their structures and performance characteristics differ significantly. Understanding these differences is key to choosing the right solution for your project’s specific needs.

The 3PE coating is often seen as an evolution of earlier coating systems, integrating the benefits of FBE with the mechanical toughness of polyethylene. Below, we’ll compare 3PE directly with FBE and 2PE to clarify their unique advantages and applications.

Key Differences: 3PE vs FBE (Fusion Bonded Epoxy) Coatings

The main distinction between a 3PE and an FBE coating lies in their structure and performance. FBE coating is a single-layer system made of fusion-bonded epoxy powder applied directly to the heated steel pipe. It offers good corrosion resistance but is more susceptible to mechanical damage.

In contrast, a 3PE coating steel pipe adds two more layers on top of the FBE base: an adhesive and a tough polyethylene layer. This multi-layer approach provides superior mechanical protection and water resistance, significantly enhancing the pipe’s durability and service life, especially in harsh underground environments.

Here is a simple breakdown of the differences:

Feature | 3PE Coating | FBE Coating |

|---|---|---|

Structure | Three layers (FBE, adhesive, polyethylene) | Single layer (Fusion Bonded Epoxy) |

Application | External coating only | Can be used for internal or external coating |

Mechanical Protection | Excellent | Moderate; less resistant to impact and abrasion |

Water Resistance | Very high due to the polyethylene layer | Good, but lower than 3PE |

Distinguishing Between 2PE and 3PE Coated Steel Pipes

While they sound similar, 2PE and 3PE coated steel pipes have a critical structural difference that impacts their performance. Both systems use an outer layer of polyethylene and an adhesive layer, but they differ at the foundational level, right at the pipe’s surface.

A 2PE coating system consists of just two layers: an adhesive layer and a layer of polyethylene. It provides good mechanical and corrosion protection but lacks the enhanced bonding strength of its three-layer counterpart.

The key differentiator in a 3PE coating steel pipe is the addition of a fusion-bonded epoxy (FBE) layer as the first layer. This FBE primer bonds directly to the steel, offering superior corrosion resistance and a much stronger adhesion for the subsequent adhesive and polyethylene layers. This addition makes 3PE a more robust and reliable choice for long-term pipeline protection.

The 3PE Coating Process: Steps and Standards

The manufacturing process for a 3PE coating steel pipe is straightforward yet precise, designed to ensure each layer adheres perfectly for maximum protection. The process begins with preparing the steel surface to create a clean and ideal foundation for the coating.

After preparation, the pipe is heated, and the layers are applied in sequence: first, the epoxy powder, followed by the copolymer adhesive, and finally the outer polyethylene layer using a hot melt application. This process is governed by specific industry standards to guarantee quality and consistency. Let’s look closer at the preparation techniques and the standards that guide this process.

Surface Preparation and Application Techniques

Proper surface preparation is the most critical step in creating a durable 3PE coating steel pipe. If the pipe surface is not perfectly clean, the epoxy primer will not adhere correctly, compromising the entire coating system and its protective qualities. The goal is to achieve a smooth surface free of contaminants.

The process typically involves several stages to prepare the pipe for coating. These steps ensure that the epoxy primer can form a strong, lasting bond with the steel, which is essential for the coating’s long-term mechanical properties and corrosion resistance. The welding process areas also require careful attention.

Key surface preparation steps often include:

- Abrasive blast cleaning to remove rust, scale, and other contaminants.

- Heating the pipe to the required temperature for application.

- Applying the FBE epoxy primer electrostatically.

- Applying the adhesive and polyethylene layers over the primer.

Industry Standards and Specifications for 3PE Coated Steel Pipes

To ensure reliability and safety, the manufacturing process of 3PE coated steel pipes is guided by strict industry standards and specifications. These standards dictate everything from the raw materials used to the final thickness of each coating layer. Adhering to these guidelines is essential for producing a high-quality product that performs as expected.

These specifications provide a framework for manufacturers to follow, ensuring consistency across different batches and suppliers. They cover crucial parameters like surface preparation, application temperatures, layer thickness, and adhesion strength. This standardization means you can be confident that the 3PE coating will meet specific performance criteria.

Following these industry standards ensures that the final steel pipe can withstand its intended service environment, including different pressure conditions and exposure to corrosive elements. This commitment to quality control is a major reason why 3PE coating is trusted for critical infrastructure projects around the world.

Industrial Applications and Advantages of 3PE Coated Steel Pipes

Thanks to its exceptional durability, 3PE coated steel pipes are used across various industries for critical applications. They are especially favored for transporting fluids like natural gas, oil, and water over long distances. The coating’s superior mechanical protection makes it the go-to choice for underground pipelines.

The primary advantage of using a 3PE coating is the significant extension of the pipe’s service life, which can exceed 50 years. This longevity, combined with its resistance to damage and corrosion, makes it a cost-effective and reliable solution. Let’s examine some common uses and the specific benefits it offers.

Common Uses in Oil, Gas, Water, and Underground Pipelines

The robust nature of 3PE coating makes it suitable for some of the most demanding pipeline projects. Its ability to protect steel pipelines from corrosion and mechanical stress is why it is so widely adopted for transporting valuable and essential resources.

You will find 3PE coated pipes in various applications, particularly for underground pipelines where inspection and repair are difficult and costly. The coating can be applied to different types of pipes, including carbon steel pipe and stainless steel pipe, making it a versatile solution for many projects.

Common applications include:

- Transportation of natural gas and artificial gas

- Long-distance crude oil pipelines

- Urban fuel gas piping systems

- Water piping systems and storage tanks

- Protection for pipes in electricity and communication industries

Benefits of Choosing 3PE Coating for Longevity and Performance

Choosing a 3PE coating for your steel pipes brings a host of benefits that contribute to both longevity and performance. Its multi-layer design provides a level of protection that uncoated pipes simply cannot match, leading to significant long-term advantages.

The primary benefit is improved durability. A 3PE coating dramatically extends the service life of a pipe to over 50 years by providing superior corrosion resistance and protection from mechanical damage. This is especially true in harsh environments where pipes are exposed to soil stress, moisture, and chemicals. The excellent adhesion of the epoxy layer ensures the coating stays intact.

The overall advantages deliver obvious economic benefits by reducing the need for maintenance and replacement. Key benefits include:

- Exceptional impact resistance due to good impact performances.

- Flexibility that allows pipes to bend without damaging the coating.

- Low water absorption, improving isolation from seawater.

- A smooth internal surface that can reduce pressure loss during transport.

Conclusion

In summary, 3PE coating offers a robust solution for enhancing the longevity and performance of steel pipes in various industrial applications. By understanding its structure, protective qualities, and industry standards, you can make informed decisions that align with your project needs. The benefits of choosing 3PE over other coatings are clear, particularly in terms of corrosion resistance and environmental protection. Whether you’re working in oil, gas, or water industries, leveraging 3PE technology can significantly contribute to the efficiency and durability of your pipelines. For further insights or questions about implementing 3PE coatings, don’t hesitate to reach out for a free consultation.

Frequently Asked Questions

Are 3PE and 3LPE coatings the same for steel pipes?

Yes, 3PE and 3LPE are terms used interchangeably to describe the same three-layer coating system for a steel pipe. Both refer to a coating steel pipe that includes a fusion-bonded epoxy base, an adhesive layer, and an outer polyethylene layer for protection.

Why is 3PE coating preferred for underground pipeline protection?

The 3PE coating is preferred for an underground pipeline because it offers superior protection against mechanical damage, soil stress, and moisture. Its excellent corrosion resistance and toughness ensure the steel pipe remains secure and functional for a very long service life, minimizing the need for costly excavation and repairs.

What are the main benefits over uncoated steel pipes?

Compared to an uncoated steel pipe, a 3PE coated pipe offers significantly better corrosion resistance and protection from mechanical damage. This leads to a much longer service life (over 50 years), improved impact resistance, and lower maintenance costs over the lifetime of the pipeline.